Forming mold for precast beam plate

A technology for forming molds and prefabricated beams, applied in the direction of molds, mold separation devices, etc., can solve the problems of inability to ensure that the templates are exactly the same, low production efficiency, and low efficiency, so as to avoid repeated disassembly and assembly of templates, save labor and materials, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

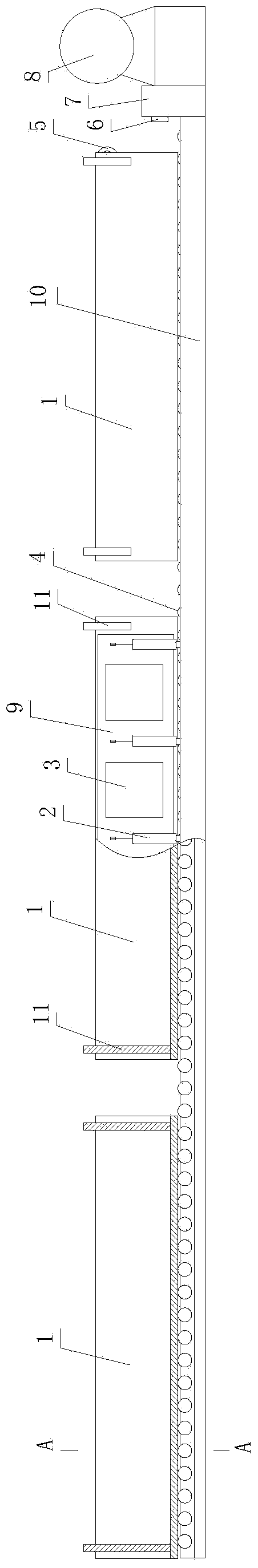

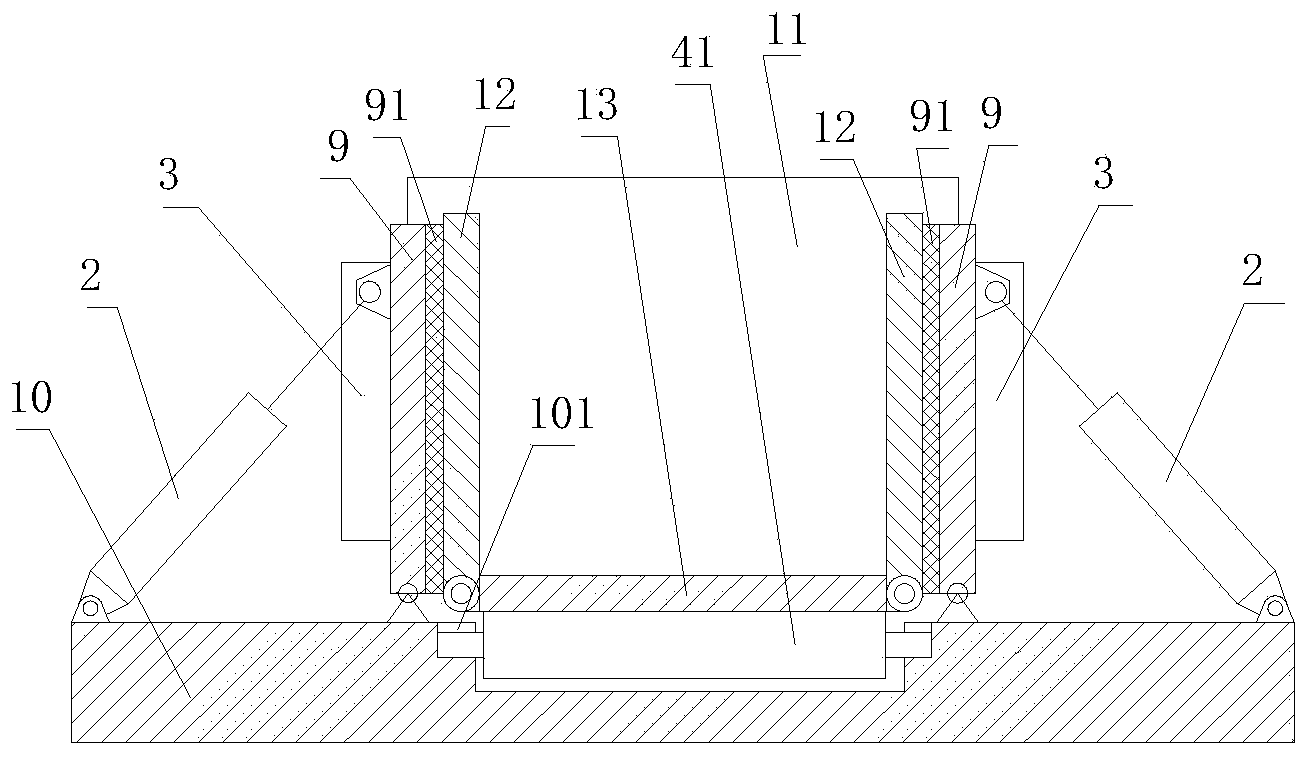

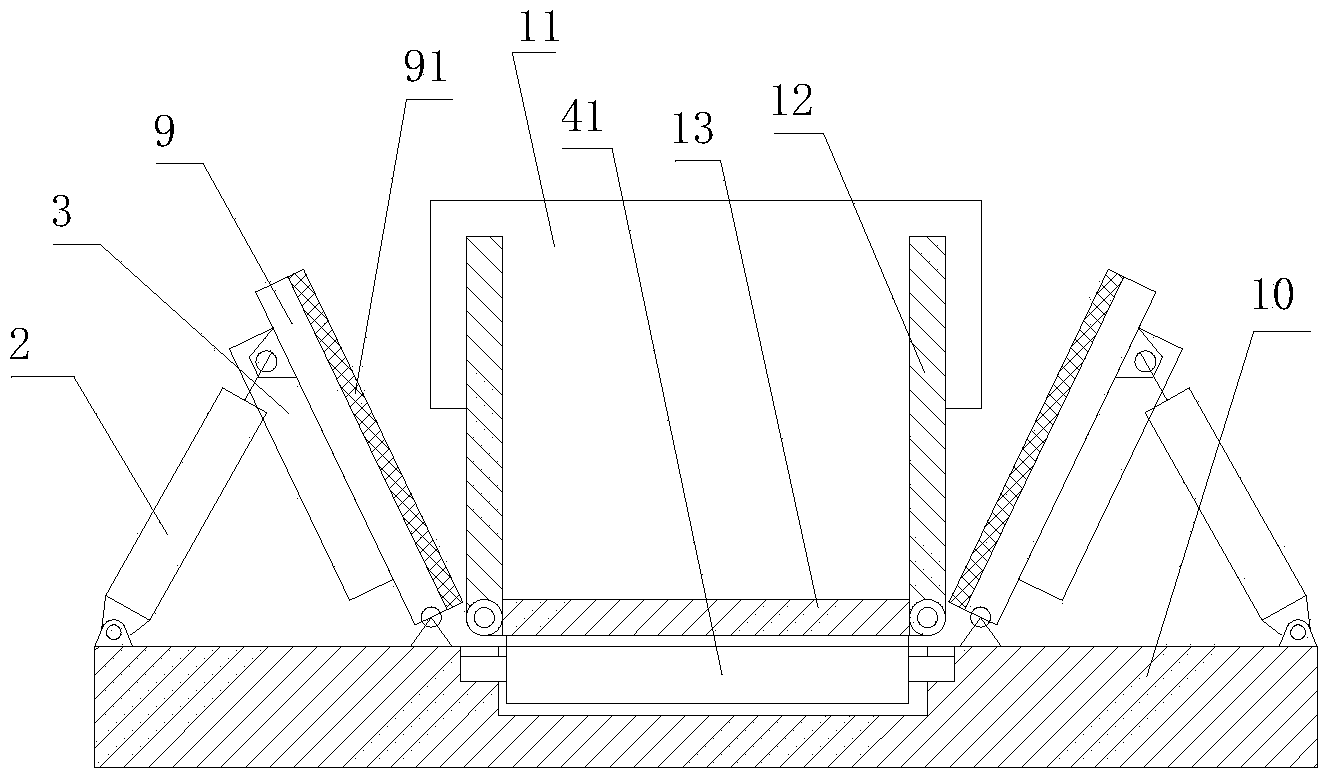

[0015] Embodiment 1: refer to Figure 1-7 . A prefabricated beam slab molding die, comprising a bottom plate 10, a vibrating plate and a formwork 1, the formwork 1 is composed of a base plate 13 placed on the bottom plate 10, two sets of side formworks 12 and two sets of end formworks 11, two sets of The side templates 12 are respectively connected to the top of the base plate 13 and are arranged oppositely front and back. Two groups of end templates 11 are connected to the left and right ends of the two groups of side templates 12 above the base plate 13. The vibration plates 9 are respectively located outside the two groups of side templates 12, and Its lower end is respectively hinged with the bottom plate 10, and a number of attached high-frequency vibrators 3 are respectively provided on the outer sides of the vibration plates 9 on the front and rear sides, and a rubber pad 91 is provided on the inner wall between the vibration plate 9 and two groups of side templates 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com