Patents

Literature

65results about How to "Realize mechanized mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial alginate composite functional dressing and preparation method thereof

InactiveCN107469128AAntibacterial Broad Spectrum High EfficiencySmall dosagePharmaceutical delivery mechanismAbsorbent padsFiberChitosan coating

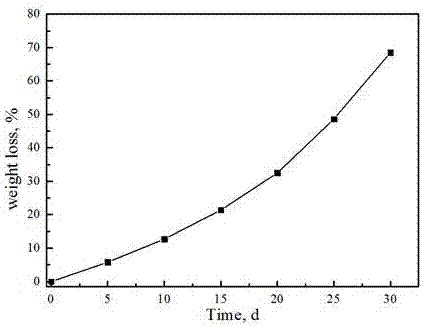

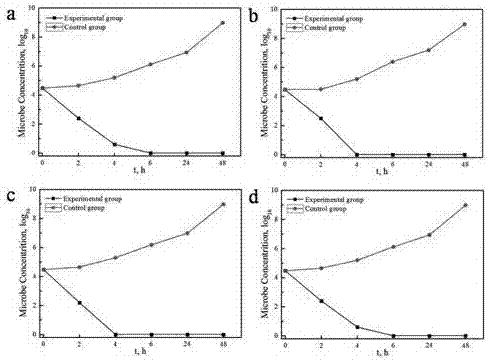

The invention relates to an antibacterial alginate composite functional dressing and a preparation method thereof. The dressing is prepared from alginate, sodium carboxymethylcellulose, chitosan and a guanidine antibacterial agent and has good biosecurity, bleeding stopping performance and antibacterial performance. The preparation method comprises the steps as follows: firstly, sodium alginate and sodium carboxymethylcellulose are dissolved, the solution is extruded into a calcium ion coagulating bath via spinneret orifices, and fiber filaments are formed; then, a chitosan solution is prepared, and prepared alginate fiber is subjected to chitosan coating; next, a guanidine antibacterial agent solution is prepared and the fiber is impregnated in the guanidine antibacterial agent solution; finally, composite fiber is subjected to combing, needling and hot rolling treatment, cutting, packaging and sterilization are performed, and the dressing is prepared. The preparation method is simple and low in production cost. The prepared antibacterial alginate composite functional dressing has good antibacterial performance and can meet wound bleeding stopping, antibacterial and healing promoting requirements.

Owner:WUHAN YIJIABAO BIOMATERIAL CO LTD

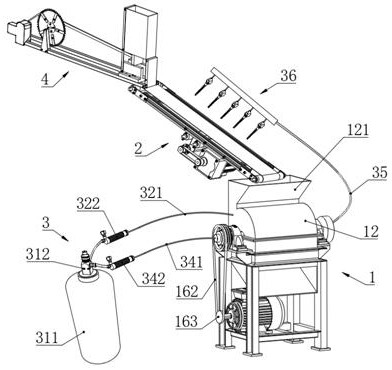

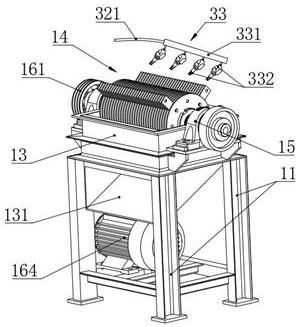

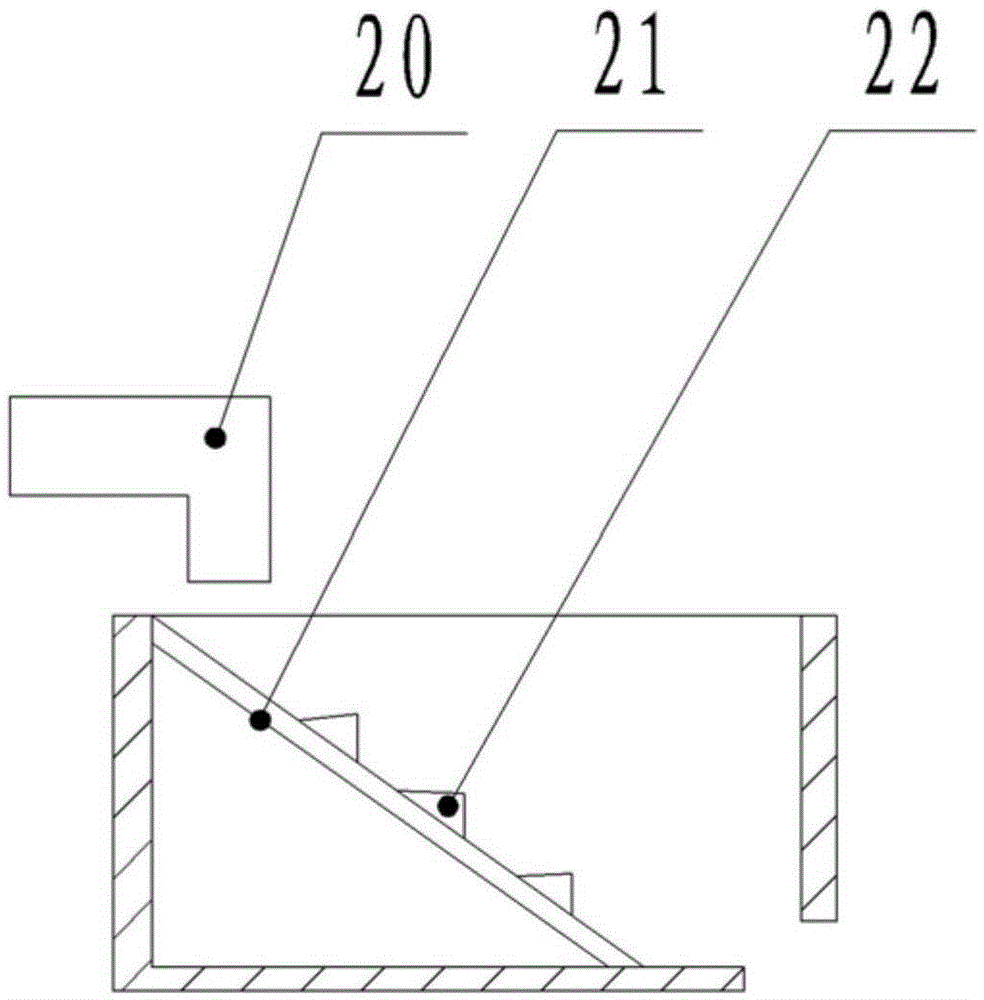

Brown sugar processing equipment and use method

ActiveCN112169948AIncrease temperatureIncrease the speed of crushingDomestic cooling apparatusLighting and heating apparatusEngineeringProcess engineering

The invention belongs to the technical field of brown sugar processing, and particularly relates to brown sugar processing equipment. The brown sugar processing equipment comprises a pulverizer, a conveying device and a cooling device, wherein the pulverizer is arranged on the back end of the conveying device, and a high-pressure tank of the cooling device is located on one side of the pulverizer.After the brown sugar processing equipment is operated for a long time, the temperature of cutters can be prevented from being increased, and brown sugar powder cannot be melted into blocks; and additionally, moisture in the brown sugar powder is condensed into ice crystals before processing, the brown sugar powder cannot be caked due to cooling of the cooling device, the crushing speed and the crushing quality are increased, and the influence on the processing efficiency is reduced. The invention further provides a use method of the equipment. The use method comprises the steps of preprocessing brown sugar blocks, cooling the brown sugar blocks, cooling the interiors of the cutters, and crushing the brown sugar blocks. According to the use method, the crushing operation can be performedwhen the water content of brown sugar is lower than 7%, the processing range is large, dehydration treatment is not needed, and the cost is reduced; and additionally, the use method has the advantagesof high degree of mechanization and high processing efficiency and processing quality and is suitable for large-scale processing.

Owner:湛江市金丰糖业有限公司

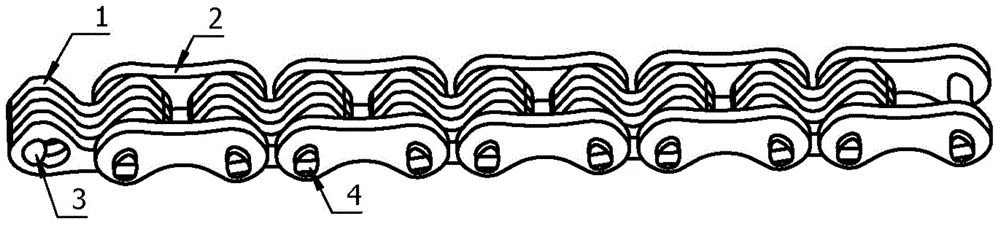

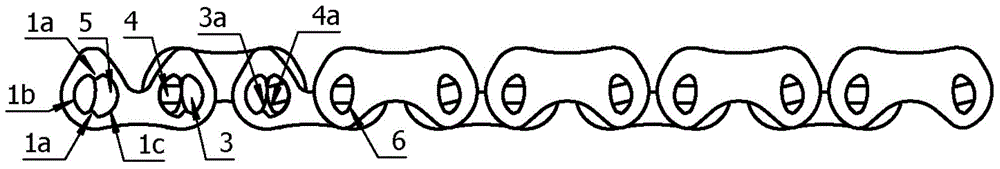

Tooth-shaped chain

InactiveCN103557270AReduce shockReduce vibrationChain linksDriving chainsInterference fitFriction loss

The invention provides a tooth-shaped chain which comprises inner chain plates, outer chain plates, short pin shafts and long pin shafts, wherein the inner chain plate holes formed in the inner chain plates are circular holes or non-circular profile holes; a pair of tooth-shaped bulges is formed in each inner chain plate hole; the inner chain plate holes are divided into outer side slots and inner side hole grooves through the bulges; the short pin shafts are axially positioned through the bulges and the outer side slots, and are fixed together with the inner chain plates in an interference fit manner; multiple inner chain plates are overlapped to form an inner link; the long pin shafts penetrate through the inner side hole grooves of the inner chain plates and are riveted together with the two outer chain plates tightly to form an outer link; the short pin shafts of the inner link is in contact with the long pin shafts of the outer link through arc working surfaces to form a rotation pair which can rotate within a certain range. According to the tooth-shaped chain provided by the invention, the structural constraints of the conventional tooth-shaped chain and Hy-Vo tooth-shaped chain are broken through, the friction loss and impact vibration between the pin shafts and chain plates are reduced by changing the assembling mode of the pin shafts and the arrangement mode of the inner chain plates, and the mechanized and scale production of high-speed tooth-shaped chains is achieved.

Owner:金雁冰 +1

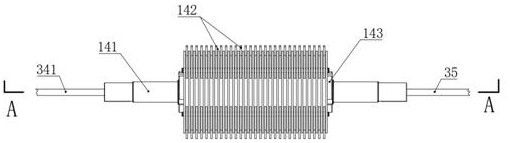

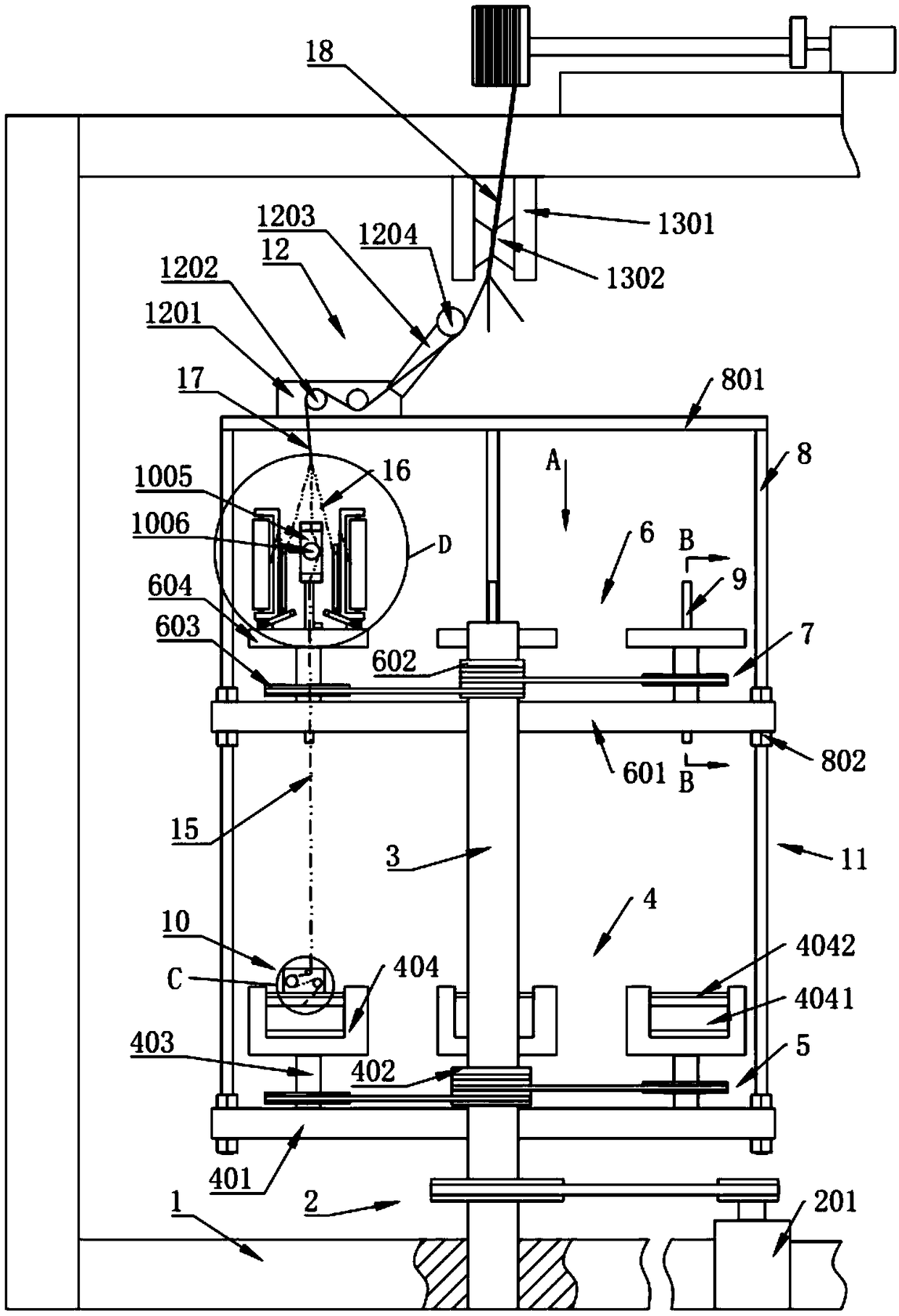

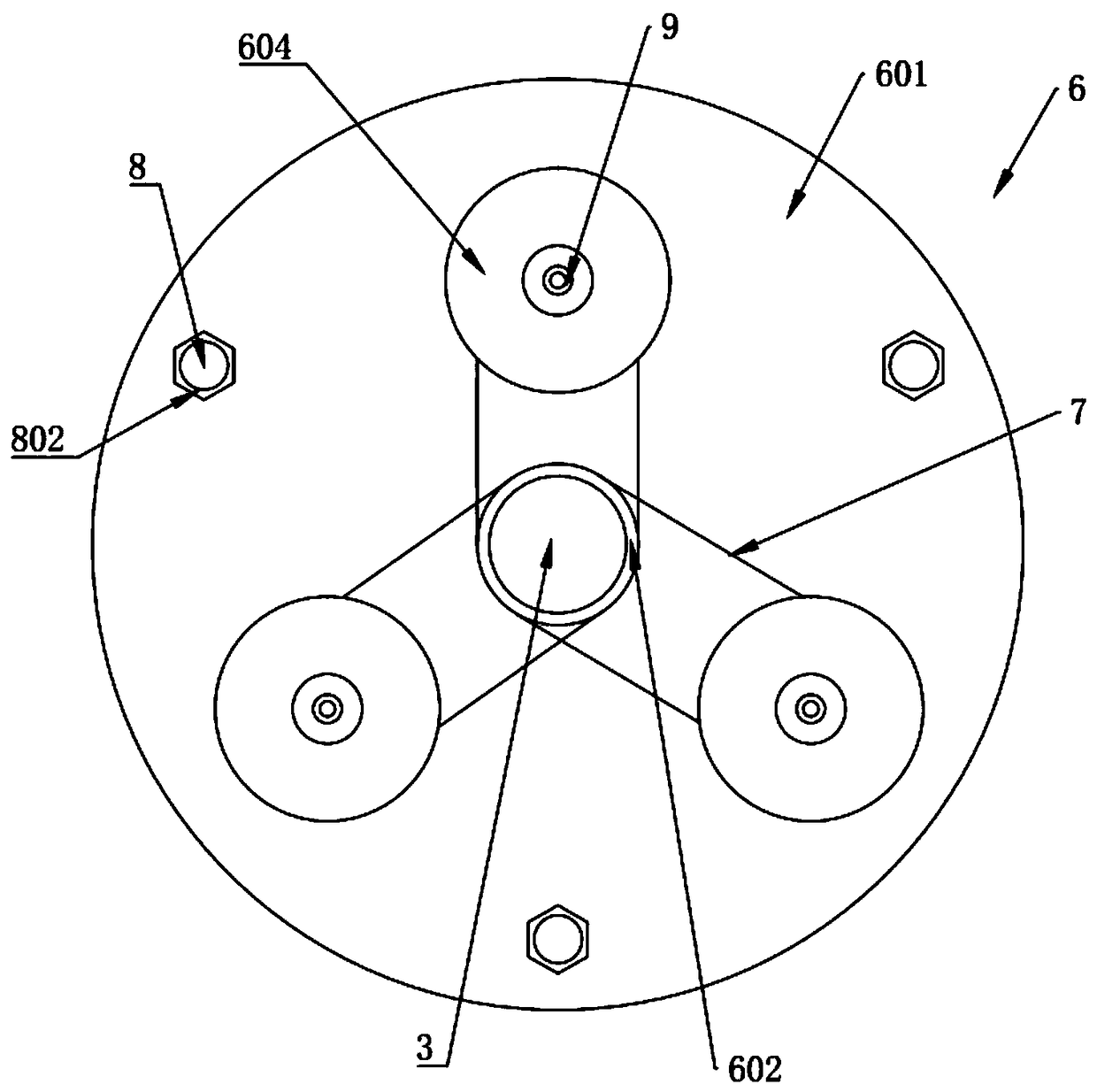

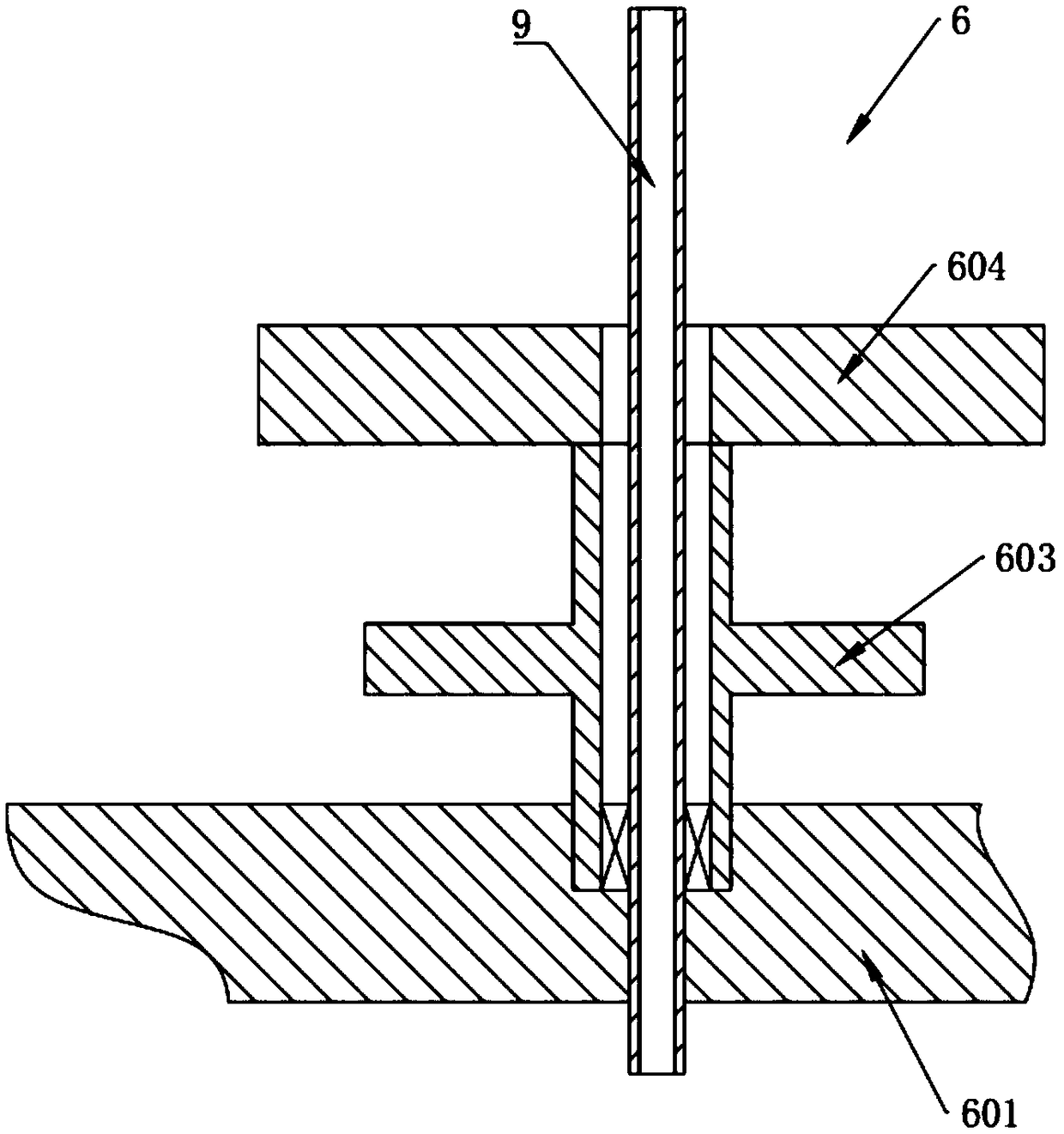

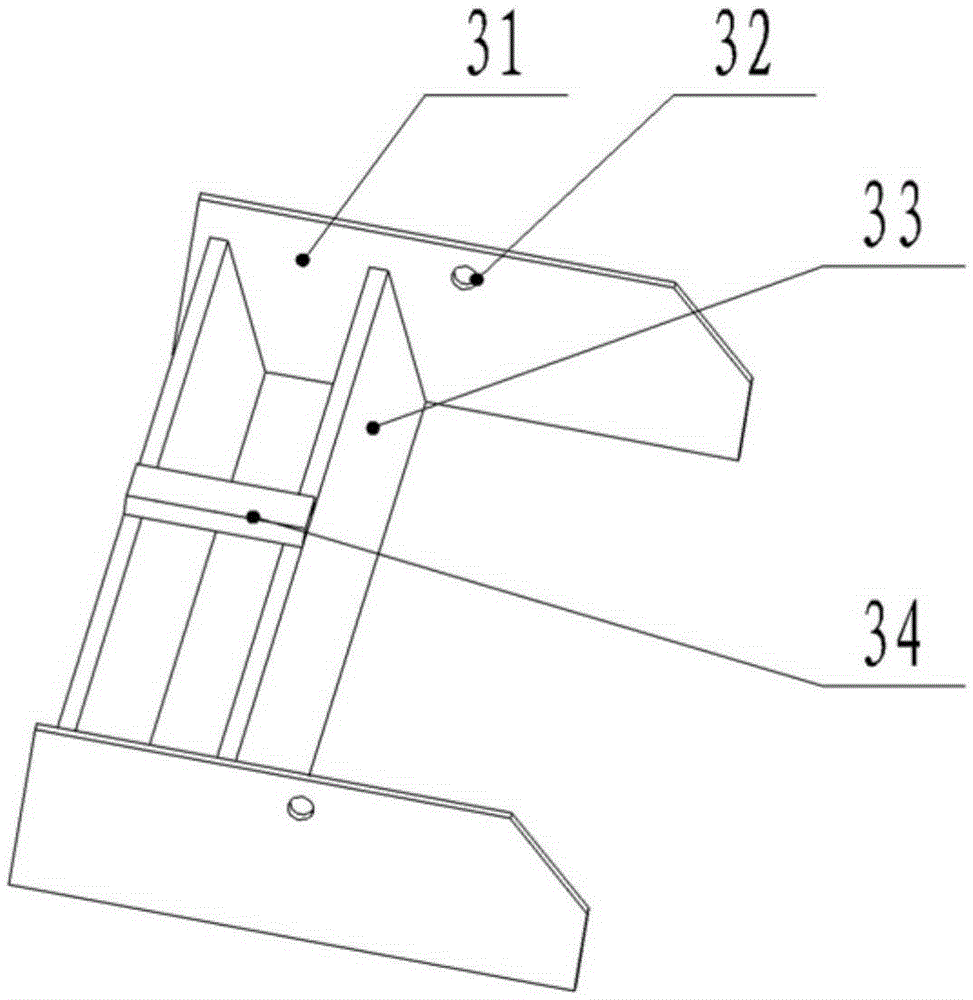

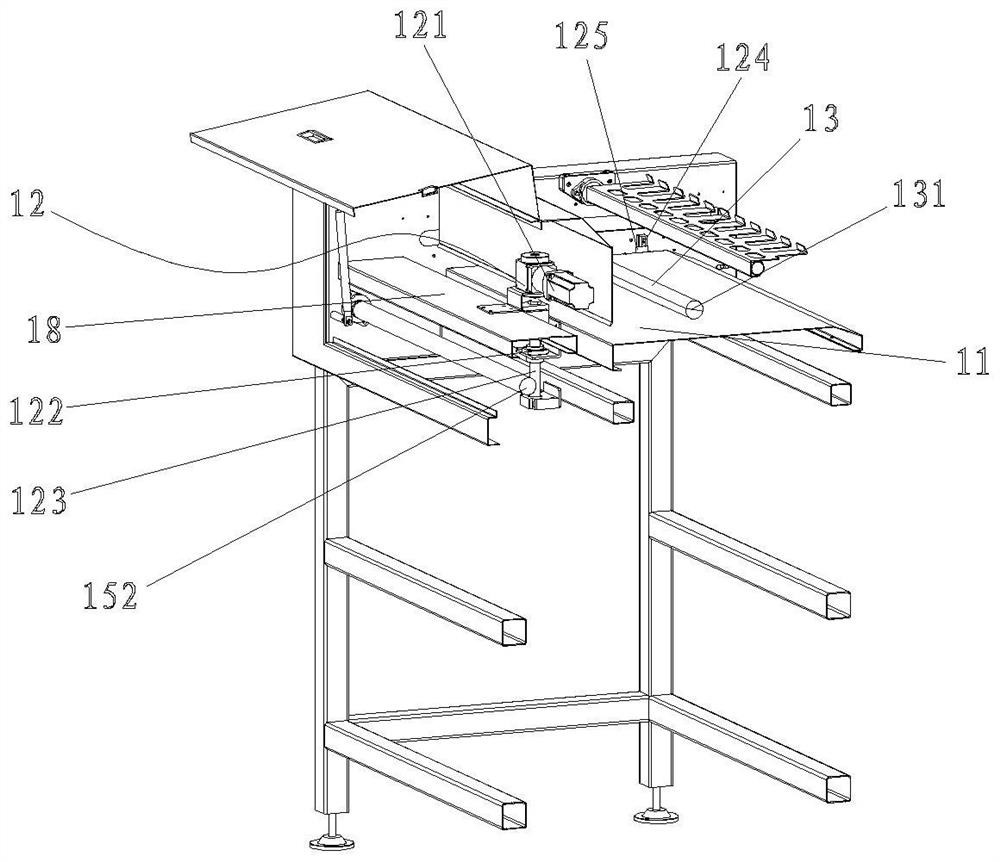

Core three-stranded-rope forming machine

PendingCN109137586ARealize mechanized mass productionGood molding effectRope making machinesPolyesterDrive shaft

The invention discloses a core three-stranded-rope forming machine. The machine comprises a frame. A driving shaft is rotatably arranged on the frame. The driving shaft is driven by a first transmission mechanism and is provided with a veil output assembly and a polyester filament output assembly. A second transmission mechanism is arranged between the veil output assembly and the driving shaft. The polyester filament output assembly is located above the veil output assembly and a third transmission mechanism is arranged between the polyester filament output assembly and the driving shaft. Thepolyester filament output assembly is provided with three conduit tubes. The veil output assembly is provided with three veil guide sending mechanisms forming one-to-one correspondence with the conduit tubes. A connection mechanism is arranged between the veil output assembly and the polyester filament output assembly. A single-strand core rope guide sending mechanism is arranged on the connection mechanism located above the polyester filament output assembly. A three-stranded forming rope derivation mechanism is arranged on the frame located above the single-strand core rope guide sending mechanism. The mechanized batch production of core three-stranded ropes is realized, work efficiency and production and forming efficiency are high, labor intensity is reduced, and a labor quantity andlabor cost are decreased.

Owner:潍坊市佳田纺织有限公司

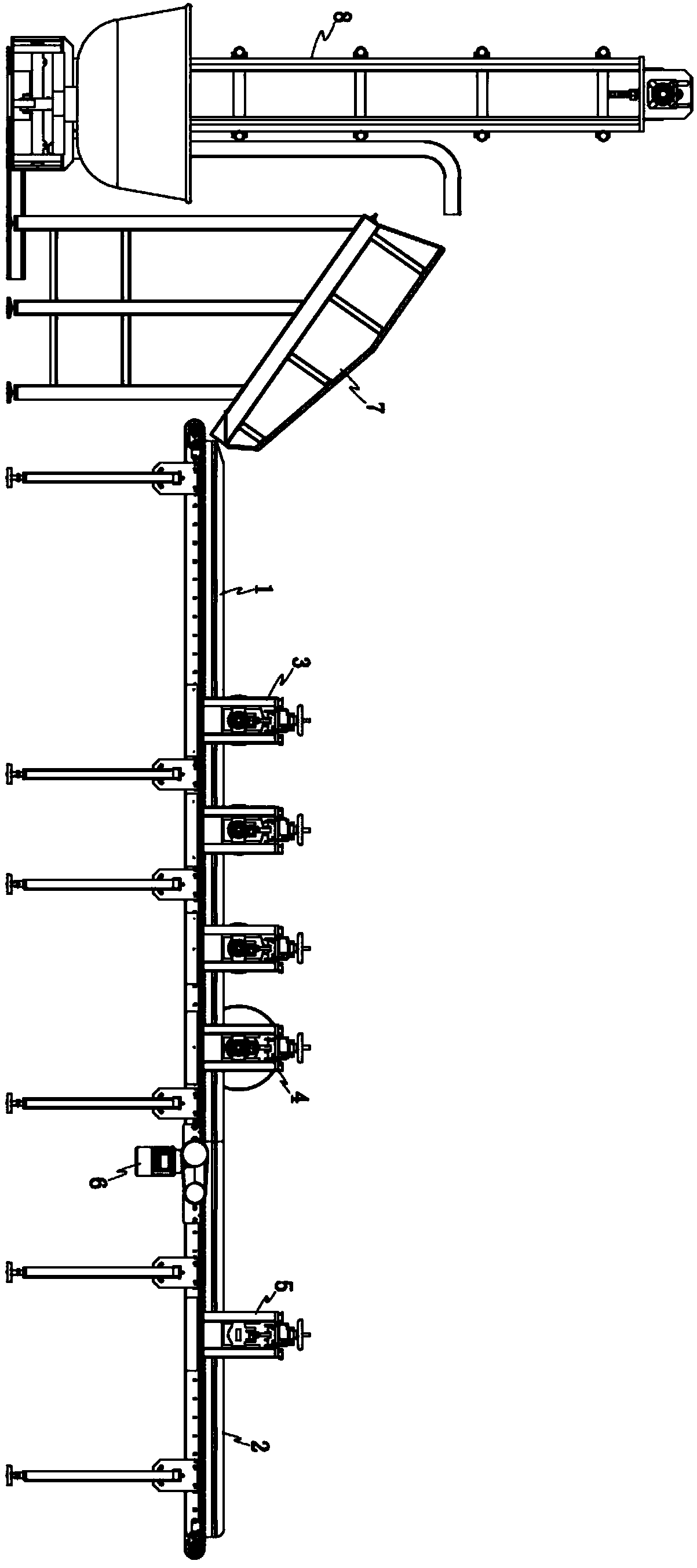

Rice cake production device

InactiveCN108272010ARealize mechanized mass productionIncrease productivityMetal working apparatusRotary pressEngineeringProduction quality

The invention relates to a rice cake production device. The device comprises a first conveyer belt, a second conveyer belt which is arranged at one end part of the first conveyer belt and an introduction plate frame which is arranged at the other end part of the first conveyer belt; a rolling pressing mechanism and a rolling cutting mechanism are arranged in parallel on the first conveyer belt, and a vertical cutting mechanism is arranged on the second conveyer belt; and the feeding end of the introduction plate frame is provided with a rice mixing and lifting mechanism. The device realizes mechanized batch production of rice cakes, not only reduces manpower investment, but also improves the production efficiency of the rice cakes. Meanwhile, the produced rice cakes are consistent in size,and the device improves the production quality of the rice cakes, and meets commercial production requirements.

Owner:杭州巧狮信息科技有限公司

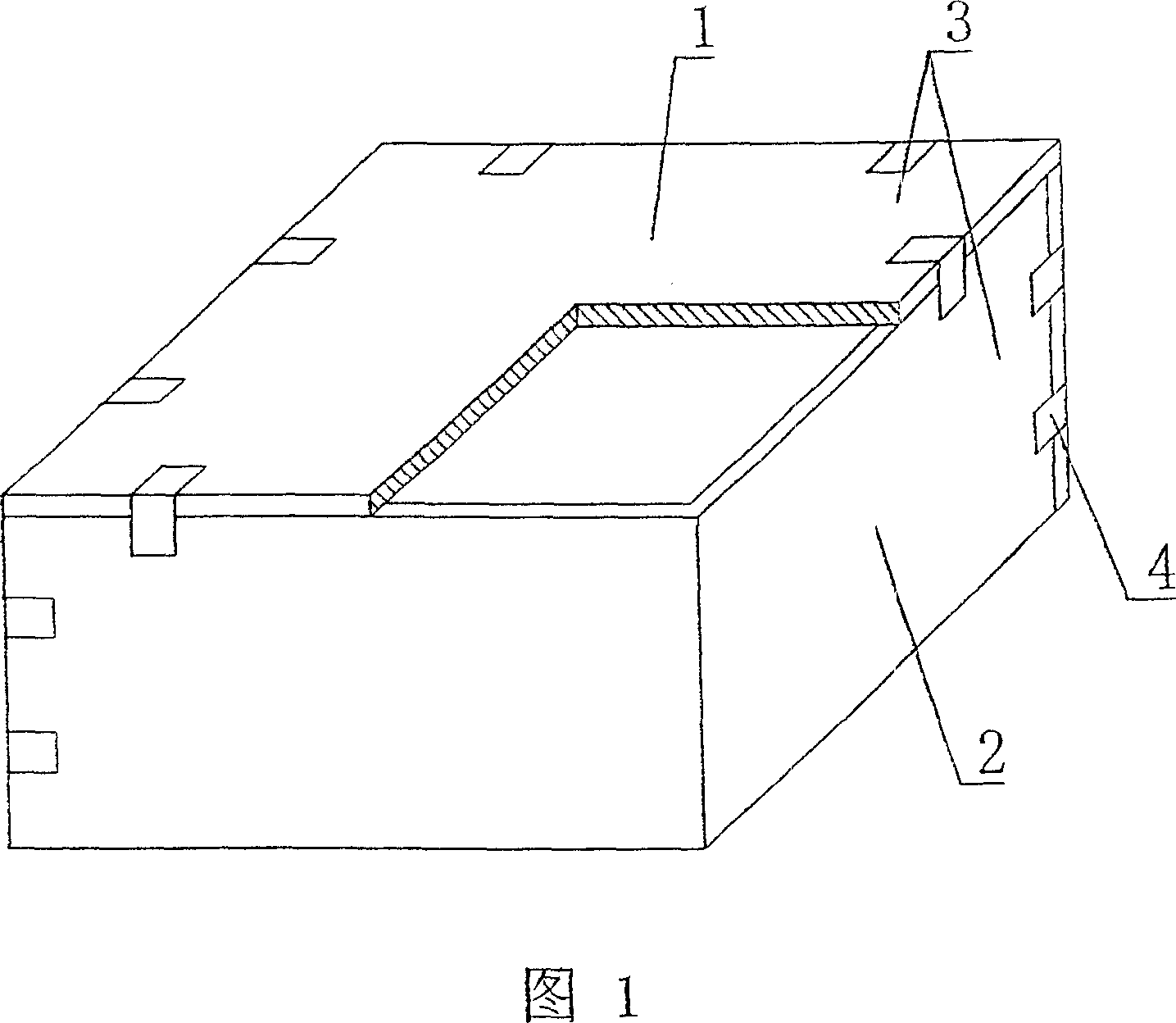

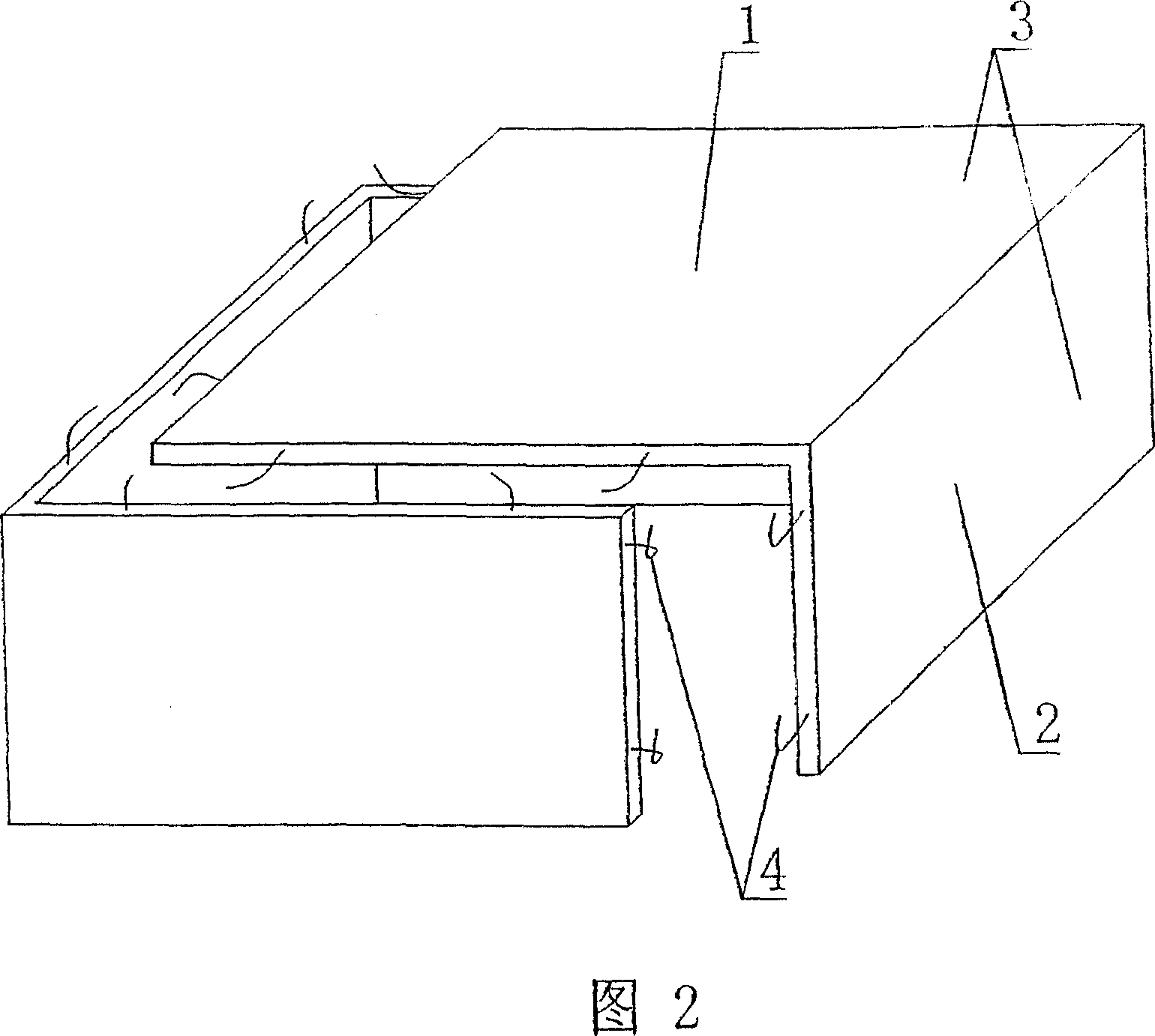

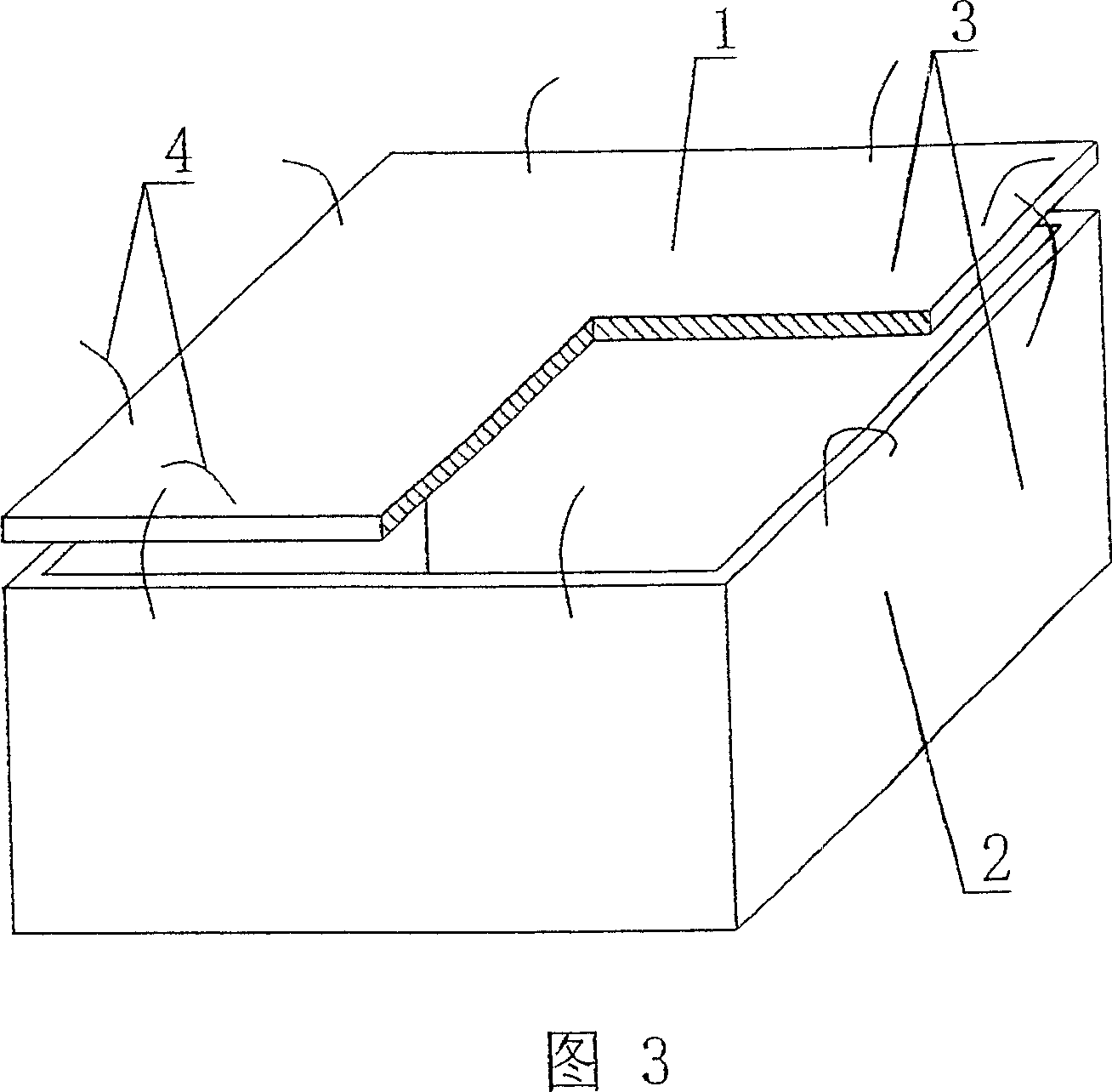

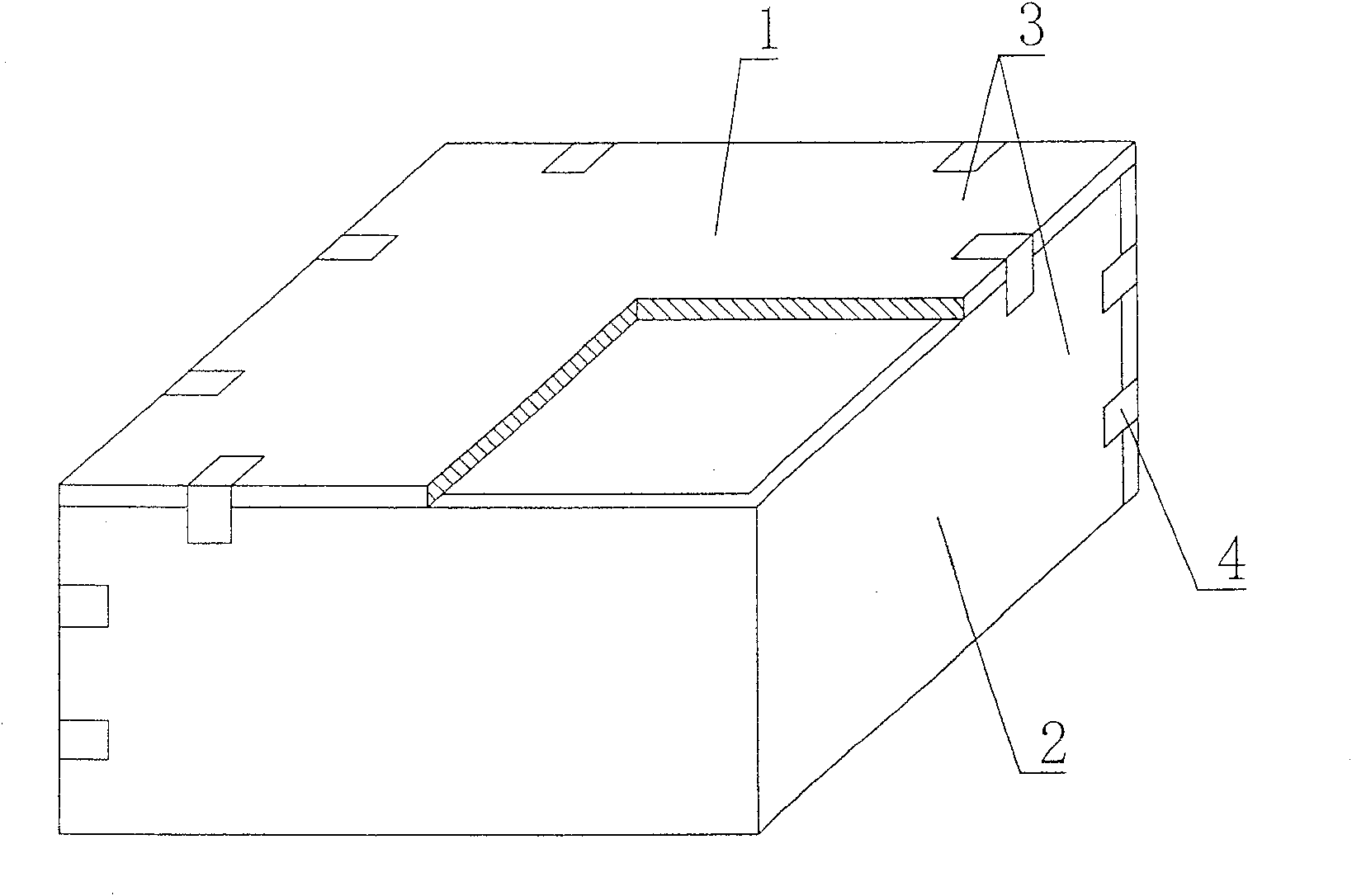

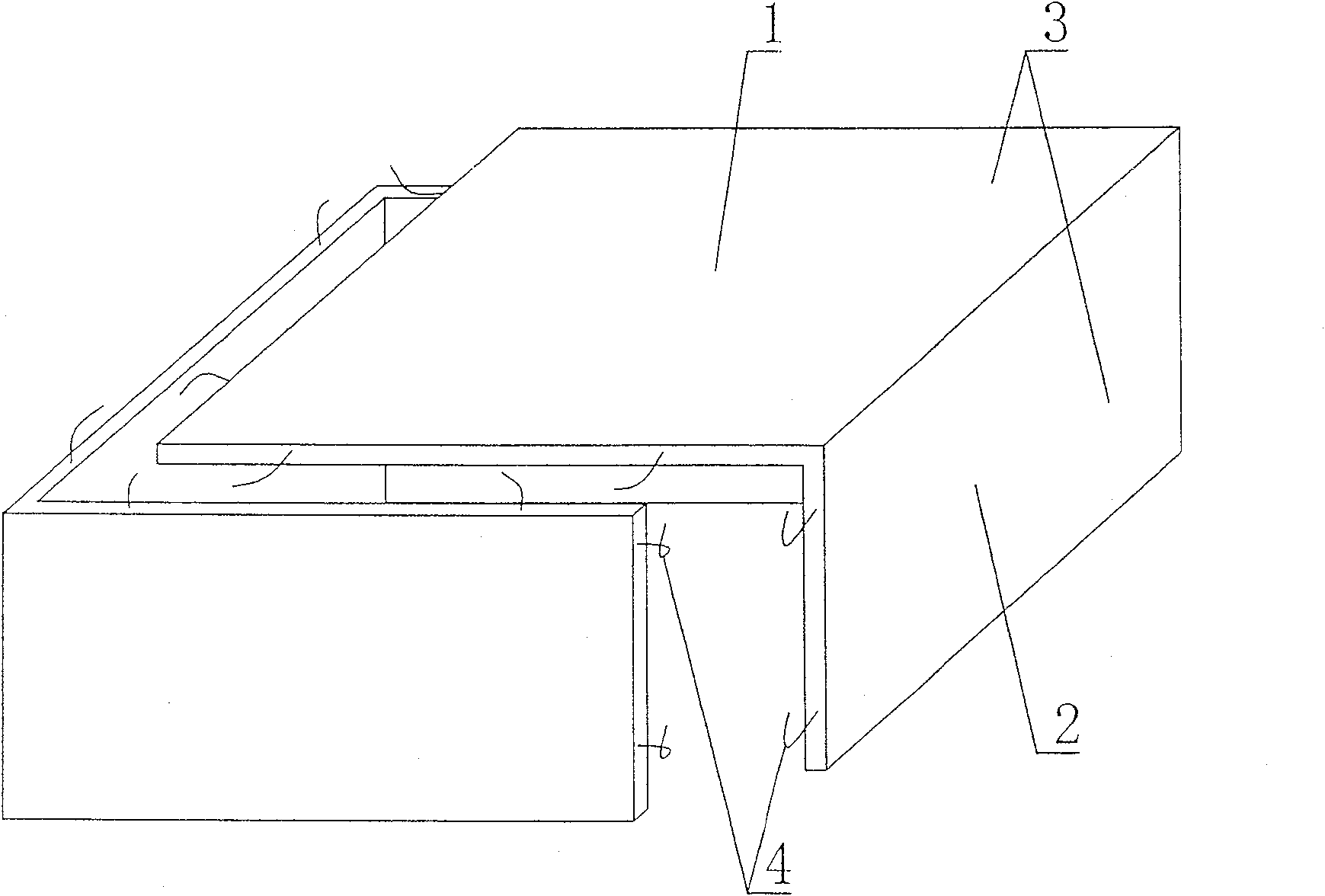

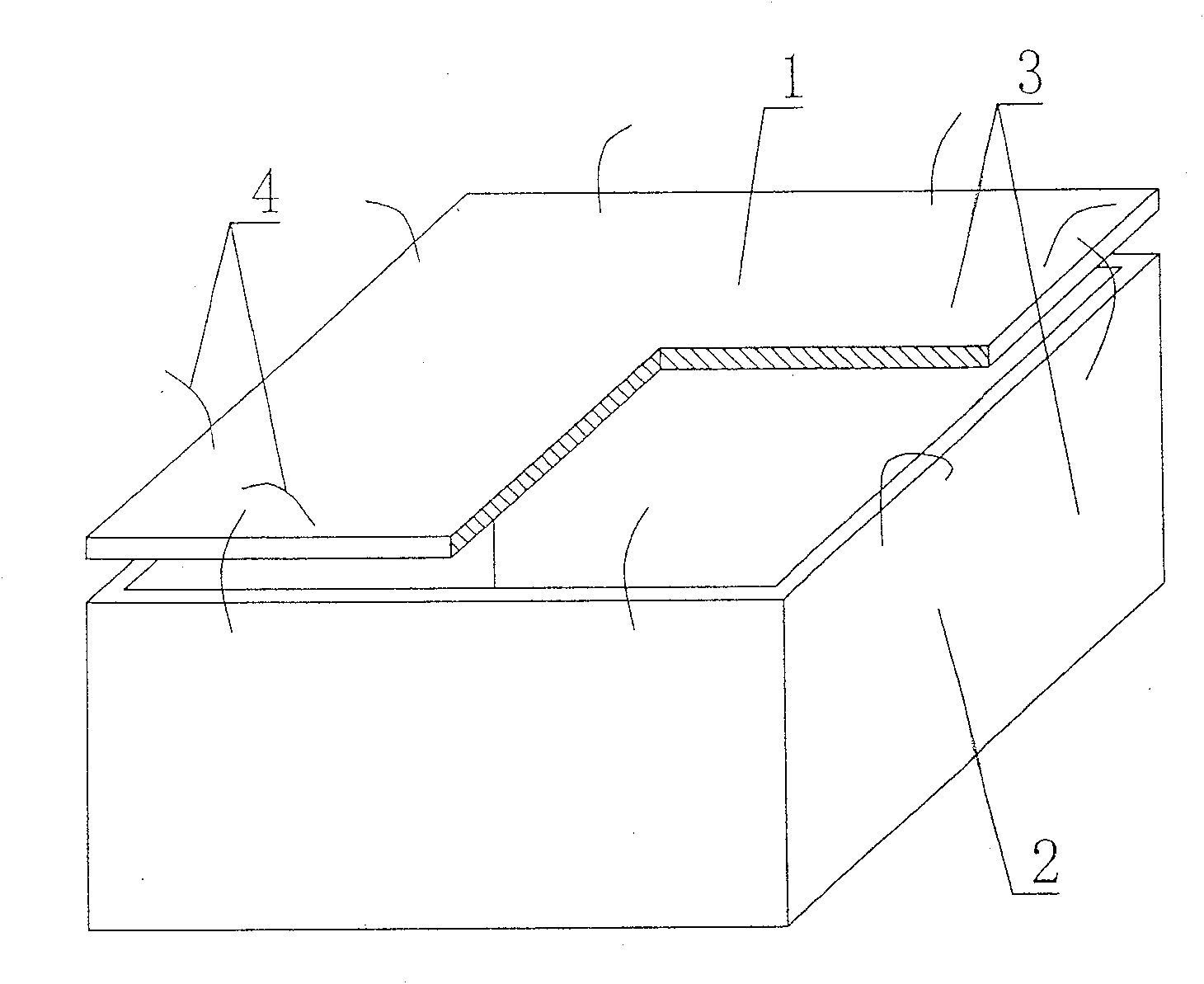

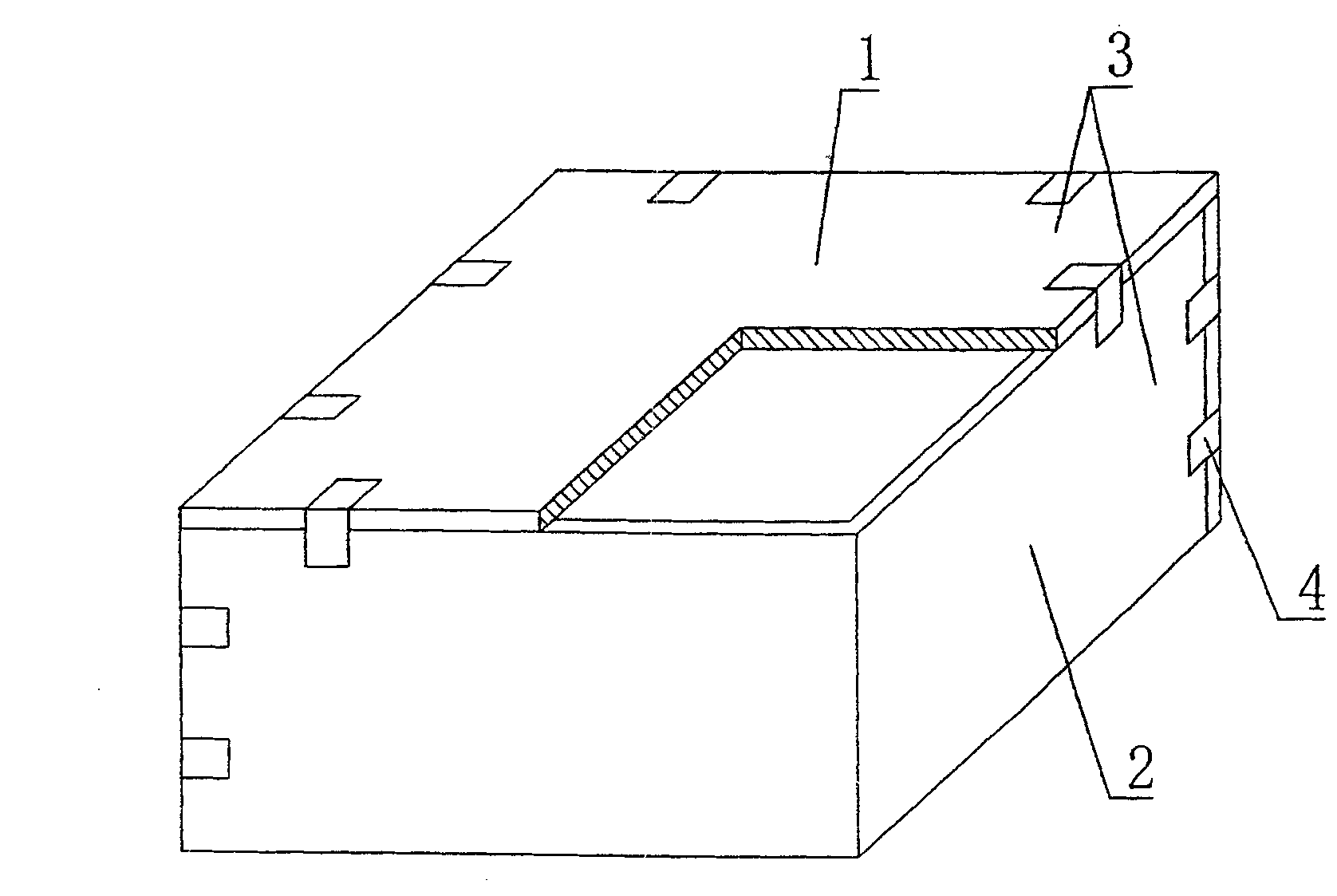

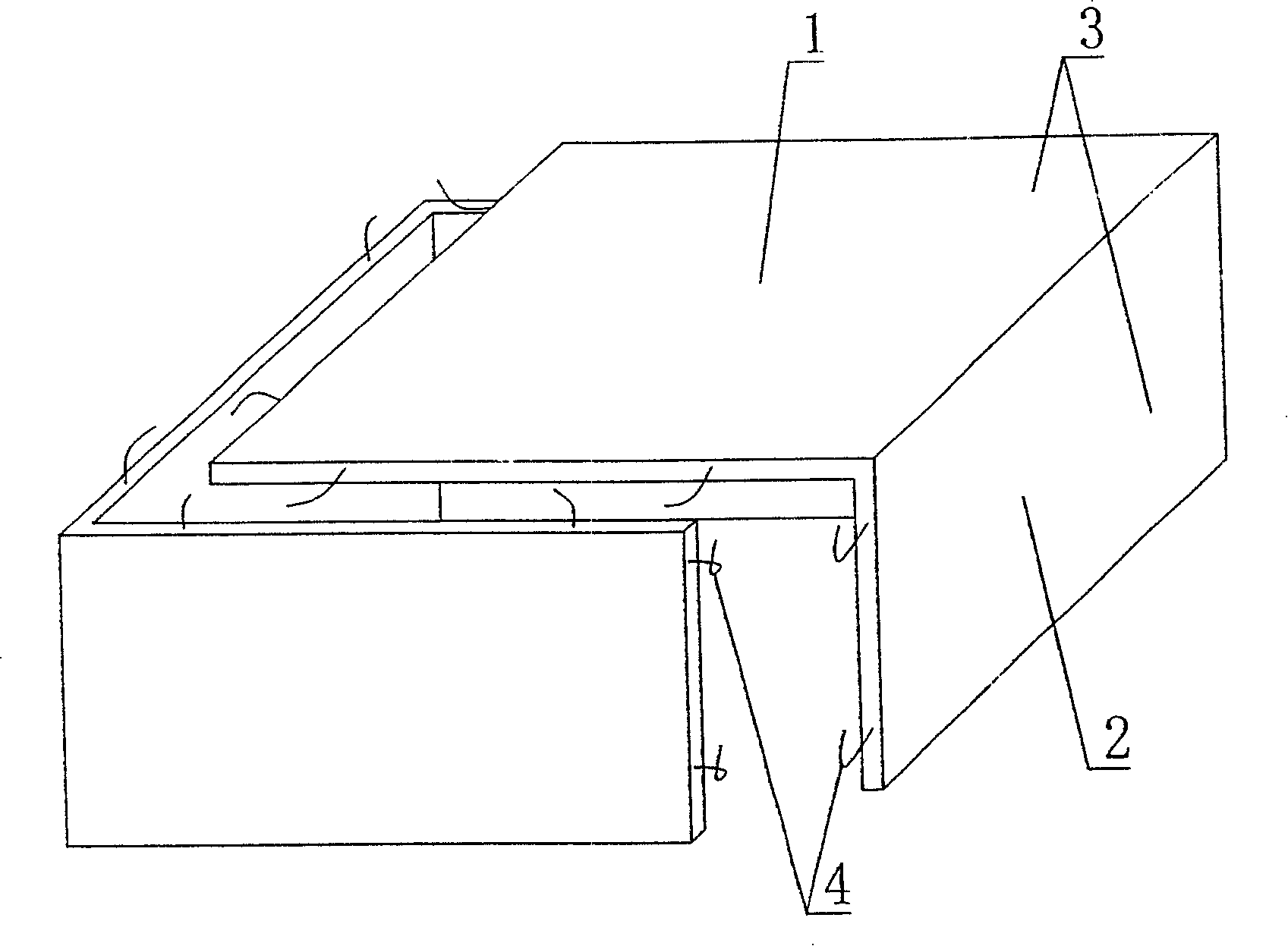

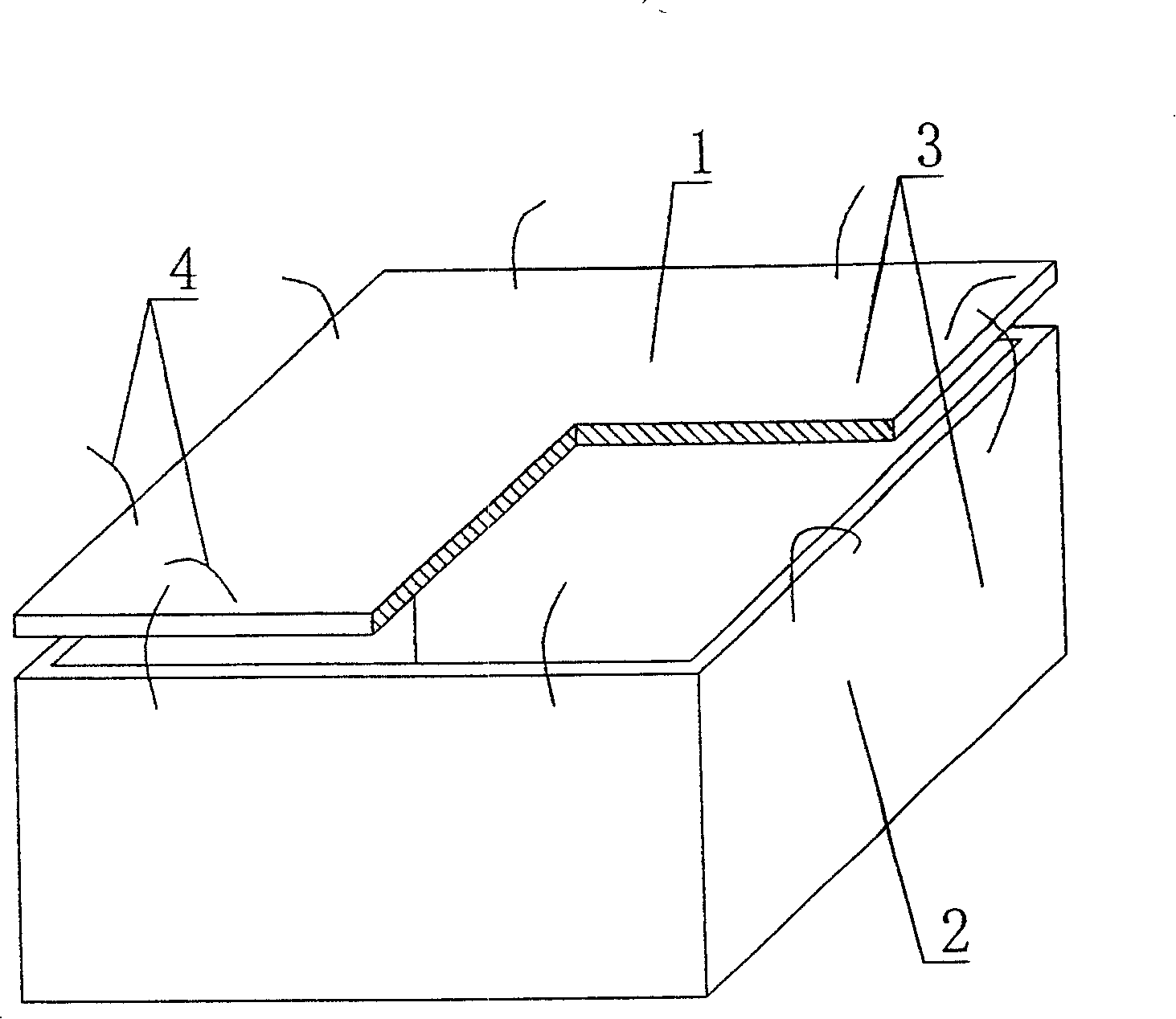

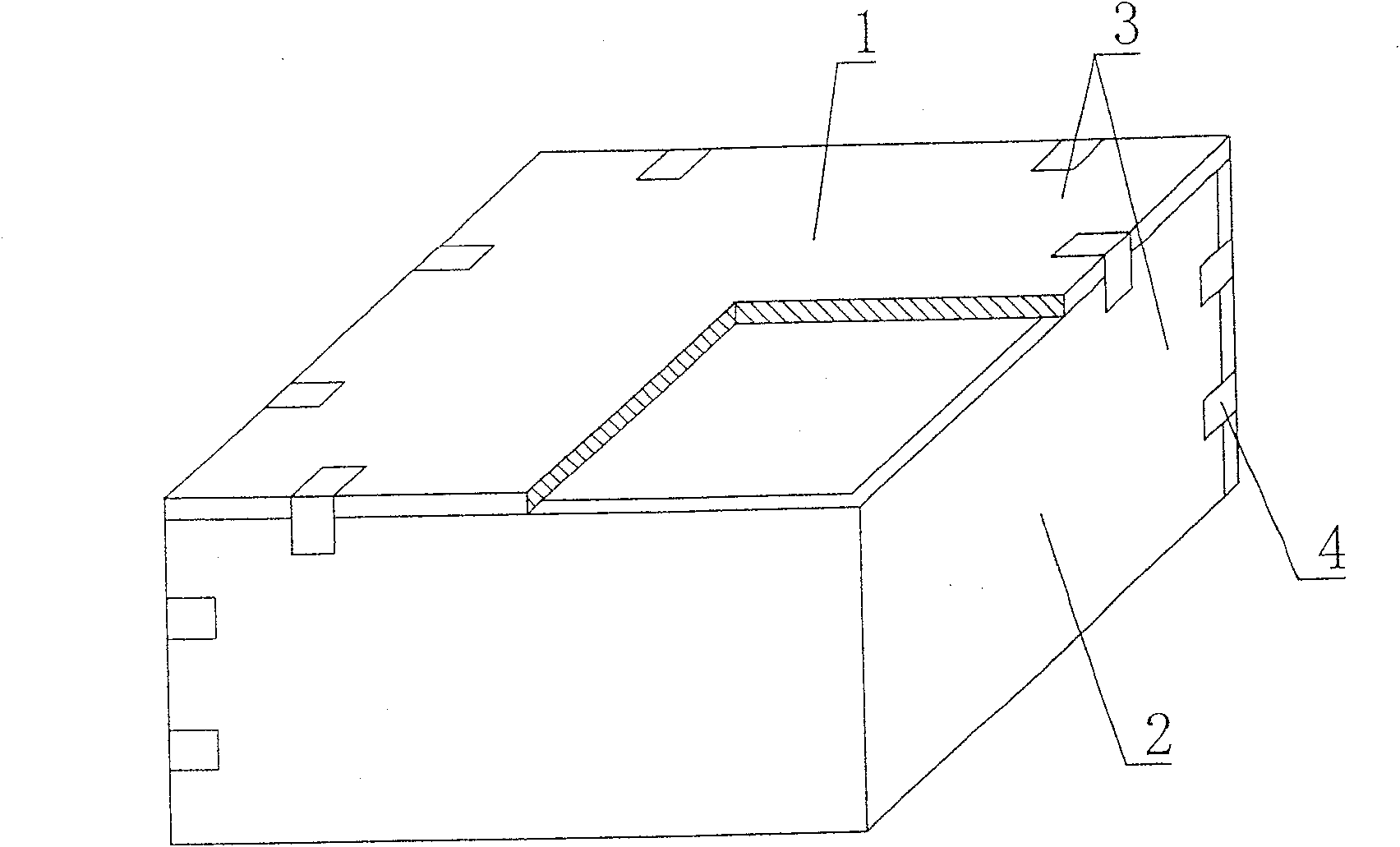

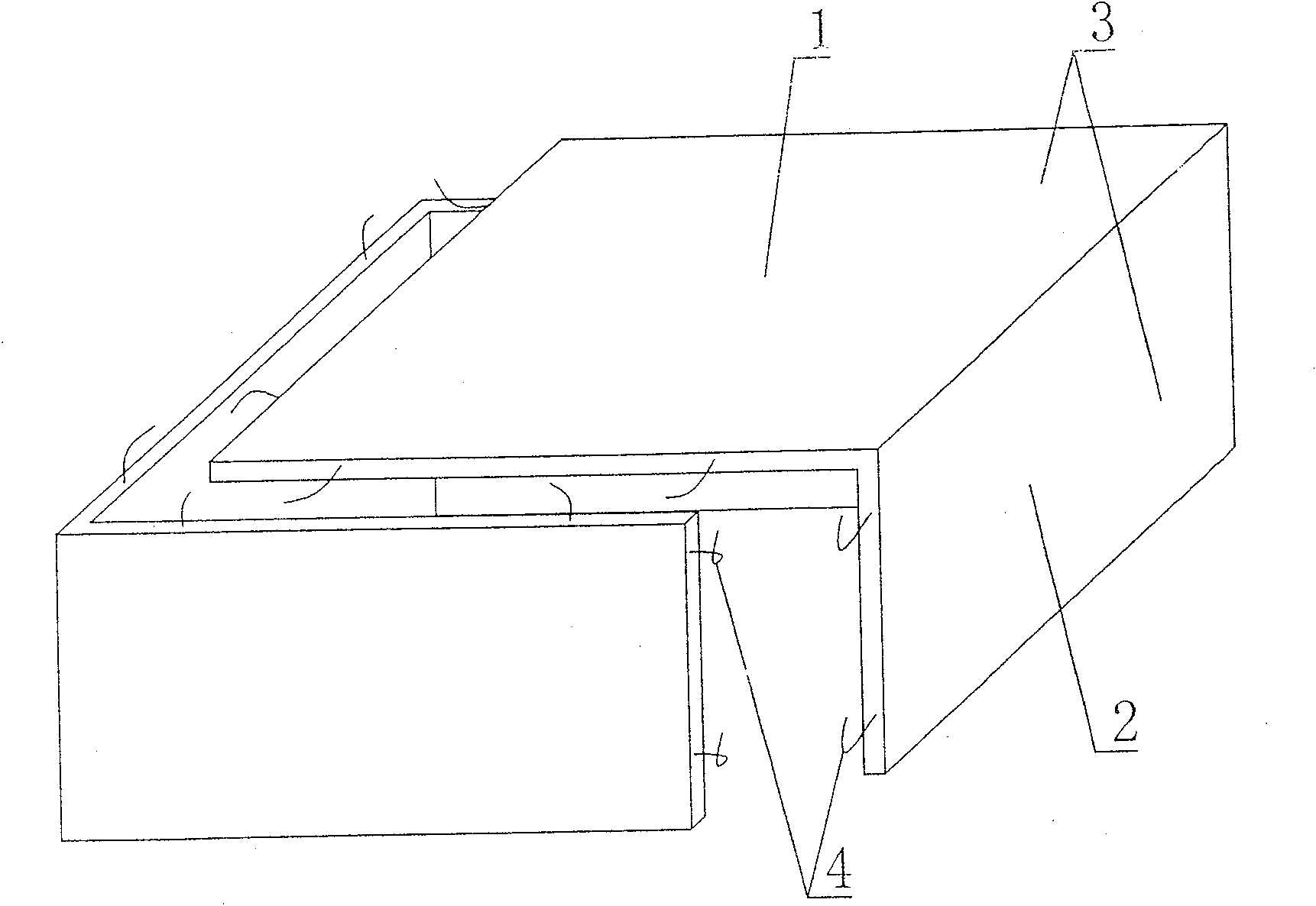

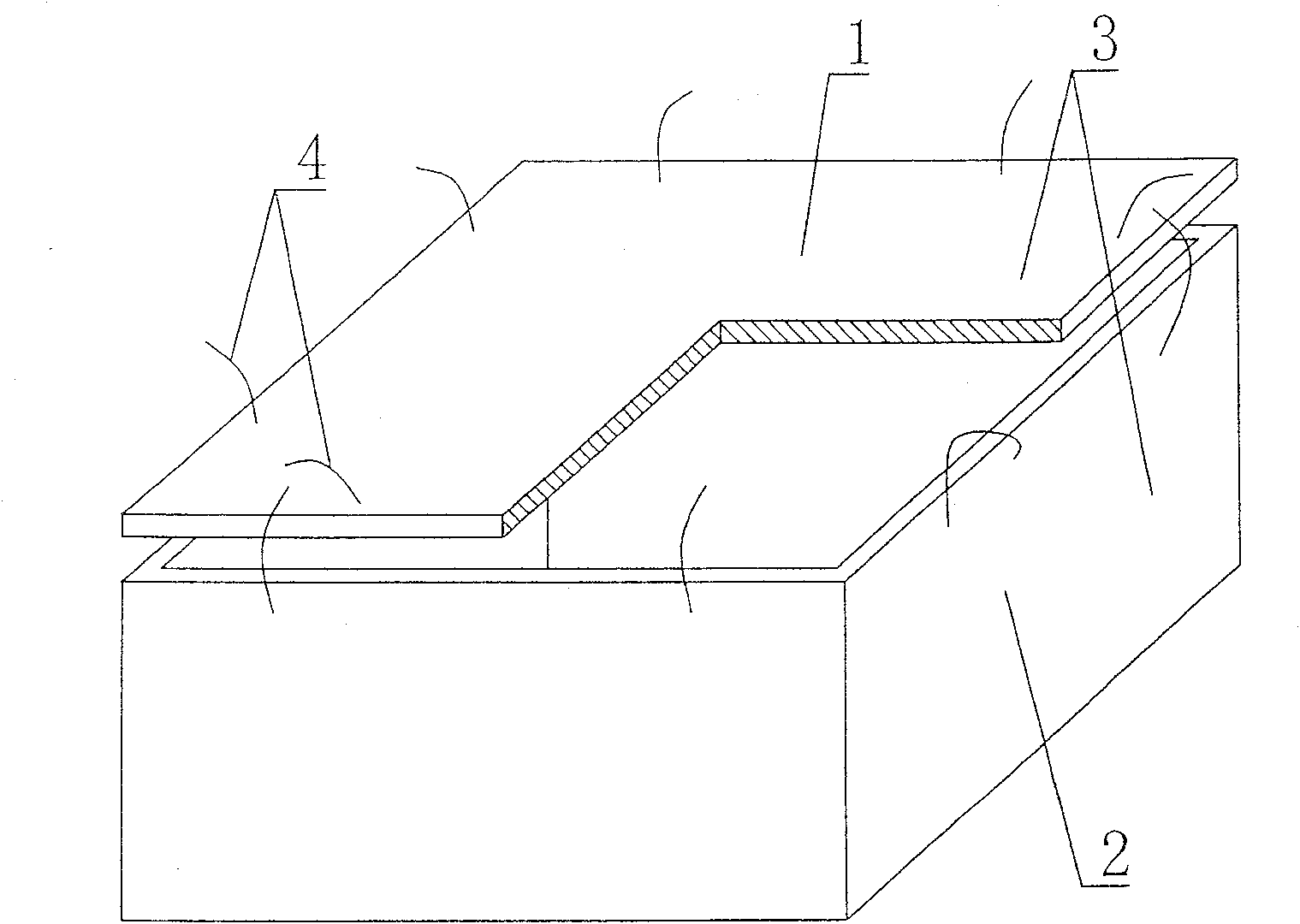

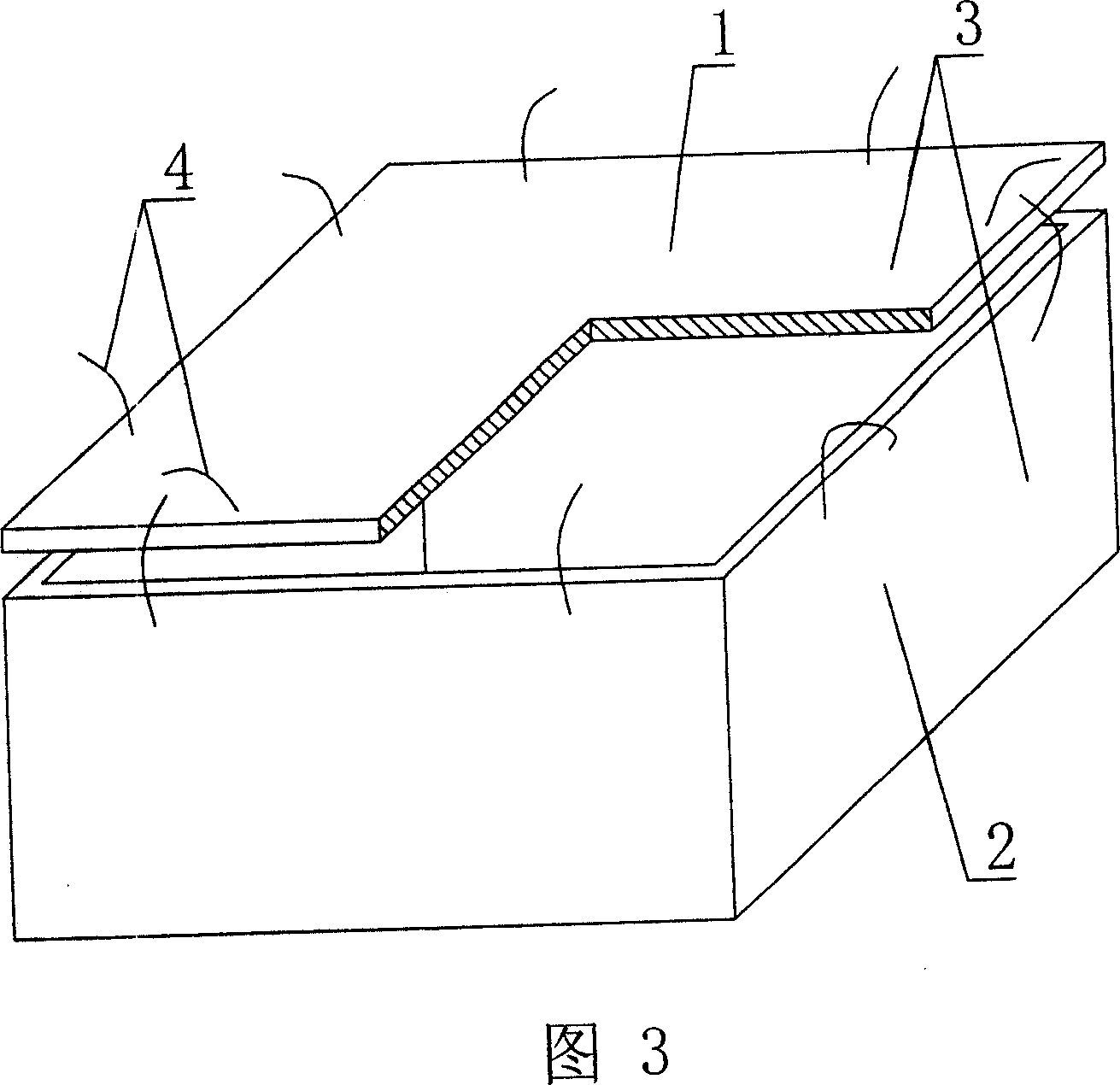

Component part in cavity die body for filling concrete

InactiveCN1626744ASimple production processReduce manufacturing difficultyFloorsMechanical engineeringEngineering

The invention relates to a concrete infilling hollow cavity form member, including upper plate and peripheral side wall. Said upper plate and peripheral side wall are combined together and formed into an open hollow cavity form. It is characterized by that the described hollow cavity form has at least two blocks spliced by prefabricated plates, and in said prefabricated plates there are at least two conjoined prefabricated plates, there prefabricated plates can be combined into open hollow cavity or closed hollow cavity, and between prefabricated plates a connecting component can be used for connecting them into one body.

Owner:湖南邱则有专利战略策划有限公司

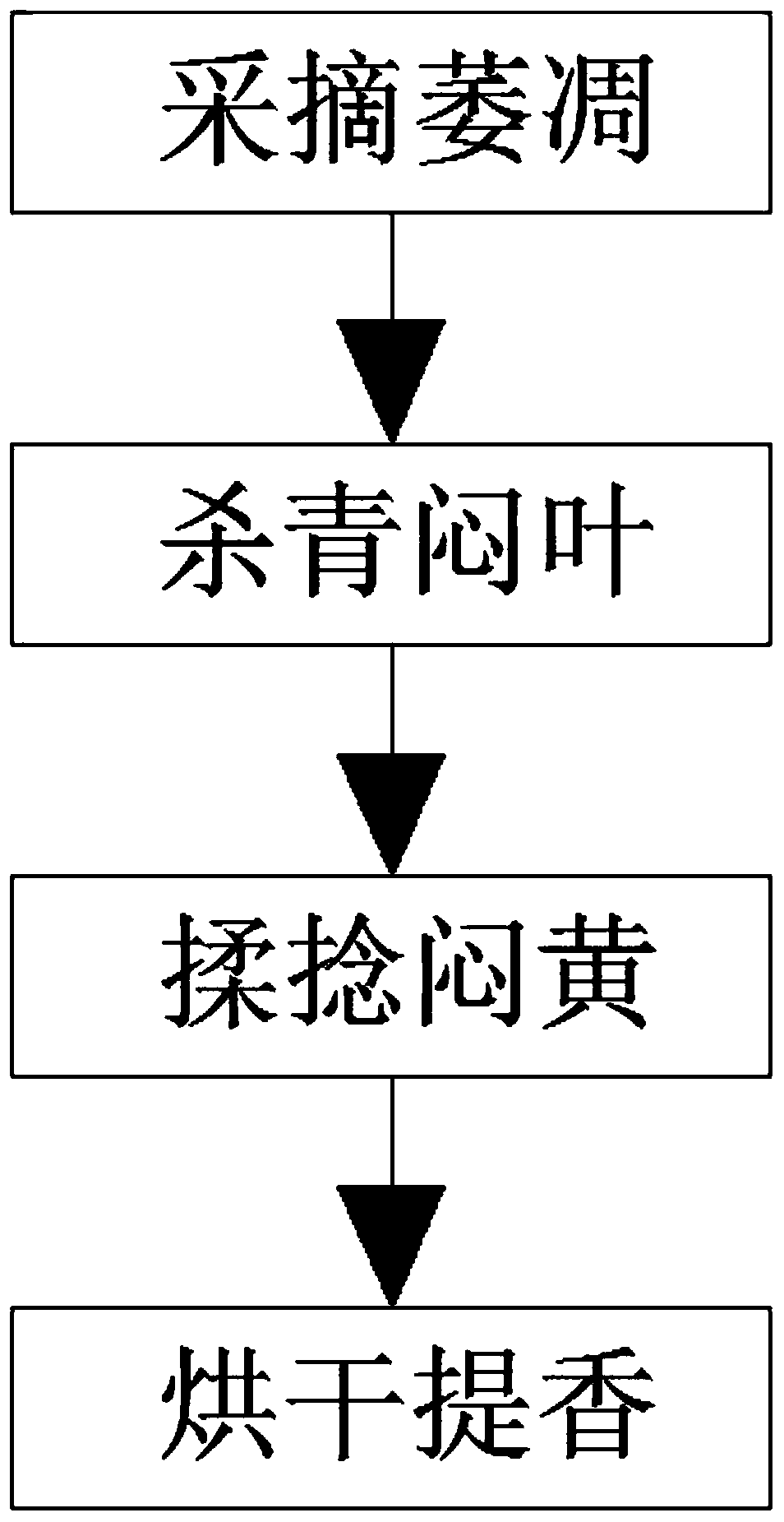

Huoshan yellow tea processing technology

The invention discloses a Huoshan yellow tea processing technology, and belongs to the technical field of tea leaves. The technology comprises the following steps of S1 picking deterioration, S2 fixation heaping, S3 rolling heaping for yellowing and S4 drying and flavor extracting, wherein fresh leaves are used for picking, the standard for tea leaves is increased, due to second-time fixation, rolling and repeated heaping for yellowing, tea leaf stable fermentation is promoted, the tea leaf content transfer is facilitated, the finished tea leaf is brown yellow in color, the tea color is apricot yellow and bright, the fragrance is mellow, the taste is mellow, the technology is high in controllability in manufacturing process, mechanical large-batch production can be achieved, existing tea leaf resources are sufficiently utilized, the Huoshan yellow tea variety is added, and tea leaf production in autumn can be achieved; the tea grower picking enthusiasm is mobilized, the tea leaf picking period is prolonged, and the income of tea growers is increased.

Owner:刘劲堂 +1

Forming method of cement decorating plate with preset anchor bolt holes

InactiveCN104690825ARealize mechanized mass productionIncrease productivityCovering/liningsMouldsEngineeringDistributor

The invention belongs to a production forming method of a cement decorating plate, in which anchor bolt holes are formed in advance. According to the forming method, a forming mold box formed by stacking movable mold boxes and a forming machine mold box is adopted; in the forming process, pre-embedded sleeves of the anchor bolt holes sleeve cylindrical lug bosses on the bottom surfaces of the plastic mold boxes of the movable mold boxes; a circulating conveyor system comprising an output chain machine, an input chain machine, a forming machine, a material distributor, two hydraulic propelling devices and the four movable mold boxes is adopted; the movable mold boxes are synchronously moved at a time in the conveying direction of the circulating conveyor system every a certain time, and the later movable mold box is moved to the position of the former movable mold box every time; the stopping position of each movable mold box is enabled to correspond to a station. According to the method, the forming steps in the production process are completed at various stations of the circulating conveyor system to realize current production, so that the mechanical production of the cement decorating plate is realized, and the production efficiency is high.

Owner:上海欧墅节能科技股份有限公司 +1

A mechanized preparing method for high-quality green tea

InactiveCN105746737ARealize mechanized mass productionSolve outputPre-extraction tea treatmentClimate change adaptationGreen teasEngineering

A preparing process of high-quality green tea is disclosed. The process inherits traditional sunning, green rocking, fixing, rolling and drying steps and processes, but adopts mechanized operation. Process parameters such as temperature, humidity and time are accurately controlled according to characteristics of green tea in the production process. Quality of a green tea finished product is greatly improved, and can meet quality of high-quality green tea prepared through traditional tea preparing handicrafts. Mechanized and mass production of the high-quality green tea is achieved. A problem that tea preparing handicrafts are low in yield and low in production efficiency is overcome. The method ensures tea product quality, allows the high-quality green tea to be polarized more widely, and allows common green tea aficionados to taste the high-quality green tea.

Owner:重庆市万盛区盛泉茶厂

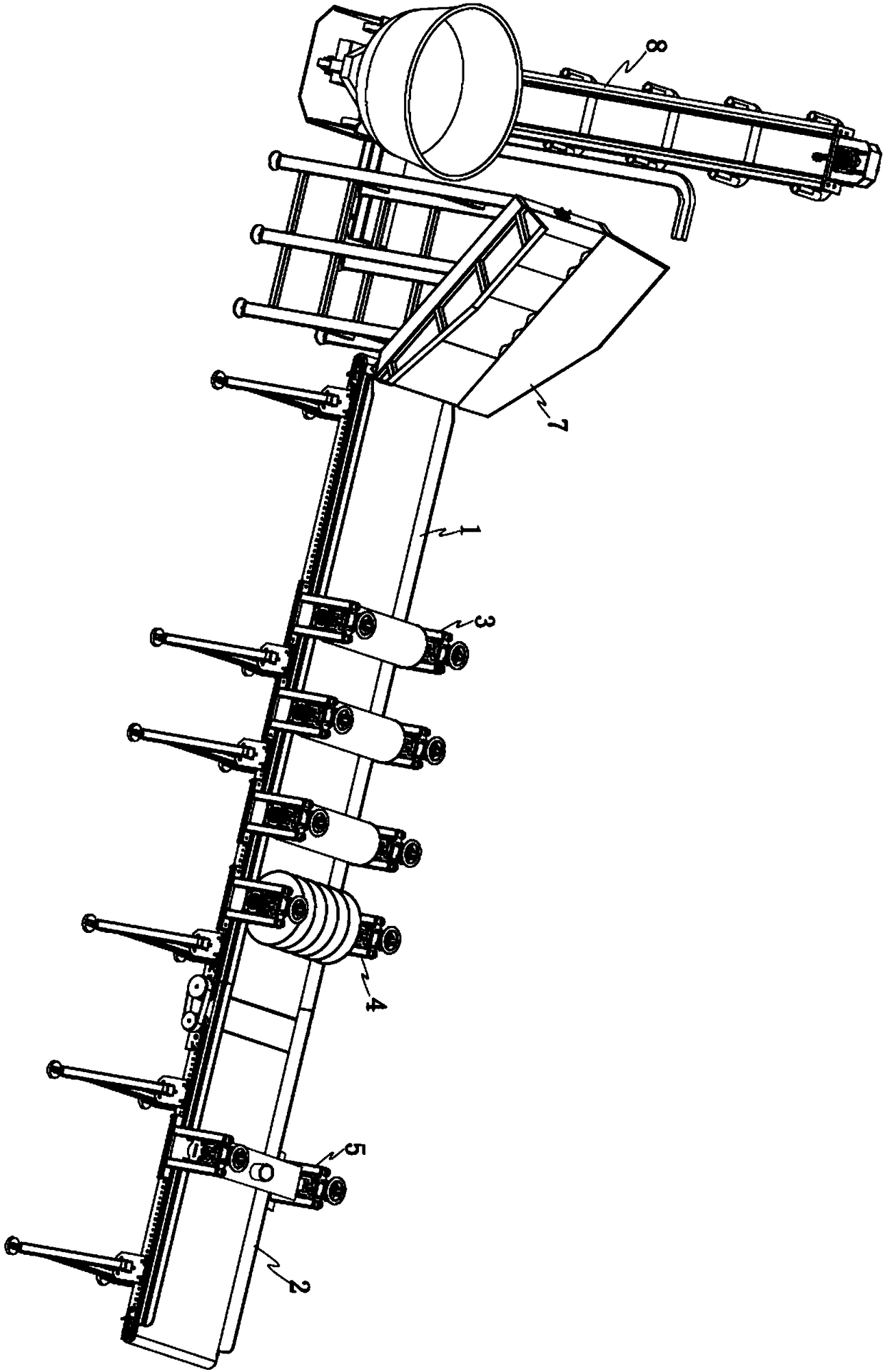

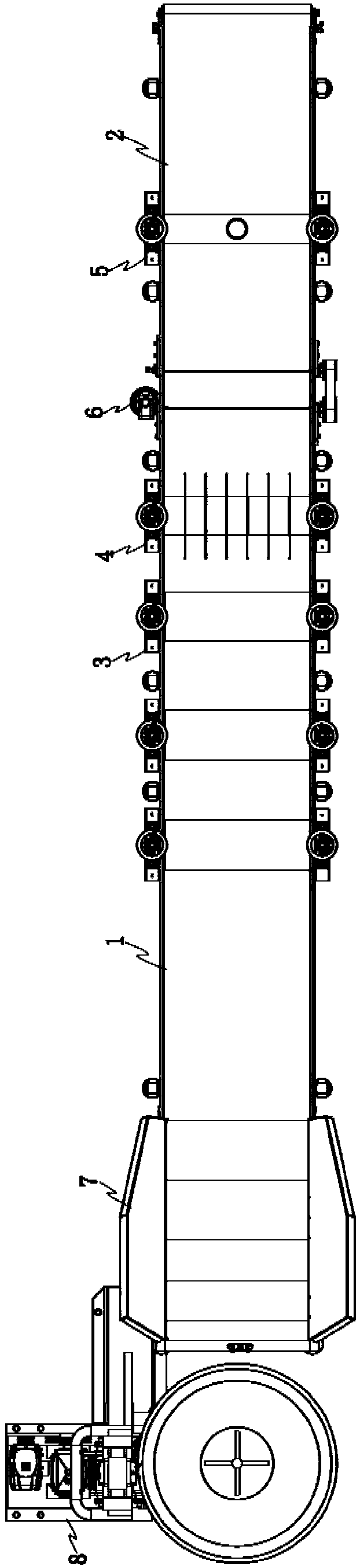

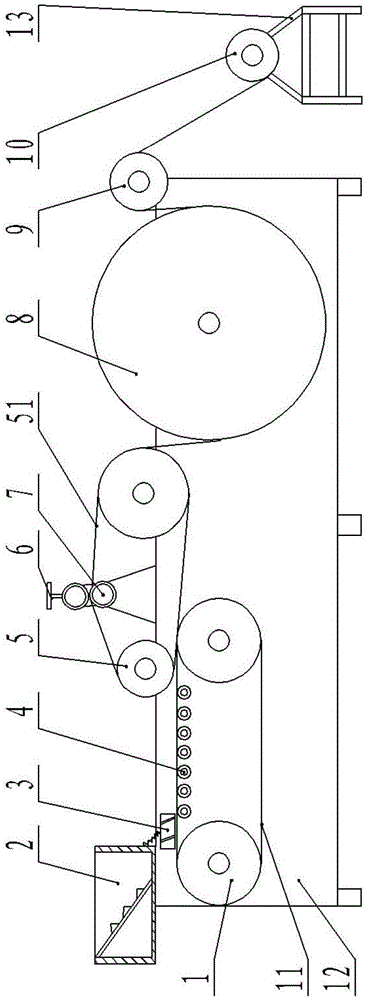

Mechanized production equipment for Chinese art paper

InactiveCN105386358ARealize mechanized mass productionAchieve dryingPaper-making machinesPaper manufacturingPulp and paper industry

The invention relates to mechanized production equipment for Chinese art paper. The mechanized production equipment comprises a bamboo curtain support. The two sides of the bamboo curtain support are provided with preformed rotary drums. Carrier rollers are arranged above the bamboo curtain support. A bamboo curtain is arranged on the outer sides of the preformed rotary drums and above the carrier rollers. A paper pulp barrel is arranged on the left side of the bamboo curtain support. A paper pulp laying auxiliary device is connected to the lower right portion of the paper pulp barrel through a lock chain. A pair of water removal rotary drums and a pair of squeezing rotary drums are arranged above the right side of the preformed rotary drums. A forming blanket is wound around the water removal rotary drums and penetrates through the position between the squeezing rotary drums. A drying rotary drum and a guide rotary drum are arranged on the right side of the water removal rotary drums. A winding table is arranged on the right side of the guide rotary drum. A winding rotary drum is arranged on the winding table. The carrier rollers are fixed below the bamboo curtain side by side and are parallel to one another; mechanized volume production of Chinese art paper manufacturing is achieved, the Chinese art paper can be formed and dried at a time, and therefore the yield of the Chinese art paper is improved; by means of the cooperated action of an inclined plate in the paper pulp barrel and the paper pulp laying device, the manufactured Chinese art paper is more uniform in thickness, and paper pulp loss is reduced.

Owner:ANHUI CHANGCHUN PAPER CO LTD

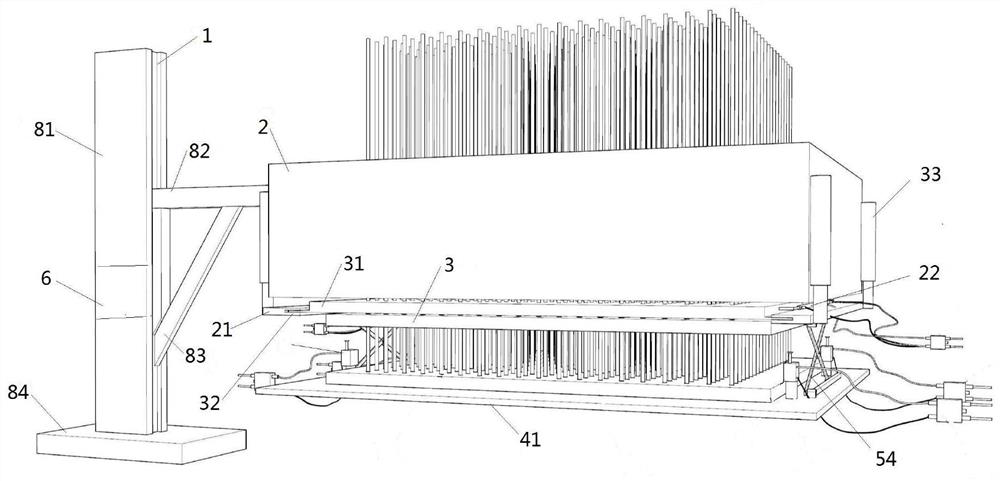

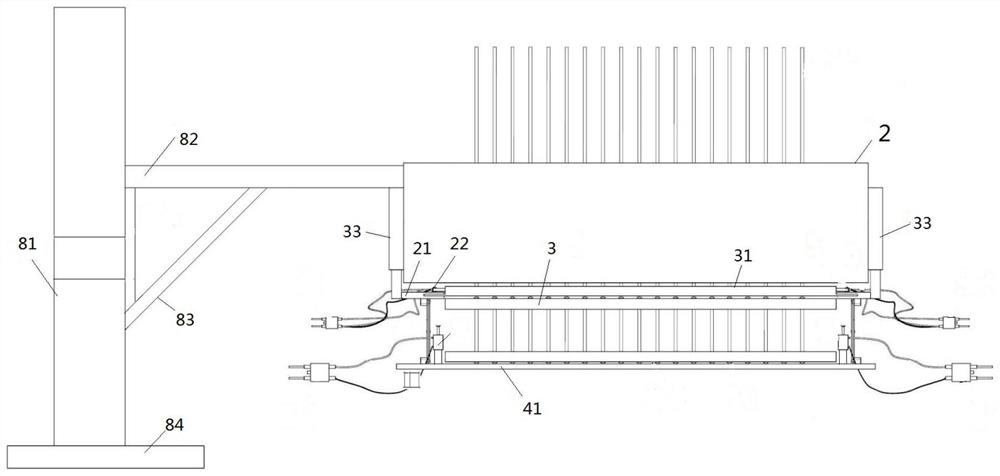

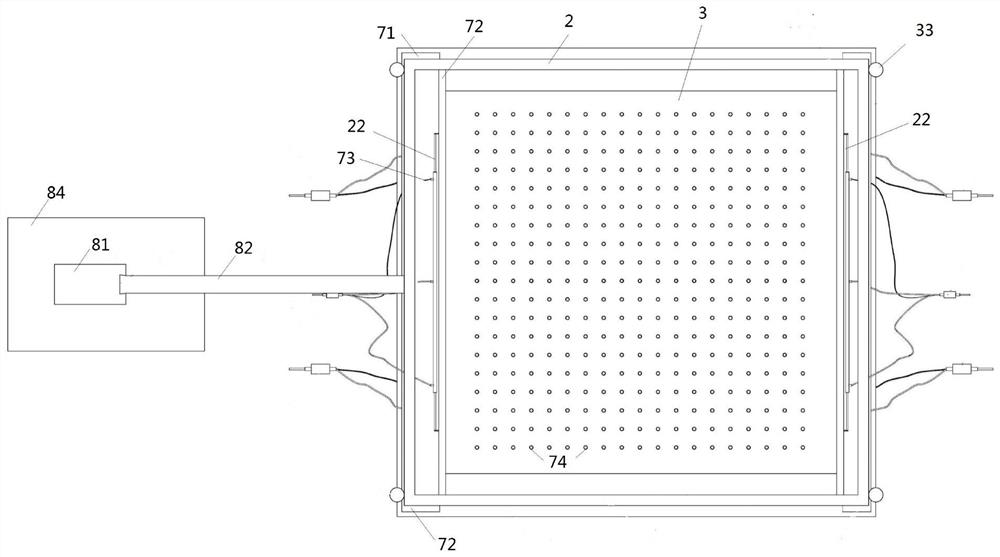

Preparation device for light-transmitting cement-based material and using method thereof

PendingCN112917642AQuality improvementInfluential impactAuxillary shaping apparatusFiberMechanical engineering

The invention relates to a preparation device for a light-transmitting cement-based material and a using method thereof, and belongs to the technical field of production equipment for light-transmitting cement-based materials. The preparation device comprises a support, a placing frame, a paying-off assembly, a plurality of frame plates, a fixing assembly and a cutting assembly, wherein the placing frame is vertically arranged on one side of the support and is suspended, and the placing frame is connected with the support; the paying-off assembly is arranged right above the placing frame and is used for fixing optical fibers; the plurality of frame plates are horizontally stacked in the placing frame; the fixing assembly is arranged in the placing frame and is used for fixing the frame plates; and the cutting assembly is arranged below the placing frame and is used for cutting off the optical fibers in the horizontal direction. According to the preparation device, the standard of frame construction is guaranteed through the gravity of the frame plates and the optical fibers, and electric heating rivet plates can cut the optical fibers and can also enable the optical fibers and the frame plates to form connecting anchor points, so that the displacement of the optical fibers in the pouring process is prevented, and the quality of the prepared light-transmitting cement-based material is improved; and the preparation device is simple to operate, convenient to use, high in practicability and worthy of popularization.

Owner:武夷学院

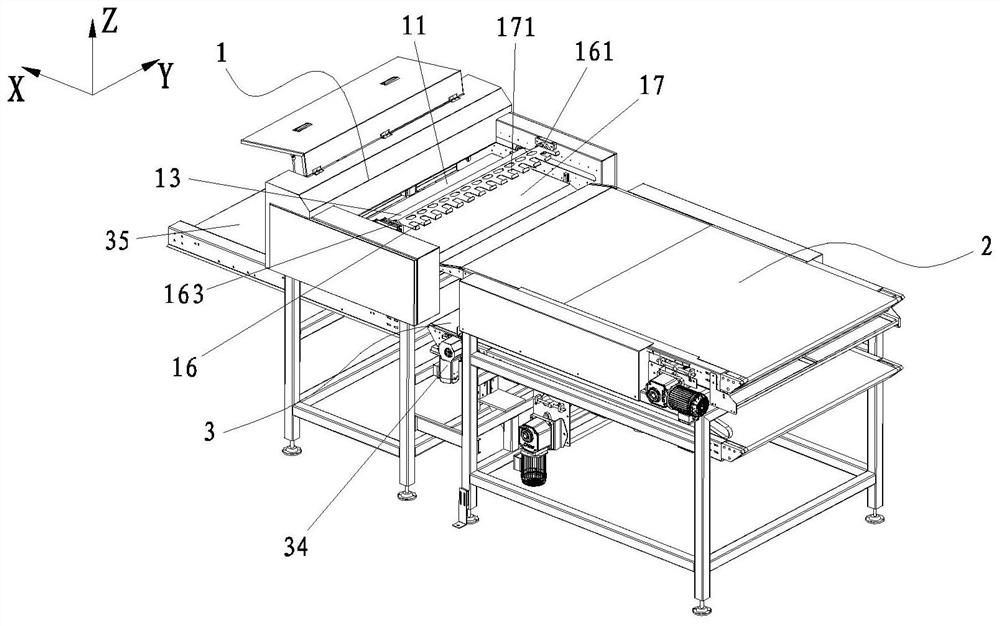

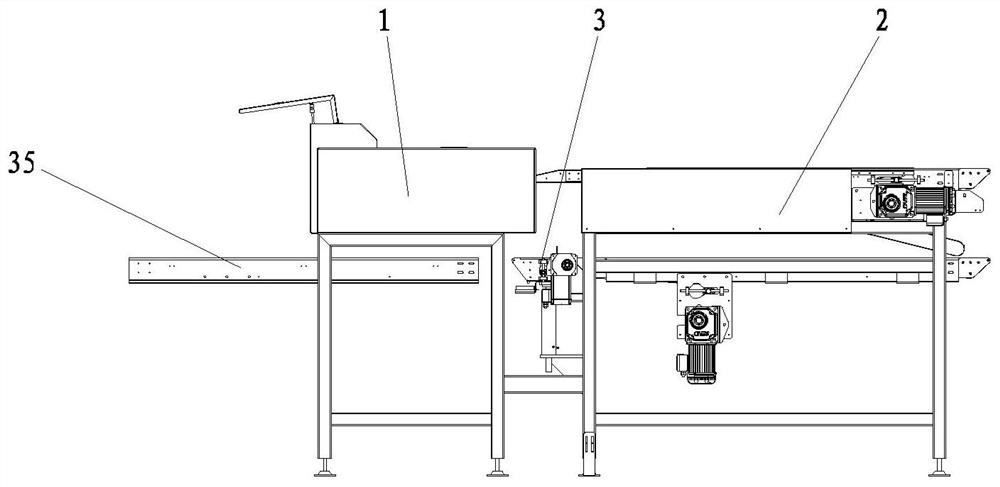

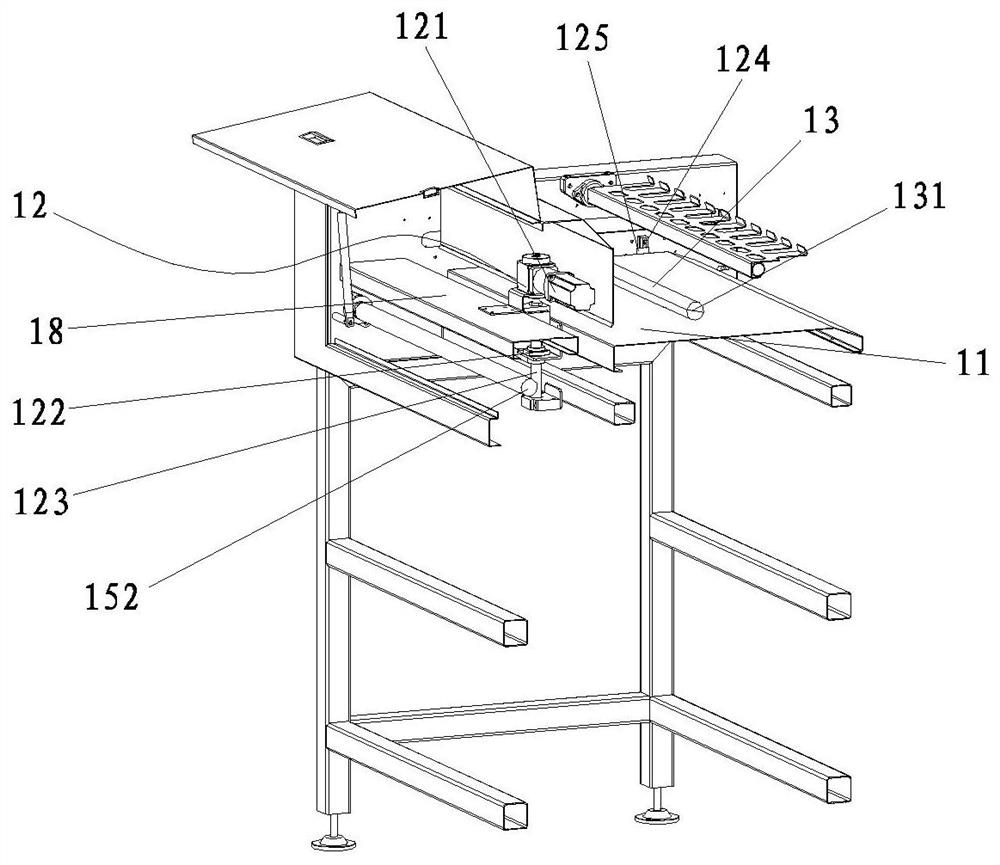

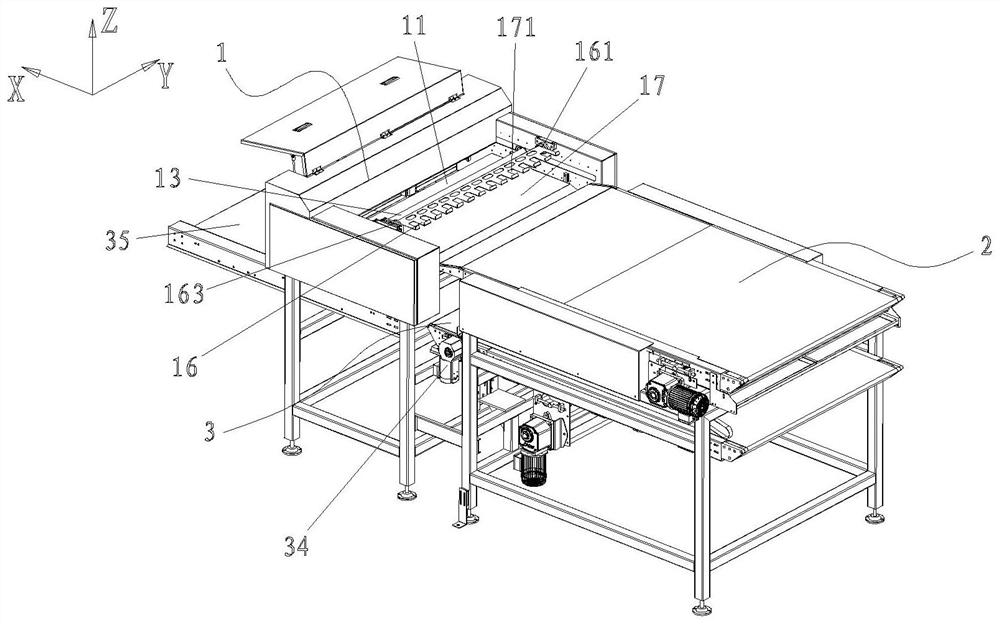

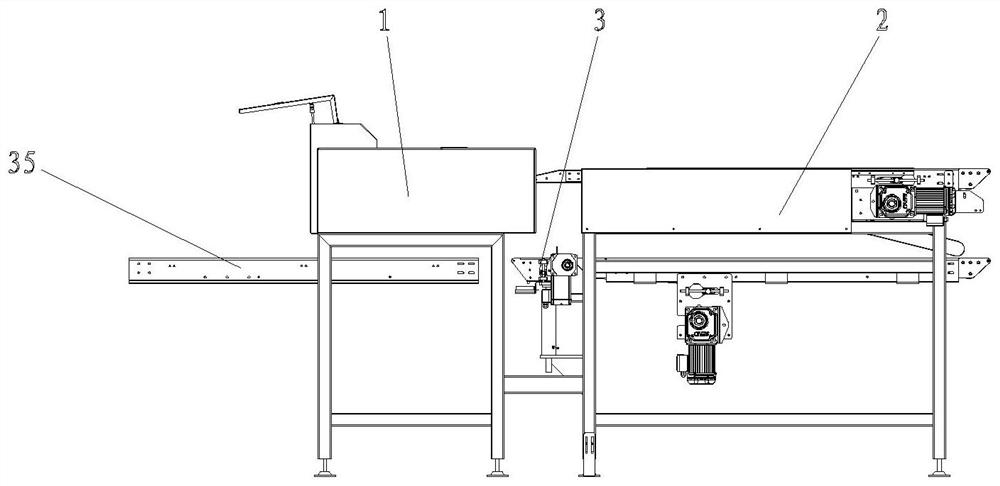

Automatic cake rolling machine

ActiveCN113197237ARealize mechanized mass productionUniform sizeBaked articles handlingWorkbenchEngineering

The invention discloses an automatic cake rolling machine which comprises a cake layer rolling mechanism, a cake blank conveying mechanism and a lifting belt conveying mechanism arranged between the cake layer rolling mechanism and the cake blank conveying mechanism, and the cake layer rolling mechanism comprises a first rack, a lifting workbench, a lifting driving mechanism for driving the lifting workbench to do lifting motion, a winding roller which is arranged above the lifting workbench, a first driving device whic is used for driving the winding roller to rotate, a first translation driving mechanism whic is used for driveing the winding roller to move horizontally, a baffle mechanism which is arranged at the rear end of the lifting workbench, and a winding cloth which is connected between the winding roller and the workbench; the winding roller is provided with a cloth clamping groove; one end of the winding cloth is embedded into the cloth clamping groove, and the other end of the winding cloth is connected with the side edge of the lifting workbench. Compared with the prior art, the cake rolling machine has the advantages that cakes can be automatically rolled, the production efficiency of the rolled cakes is improved, the labor cost is greatly reduced, the prepared rolled cakes are more compact and more regular and attractive in appearance, and the product quality of the cakes is further improved.

Owner:云峰机械(福建)有限公司

An automatic cake rolling machine

ActiveCN113197237BRealize mechanized mass productionUniform sizeBaked articles handlingStructural engineeringMachine

The invention discloses an automatic cake rolling machine, which comprises a cake rolling layer mechanism, a cake embryo conveying mechanism, and a lifting belt conveying mechanism arranged between the cake rolling layer mechanism and the cake embryo conveying mechanism. The cake rolling layer mechanism includes a first A frame, a lifting table, a lifting drive mechanism for driving the lifting movement of the lifting table, a winding roller arranged above the lifting table, a first driving device for driving the winding roller to rotate, and a first translation driving mechanism for driving the winding roller to move horizontally , the baffle mechanism arranged at the rear end of the lifting table and the winding cloth connected between the roll and the table, the roll is provided with a cloth slot, and one end of the winding cloth is embedded in the slot for connection and The other end is connected with the side of the lifting table. Compared with the prior art, the present invention can automatically curl the cake, improve the production efficiency of the layered cake, greatly reduce the labor cost, and the prepared layered cake is more rigid, has a more regular and beautiful appearance, and further improves the product quality of the cake.

Owner:云峰机械(福建)有限公司

Absorbable suture thread and making method thereof

InactiveCN107213507AHigh tensile strengthGood flexibilitySuture equipmentsCoatingsAbsorbable sutureUltimate tensile strength

The invention relates to an absorbable suture thread and a making method thereof. The suture line is composed of polyglycolic acid (PGA), calcium stearate and chitosan, and has a good tensile strength and antibacterial property. The making method comprises the following steps: spinning the polyglycolic acid on a self-made small spinning machine to make PGA threads; preparing a chitosan solution having a certain concentration, and coating the PGA threads with chitosan in a coating machine; mixing and dissolving calcium stearate and the PGA to obtain a coating solution, and coating the chitosan-coated PGA threads in the coating machine; and finally carrying out plying braiding the PGA threads in a vertical spindle braiding machine to make the absorbent suture thread. The making method is simple, and can realize mechanical large-scale production. The produced absorbable suture thread has a good tensile strength and an antibacterial property, and can meet the needs of wound surgical suture.

Owner:WUHAN YIJIABAO BIOMATERIAL CO LTD

Grid treadle bar and manufacturing method thereof

The invention relates to a grid treadle bar and a manufacturing method thereof. The grid treadle bar is an accessory for doors, and belongs to the field of daily life. The grid treadle bar comprises the following raw materials in portions by weight: 60-65 portions of unsaturated polyester resin, 35-40 portions of saturated polyester type low shrink additive, 10-20 portions of reinforcing fiber, 30-60 portions of inorganic filler the length-to-diameter ratio of which is greater than 2, 100-140 portions of calcium carbonate or aluminum hydroxide with the grain size of 400-600 meshes, 1-4 portions of active magnesium oxide paste, 0.5-3 portions of organic peroxide, 0.01-1 portion of para-benzoquinone, 1-4 portions of zinc stearate, 0.5-4 portions of technical assistant and 1-5 portions of pigment. The invention has the advantages of reasonable formula design, stable product quality, low manufacturing cost, reasonable technical steps and quantifiable performance indexes.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

Traditional Chinese medicine earthworm decoction piece processing method

ActiveCN105596374AMeet the actual needs of large-scale processingRealization of actual needs for large-scale processingRespiratory disorderBlood disorderProduction lineDigital imaging

The invention provides a traditional Chinese medicine earthworm decoction piece processing method. Traditional Chinese medicine earthworm decoction pieces are obtained through the steps of preprocessing, digital imaging, graphic processing, laser cutting, tray material pouring, continuous washing, airing and the like. Eyes, brains and hands of people are replaced with a digital camera, a computer and a laser machine, cutting, washing and drying of earthworm medicinal materials are designed into a line production linkage production line, and the intelligent processing process of traditional Chinese medicine earthworms is achieved. Compared with an existing manual work mode, the method has the advantages that labor is saved, efficiency is high, notches are smooth, continuous work is achieved and ash is reduced, and the method is suitable for industrialized application.

Owner:ZHEJIANG UNIV

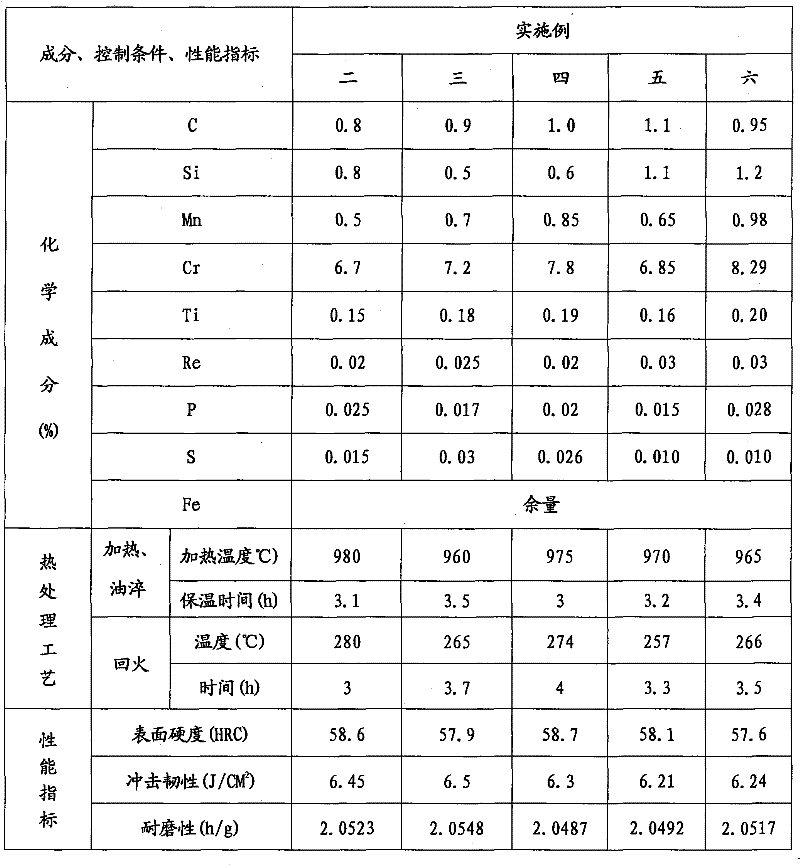

Super wear-resistant cast steel grinding ball and preparation method thereof

InactiveCN101748332BRealize mechanized mass productionRealize cleaner productionFurnace typesHeat treatment furnacesWear resistantMineral industries

Owner:HEBEI HEROIC WEAR RESISTANT

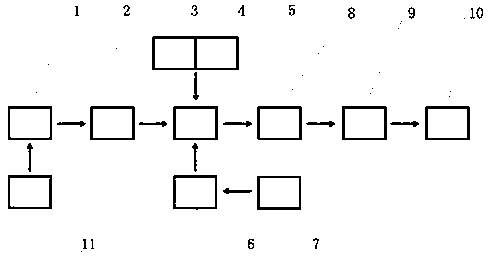

Preparation method and preparation machine of cattle and sheep feed prepared by fermentation of potato residues and straw powder

The invention relates to a preparation method and preparation machine of cattle and sheep feed prepared by fermentation of potato residues and straw powder fermented. The preparation machine comprisesa straw crusher, a straw dust remover, a mixing mixer, a mixing hopper and a quantitative briquetting sealing packaging machine which are connected in sequence through a conveying device, and the preparation machine also comprises a first auxiliary material hopper, a second auxiliary material hopper and a potato residue hopper which are connected with the mixing mixer through the conveying device, wherein a strain spraying device is arranged in the potato residue hopper. The preparation method of the feed provided by the invention is simple and easy to implement, and potato waste residues canbe well fermented. Agricultural wastes are fully utilized as main materials, the excellent cattle and sheep feed is produced on the basis of adding a small amount of grain auxiliary materials, and onthe premise of not adding antibiotics and hormones into the feed, the feed has a high nutritional value. Through microbial fermentation treatment, the protein content of the potato residues can be greatly improved, the fiber structure of coarse fibers can be improved, and palatability of the feed is improved.

Owner:泰安市岱岳区泰峰农牧机械厂

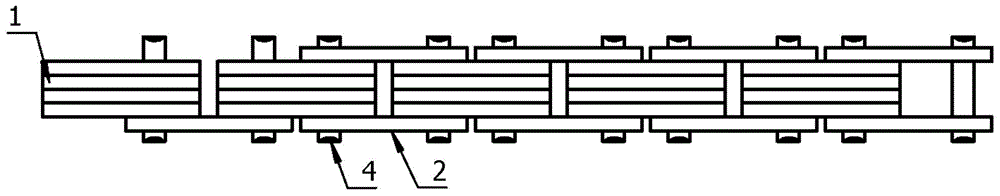

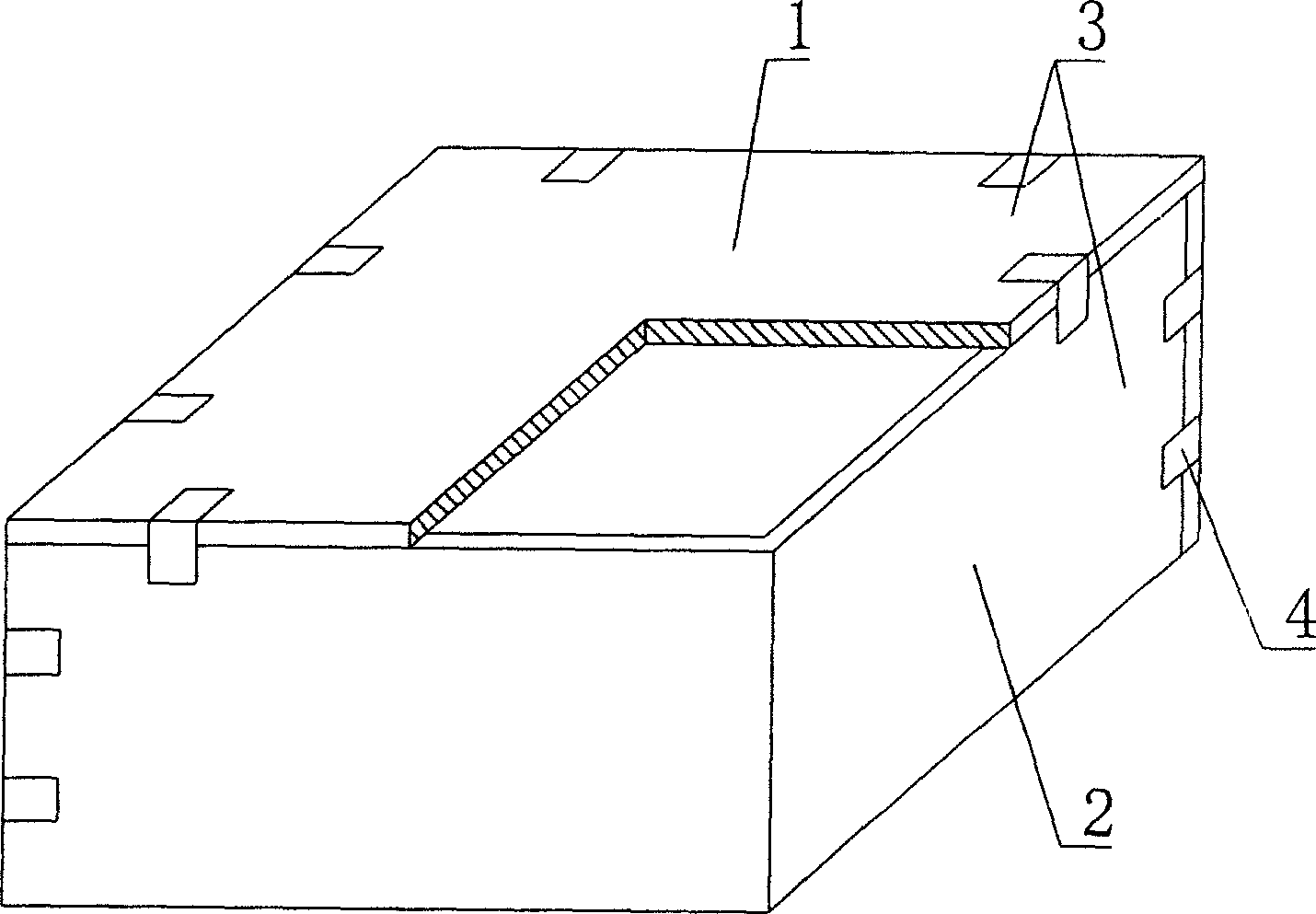

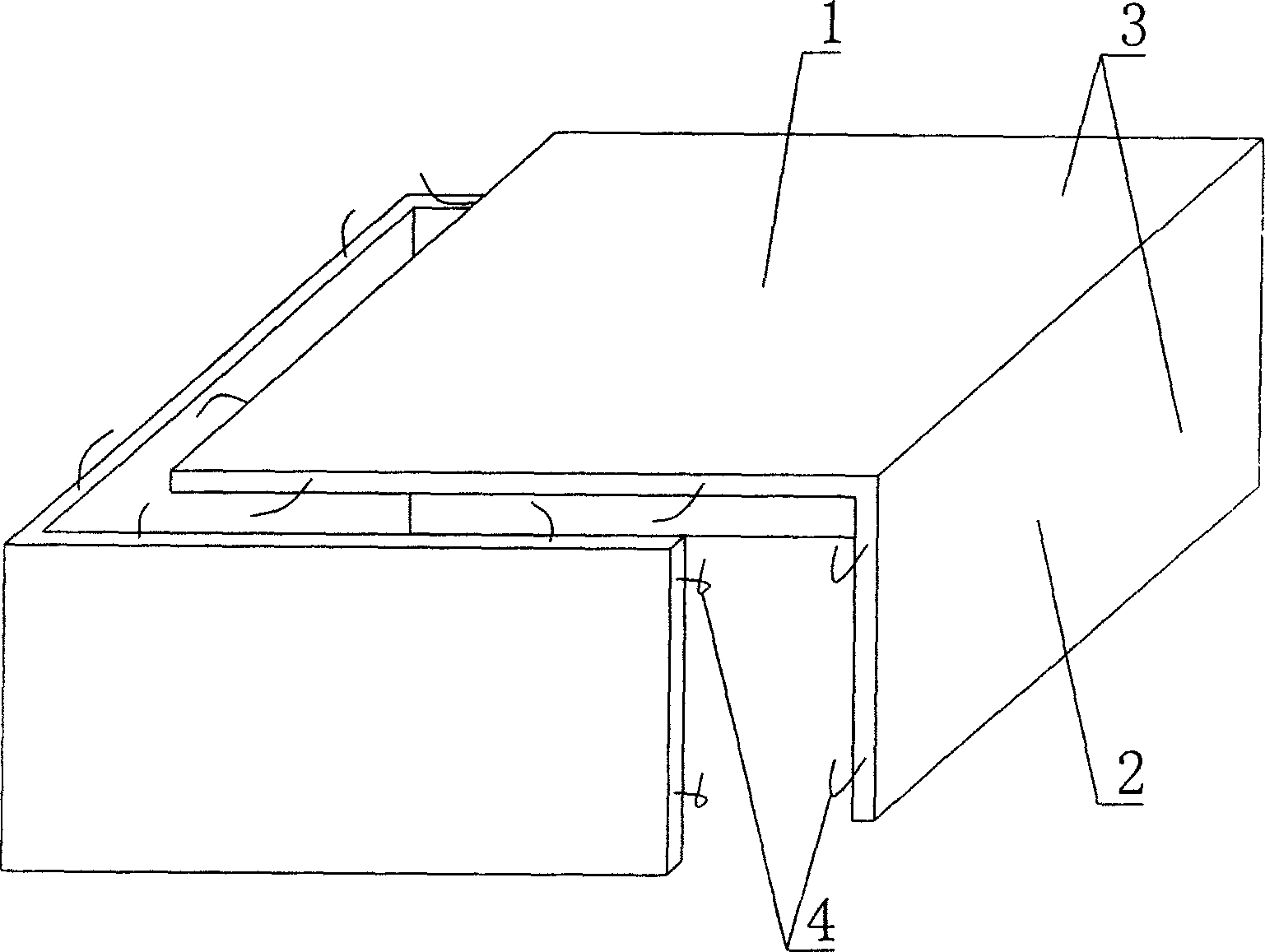

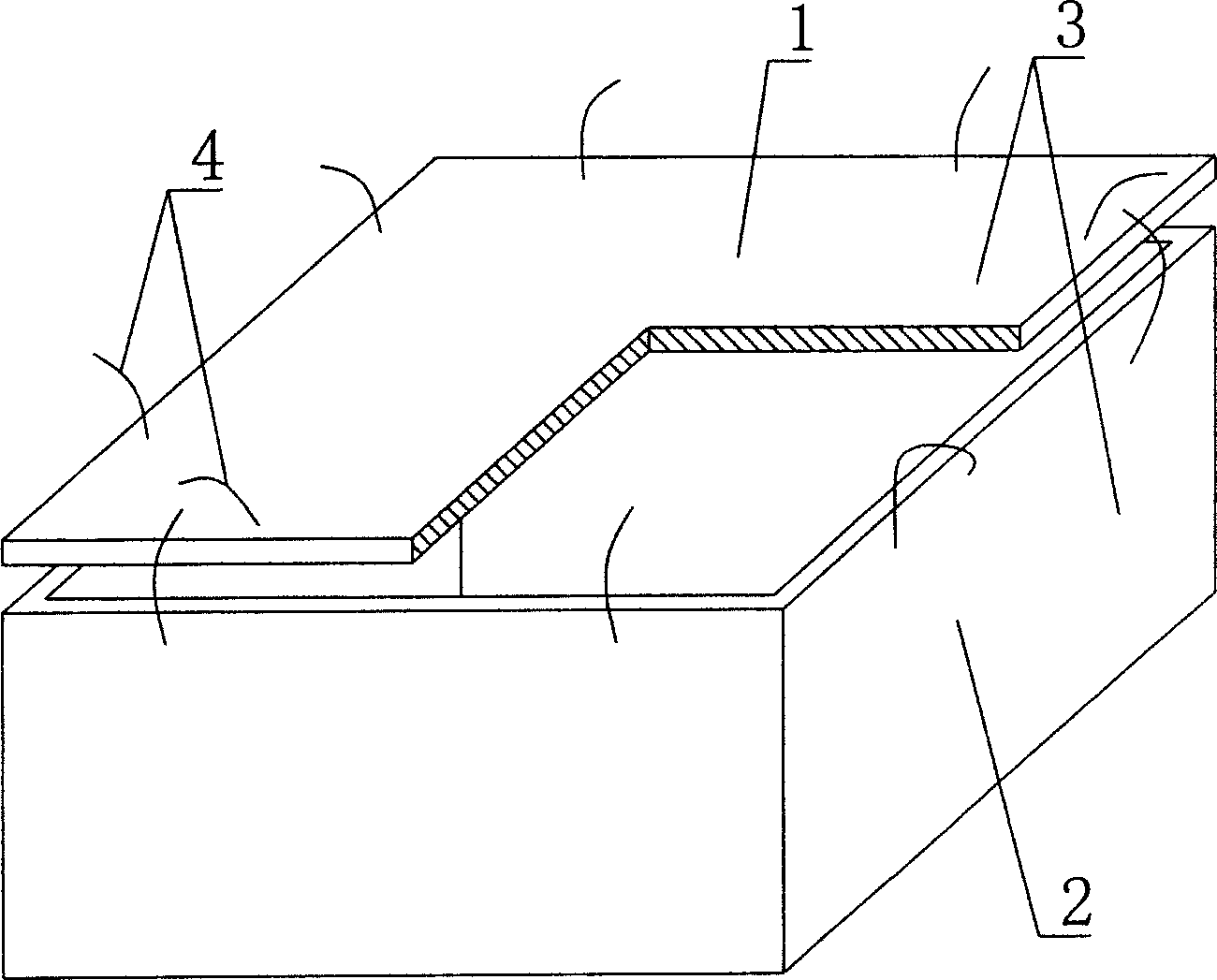

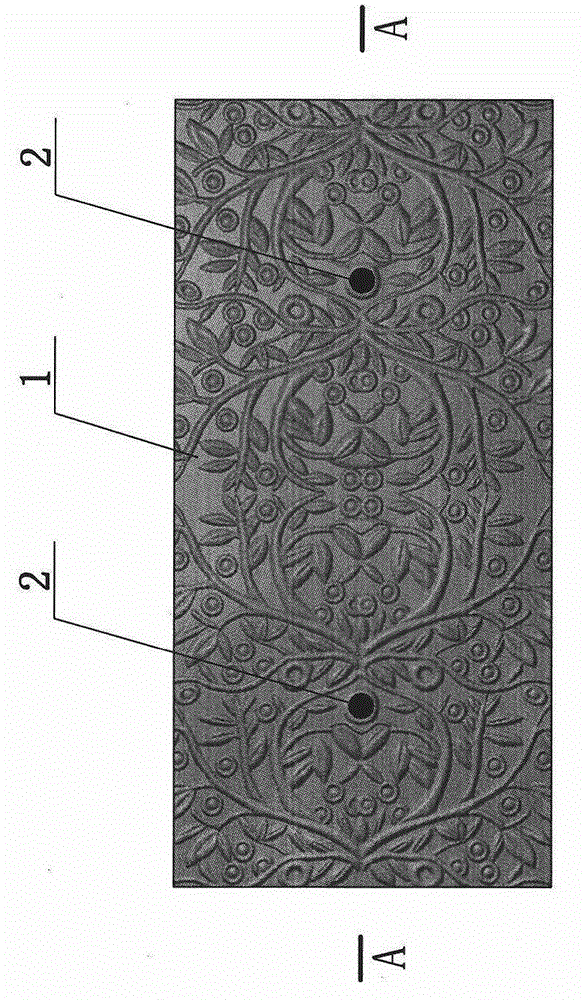

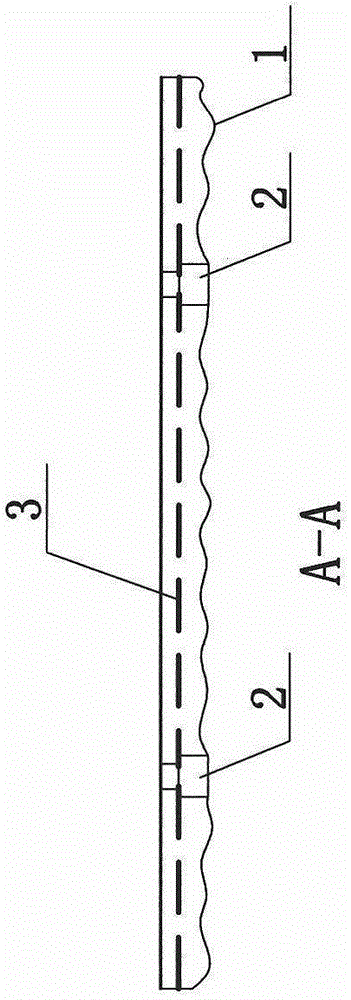

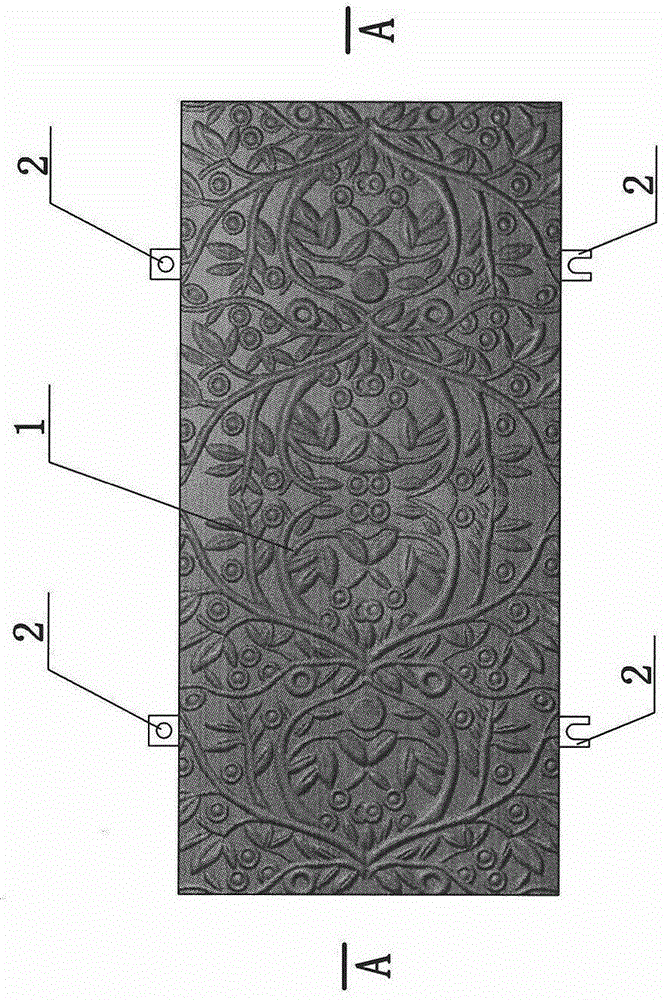

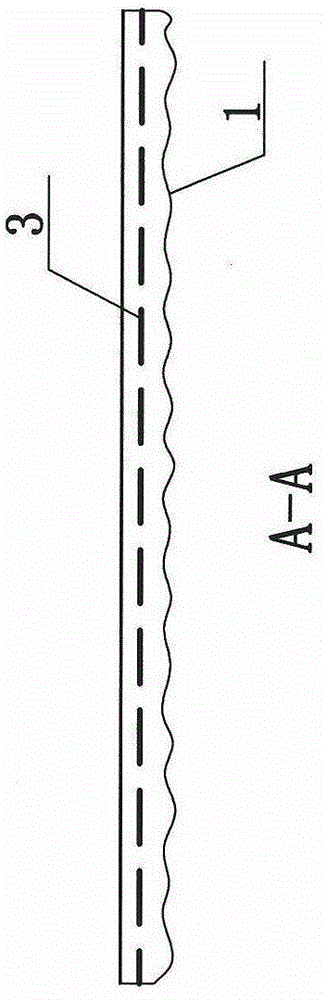

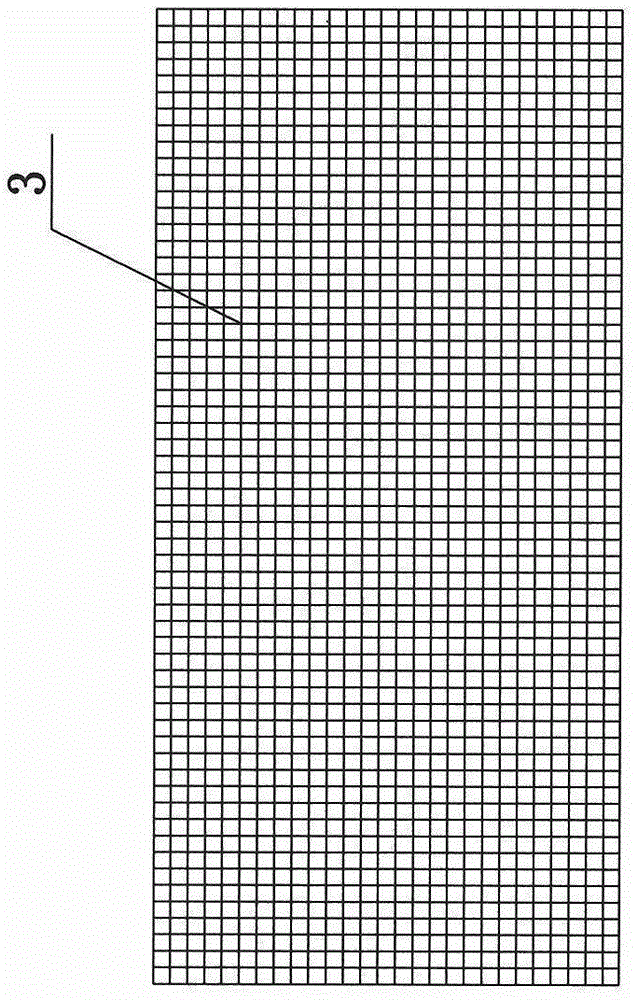

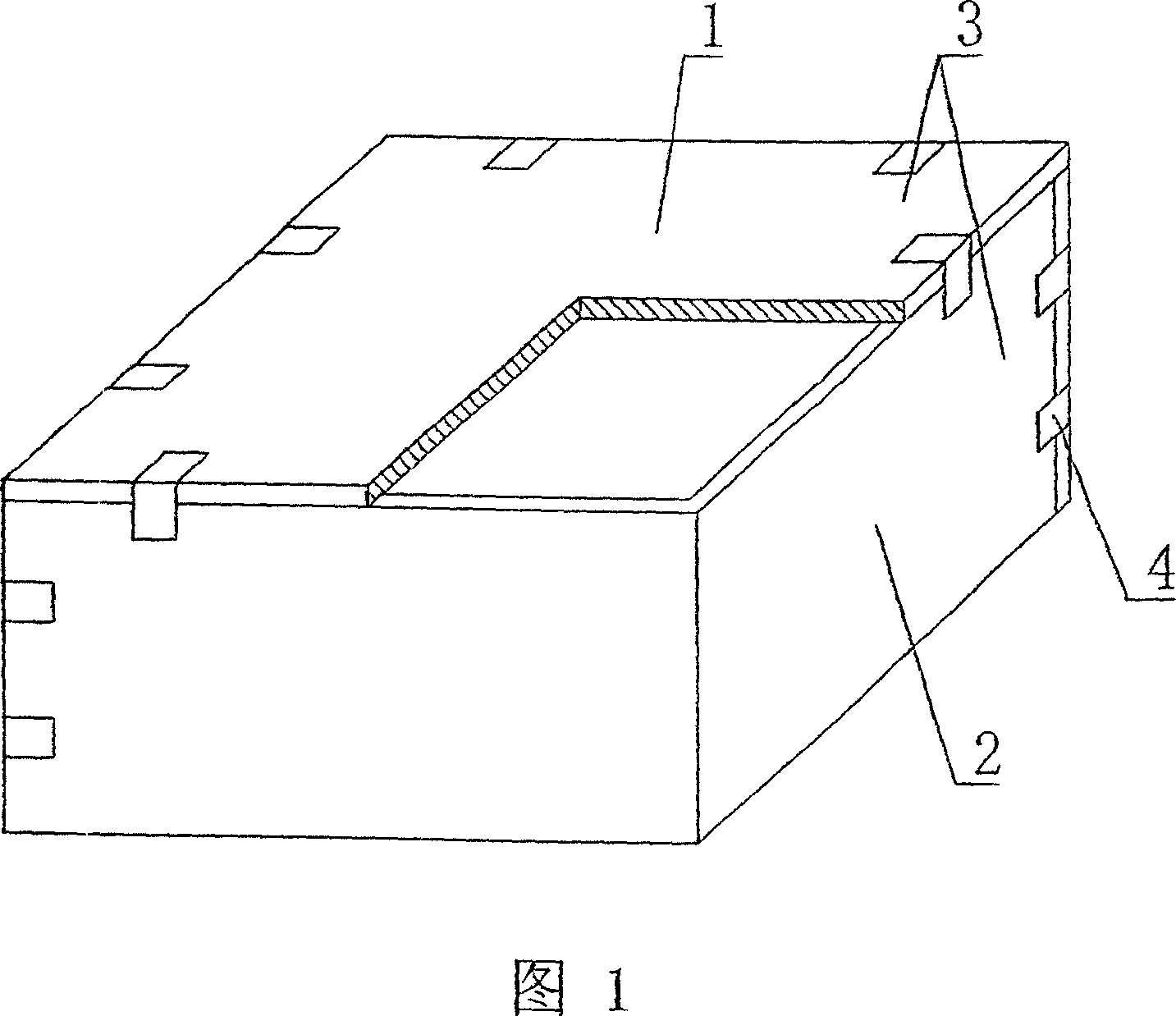

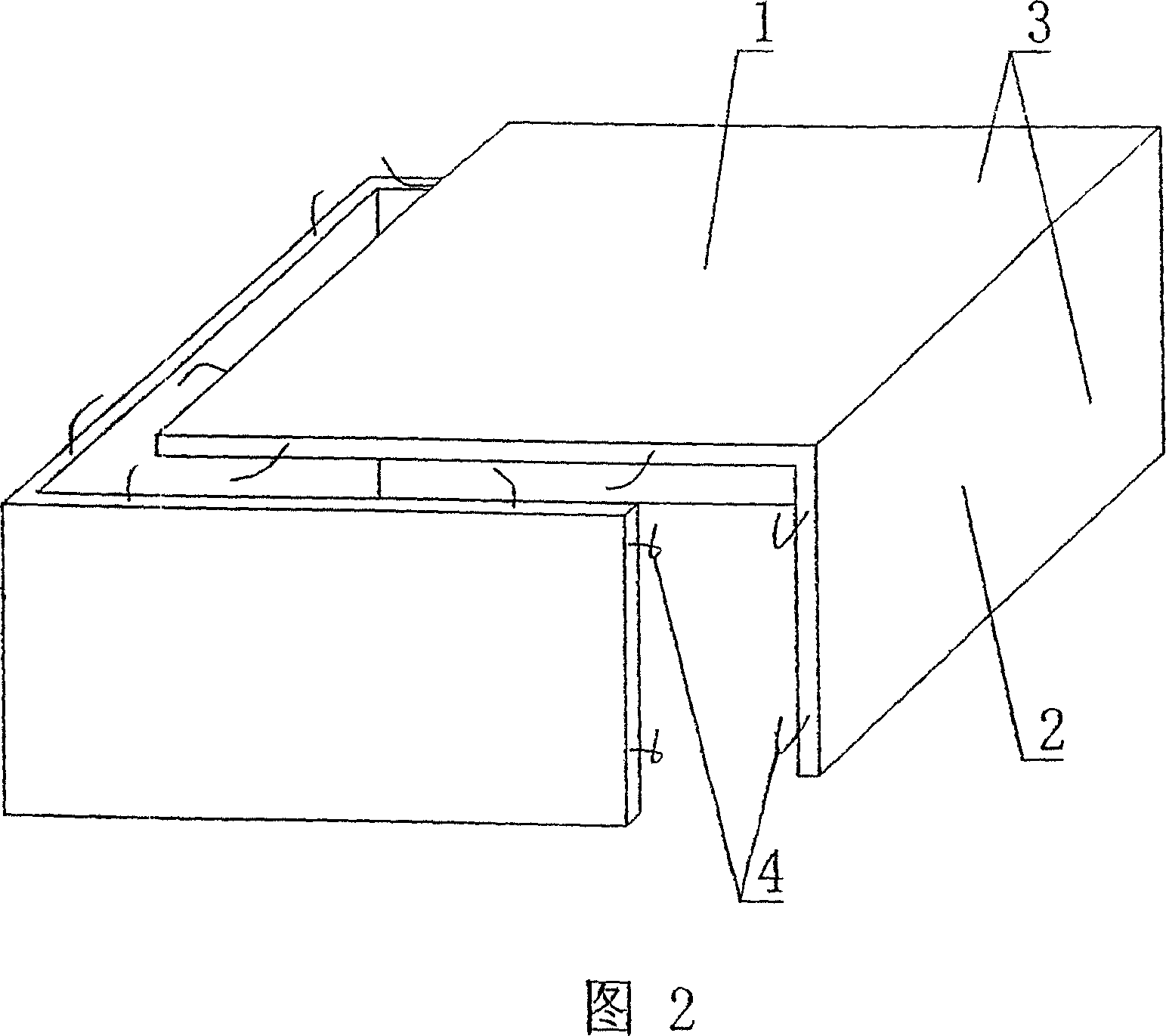

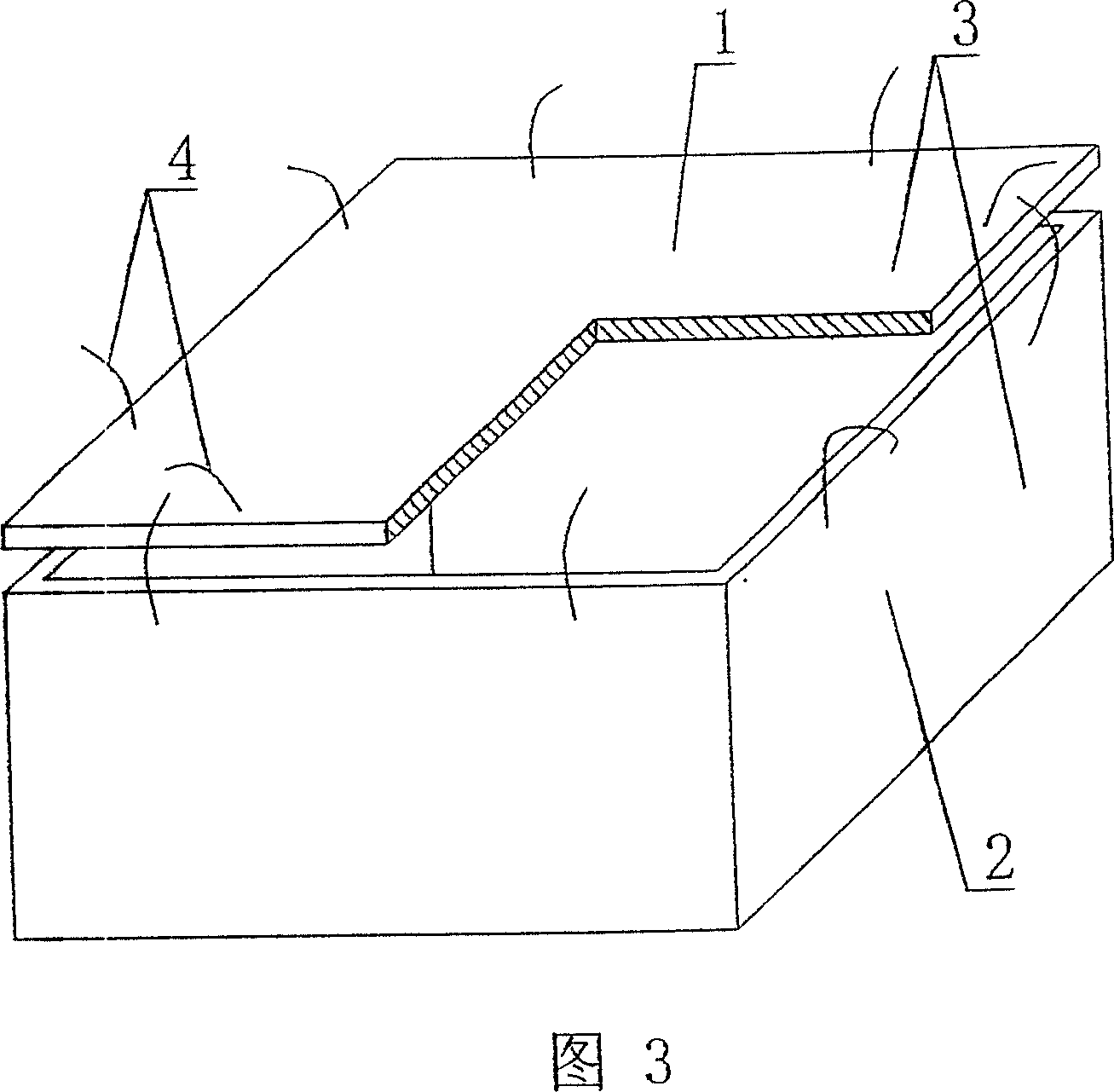

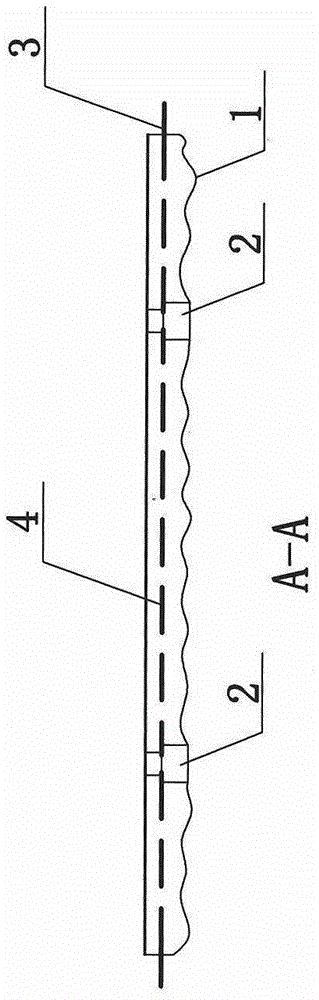

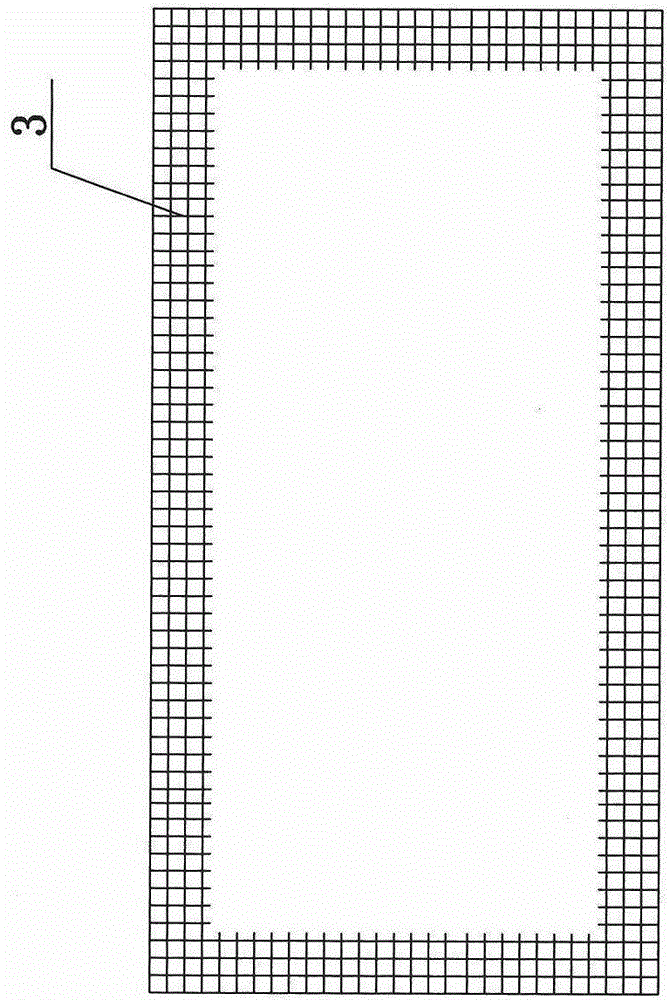

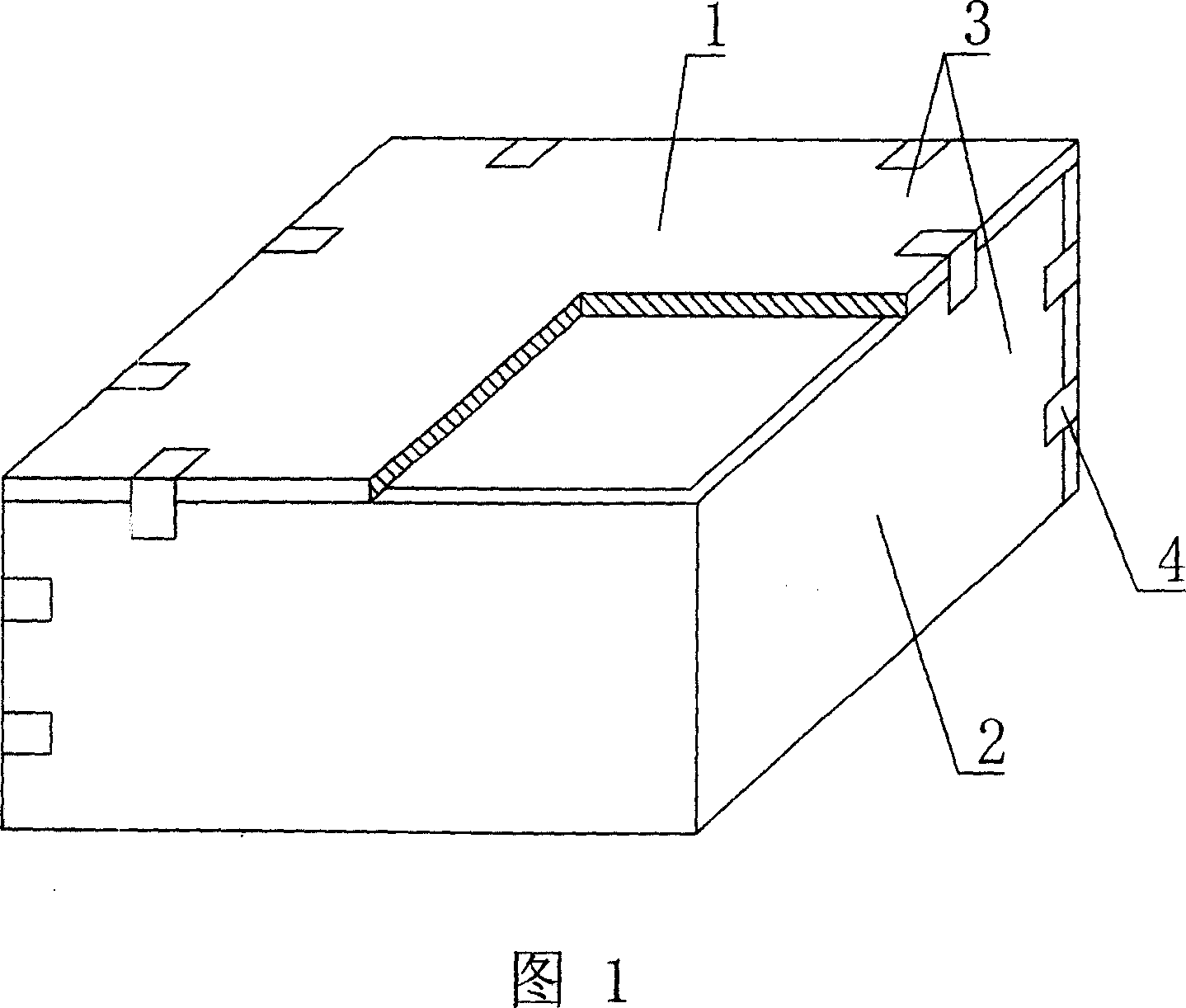

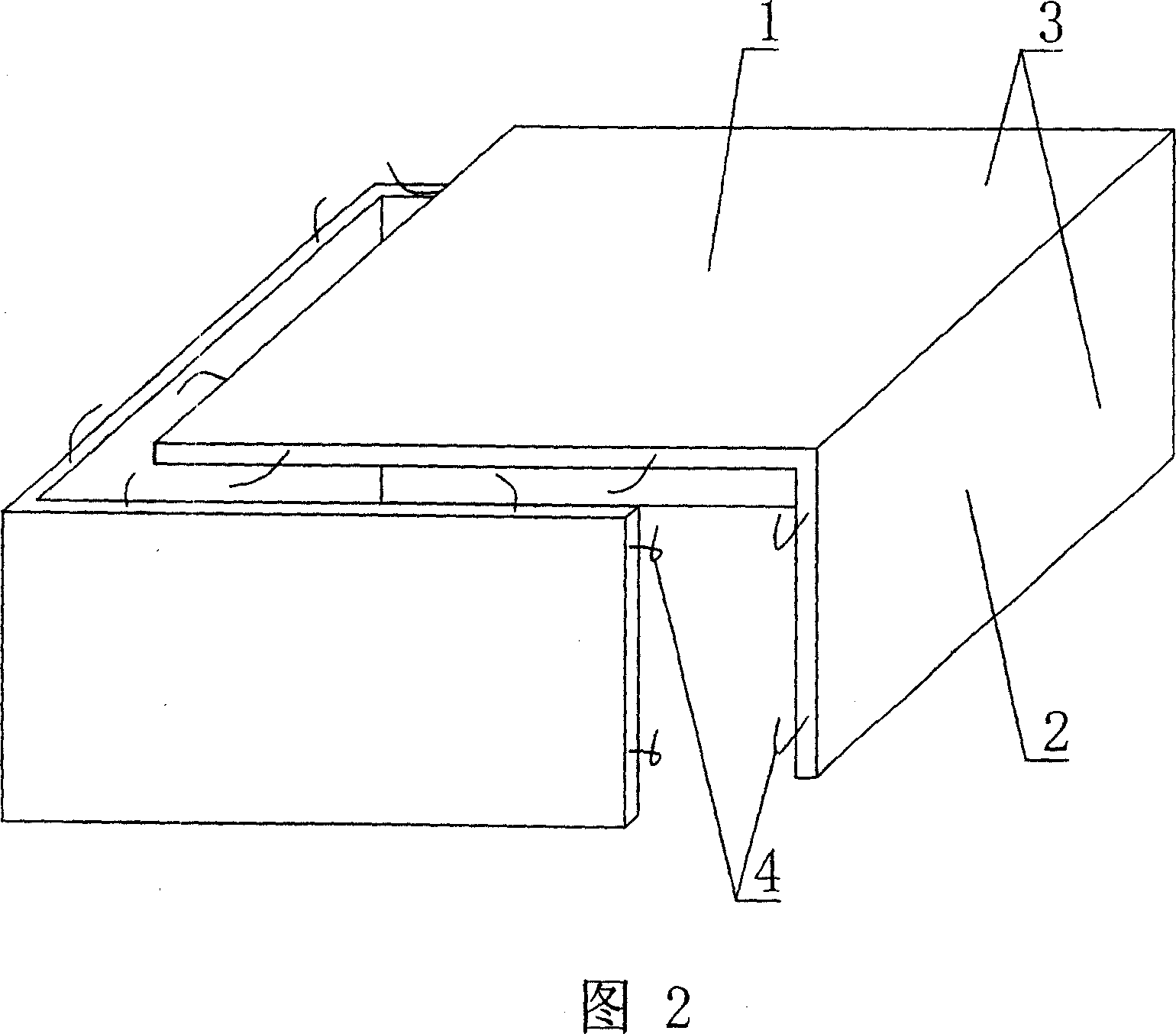

Cavity form component for concrete filling

InactiveCN1991031ASimple production processReduce manufacturing difficultyFloorsHollow coreReinforced concrete

Disclosed is a hollow concrete shuttering member for concrete filling, which comprises an upper board (1) and peripheral side panels (2), wherein the upper board (1), the peripheral side panels (2) enclose open hollow shuttering members, characterized in that at least two of the hollow shuttering members are pasted from prefabricated panels (3), forming open chambers or closed chambers, the prefabricated panels (3) are connected into an integrality through a connecting member (4), the invention can be applied to cast-in-situ reinforced concrete or prestressed reinforcement concrete's hollow storied-building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

Cavity form component for concrete filling

InactiveCN100549316CSimple production processReduce manufacturing difficultyFloorsReinforced concreteHollow core

Owner:湖南邱则有专利战略策划有限公司

Cavity form component for concrete filling

InactiveCN1991051BSimple production processReduce manufacturing difficultyFloorsReinforced concreteHollow core

Disclosed is a hollow concrete shuttering member for concrete filling, which comprises an upper board (1) and peripheral side panels (2), wherein the upper board (1), the peripheral side panels (2) enclose open hollow shuttering members, characterized in that all of the hollow shuttering members are pasted from prefabricated panels (3), forming open chambers or closed chambers, the prefabricated panels (3) are connected into an integrality through a connecting member (4). The invention can be applied to cast-in-situ reinforced concrete or prestressed reinforcement concrete's hollow storied-building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

Cavity form component for concrete filling

InactiveCN100535302CSimple production processReduce manufacturing difficultyFloorsReinforced concreteHollow core

A cavity formwork member for concrete filling, comprising an upper plate (1), surrounding side walls (2), the upper plate (1), and surrounding side walls (2) form an open cavity formwork, characterized in that The cavity formwork has at least two prefabricated panels (3) assembled, and at least two conjoined prefabricated panels are arranged in the prefabricated panels (3), and the prefabricated panels (3) are assembled into an open cavity, The prefabricated panels (3) are connected as a whole by connecting pieces (4), and the prefabricated panels (3) of the surrounding side walls (2) are spliced at corners. It is suitable for the use of cast-in-place reinforced concrete or prestressed reinforced concrete hollow floors, roofs, walls, foundation floors and hollow bridges, especially for hollow beamless floors.

Owner:湖南邱则有专利战略策划有限公司

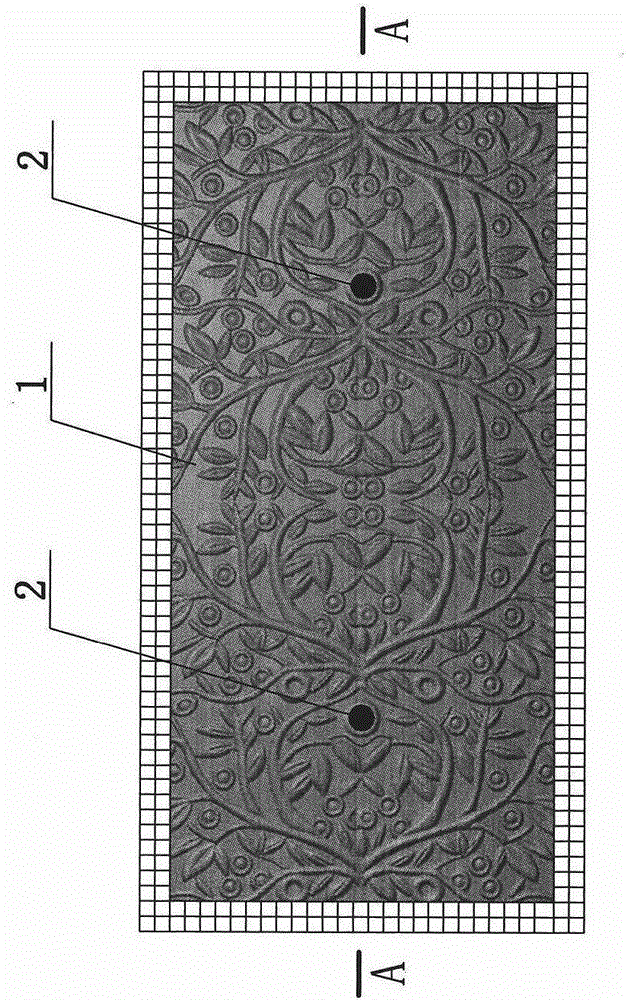

Forming method of cement decorative board with pre-embedded pendants

InactiveCN104690807BRealize mechanized mass productionIncrease productivityShaping conveyorsDistributorMaterials science

The invention belongs to a production forming method of a cement decorating plate. Metal hanging pieces are pre-buried on the upper end face and the lower end face of the cement decorating plate. According to the forming method, a forming mold box formed by stacking movable mold boxes and a forming machine mold box is adopted; in the forming process, the metal hanging pieces are temporarily fixed in grooves in the upper edges of the plastic mold boxes; a circulating conveyor system comprising an output chain machine, an input chain machine, a forming machine, a material distributor, two hydraulic propelling devices and the four movable mold boxes is also adopted; synchronously moving the movable mold boxes are synchronously moved at a time in the conveying direction of the circulating conveyor system at a certain time, and the later movable mold box is moved to the position of the former movable mold box every time; the stopping position of each movable mold box is enabled to correspond to a station. According to the method, the forming steps in the production process are completed at various stations of the circulating conveyor system to realize current production, so that the mechanical production of the cement decorating plate is realized, and the production efficiency is high.

Owner:上海欧墅节能科技股份有限公司 +1

Cavity form component for concrete filling

InactiveCN1991015ASimple production processReduce manufacturing difficultyFloorsHollow coreReinforced concrete

Disclosed is a hollow concrete shuttering member for concrete filling, which comprises an upper board (1) and peripheral side panels (2), wherein the upper board (1) and the peripheral side panels (2) enclose open hollow shuttering members, characterized in that at least two of the hollow shuttering members are pasted from prefabricated panels (3), forming open chambers or closed chambers, the prefabricated panels (3) are connected into an integrality through a connecting member (4), the invention can be applied to cast-in-situ reinforced concrete or prestressed reinforcement concrete's hollow storied-building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

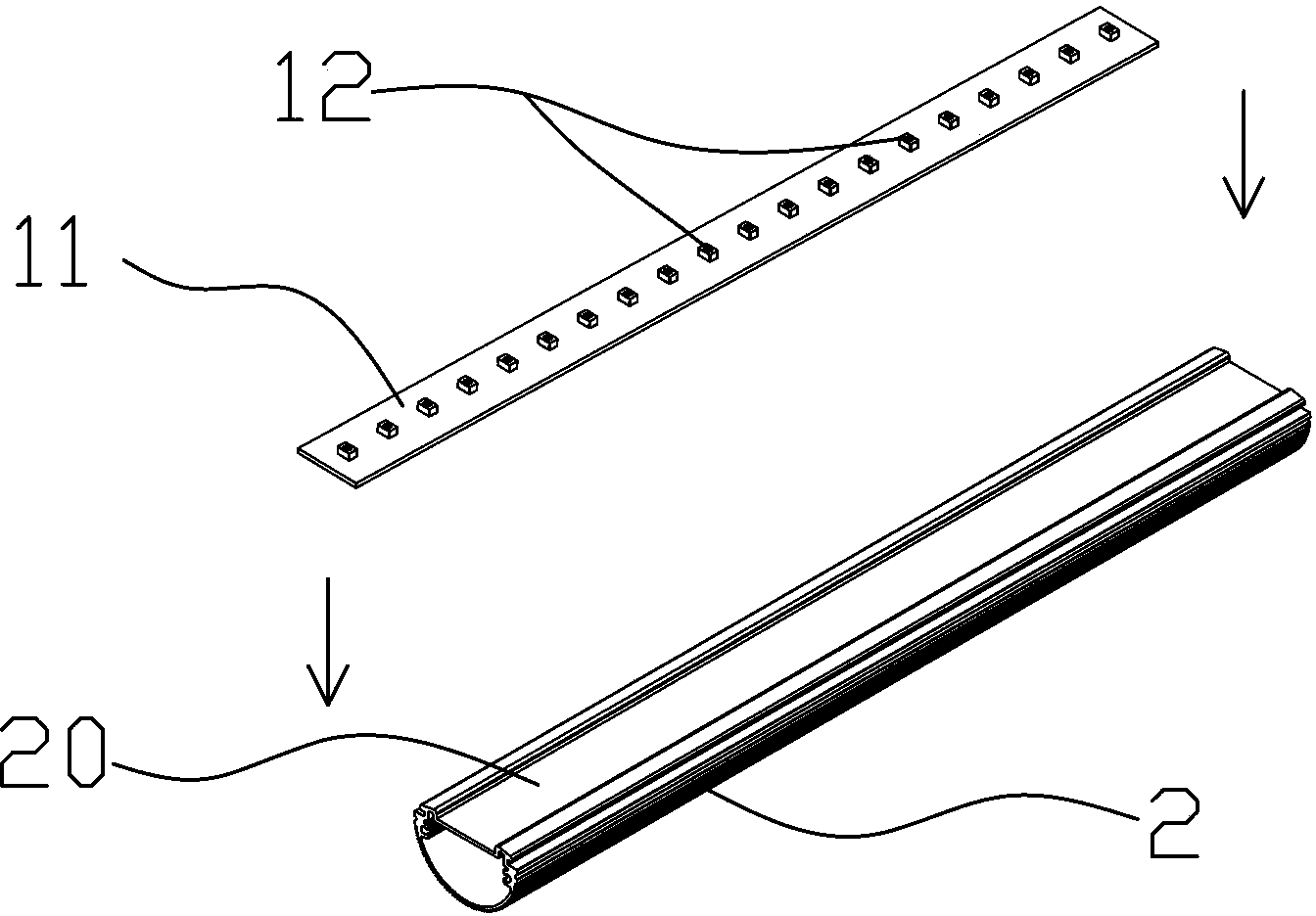

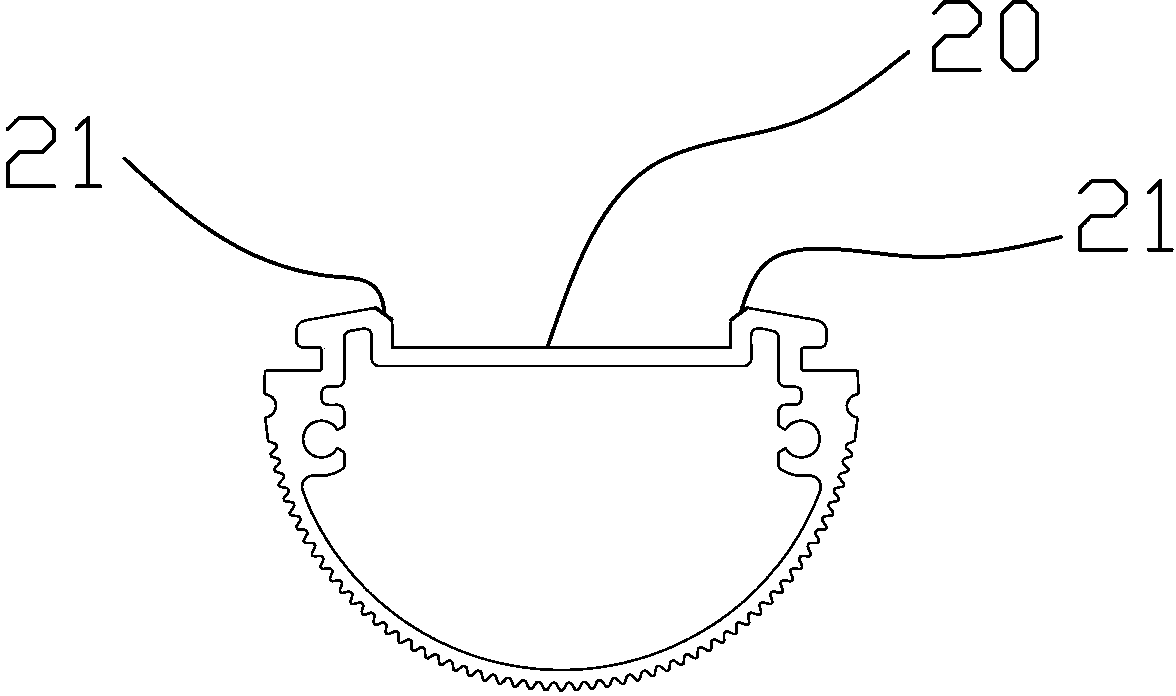

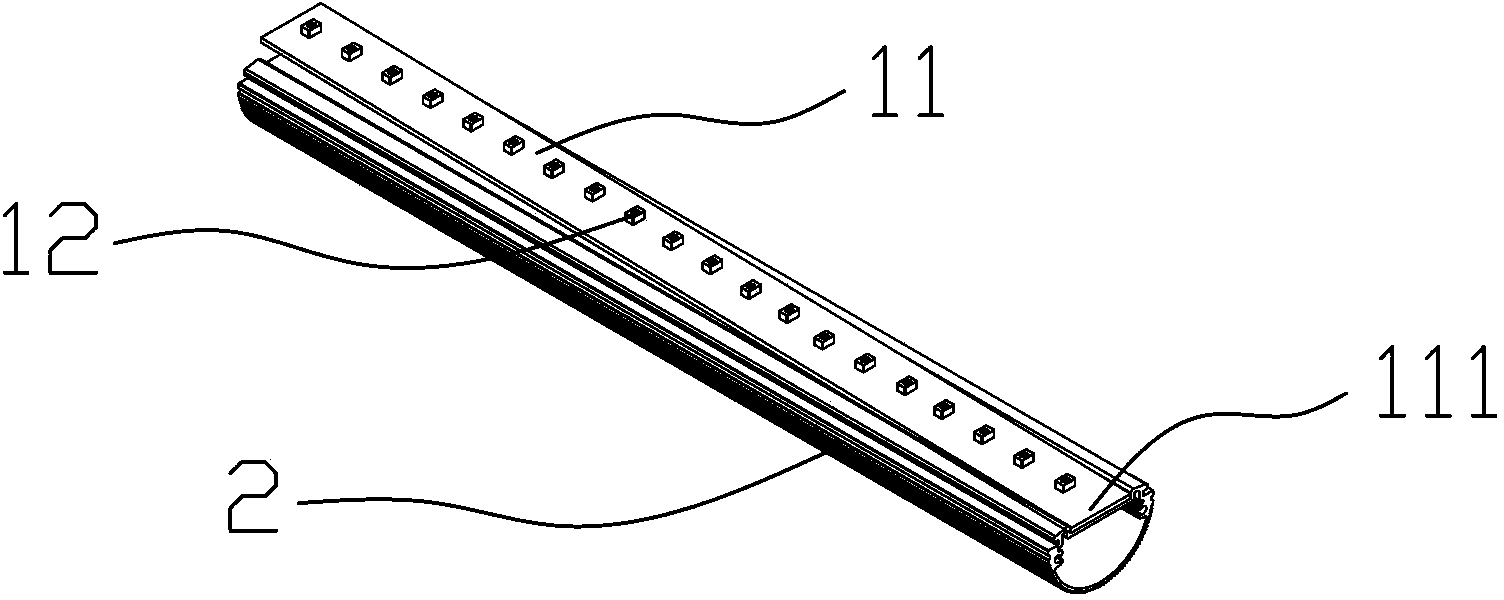

Fixing structure of LED light source substrate and installing method

InactiveCN103542381ASimple structural assemblyEasy to operatePoint-like light sourceElongate light sourcesEngineeringMaterials science

The invention provides a fixing structure of an LED light source substrate and an installing method of the fixing structure of the LED light source substrate. The fixing structure of the LED light source substrate comprises the LED substrate and a heat dissipation sectional bar, wherein the LED substrate comprises a substrate body and LEDs arranged on the substrate body, the heat dissipation sectional bar is of a hollow columnar structure, the length of the heat dissipation sectional bar is equal to that of the substrate body, a clamping groove used for containing the substrate body is formed in one side of the heat dissipation sectional bar, and slopes which incline in an inwards-downward mode are arranged on the two side edges of the clamping groove respectively. Further, the clamping groove and the substrate body are in interference fit, and the width of the clamping groove is smaller than that of the substrate body. Due to the design, the substrate body can be more closely embedded into the heat dissipation sectional bar, and the optimal heat dissipation effect is achieved. Due to the fixing mode of the LED fluorescent tube light source substrate, assembly is carried out with the help of machines, the assembly is easier, the production cost is greatly reduced, the reliability is high, and the heat conduction performance can be improved.

Owner:HUBEI AISAN PHOTOELECTRIC

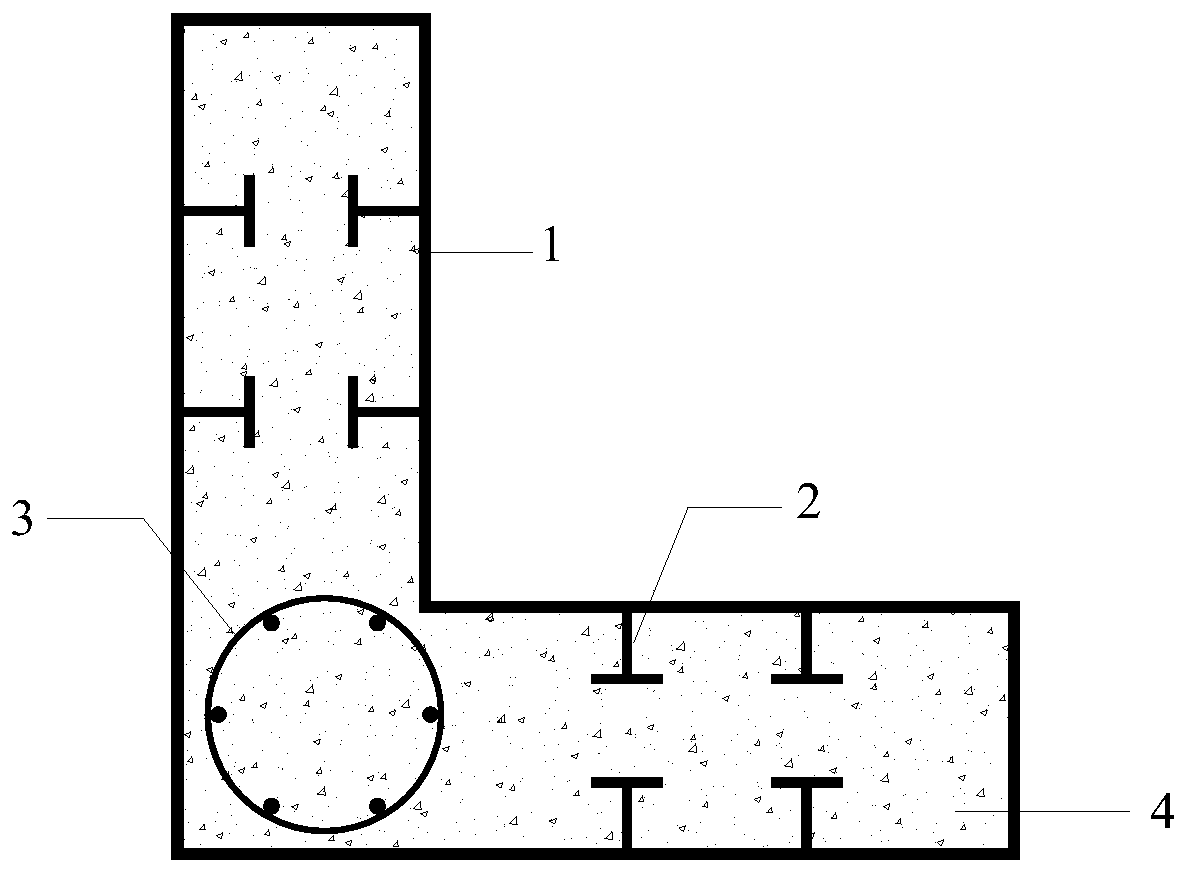

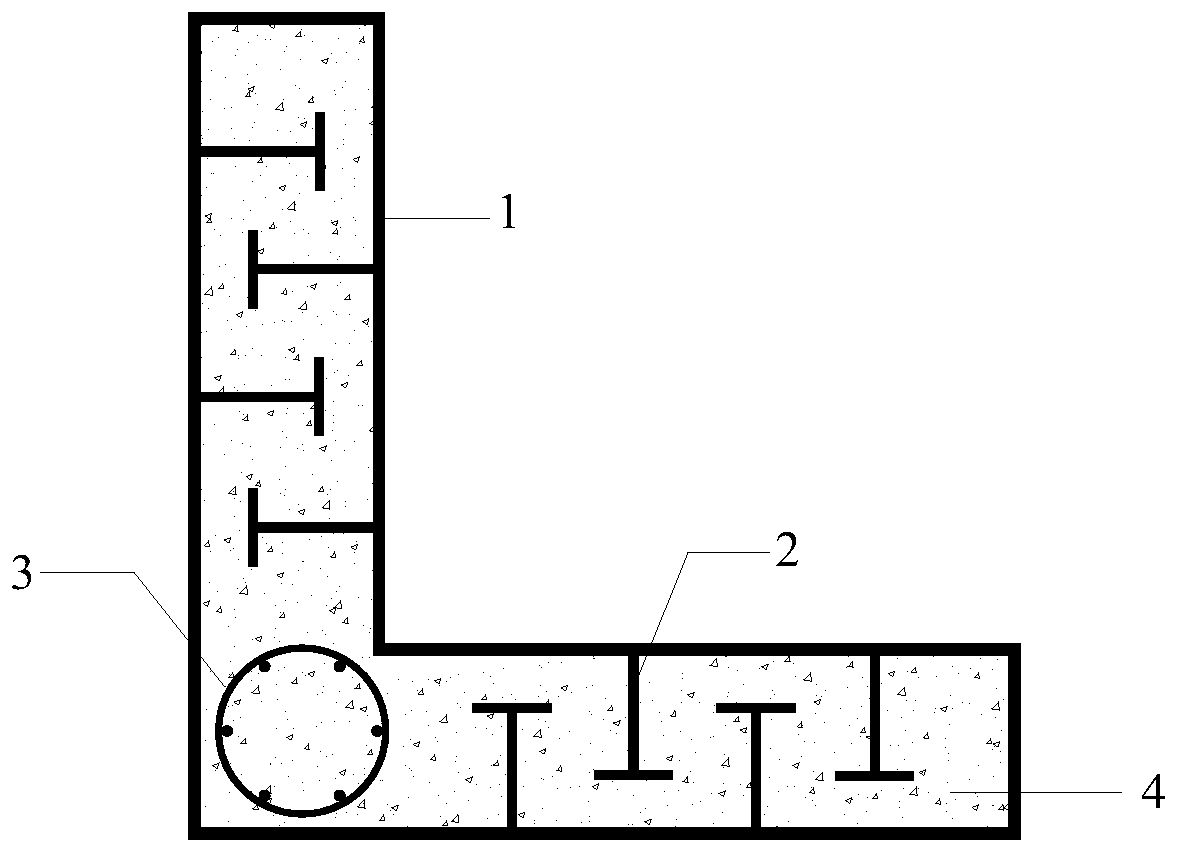

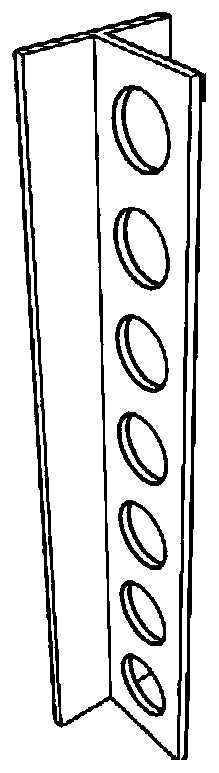

L-shaped steel pipe recycled concrete specially-shaped column provided with perforated T-shaped ribs and manufacturing method

PendingCN110607877ALimit separationImprove insufficient adhesionStrutsPillarsCarrying capacityEngineering

The invention discloses an L-shaped steel pipe recycled concrete specially-shaped column provided with perforated T-shaped ribs and a manufacturing method. The specially-shaped column comprises an L-shaped steel pipe framework, a T-shaped rib framework, a reinforcing hoop framework and full recycled concrete; the L-shaped steel pipe framework is formed through welding of multiple steel plates; theT-shaped rib framework is formed through welding of two steel plates; holes are formed in webs; the perforated T-shaped ribs are welded to the inner walls of an L-shaped steel pipe in a parallel or staggered manner; the reinforcing hoop framework is a reinforcement cage formed through binding of a spiral stirrup and longitudinal bars; and all coarse aggregate of the full recycled concrete comes from waste concrete. According to the scheme, the carrying capacity of the full recycled concrete can be improved by the aid of the L-shaped steel pipe and the reinforcing hoop, so that the recycling extent of the waste concrete is increased; the bonding performance of the steel pipe and the full recycled concrete can be improved by the aid of the perforated T-shaped ribs, so that local buckling ofthe steel pipe is delayed; and meanwhile, the specially-shaped column can be prefabricated in a factory, no formwork is required during onsite construction, and the production efficiency and the quality of the full recycled concrete are improved.

Owner:HENAN POLYTECHNIC UNIV

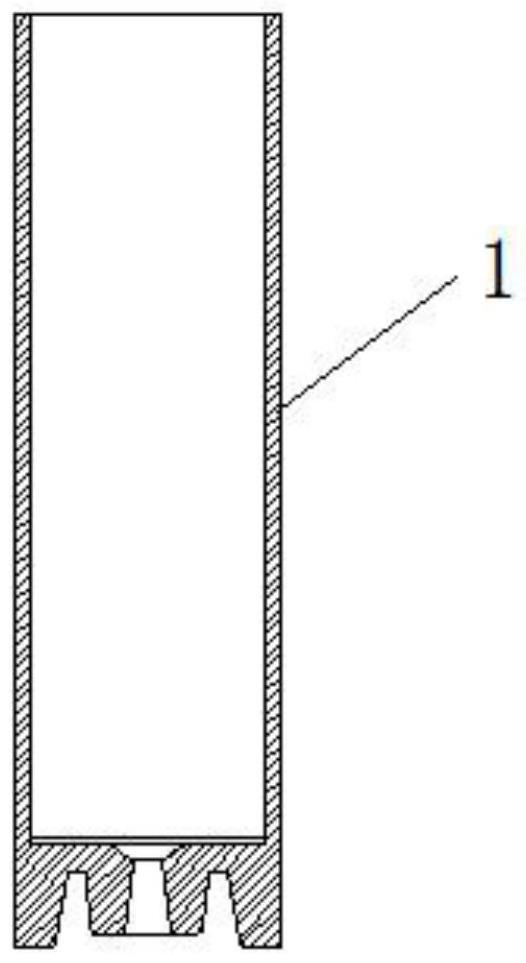

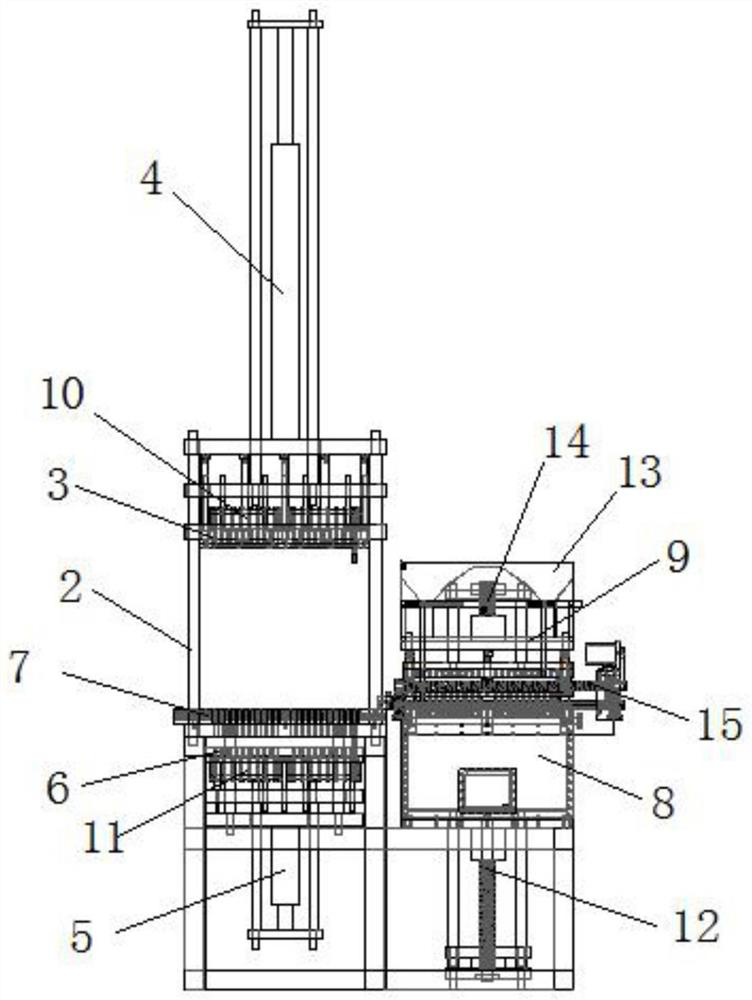

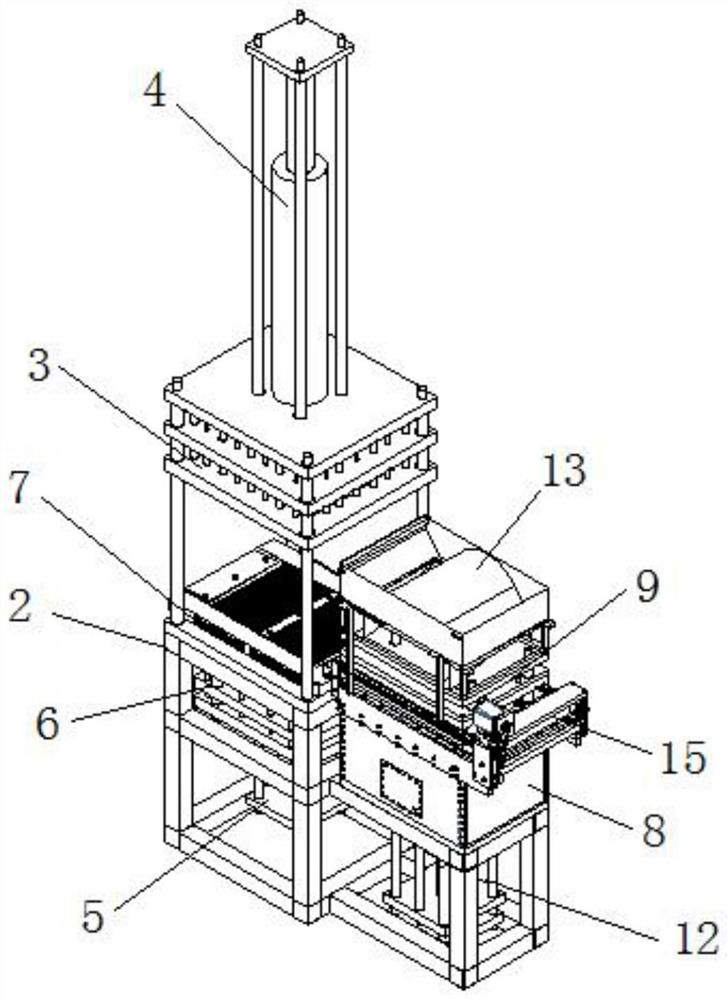

Full-automatic inner cylinder machine

PendingCN114526644ARealize mechanized mass productionIncrease productionFireworksStructural engineeringMachine

The invention discloses a full-automatic inner barrel machine which comprises a rack, an upper pushing mechanism and an upper pressing device are installed on the upper portion of the rack, a lower pushing mechanism and a lower pressing device are installed on the lower portion of the rack, the upper pressing device comprises an upper pressing plate and an upper forming rod, and the lower pressing device comprises a lower forming rod and a lower pressing plate. A forming device is arranged between the upper pressing device and the lower pressing device, a plurality of forming through holes are formed in the forming device, the lower forming rods are matched with the forming through holes in shape and can slide up and down in the forming through holes, the upper forming rods are matched with the inner portion of the inner cylinder in shape, and the lower forming rods can slide up and down in the forming through holes. The upper forming rod can stretch into the forming through hole, the upper forming rod and the lower forming rod are matched with each other and pressed tightly, and an inner cylinder is formed in the forming through hole of the forming device. The problems that an existing inner cylinder is low in manufacturing speed, low in yield and high in cost are solved.

Owner:LIUYANG HENGBANG MACHINERY FACTORY

Forming method of cement decorative board with preset anchor bolt holes and reserved steel mesh lap joints

InactiveCN104695645BRealize mechanized mass productionIncrease productivityCovering/liningsShaping press ramLap jointPre embedding

Owner:上海欧墅节能科技股份有限公司 +1

Cavity form component for concrete filling

InactiveCN1991007ASimple production processReduce manufacturing difficultyFloorsHollow coreReinforced concrete

Disclosed is a cast-in-situ hollow concrete shuttering member for concrete filling, which comprises an upper board (1), peripheral side panels (2), the upper board (1), the peripheral side panels (2) enclose an open basin shape shuttering members, The invention can be applied to cast-in-situ reinforced concrete or prestressed reinforcement concrete's hollow storied-building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

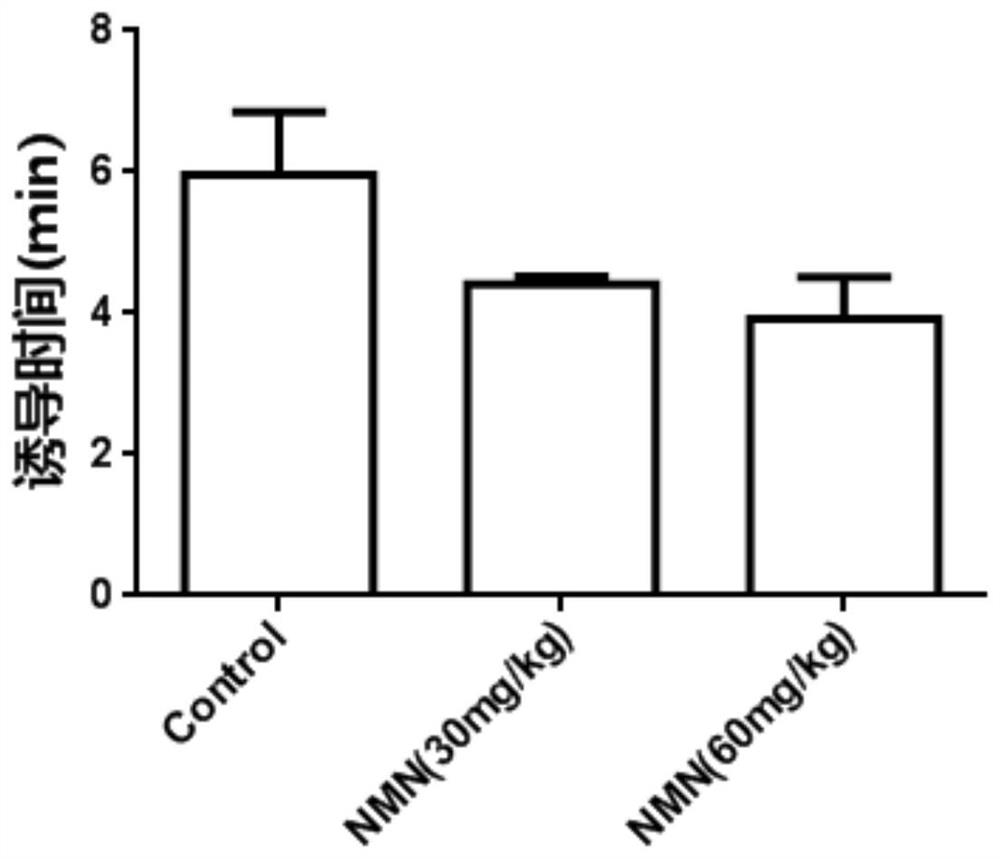

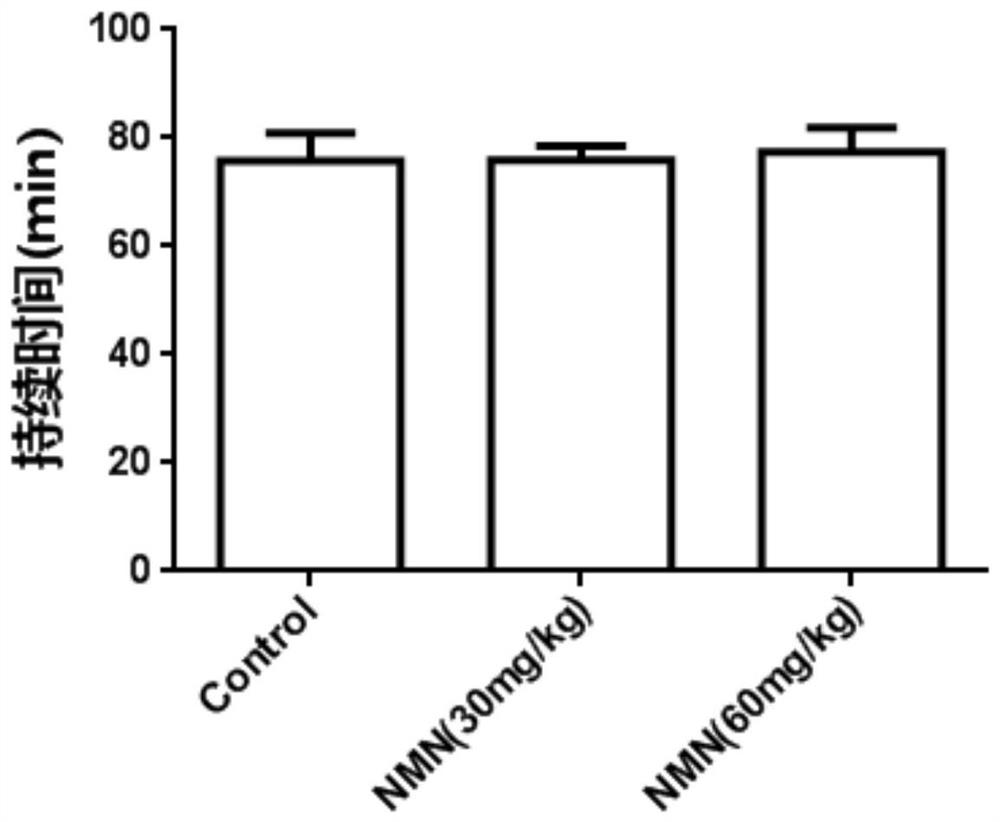

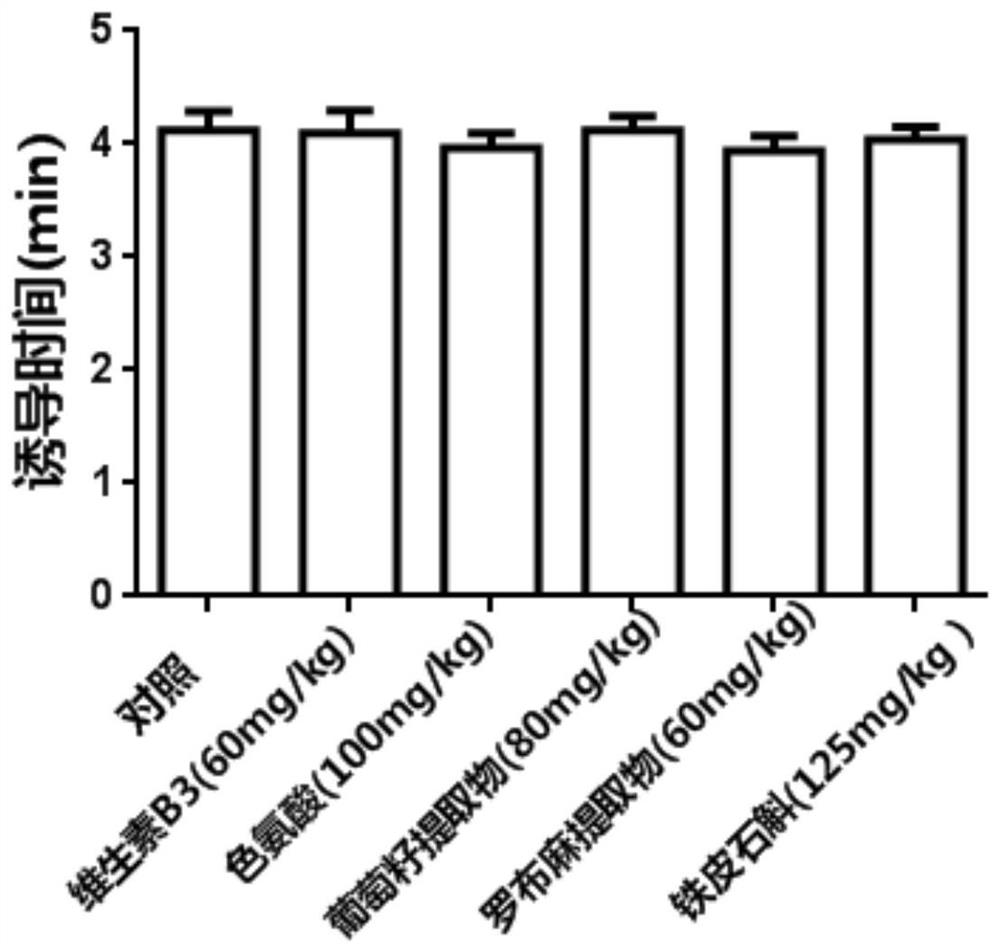

Pharmaceutical composition comprising NMN and application thereof

ActiveCN113181205AImprove sleepingExcellent for improving sleepOrganic active ingredientsNervous disorderApocynum venetumExtracted grape seeds

The invention provides a pharmaceutical composition containing NMN and application of the pharmaceutical composition, and further provides application of tryptophan or a composition containing tryptophan and vitamin B3 in preparation of an NMN synergist. It is found that no obvious sleep improving effect exists when the NMN, the vitamin B3 and the tryptophan are singly used, but the tryptophan or a composition of the tryptophan and the vitamin B3 can improve the sleep improving effect of the NMN, so that the tryptophan and the vitamin B3 can form a compound with the obvious sleep improving effect together. Herein, the pharmaceutical composition comprises tryptophan and NMN, or the pharmaceutical composition comprises tryptophan, vitamin B3 and NMN, or the pharmaceutical composition comprises tryptophan, vitamin B3, NMN, a grape seed extract, an apocynum venetum extract and dendrobium officinale. The composition not only has the effect of remarkably improving sleep, but also has the effect of improving sleep remarkably superior to that of a single component.

Owner:SUZHOU RENBEN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com