A kind of flexible solar module and its manufacturing method

The technology of a solar module and its manufacturing method, which is applied in the field of solar photovoltaic power generation, can solve the problems that single-chip batteries cannot be connected in series without gaps and short circuit, and achieve the effects of simple and convenient processing, narrow volume, and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

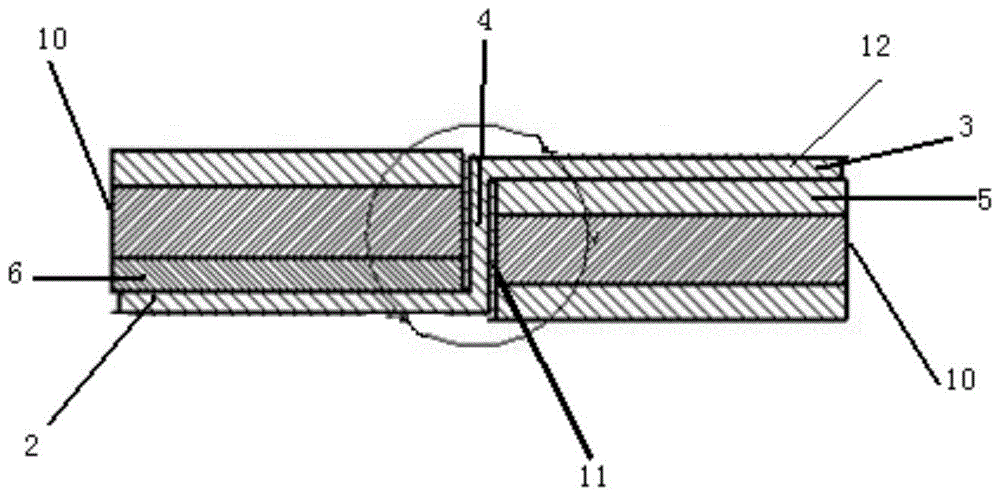

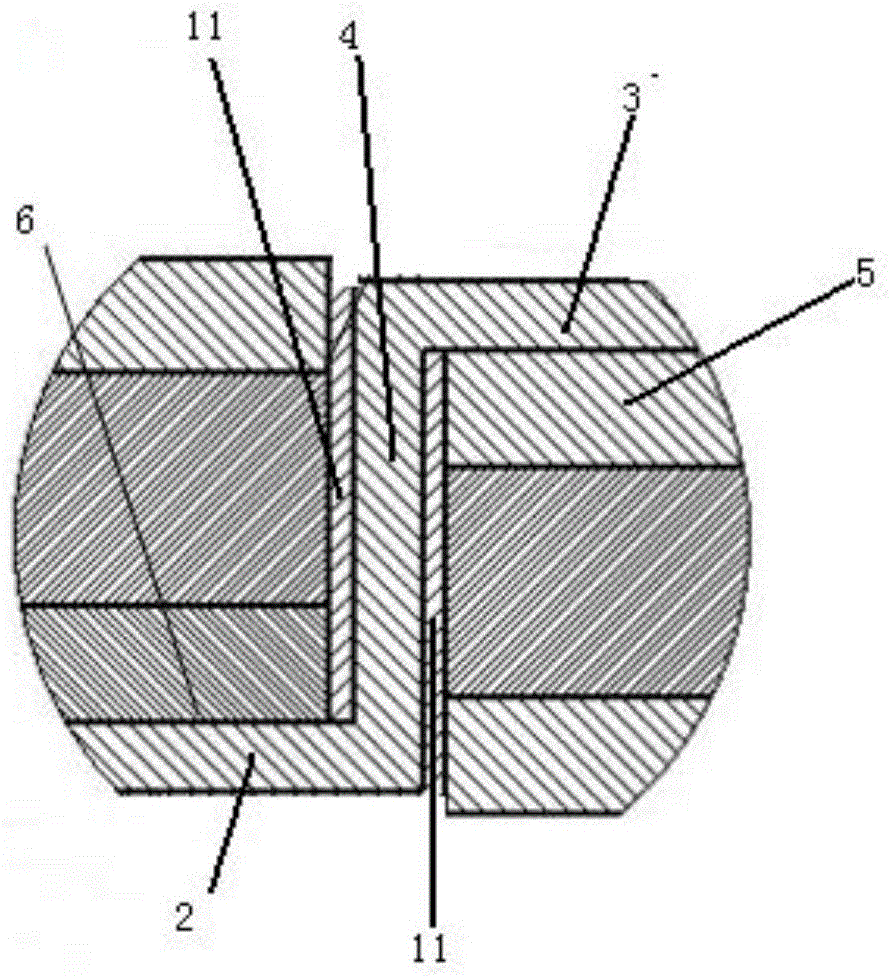

[0051] This embodiment provides a kind of flexible solar module, such as Figure 1A As shown, it includes an insulating component 11, a conductive component 12 and a photoelectric conversion component 10. The conductive component 12 includes two extension arms 2, 3 and a connecting arm 4 respectively connecting one end of the two extension arms 2, 3. A photoelectric The first electrode layer 5 of the conversion part 10 is arranged close to the inner side of one of the extension arms 3, and the second electrode layer 6 of the other photoelectric conversion part 10 is arranged close to the inner side of the other extension arm 2. The two sides of the arm 4 are provided with insulating parts 11. In this embodiment, the insulating parts 11 are insulating arms covering both sides of the connecting arm 4. The two photoelectric conversion parts 10 on both sides are respectively connected to the connecting arms 4 insulation. As another alternative embodiment, for the convenience of pr...

Embodiment 2

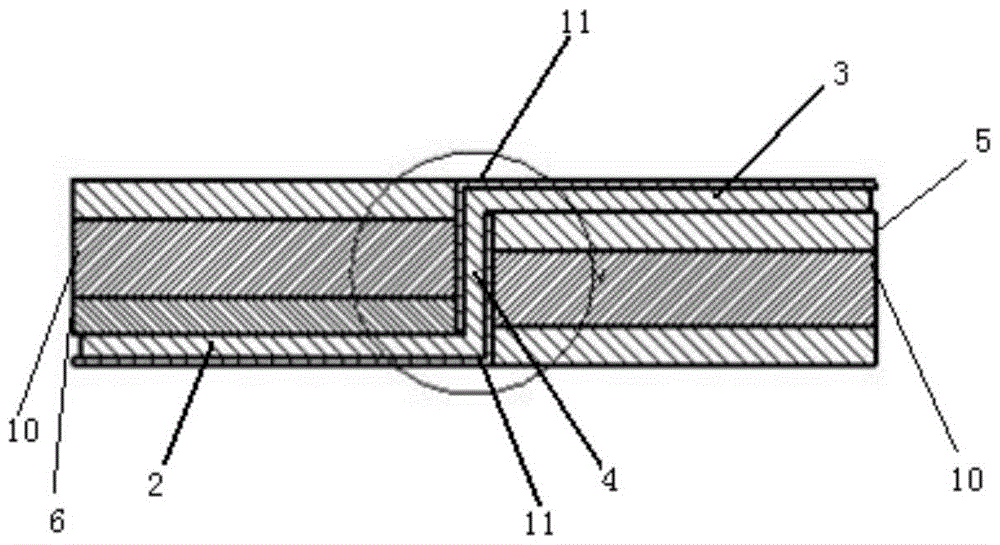

[0053] In the flexible solar module in this embodiment, on the basis of the above embodiments, an insulating member 11 is also provided on the outside of the extension arms 2, 3, such as Figure 1C As shown, the insulating part is an insulating surface or an insulating arm capable of covering the extension arms 2 and 3. In this embodiment, the insulating parts on the outside of the extension arms 2 and 3 and the insulating parts on both sides of the connecting arm 4 are insulating surfaces. The insulating surface on the outer side of the extension arm 2 perpendicularly intersects the insulating surface on the right side of the connecting arm 4 , and the insulating surface on the outer side of the extending arm 3 intersects perpendicularly on the insulating surface on the left side of the connecting arm 4 . The cross-sectional view of the flexible solar module described in this embodiment is as follows Figure 1C shown. The structure of the conductive part 12 is as Figure 3A...

Embodiment 3

[0062] The flexible solar module of the present invention includes four insulating components 11 , two conductive components 12 and two photoelectric conversion components 10 . The insulating part 11 is an insulating surface, and the two conductive parts 12 each include an extension arm 2, an extension arm 3 and a connecting arm 4, see Figure 6C as well as Figure 7 , Figure 8 The photoelectric conversion component 10 includes a first electrode layer 5 (that is, the light-incident surface electrode layer), a second electrode layer 6 (that is, the light-incident surface electrode layer) and a photoelectric conversion layer 7 . Both the right side of the connecting arm 4 and the outer side of the extension arm 2 are provided with insulating parts 11 , and the left side of the connecting arm 4 and the outer side of the extension arm 3 are also provided with insulating parts 11 . Photoelectric conversion components 10 are respectively arranged inside the two extension arms 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com