Preparation device for light-transmitting cement-based material and using method thereof

A technology of cement-based materials and preparation devices, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., and can solve the problems of difficult control of layout position accuracy, cumbersome engineering, affecting quality and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

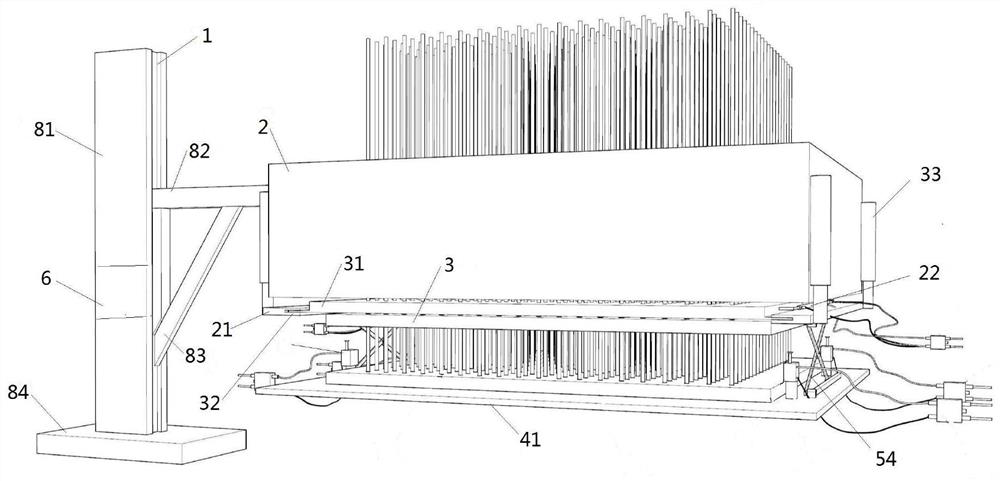

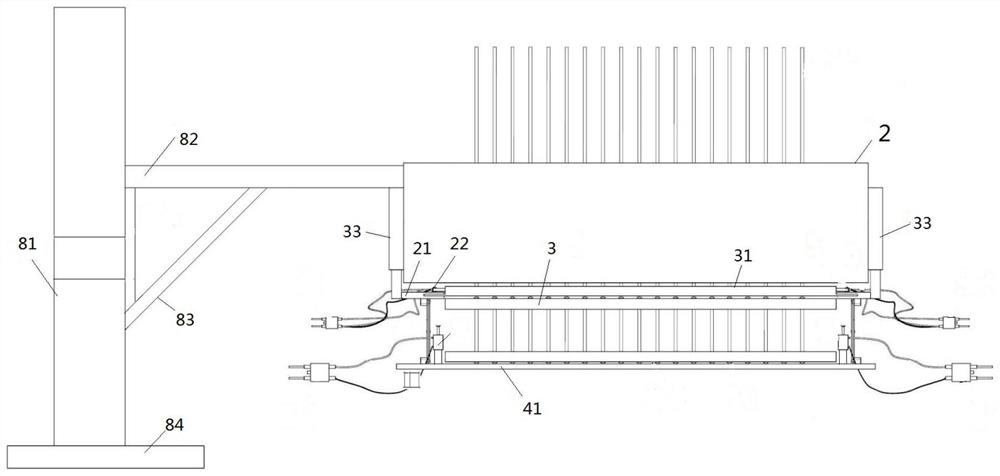

[0040] Such as Figure 1-2 Shown, a kind of light-transmitting cement-based material preparation device comprises:

[0041] bracket 1;

[0042] The placement frame 2 is vertically arranged on one side of the support 1 and suspended in the air, and the placement frame 2 is connected to the support 1;

[0043] The pay-off assembly is arranged directly above the placing frame 2, and is used to realize fixing the optical fiber;

[0044] A plurality of frame plates 3 are horizontally stacked inside the placement frame 2;

[0045] The fixing component is arranged inside the placement frame 2 and is used to fix the frame plate 3;

[0046] The cutting assembly is arranged under the placing frame 2, and is used to cut the optical fiber along the horizontal direction;

[0047] The guide assembly is arranged below the cutting assembly and is used to guide the frame plate 3 to move downward;

[0048] The controller 6 is arranged on the bracket 1, and the controller 6 is electrically ...

Embodiment 2

[0051] A method for using a light-transmitting cement-based material preparation device, comprising the following steps:

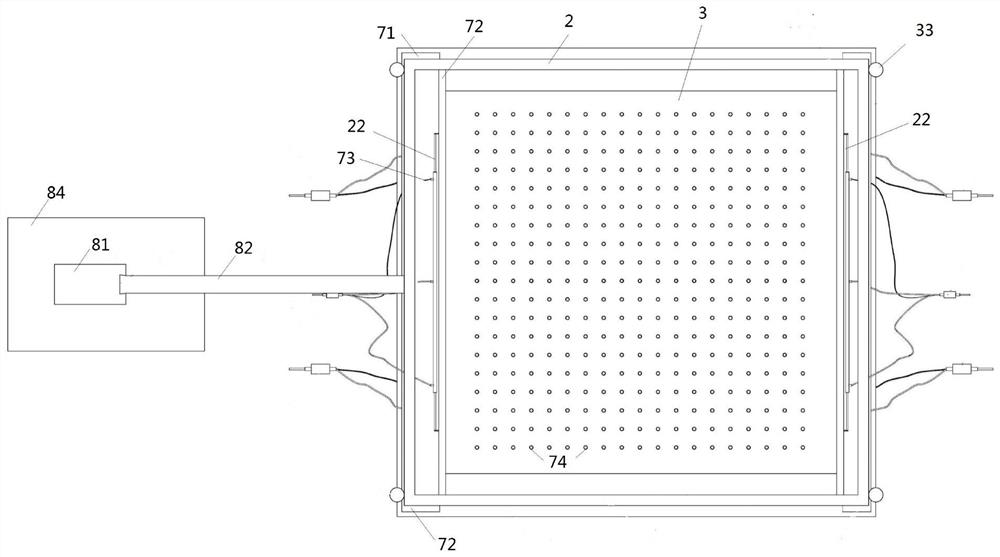

[0052] S1, stack the frame plate 3 horizontally inside the placement frame 2, and fix it by the splint 72, and then pass the optical fiber through the through hole 74 and extend out of the first frame plate at the bottom;

[0053] S2, after opening the electric heating riveting plate 31 to reach a predetermined temperature, start the electric heating riveting plate 31 to cut the optical fiber along the lower side of the first frame plate and form a riveting head to fix it;

[0054] S3, moving the first frame plate downward to the bottom plate 41 by pulling the manipulator;

[0055] S4, the second frame plate is pulled by the manipulator and moved down to the bottom of the electric heating riveting plate 31, and the optical fiber is cut along the upper side of the second frame plate through the electric heating riveting plate 31 and fixed with a riveting he...

Embodiment 3

[0059] In order to further improve the smoothness and rapidity of optical fiber cutting, a bidirectional cylinder is set to drive the cutter to slide for cutting;

[0060] Preferably, the cutting assembly includes two cutters, and the two cutters are symmetrically arranged on both sides of the bottom of the placement frame 2 respectively, and two guide plates 21 are respectively provided at both ends of the cutter, and the two ends of the cutter are respectively connected to The guide plate 21 is slidably connected, and a two-way cylinder 22 is fixed in the middle of the top of the guide plate 21. The output ends of the two-way cylinder 22 are respectively connected to the cutters on both sides, the guide plate 21 is connected to the placement frame 2, and the two-way cylinder 22 is connected to the controller 6 electrical connection.

[0061] When the optical fiber needs to be cut, the two-way cylinder is controlled by the control panel to drive the cutter to slide relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com