A kind of preparation method of polycarbonate resin fluorescent composite material and fluorescent LED lampshade

A polycarbonate resin and LED lampshade technology, applied in the field of LED lampshades, can solve the problems of waste of equipment resources, high cost, narrow light angle, etc., achieve the effects of reducing capital investment and waste of resources, uniform color, and lower chip temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail by the following examples, but the present invention is not limited.

[0029] The preparation method is as follows:

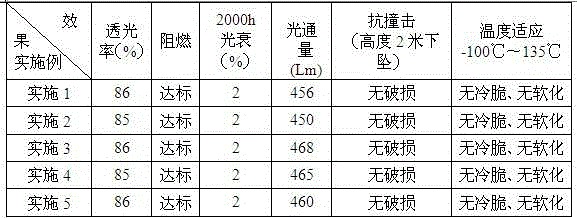

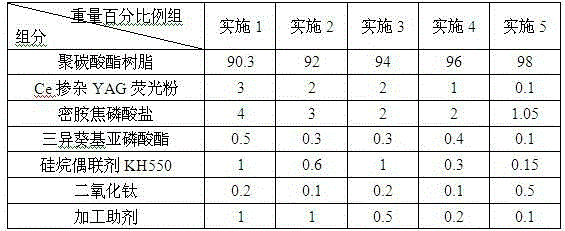

[0030] For example, the present invention adopts polycarbonate resin fluorescent composite material, which is composed of polycarbonate resin, fluorescent powder, melamine pyrophosphate, triisodecyl phosphite, silane coupling agent KH550, titanium dioxide and processing aids. See the table below for each component and weight percentage in the specific implementation process.

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com