Fixing structure of LED light source substrate and installing method

A technology of LED light source and LED substrate, which is applied in the field of LED lighting, can solve problems such as large contact thermal resistance, time-consuming, and potential safety hazards, and achieve the effects of increasing the heat conduction area, improving heat conduction performance, and improving heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a non-limiting description of the LED light source substrate fixing structure and installation and use method of the present invention in conjunction with the accompanying drawings, in order to facilitate the public to better understand the technical content.

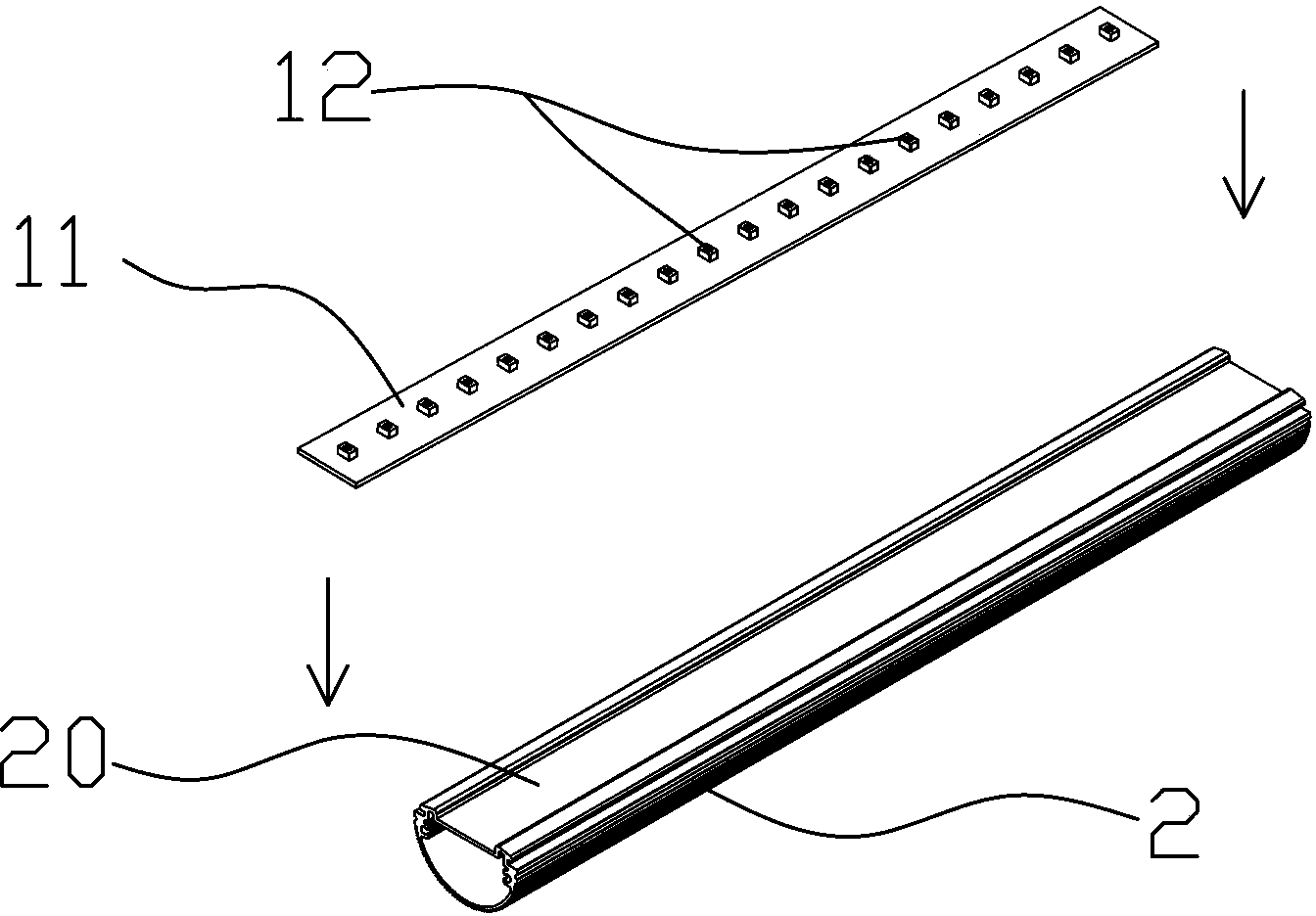

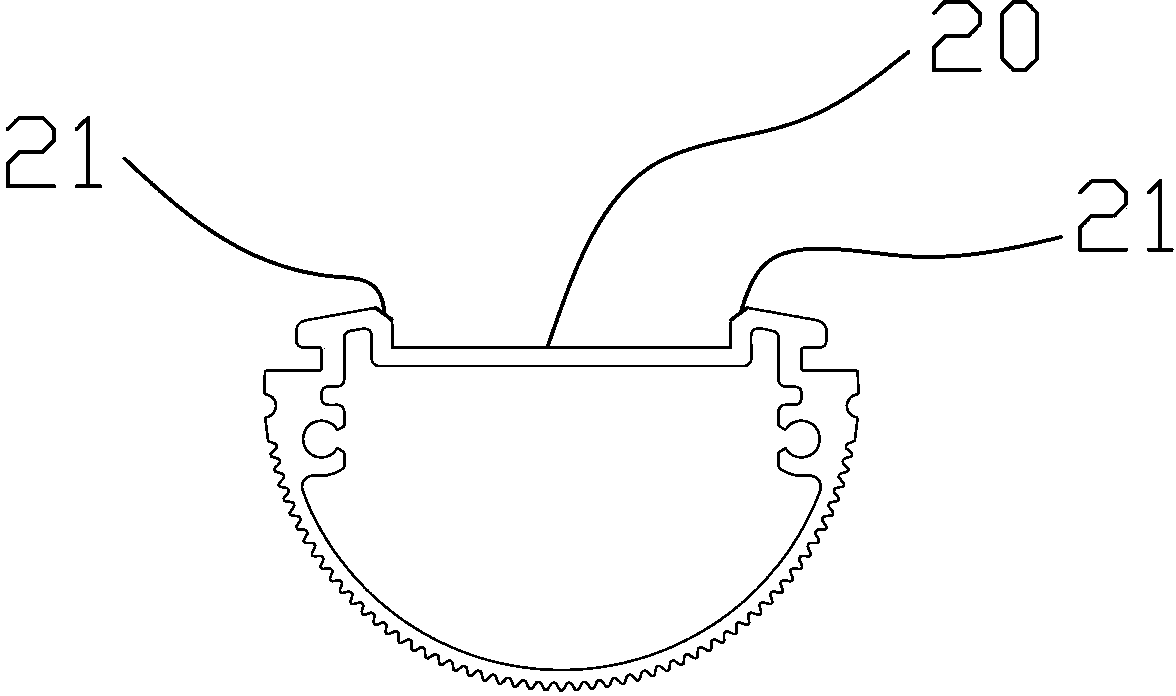

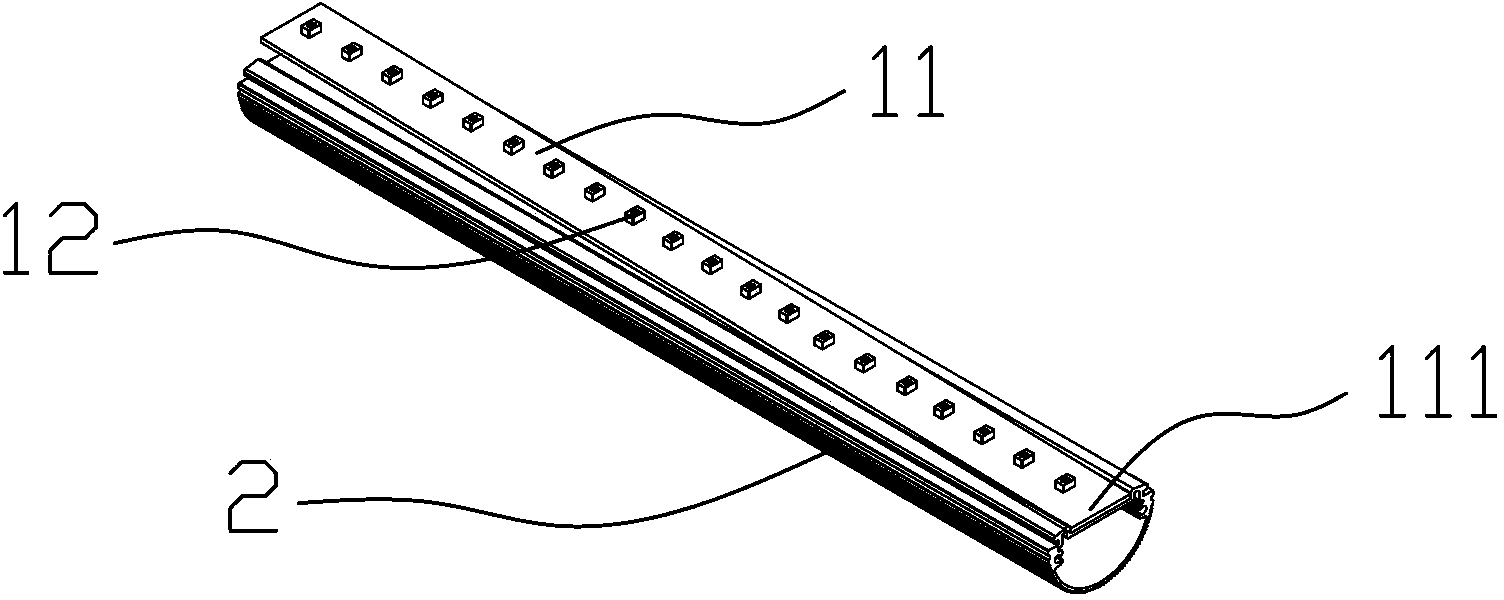

[0029] like Figure 1-6 , the LED light source substrate fixing structure of the present invention includes an LED substrate and a heat dissipation profile, wherein the LED substrate includes a substrate 11 and a plurality of LEDs 12 arranged on the substrate 11, and the heat dissipation profile 2 is a hollow columnar structure with the same length as the substrate 11 One side is provided with a slot 20 for accommodating the substrate 11 , and the two sides of the slot 20 are respectively provided with slopes 21 inclined inwardly and downwardly. In this embodiment, the substrate 11 and the heat dissipation profile 2 are made of aluminum or aluminum alloy, which has better heat conduction effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com