Quick centering positioning device and method for chassis transmission system test

A transmission system, centering positioning technology, applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve the problem of increased motor load and test bench vibration, motor overload tripping damage, and poor adjustment accuracy To meet the requirements and other issues, to achieve the effect of saving installation and adjustment time, high installation accuracy, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

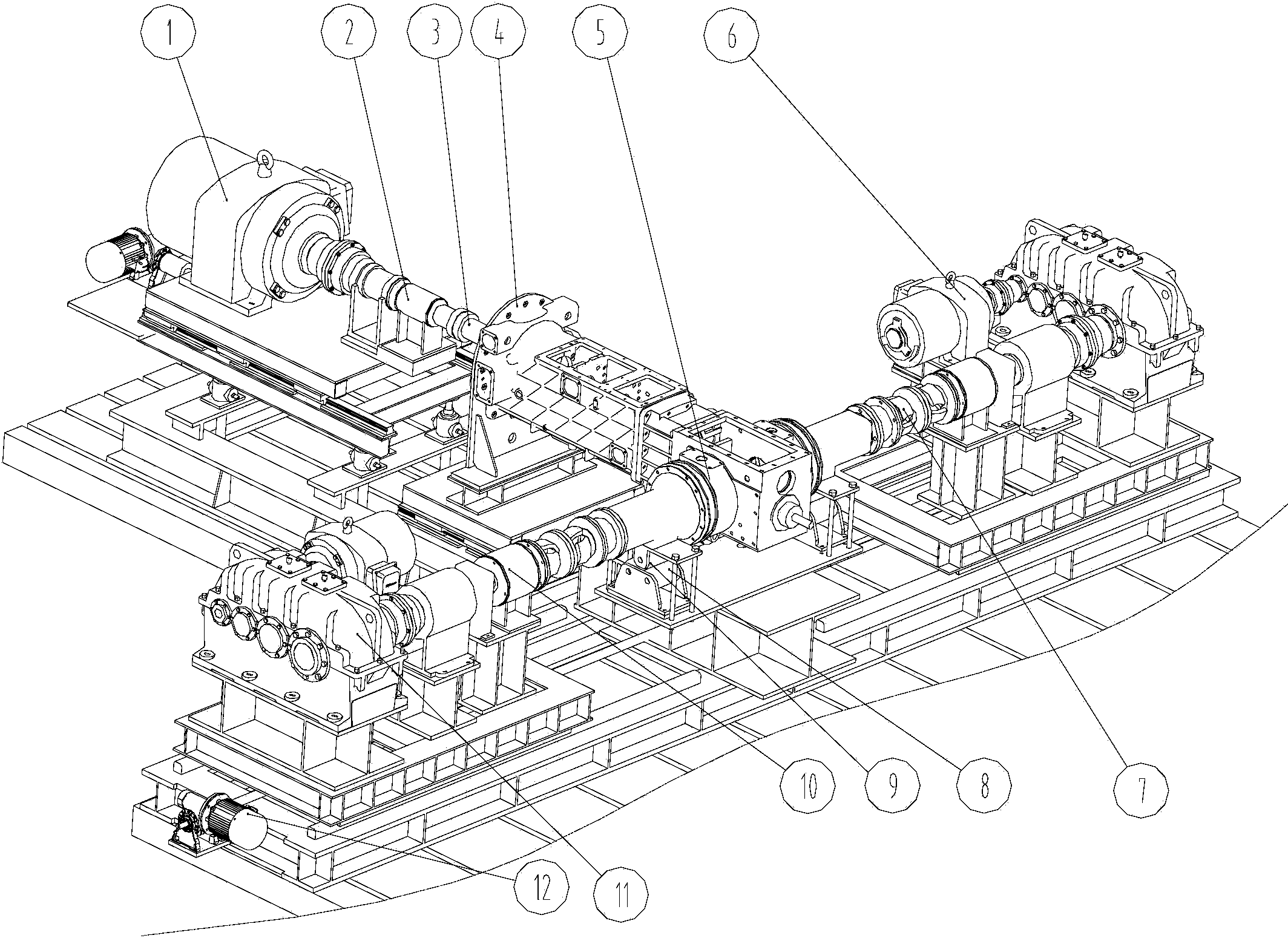

[0026] See figure 1 , a chassis transmission system test fast centering positioning device, including a test bench base, a longitudinal drive slide, two lateral loading slides and driving the two lateral loading slides are arranged on the test bench base Synchronous horizontal sliding table driving device 12 that moves equidistantly or in reverse, the longitudinal driving sliding table is provided with a longitudinal driving unit, and the two lateral loading sliding tables are symmetrical about the axis of the output shaft of the longitudinal driving unit Ground setting, wherein each lateral loading slide table is centered with a loading unit, the loading unit is correspondingly connected with the output shaft of the rear axle of the tested c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com