Sucker special for threaded rod

A suction cup and screw technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of easy slipping and small contact area of suction cups, and achieve the effect of low cost, simple structure and stable suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

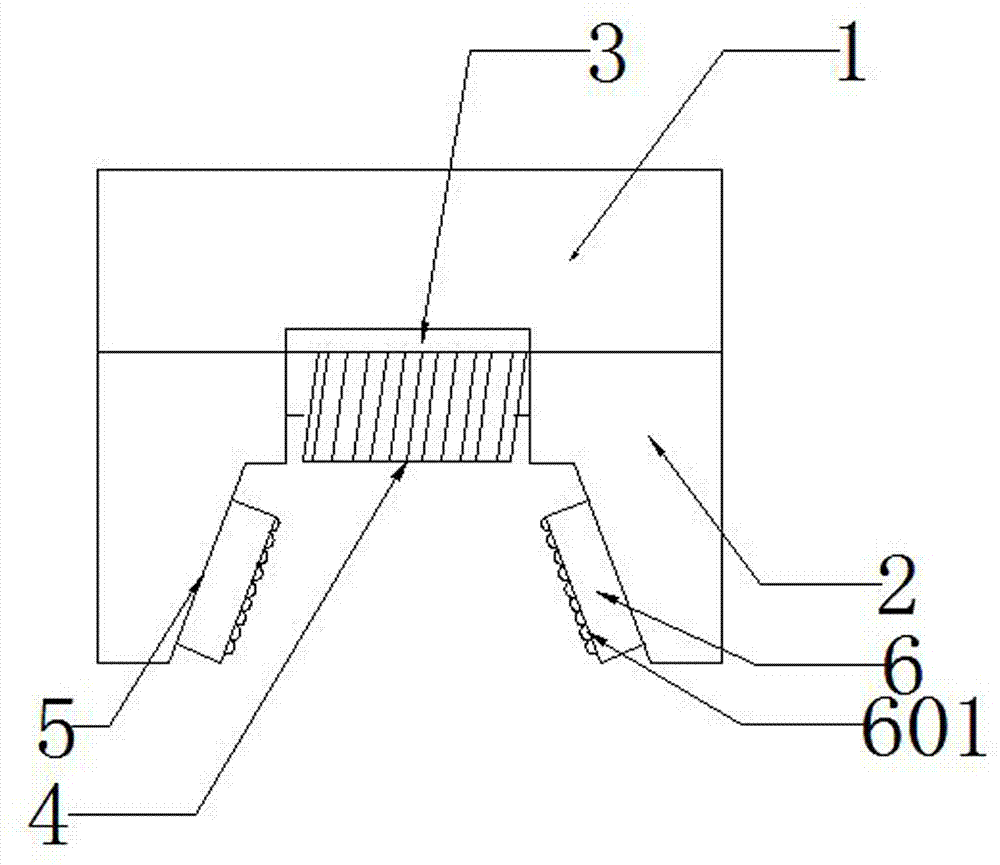

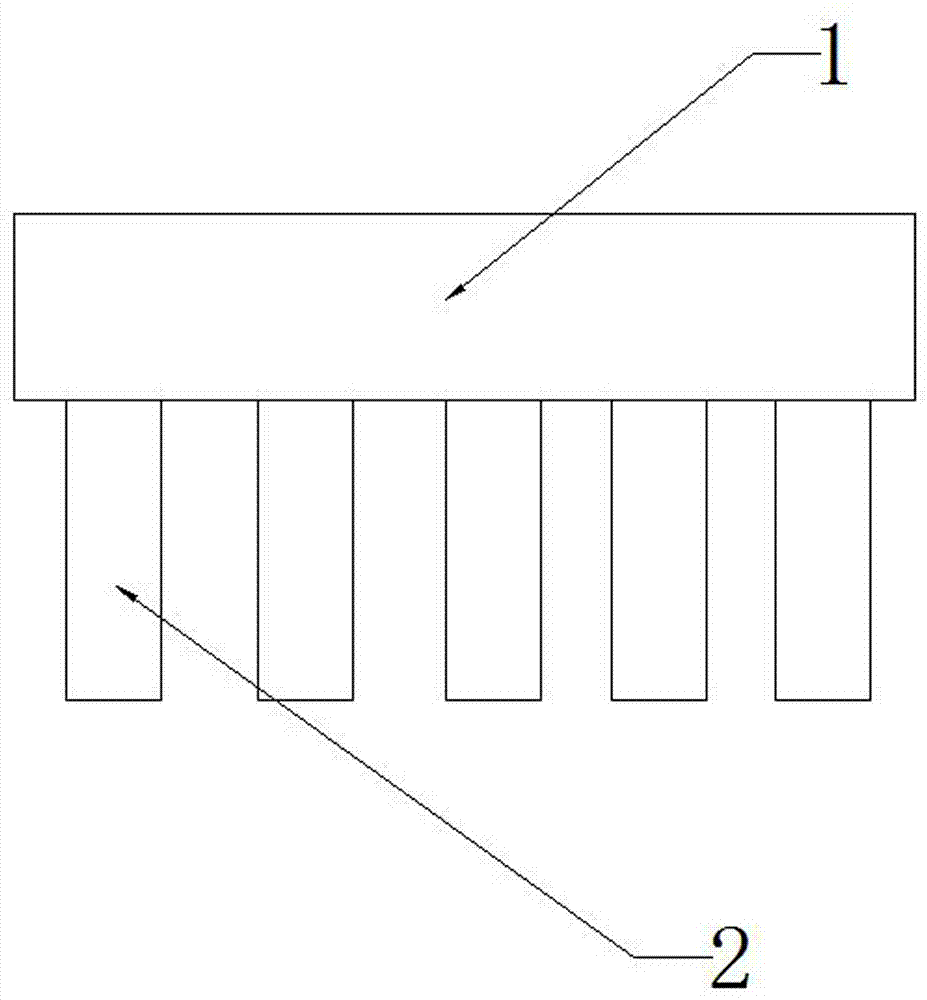

[0018] Suction cups for screw rods, including: suction cup body 1, a plurality of concave suction nozzles 2 fixed on the suction cup body 1, the concave suction nozzles 2 are arranged in a row, and the concave suction nozzles 2 are composed of: suction port 3, placed on both sides of the suction port 3 Two axisymmetric limiting parts, connecting the elastic parts of the two limiting parts, as a kind of preference, the elastic part is spring 4; the setting of spring 4 can buffer the impact force when the screw rod is sucked, and can automatically move the screw rod The center of gravity is aligned with the center of the suction port 3.

[0019] In order to further prevent the screw from slipping, and adapt to the cylindrical shape of the screw, inclined surfaces 5 are provided on the opposite side walls of the two limiters. The slope 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com