Double-shutoff valve device applicable to press pouring of reinforced concrete

A technology of reinforced concrete and shut-off valve, which is applied in the direction of valve device, construction material processing, construction, etc., to achieve the effect of light airtightness, guarantee of airtightness and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

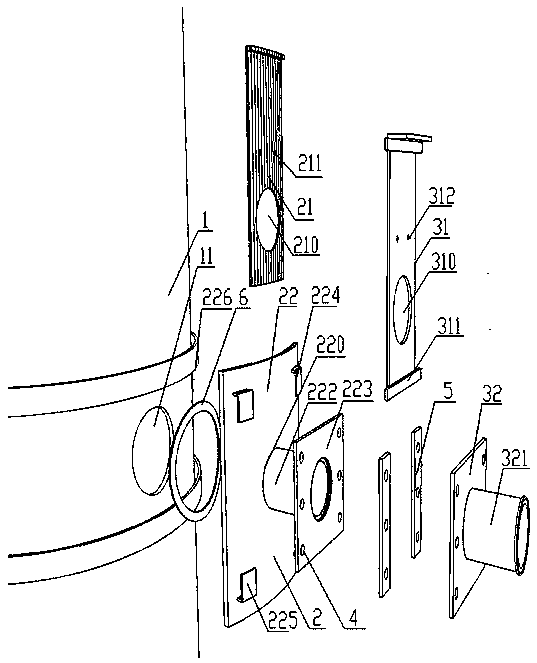

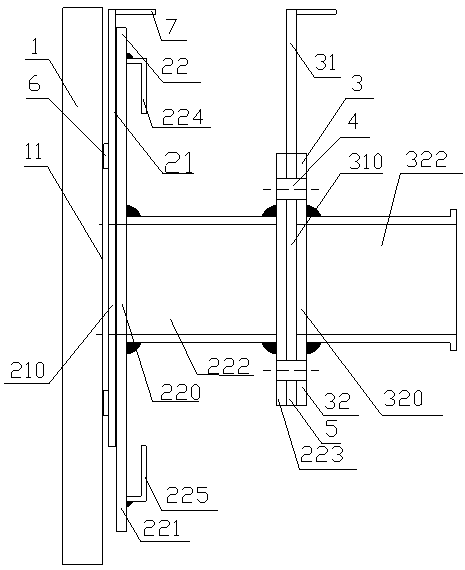

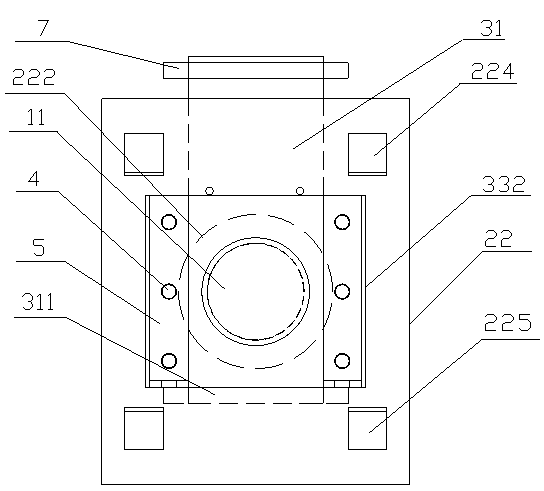

[0025] The present invention will be further described below in combination with principle diagrams and specific operation examples.

[0026] combine Figure 1 to Figure 4 As shown in , a double shut-off valve device suitable for pouring reinforced concrete under pressure, the double shut-off valve device is installed on the pre-opening hole 11 below the side wall of the steel pipe 1, wherein the double shut-off valve device includes: a first shut-off valve 2. The first cut-off valve 2 includes a first cut-off piece 21 and a first cut-off valve seat 22. Specifically, the shape of the first cut-off piece 21 is adapted to the shape of the steel pipe 1. In practice, the first cut-off piece The piece 21 is made of a steel plate, and it is made into an arc shape as a whole, and its curvature matches the curvature of the steel pipe, so that the whole of the first intercepting piece 21 can fit well on the surface of the steel pipe 1 . During implementation, a pre-opening hole 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com