Capacitive touch screen

A capacitive touch screen and touch screen technology, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of unavoidable, a large number of air bubbles, and rising material costs, so as to improve product quality and ease heights. Poor, the effect of resolving bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

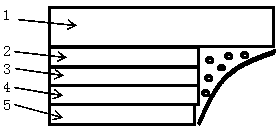

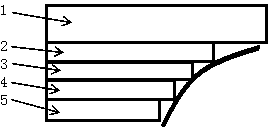

[0012] The capacitive touch screen of the present invention includes a glass layer and an ink layer printed on the back of the glass layer, and the ink layer is printed around the non-window area of the glass. Due to the shading requirements, the ink layer needs to be printed in layers to form a thicker shading ink layer. The present invention adopts a stepwise printing method when printing the ink layer, that is, the edge of the ink layer printed later is always farther away than the edge of the ink layer printed in the previous printing. The direction of the window area is indented to make the ink layer gradually thicken in a stepwise manner, so that when the sensor is attached to the sensing layer, there are few bubbles and they ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com