Mobile bracket for laying power cables

A technology for moving brackets and power cables, applied in the field of moving brackets, can solve the problems of damage to the outer sheath of the cable, difficulty in dragging the cable, time-consuming and laborious, etc., and achieve the effects of reducing labor intensity, simple structure, and ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

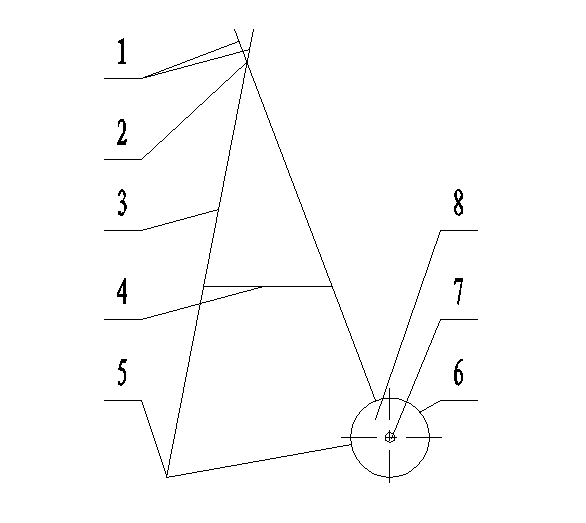

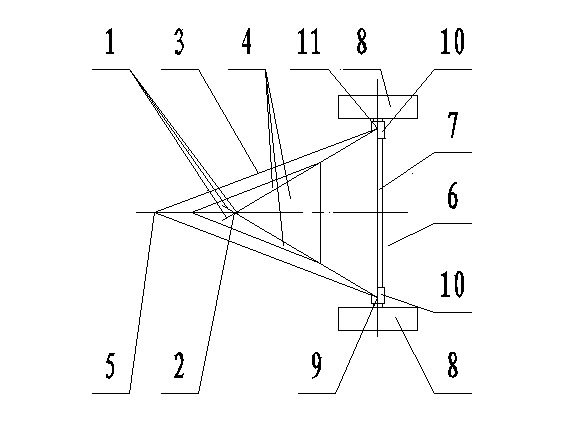

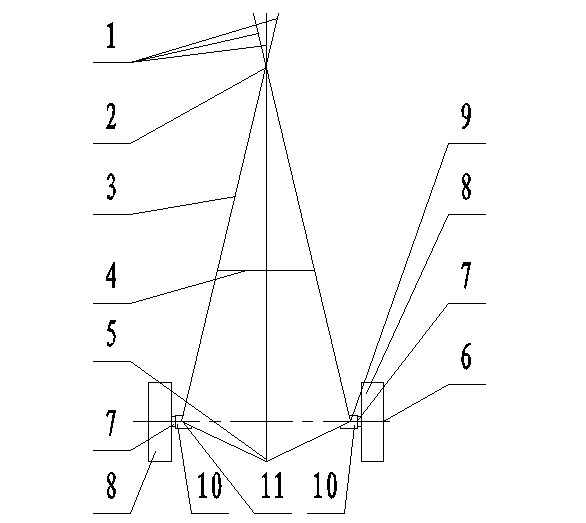

[0014] refer to Figure 1 ~ Figure 3 , the present invention is used for the mobile bracket of power cable laying, and it comprises frame body 3, supporting sleeve, moving part 6 and clamping part 1, and described frame body 3 is a triangular pyramid, and the first bottom angle of the bottom surface of frame body 3 9 and the second bottom angle 11 are respectively fixedly connected to the central coaxial shaft sleeve 10, and the shaft sleeves 10 are respectively built with fixed support sleeves, and a fixed flat plate is set between the top angle 2 and the bottom surface of the frame body 3 4. The moving part 6 is simultaneously installed in the support sleeve built in the shaft sleeve 10 fixedly connected to the first bottom corner 9 and the second bottom corner 11 of the bottom surface of the frame body 3, and is hinged to the frame body 3 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com