Cone crusher and processing plant for mineral material

A cone crusher, crushing cavity technology, used in grain processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description, the same reference numerals denote the same elements. It should be understood that the drawings shown are not exactly to scale and that the drawings are primarily for the purpose of illustrating some exemplary embodiments of the invention.

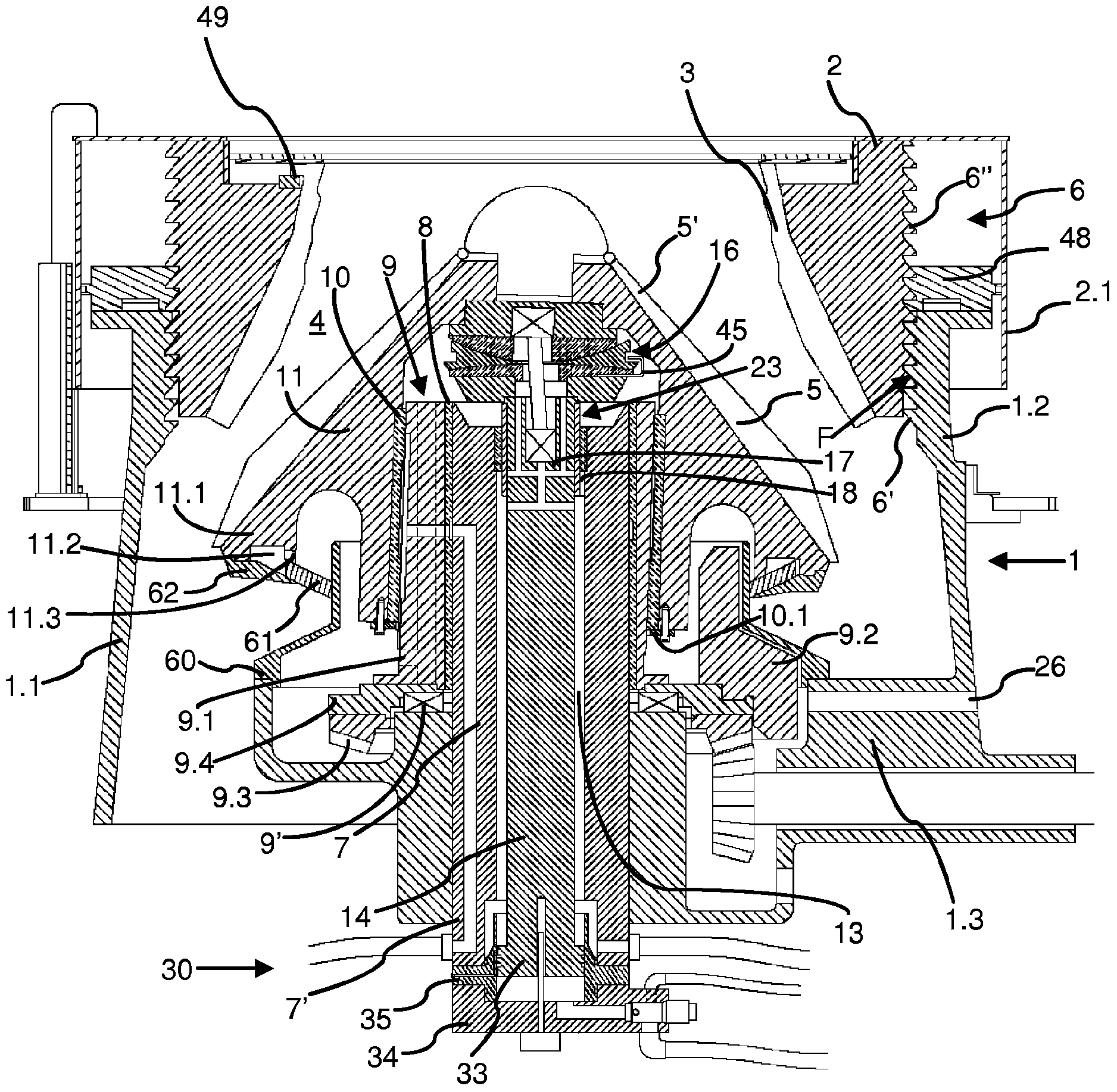

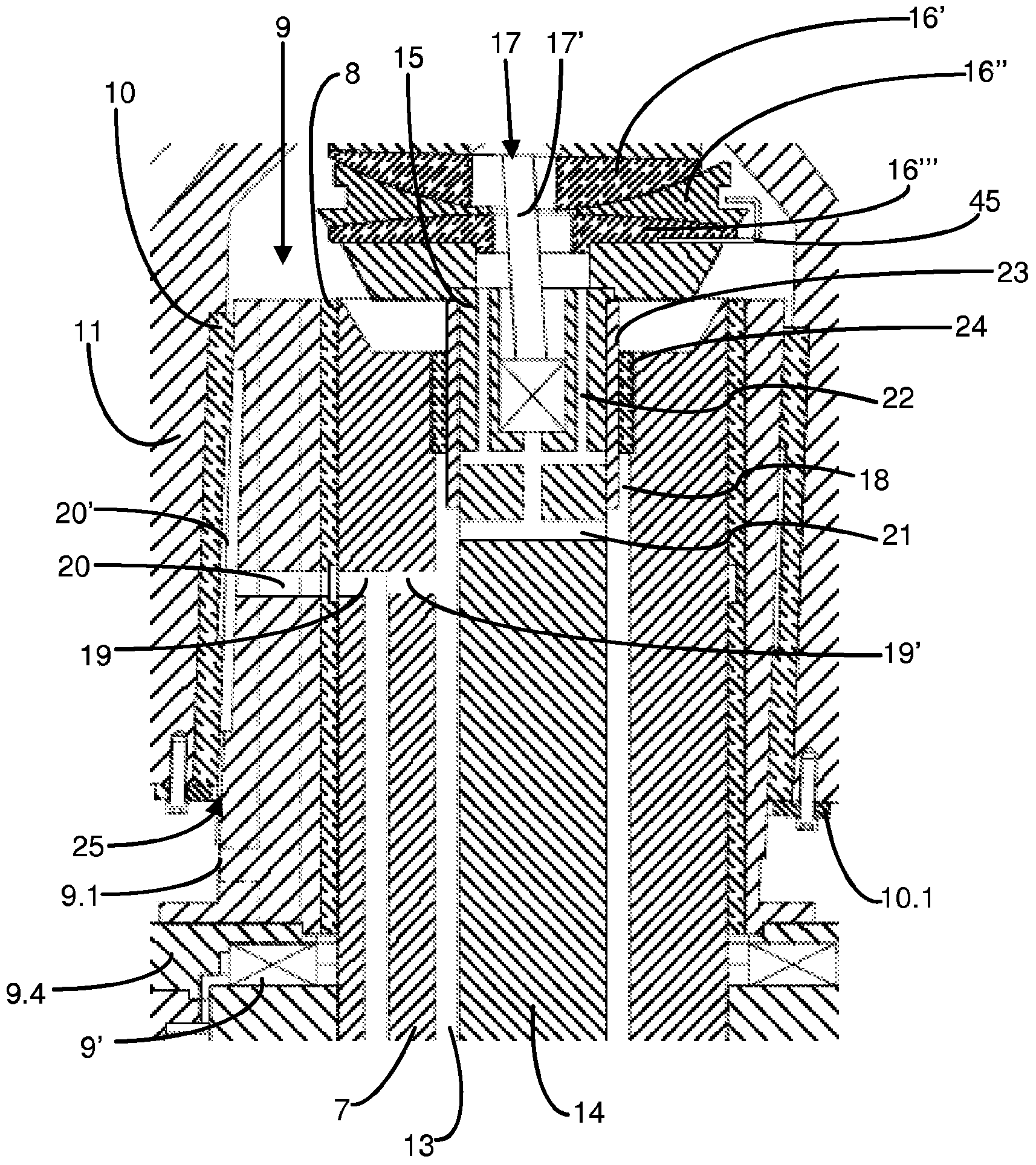

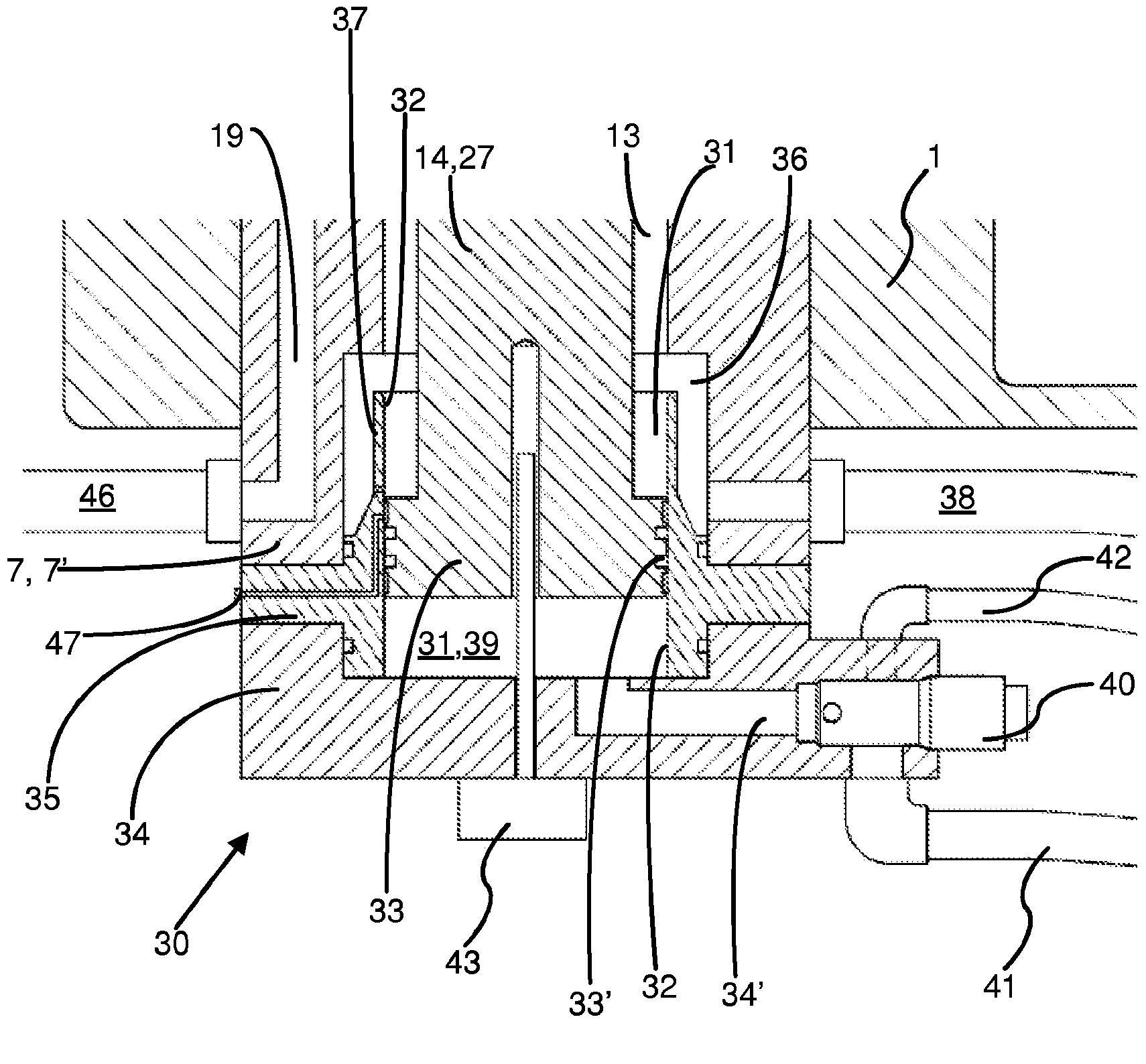

[0039] figure 1 A cone crusher is shown comprising a frame 1 and an upper part 2 of the crusher attached to the frame, to which the outer blades 3 of the crusher are attached. The outer blades can move vertically when the crushing chamber 4 is not loaded.

[0040] The crushing chamber 4 of the cone crusher is formed between the outer blade 3 and the inner blade 5 . During a crushing event, the position of the inner blade 5 changes relative to the outer blade 3, preferably as a combination of radial movement and movement around the axis of the inner blade. Optionally or additionally, the inner blade 5 can move vertically during the crushing process or in an unloaded state (the so-called idle state) si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com