CNC stationary shaft shoulder mounting structure, friction stir welding tool and welding equipment

A technology of static shaft shoulder and installation structure, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of inability to provide upsetting force, welding quality problems, etc., to reduce heat sink, improve welding quality, increase The effect of welding upsetting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

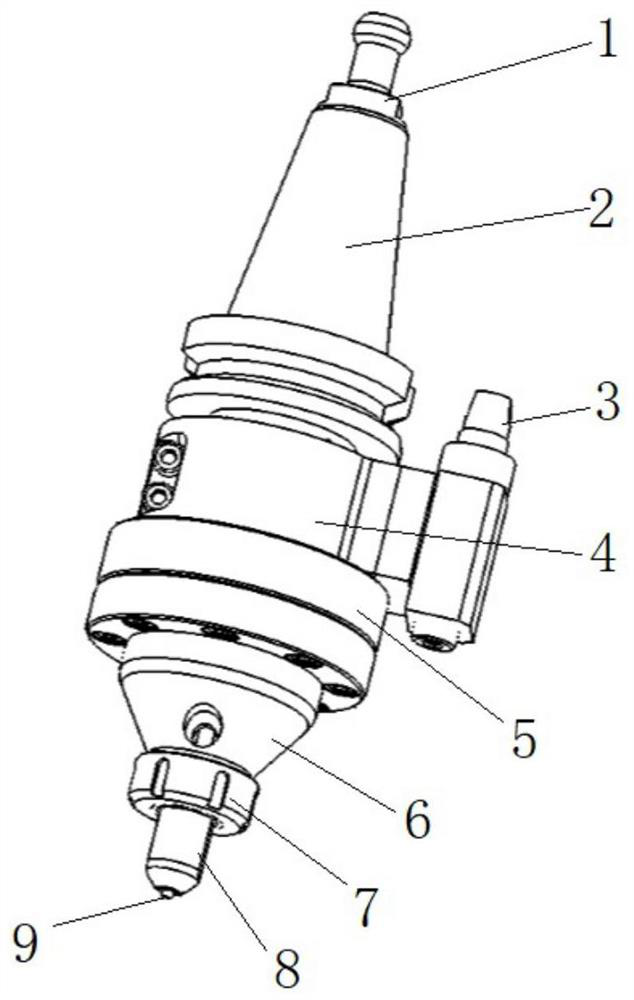

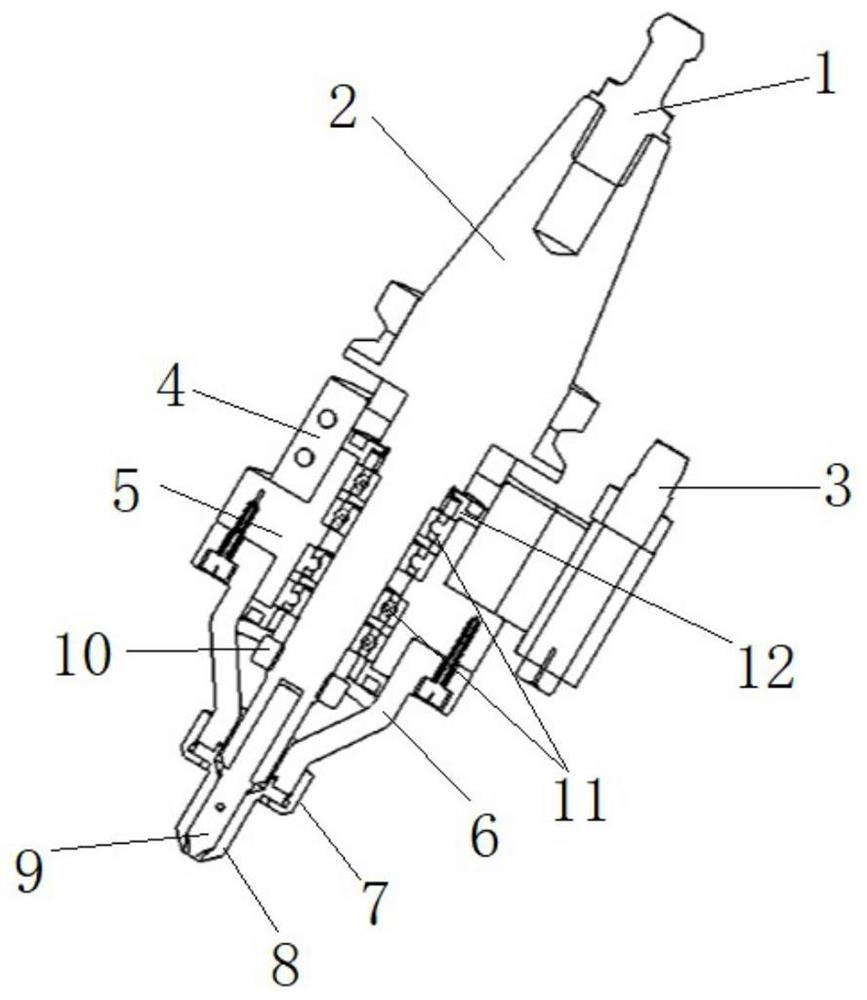

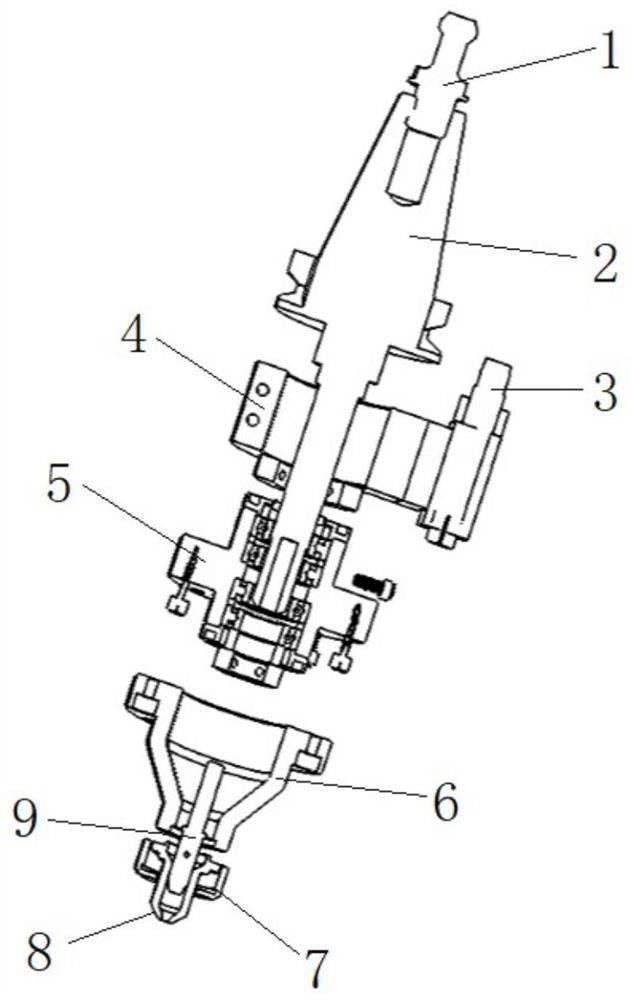

[0039] Such as Figure 1-4 As shown, this embodiment provides a CNC static shoulder installation structure, which can realize static shoulder friction stir welding on CNC equipment. Compress the material before welding to prevent the material from being scooped up. At the same time, the static shoulder is beneficial to reduce the heat sink, increase the welding upsetting force, and then improve the welding quality; and the structure is easy to install, the manufacturing cost is low, and the equipment can be reduced. purchase cost.

[0040]The CNC static shoulder installation structure provided in this embodiment includes a knife handle 2, a support ring 5, a shaft sleeve 6, a static shoulder 8 and a stirring needle 9; End, and have the working end that is suitable for installing stirring needle 9; Wherein, as Figure 1-3 As shown, the mounting end preferably has a tapered structure, and further, the top of the tapered structure can be provided with a pull stud 1; the pull st...

Embodiment 2

[0049] This embodiment provides a friction stir welding tool and friction stir welding equipment, which include CNC equipment and the static shoulder mounting structure described in Embodiment 1. The friction stir welding tool further includes a stationary shoulder and a stirring pin, wherein the stationary shoulder is mounted on the bottom of the bushing, and the stirring pin is mounted on the working end of the handle. The tool handle installation end of the static shoulder mounting structure is installed in the tool handle mounting hole of the CNC equipment; the static shoulder friction stir welding can be realized on the CNC through the friction stir welding welding tool, and the static shoulder can be in the Press the material before welding to prevent the material from being "shoveled". At the same time, the static shoulder is beneficial to reduce heat sink, increase welding upsetting force, and improve welding quality.

[0050] In addition, the friction stir welding equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com