Method for controlling tension between last two racks of multiple-rack rolling mill

A control method, tension control technology, applied in the direction of tension/pressure control, etc., can solve problems such as control dead zone, tension fluctuation, tension cannot be kept constant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

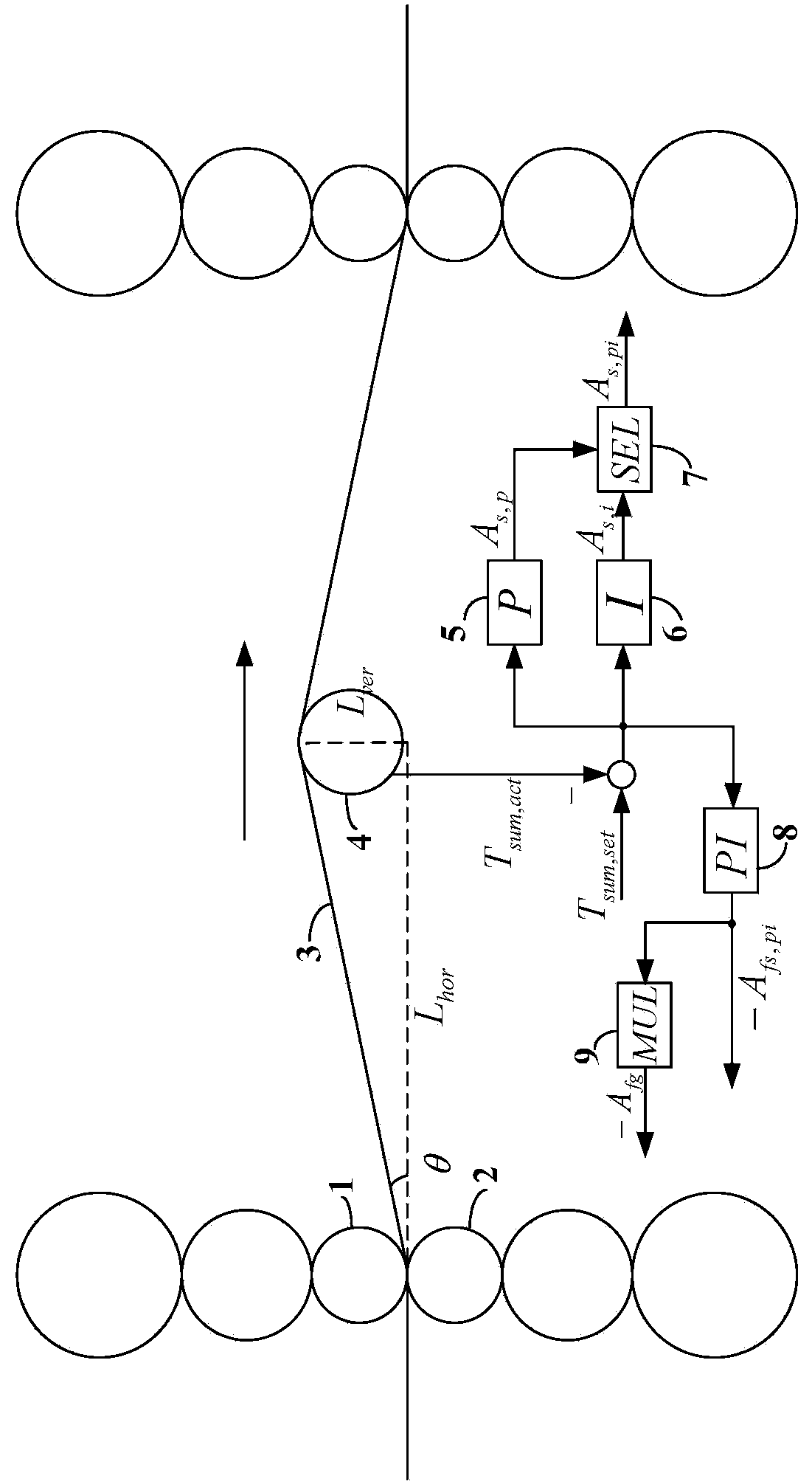

[0053] like figure 1 Shown is a schematic diagram of tension control between the last two stands of the multi-stand rolling mill of the present invention, the strip steel 3 is rolled between the last two stands, and the rolling direction is from left to right.

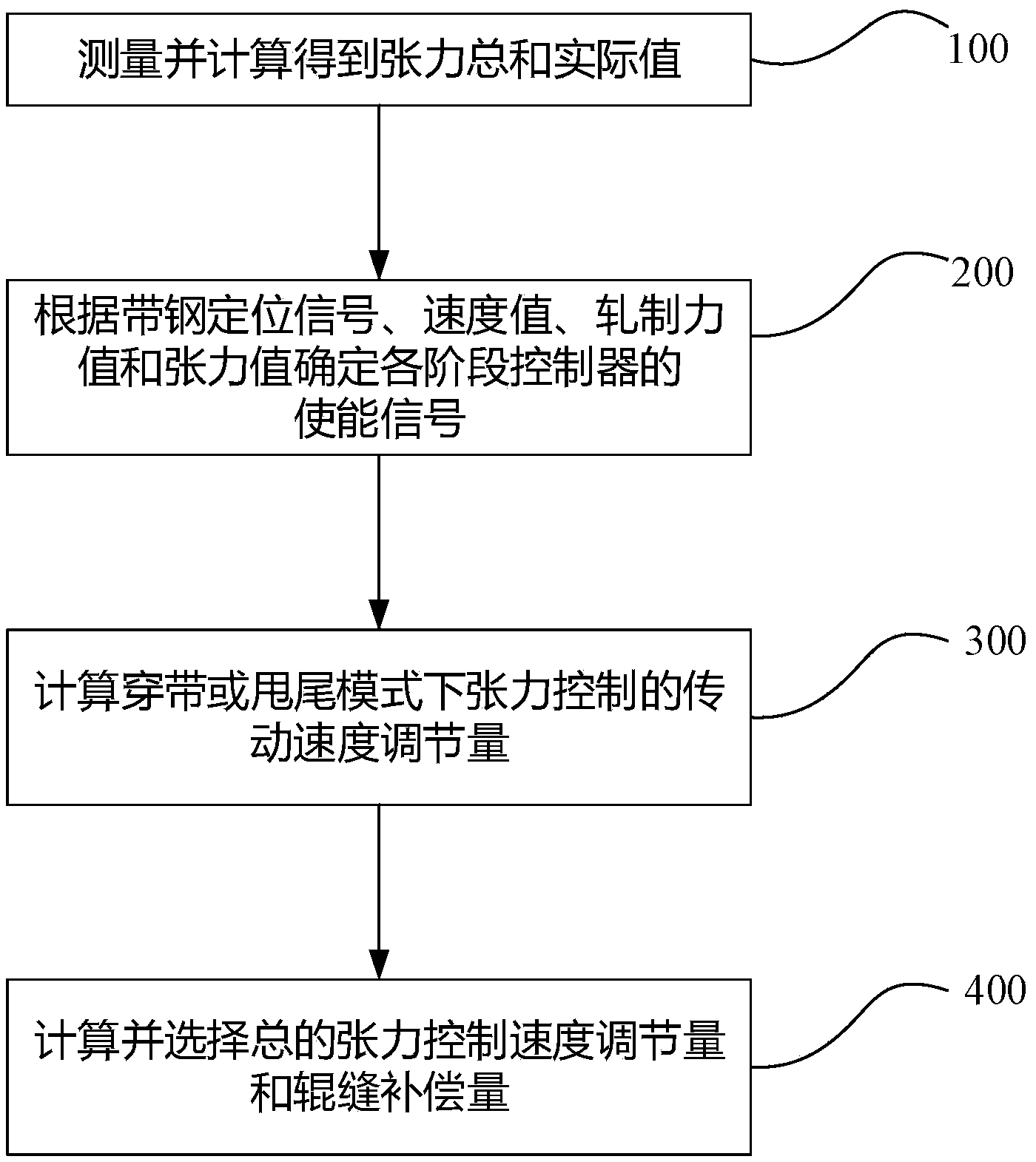

[0054] like figure 2 As shown, the tension control method between the last two stands of the multi-stand rolling mill of the present invention comprises the following steps:

[0055] Step 100, measure and calculate the actual value of the total tension.

[0056] Specifically include:

[0057] Step 101, the transmission side and the operation side of the tension roller 4 between the last two racks are respectively provided with a load cell, and the measured values of the load cells on the drive side and the operation side of the tension roll are added to obtain the sum T of the measured values sum,measure .

[0058] Step 102, determine the horizontal distance L between the tension roller and the roll gap of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com