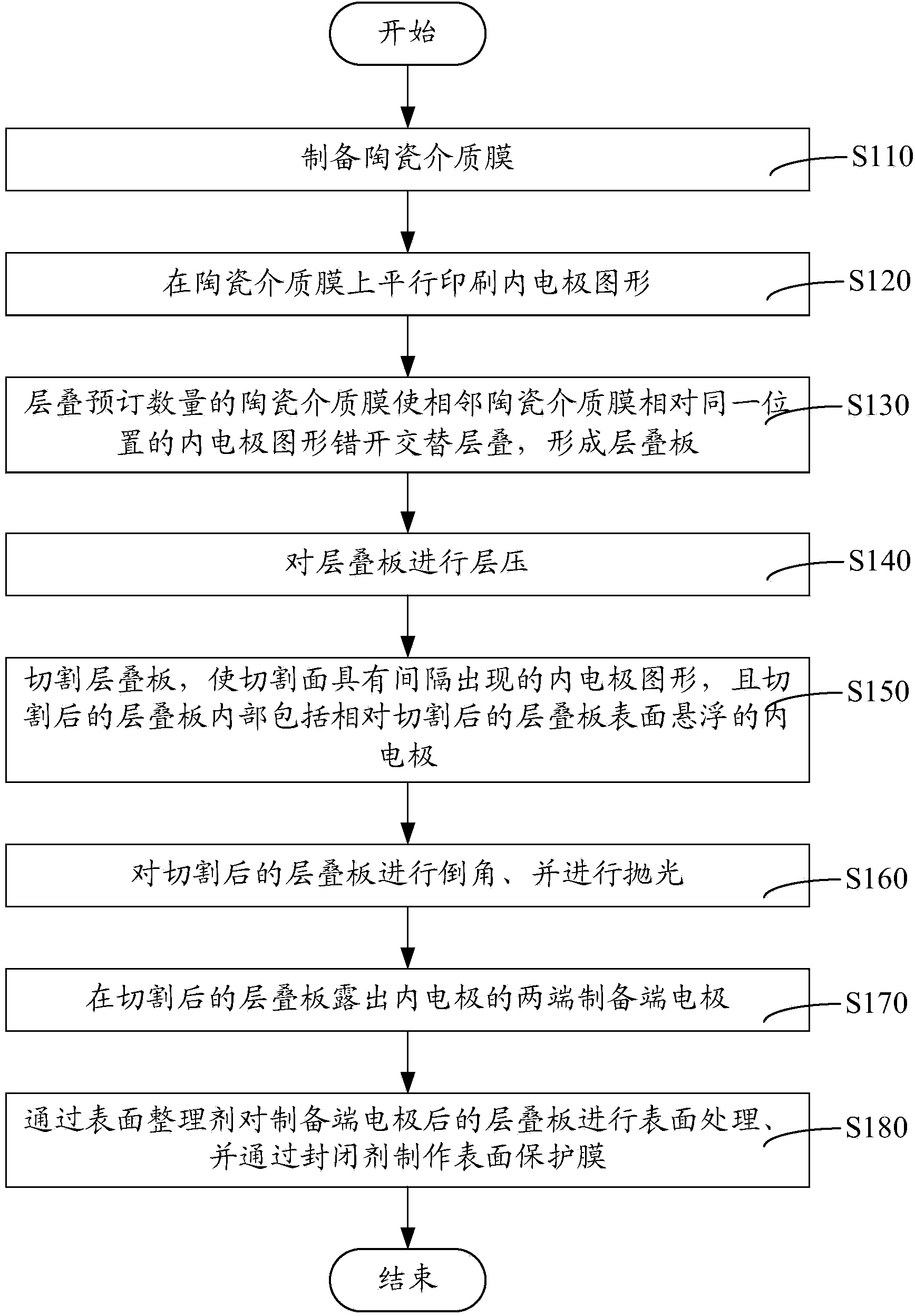

Preparation method for safety chip type multilayer ceramic capacitors

A multi-layer ceramic and safety chip technology, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor parts, etc., can solve problems such as easy cracking, electric shock crisis, capacitor failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

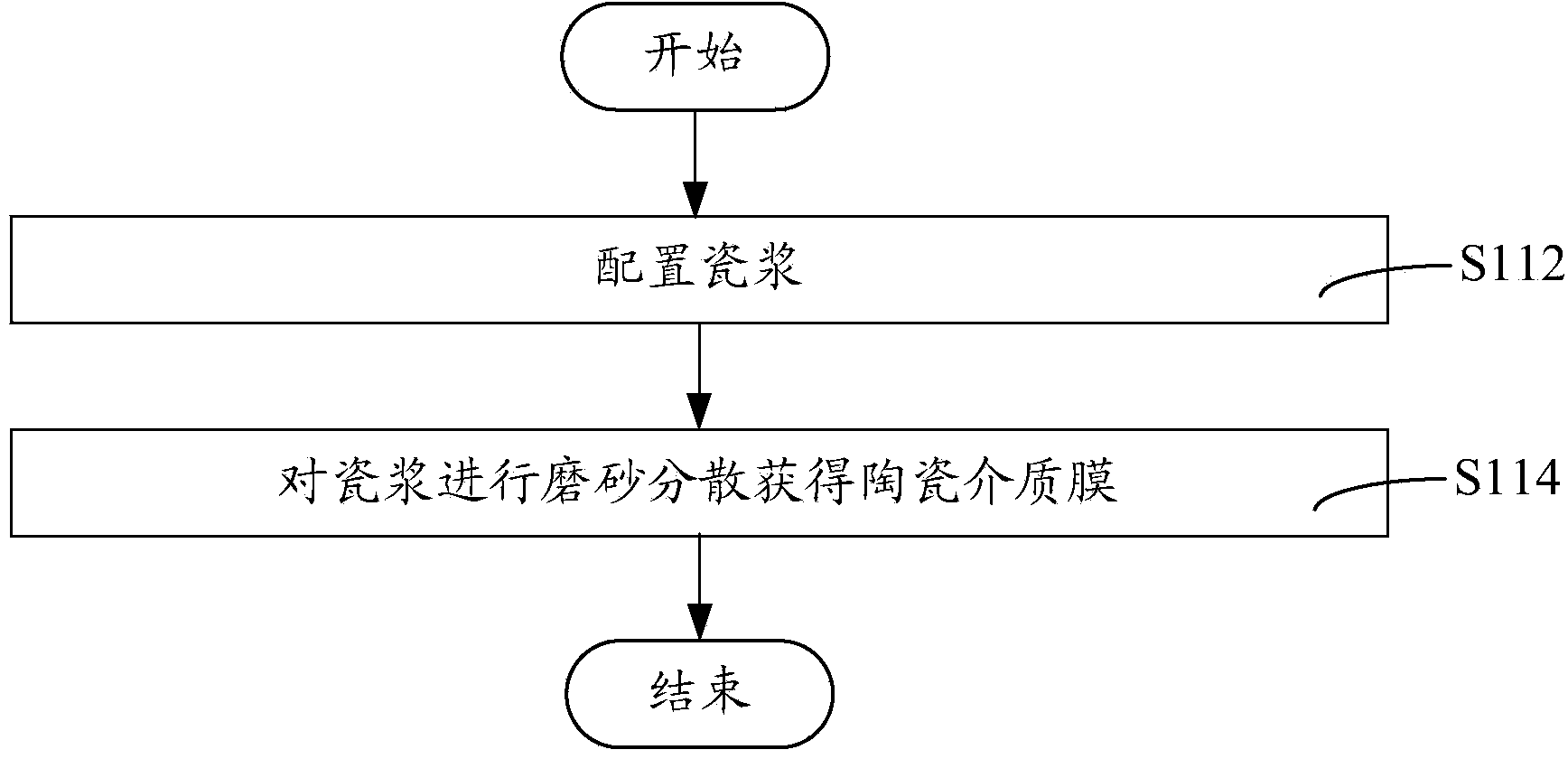

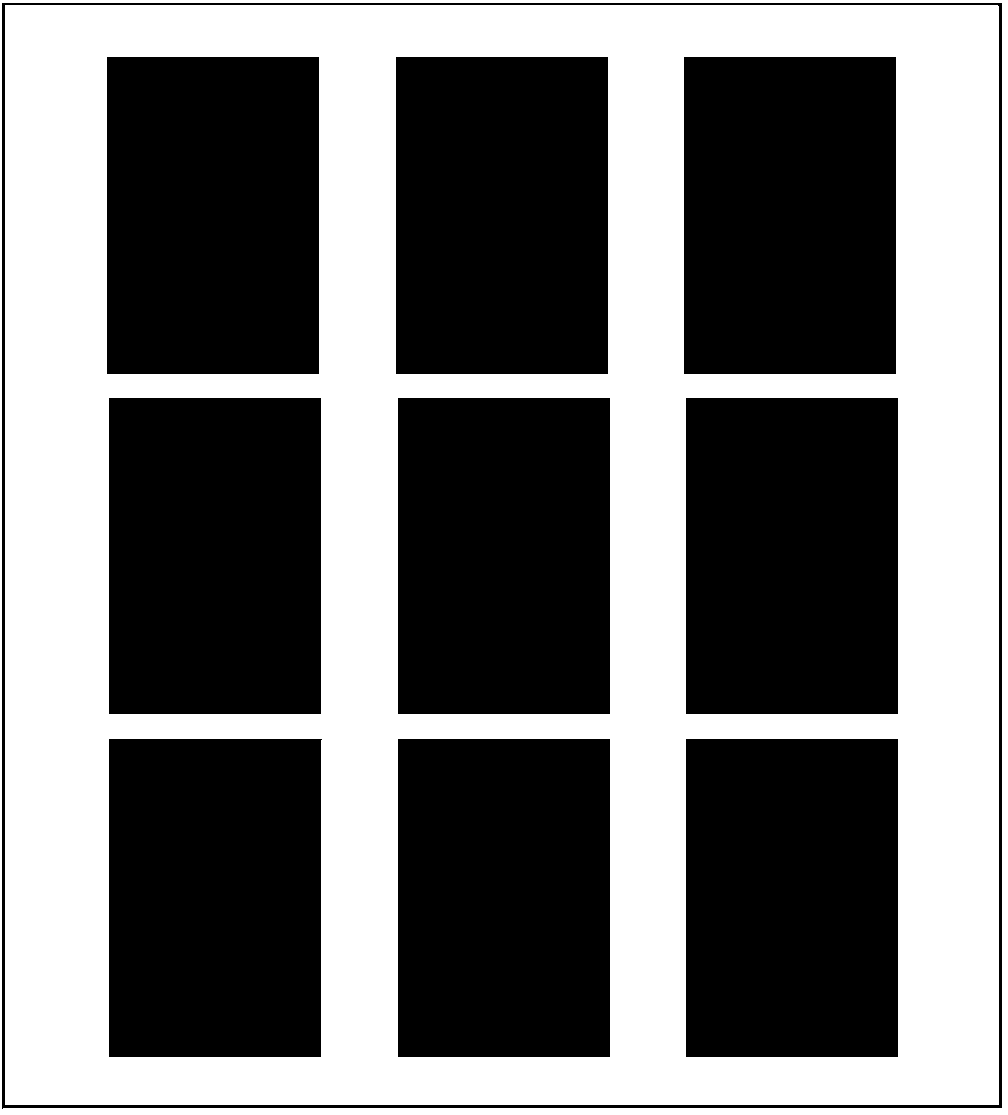

Method used

Image

Examples

Embodiment Construction

[0037] A method for preparing a safety chip multilayer ceramic capacitor. The prepared safety chip multilayer ceramic capacitor contains suspended internal electrodes to ensure that the circuit is in an open state, and avoids the problem that the capacitor is prone to short circuit when it is subjected to stress cracking. It also avoids the problem of personal safety caused by electric shock due to short circuit of the capacitor; the safety chip multilayer ceramic capacitor prepared by the above safety chip multilayer ceramic capacitor adopts smooth water chestnut internal electrodes, effectively increasing the The distance between the terminals is improved, the contact point is flat, the tip discharge phenomenon and the arc are prevented, and the safety of the capacitor under high voltage is ensured; the safety chip multilayer ceramic capacitor prepared by the above preparation method of the safety chip multilayer ceramic capacitor For ceramic capacitors, polishing technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com