Cellulose nanofibers and method for producing same, composite resin composition, molded body

A nanofiber and cellulose technology, which is applied to artificial filaments made of cellulose derivatives, plant fibers, fiber treatment, etc., can solve the problem of low resin reinforcement effect and achieve high modification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

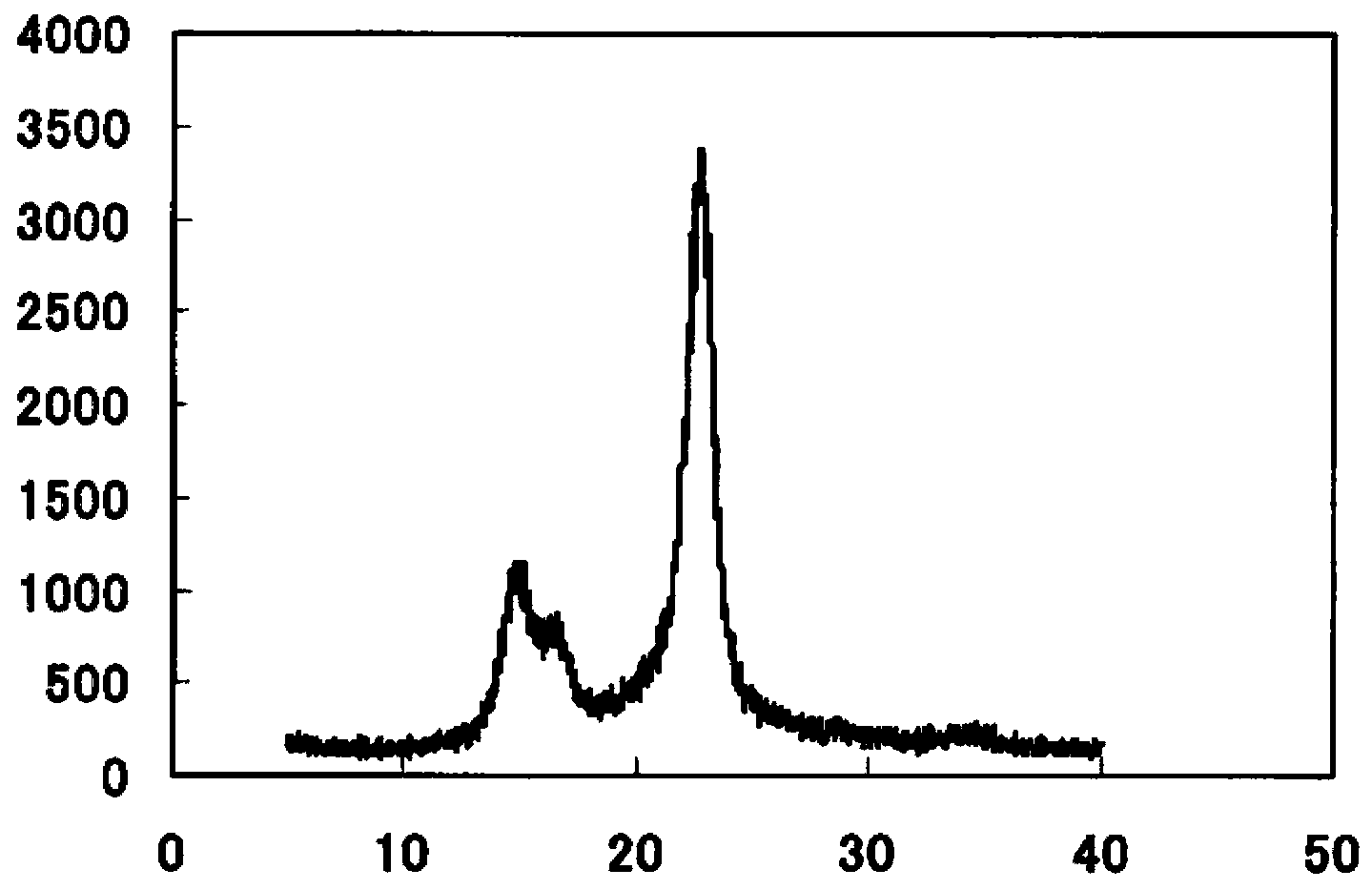

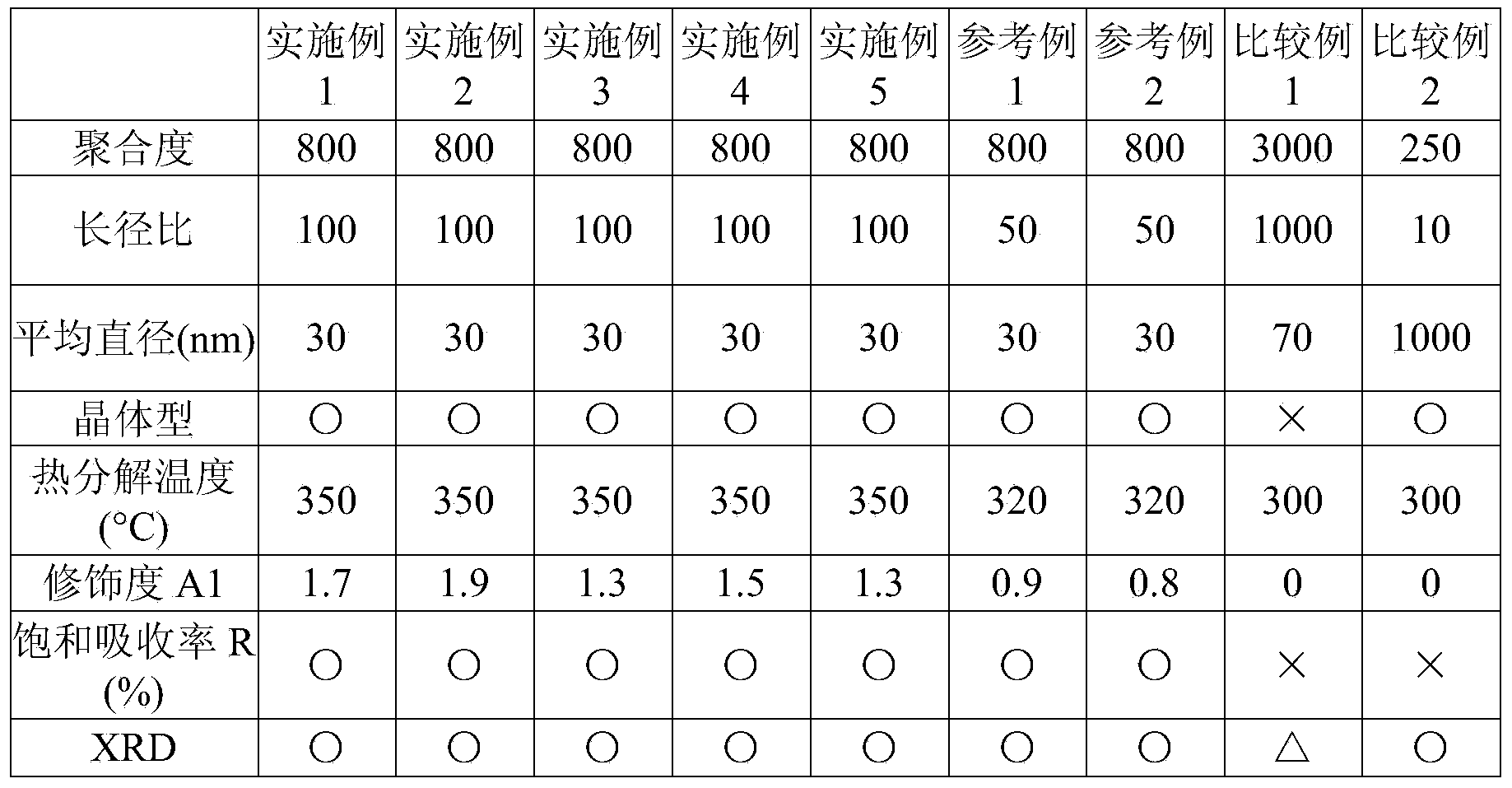

[0078] In the method for producing cellulose nanofibers according to this embodiment, the cellulose nanofibers have an average degree of polymerization of 600 to 30,000, an aspect ratio of 20 to 10,000, and an average diameter of 1 nm to 800 nm. The method for producing the cellulose nanofibers includes the step of esterifying the hydroxyl groups of the cellulose nanofibers with vinyl carboxylate for the cellulose nanofibers having an Iβ-type crystallization peak in the X-ray diffraction pattern. grooming.

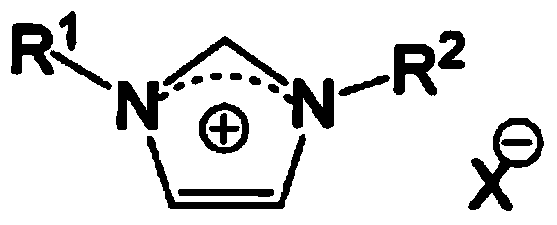

[0079] For example, when the cellulose raw material is opened in a solution containing an ionic liquid, the viscosity of the solution in which the cellulose raw material is dissolved increases. Therefore, the present embodiment is a method in which the following steps are performed in two steps: a step of hydrolyzing a cellulose part with low crystallinity with sulfuric acid in order to lower the viscosity, thereby performing a fiber opening treatment; and chemical modific...

no. 2 Embodiment approach

[0096] The method for producing cellulose nanofibers according to the present embodiment includes the steps of swelling a cellulose raw material in a solution containing an ionic liquid, adding a modifier as it is, followed by filtering and washing.

[0097] The method for producing cellulose nanofibers according to this embodiment is a method in which the following steps are performed in one step: a step of opening cellulose raw materials in a solution containing an ionic liquid; and treating the cellulose with vinyl carboxylate. The process of chemically modifying the hydroxyl group of the nanofiber (hereinafter referred to as the one-step method.).

[0098] Compared with the conventional two-step method, the one-step method according to this embodiment has fewer steps, and thus is advantageous in terms of management and cost. In addition, the amount of solvent used is small, and environmental load can be reduced.

[0099] The cellulose raw material and the ionic liquid-con...

Embodiment 1

[0112] Put 2g of filter paper cut into a 3mm square with scissors into a 200ml flask, further add 50ml of N,N-dimethylacetamide and 60g of ionic liquid 1-butyl-3-methylimidazolium chloride, and carry out Stirred. Next, after further adding sulfuric acid aqueous solution and stirring, it filtered and washed the solid content. This was processed with a homogenizer to obtain cellulose nanofibers. The cellulose nanofibers were acetylated by reacting with vinyl acetate in DMF (dimethylformamide) for 45 minutes, and washed to obtain acetylated cellulose nanofibers by a two-step method. The obtained acetylated cellulose nanofibers had a degree of modification of 1.7 and a thermal decomposition temperature of 350°C.

[0113] Next, polycarbonate (PC; manufactured by Teijin Chemicals: Panlite L-1225L, refractive index 1.58) and acetylated cellulose nanofibers dissolved in methylene chloride in advance were mixed in methylene chloride and dried. , thereby obtaining a polycarbonate com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com