Sliding rail assembling machine

A slide rail assembly machine and rack technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem that screws cannot be attached to slide rails, etc., and achieve accurate and firm fixation and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

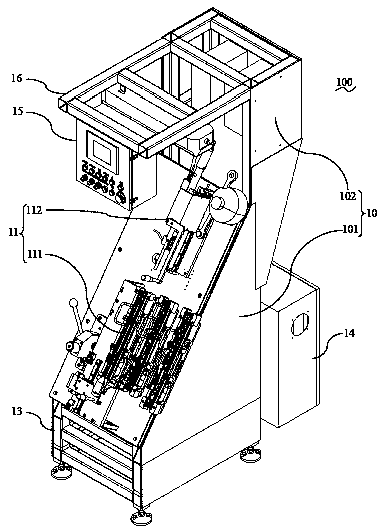

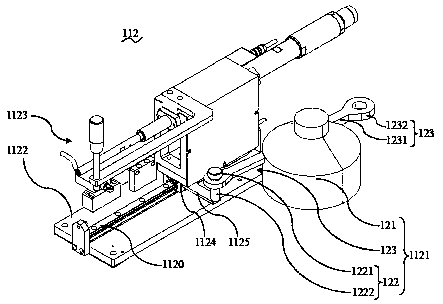

[0021] Such as figure 1 , figure 2 as shown, figure 1 It is a three-dimensional schematic diagram of the slide rail assembly machine 100 in this embodiment; figure 2 for figure 1 An enlarged perspective view of the screw attachment 112 of the shown slide rail assembly machine.

[0022] The above-mentioned slide rail assembly machine 100 includes: a frame 10, and the frame 10 specifically includes a first frame 101 arranged obliquely and a second frame 102 arranged vertically.

[0023] The slide rail assembly machine 100 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com