Full-automatic inner cylinder machine

An inner cylinder machine, fully automatic technology, applied in the direction of offensive equipment, pyrotechnics, weapon types, etc., can solve the problems of slow production speed, low degree of mechanization, and low efficiency, and achieve the goal of increasing production speed, reducing costs, and shortening the production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

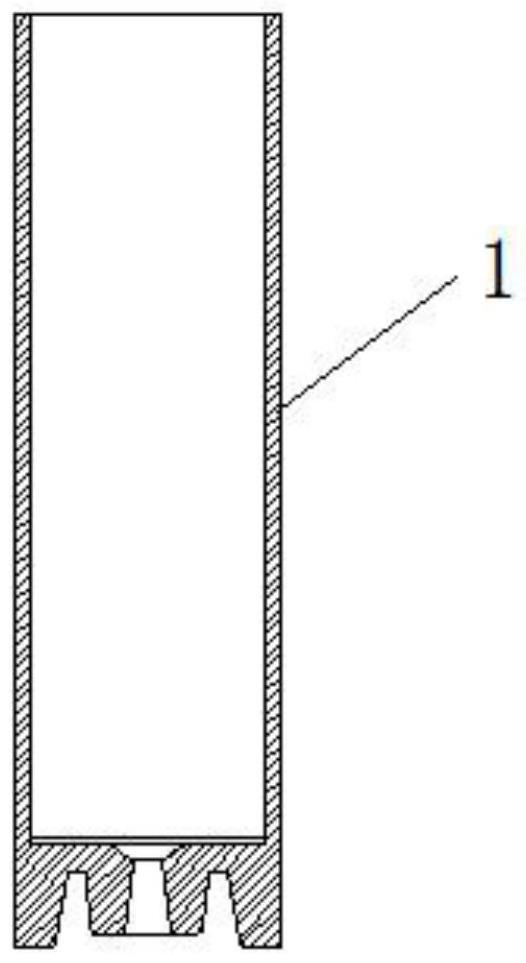

[0040] like figure 1 As shown, the inner cylinder 1 is in the prior art, the outer circumference of the inner cylinder 1 is cylindrical, the interior of the inner cylinder 1 is provided with an inner cavity that opens upward, and the bottom of the inner cylinder 1 is provided with a downward opening The center of the groove is provided with a downwardly protruding boss, and the center of the boss is provided with a lead hole. It should be noted that the inner cavity and bottom structure of the inner cylinder 1 can also adopt other shapes and structures, and can also be produced by using the fully automatic inner cylinder machine of the present invention.

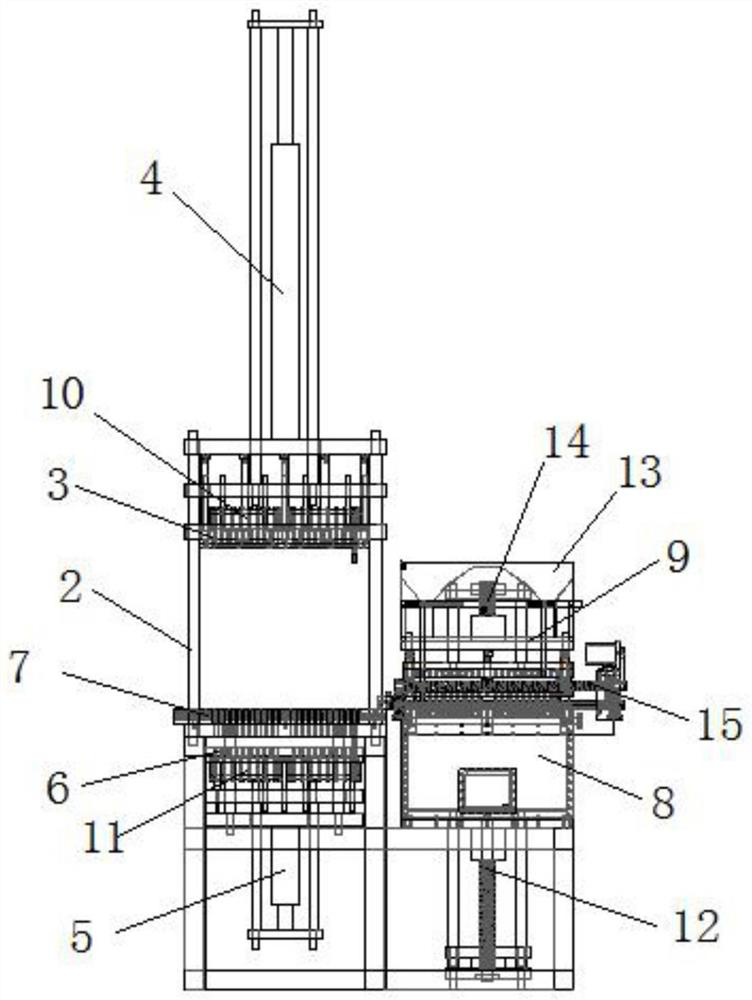

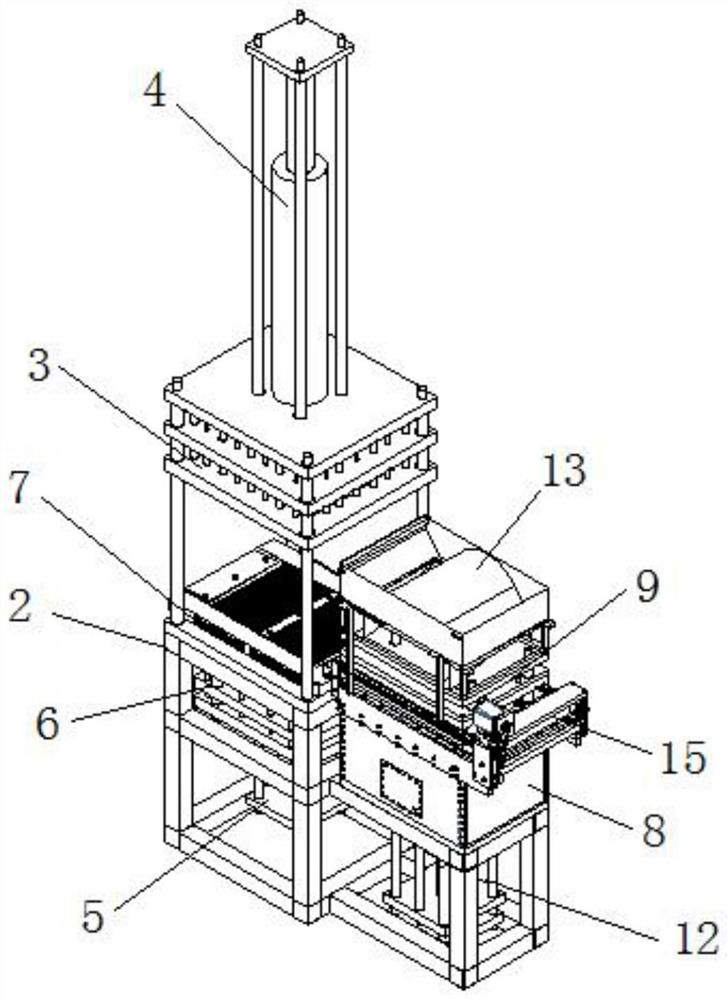

[0041] like Figure 2-12 As shown, a fully automatic inner cylinder machine includes a frame 2 , an upper pressing device 3 , an upper pushing mechanism 4 , a lower pushing mechanism 5 , a lower pressing device 6 , and a forming device 7 .

[0042] The rack 2 is composed of an upper rack 21 and a lower rack 22. The lower r...

Embodiment 2

[0071] like Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, a fully automatic inner cylinder machine includes an inner cylinder 1, a frame 2, an upper pressing device 3, an upper pushing mechanism 4, a lower pushing mechanism 5, a lower pressing device 6, and a forming device 7. The inner cylinder 1 is in the prior art, the outer circumference of the inner cylinder 1 is cylindrical, the interior of the inner cylinder 1 is provided with an inner cavity that opens upward, and the bottom of the inner cylinder 1 is provided with a groove that opens downward. The center of the groove is provided with a downwardly protruding boss, and the center of the boss is provided with a lead hole.

[0072]The frame 2 includes a base 221, a guide column 211, and a top plate 212. The base 221 is a rectangular or square base and is made of steel plate, cast steel or cast iron. The four corners of the base 221 are connected or welded by threaded holes. There are four vertically upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com