Front lug ring boring tool of HSG-series engineering cylinder

A kind of engineering and series technology, which is applied in the processing field of front earring boring, can solve problems such as the out-of-tolerance of the verticality between the hole and the thread, the deviation of the center height of the earring, and the impact on the credibility of the enterprise, so as to improve the processing accuracy, improve the product quality, The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

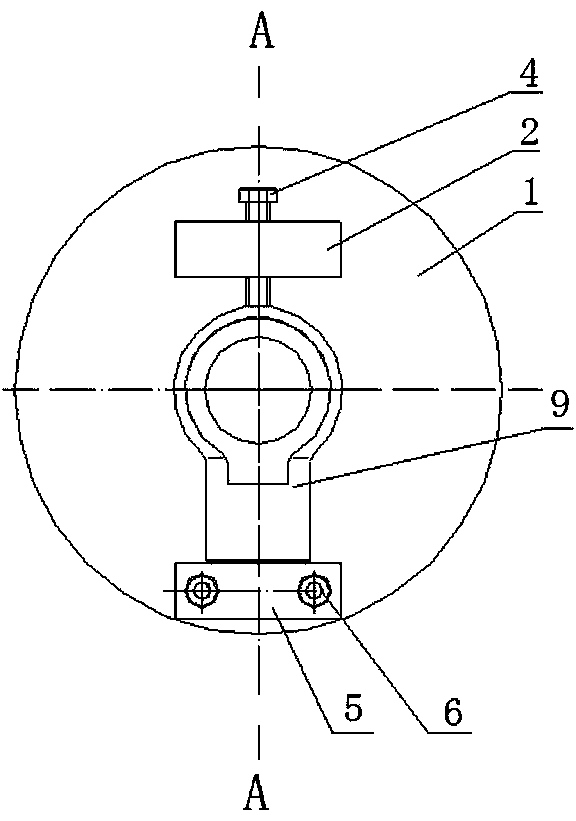

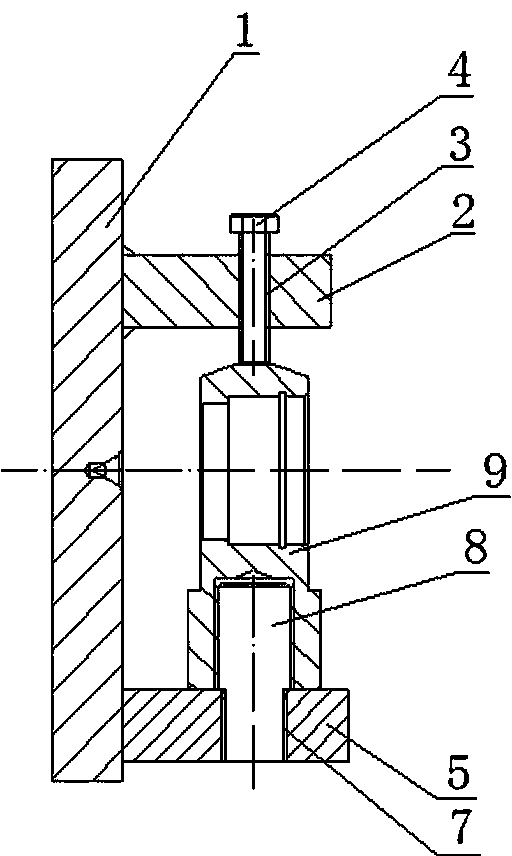

[0009] like figure 1 , 2 As shown, the present invention fixedly connects the fixed vertical plate 2 on one side of a circular chassis 1, offers threaded holes 3 on the fixed vertical plate 2, and the axial direction of the threaded holes 3 is parallel to the large surface of the circular chassis 1. The clamping bolt 4 is threadedly connected in the threaded hole 3 .

[0010] On the same side of the circular chassis 1 where the fixed vertical plate 2 is arranged, the mobile vertical plate 5 is arranged, and the mobile vertical plate 5 is arranged parallel to the fixed vertical plate 2 . The movable riser 5 is connected with the fixed riser 2 by two bolts 6 with adjustable distance, and a bolt hole 7 is offered on the movable riser 5, and a connecting pin 8 is set in the bolt hole 7. The axial direction of the pin hole 7 is parallel to the large surface of the circular chassis 1 , and the axial direction of the pin hole 7 coincides with the axial direction of the threaded hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com