Clean transformer oil granularity lab safety protection system and protection method thereof

A technology for transformer oil and safety protection, applied in instruments, alarms, comprehensive factory control, etc., can solve the problems of reducing the insulation of transformer oil, poisoning of test personnel, and asphyxiation due to lack of oxygen, so as to improve the safety of experiments and reduce the cost of experiments Risk, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

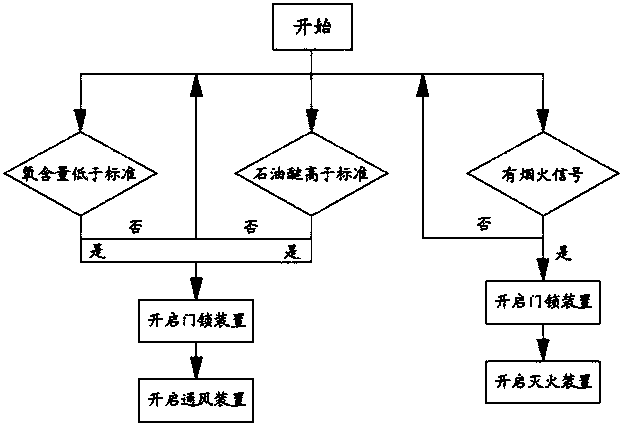

[0025] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

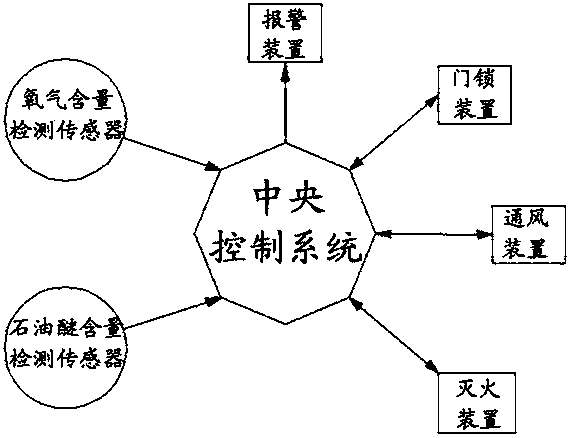

[0026] Such as figure 1 As shown, in an embodiment of the present invention, a transformer oil particle size clean laboratory safety protection system includes:

[0027] The oxygen content detection sensor installed in the clean laboratory is used to detect the oxygen content in the clean laboratory;

[0028] Alarm device, when the oxygen content detected by the oxygen content detection sensor is lower than the set value, the alarm device will alarm;

[0029] Door lock device, when the oxygen content detected by the oxygen content detection sensor is lower than the set value, the door lock device is opened, and the door of the clean laboratory is opened;

[0030] The central control system is used to receive the data detected by the oxygen content detection sensor, generate control signals, and respectively control the alarm device and the door lock device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com