Electromagnetic suspension system for overlaying transverse rotating static magnetic field

An electromagnetic levitation and lateral rotation technology, applied in the direction of the magnetic attraction or thrust holding device, electrical components, etc., can solve the problems of high static magnetic field strength, expensive, complex equipment and price, and achieve reasonable price, simple structure, and suspension system stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

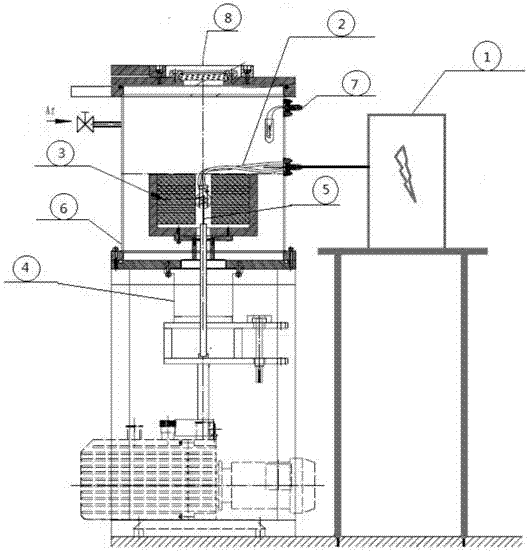

[0016] 1. Open the upper cover of the vacuum chamber, lift the material lifting tray 5 to a suitable position in the conical rewinding coil 2, and put the suspended material into the material lifting tray 5.

[0017] 2. Close the upper cover of the vacuum chamber, start the vacuum pump, pump the air pressure in the vacuum chamber to 5Pa, and turn off the vacuum pump.

[0018] 3. Open the inert gas inflation valve 9, inflate to atmospheric pressure, then rush in at a flow rate of 1L / min and discharge it through the outlet valve to maintain the pressure in the vacuum chamber 6 at atmospheric pressure.

[0019] 4. Start the circulating water pump to ensure that the return water is normal.

[0020] 5. Start the high-frequency power supply 1, adjust the power output knob until the suspended object is separated from the material lifting tray 5, and withdraw the material lifting tray 5.

[0021] 6. Start the rotating mechanism 4 to make the U-shaped yoke 3 rotate.

[0022] So far, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com