Moving sieve fault diagnosis method of coal particle size analysis in three-dimensional modeling

A technology of fault diagnosis and three-dimensional modeling, applied in particle size analysis, particle and sedimentation analysis, chemical instruments and methods, etc., can solve problems such as slow processing speed, poor stability, and high complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

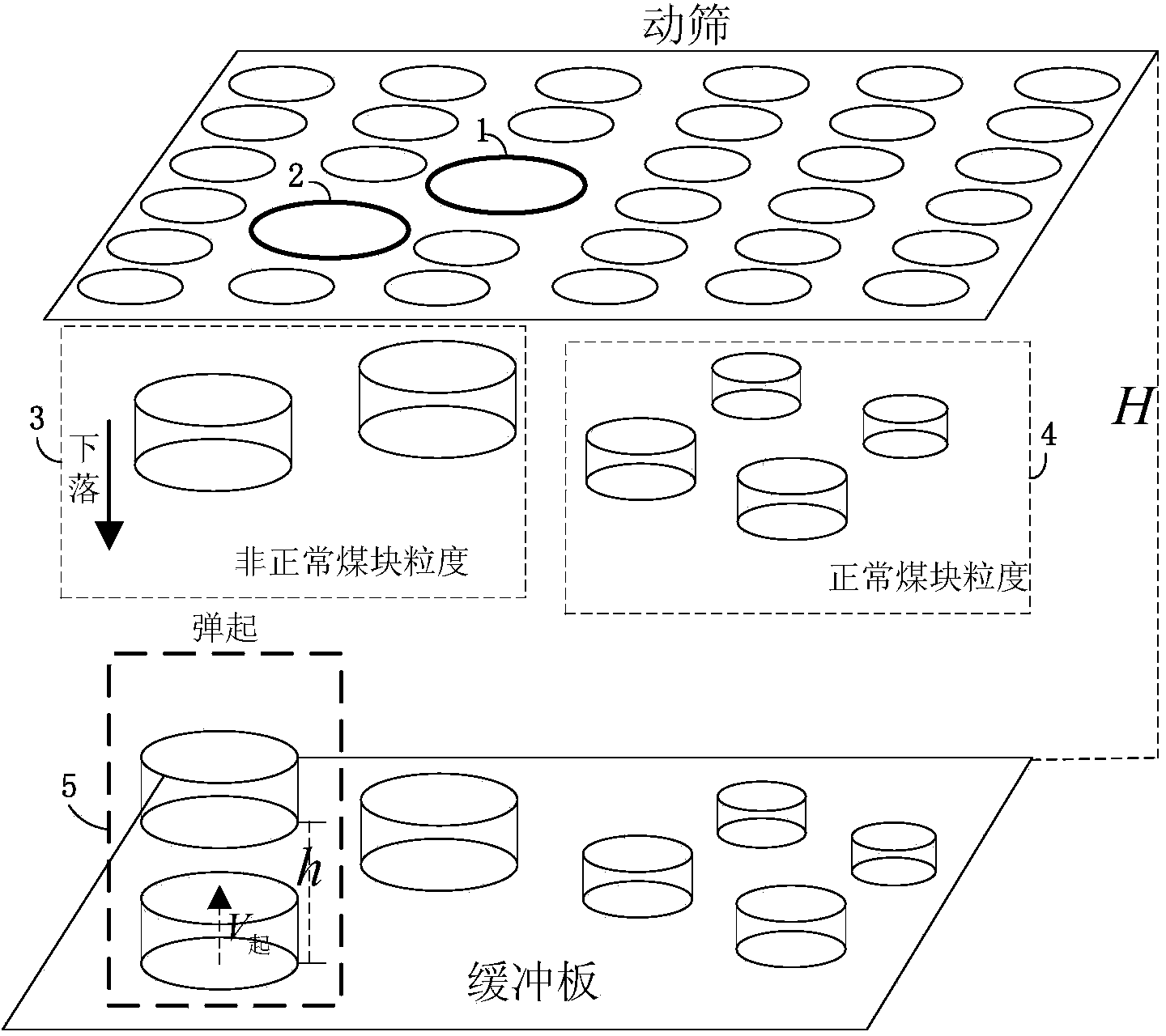

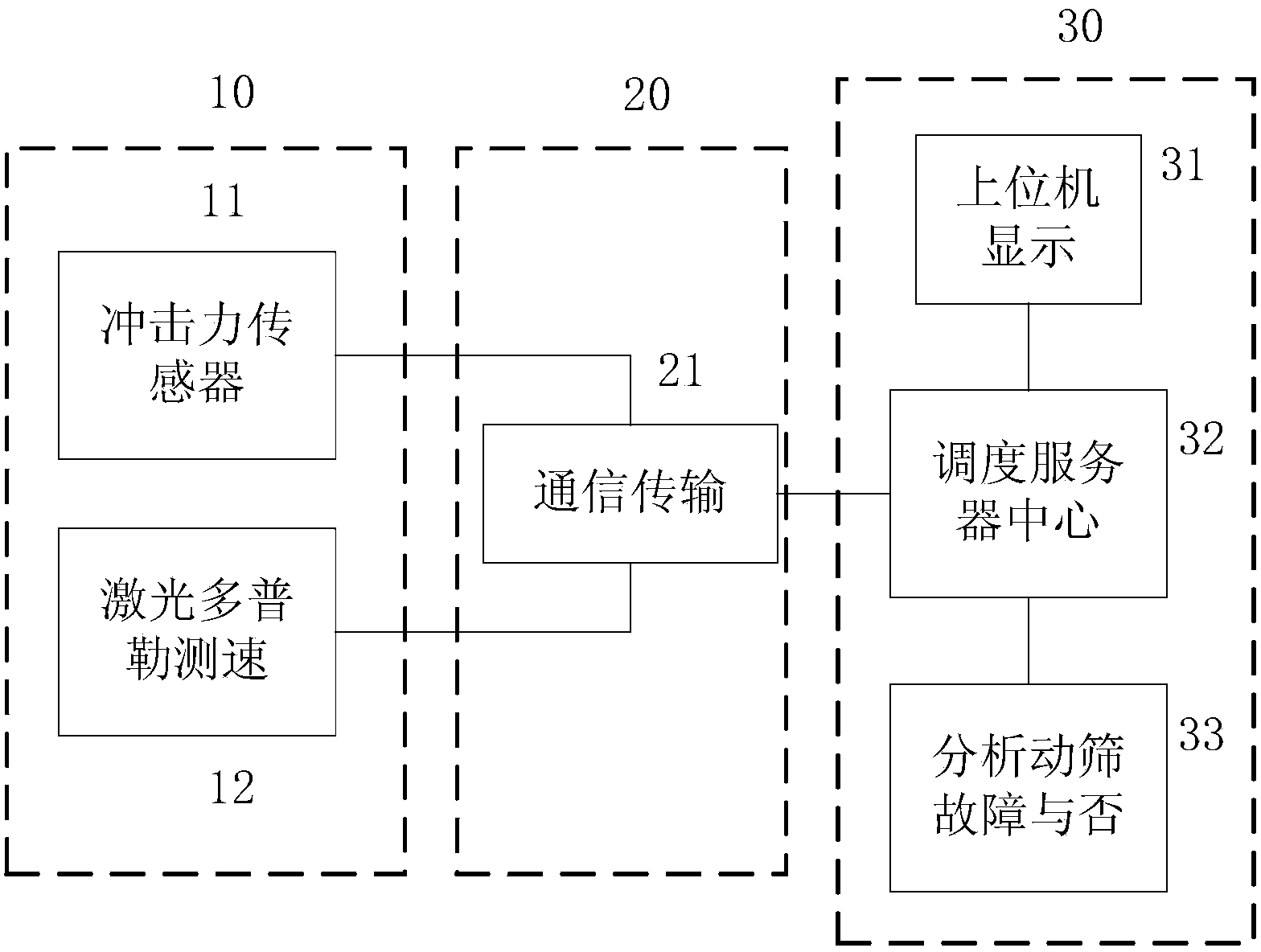

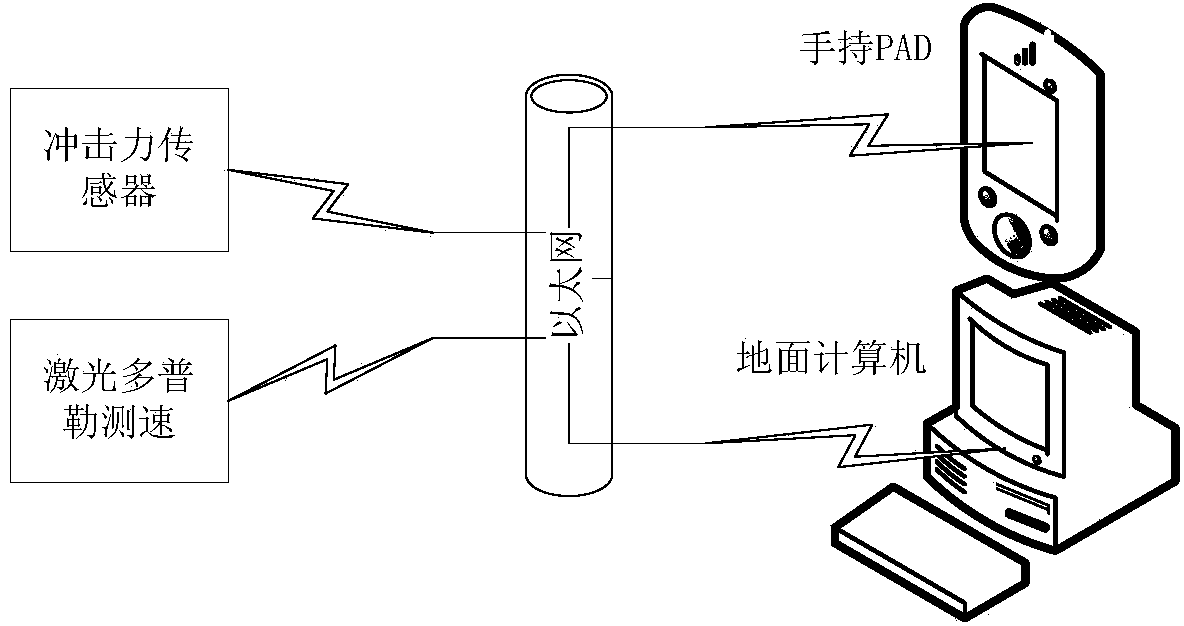

[0043] Embodiment 1: The moving sieve fault diagnosis method measures the impact strength of the coal block from the moving screen falling on the buffer plate, the take-off speed and the take-off height of the coal block after hitting the buffer plate through the impact force sensor and the laser Doppler velocimetry method as The characteristics of fault diagnosis of moving screen; 3D modeling analysis of the falling process of the coal block, the impact force P of the coal block on the buffer plate, and the initial velocity v of the coal block bouncing 0 According to the three parameters of the rising displacement h of the coal block, the cross-sectional area of the coal block is determined according to the characteristics of these three signals, compared with the cross-sectional area of the non-faulty screen hole, and the cross-sectional area and thickness of the coal block are calculated; Indirectly measure the particle size of the coal block to diagnose the fault of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com