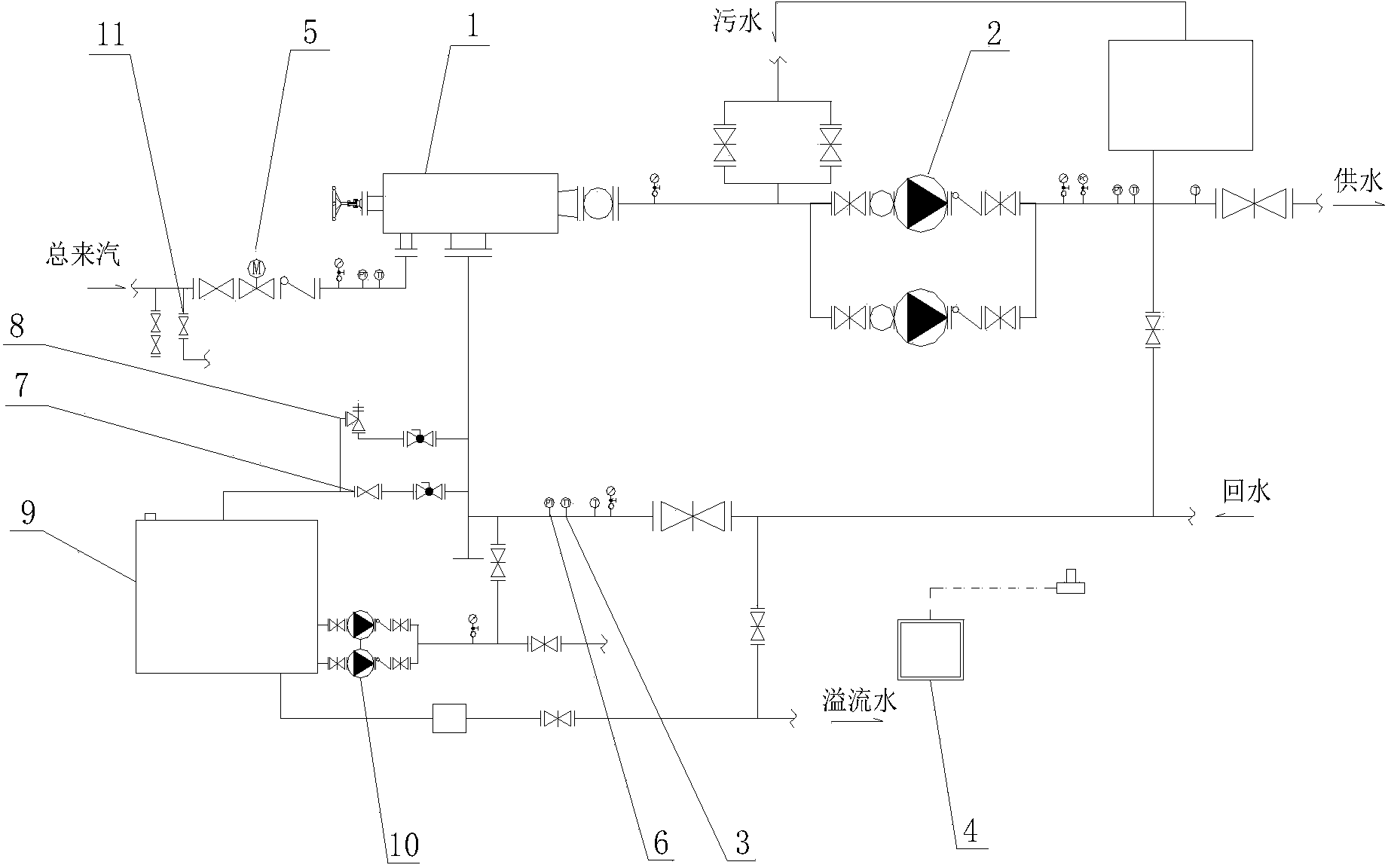

Steam-water hybrid heating apparatus for oil field

A soda-water mixing and equipment technology, applied in lighting and heating equipment, heat exchanger types, direct contact heat exchangers, etc., can solve problems such as unstable pressure, large heat loss, and unsafe operation, and achieve stable pressure, High heat exchange efficiency, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In one embodiment of the present invention, the temperature detector detects the supply water temperature at the outlet of the circulation pump, and sends the supply water temperature to the controller, and then the controller compares the supply water temperature with the predetermined temperature, and controls the steam pipe located on the steam pipeline according to the comparison result. The actuator is used to control the amount of steam entering the steam heater in the steam pipeline, thereby achieving automatic adjustment of the steam and achieving the technical effect of high heat exchange efficiency. Further, the pressure value on the return water pipeline is detected by the pressure detector, and the automatic pressure relief of the pressure relief valve is started according to the pressure value, so that the technical effect of pressure stabilization is achieved.

[0019] In order to enable those skilled in the art to understand the present invention in more d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com