Edible oil canning equipment

A technology of oil canning and equipment, applied in the field of edible oil canning equipment, to achieve the effect of easy movement, convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

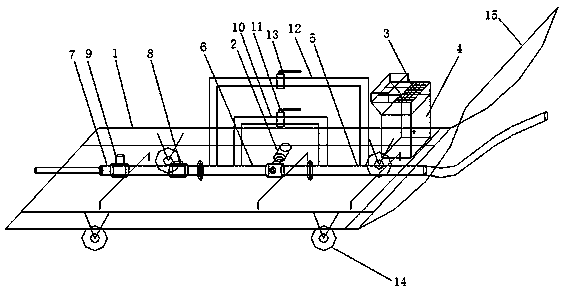

[0016] as attached figure 1 As shown, the edible oil canning equipment in this embodiment includes an oil delivery equipment support 1, an oil delivery motor 2 is installed in the middle of the equipment support 1, an oil delivery impeller is installed on the rotor shaft of the oil delivery electric 2, and the equipment support An operation panel 3 is installed on the right side of 1, and a control cabinet 4 is arranged under the operation panel 3. An electrical circuit for metering and controlling oil delivery is installed in the control cabinet 4. A stainless steel tube is installed on the right pillar of the oil delivery equipment support 1. The formed oil inlet pipe 5, the impeller oil delivery pipe 6 connected with the oil inlet pipe 5 is installed on the middle pillar of the oil delivery equipment support 1, the inside of the impeller oil delivery pipe 6 is provided with an oil delivery impeller, and the left pillar of the oil delivery equipment support 1 is installed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com