CM800 stretch worsted fancy suiting

A worsted and tweed technology, applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of difficult to control door width, easy to break ends, fabric scratches, etc., to achieve good drape, not easy to wrinkle, easy to beat the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

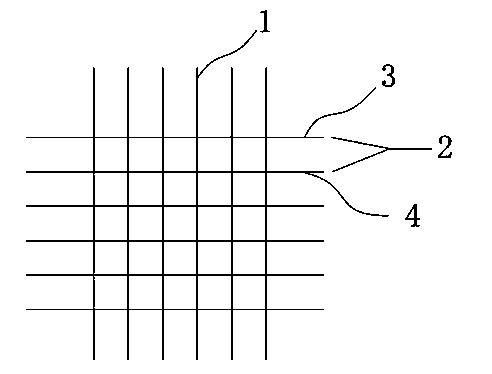

[0018] 90 first s Australian wool fiber and 2.2D polyester fiber are dyed and combed to make sliver, and then spun to make as attached figure 1 The high-count wool-polyester blended yarn shown; the sliver dyeing and combing process includes: dyeing→rewashing→mixing→secondary mixing→previous needle combing→first two needle combing→combing→last needle Combing → combing with the last two needles → combing with the last three needles → slivering; the spinning process includes: mixed sliver → head needle → two needles → three needles → four needles → roving → spun yarn → self-winding → doubling → two-for-one twisting → steamed yarn;

[0019] Then the high-count wool-polyester blended yarn and 75D / 1CM800 elastic filament are used as attached figure 1 The shown warp yarn 1 is a high-count wool-polyester blended yarn 3, and the weft yarn 2 is formed by arranging high-count wool-polyester blended yarn 3 and 75D / 1CM800 elastic filament 4 at intervals to beat weft to obtain worsted twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com