L-shaped steel pipe recycled concrete specially-shaped column provided with perforated T-shaped ribs and manufacturing method

A technology of recycled concrete and special-shaped columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of easy peeling between steel pipes and concrete, insufficient binding capacity of core concrete, and insufficient binding force of core concrete, so as to improve the overall work performance, Improve the effect of insufficient adhesion and reduce the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

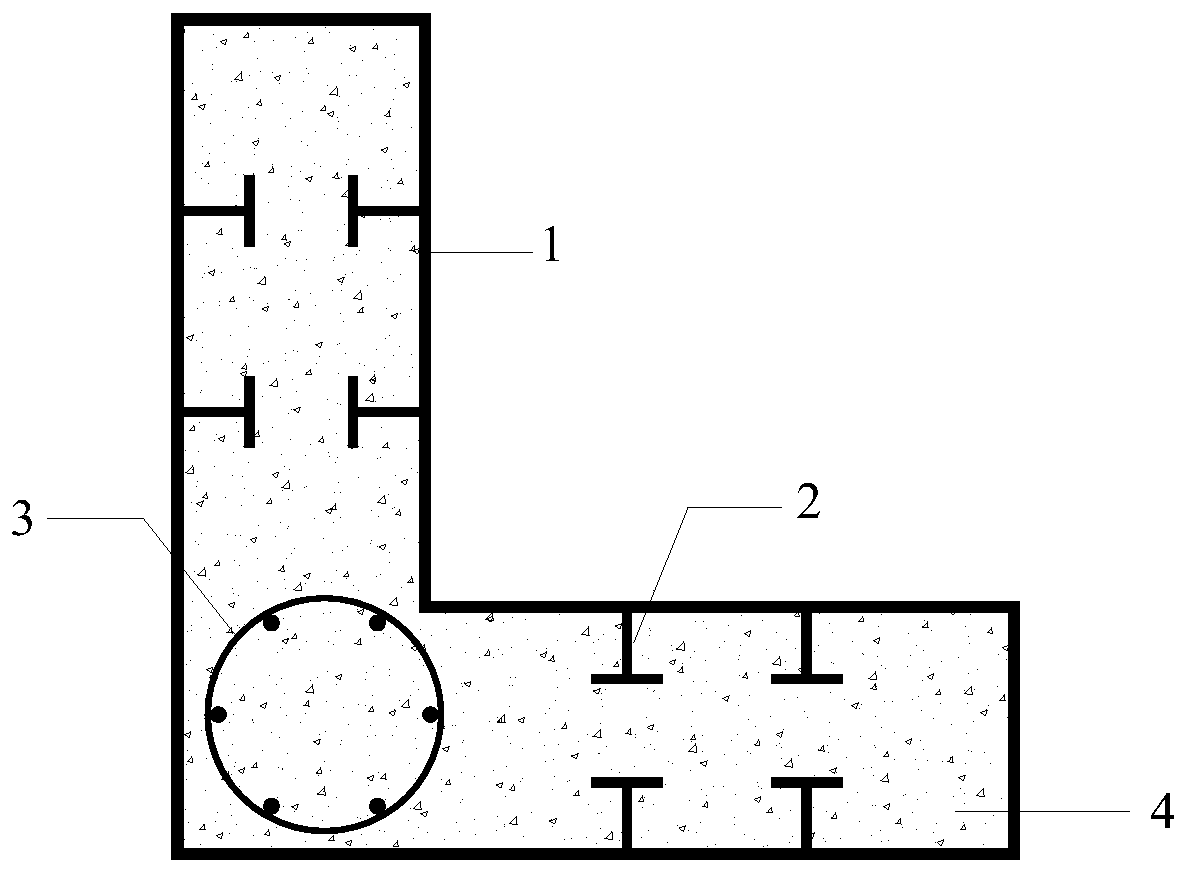

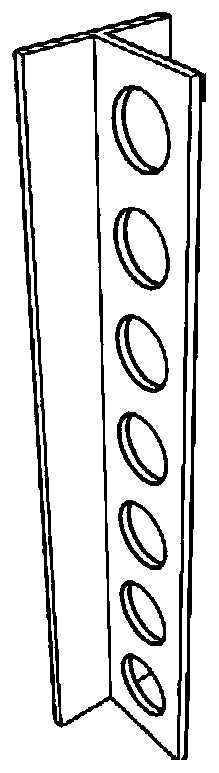

[0036] In this embodiment, the T-shaped ribs evenly and equidistantly open round holes on the web (see image 3 ), the opening process such as Figure 6 Shown: First, cut from one end of the web along the predetermined dotted line, then cut from the other end of the web along the predetermined dotted line. After the cutting is completed, two webs ① and ② are produced, and the two webs ① and ② are staggered and docked, so that the trough of the ① web is aligned with the peak of the ② web, and then combined in the horizontal section of the adjacent crest (valley) At the place, the two webs ① and ② are welded to form by butt full penetration weld. The formed web with round holes is as follows: Figure 7 shown. In this embodiment, due to the thicker L-shaped special-shaped column limbs, the T-shaped ribs with openings are welded to the inner walls of the two steel pipes opposite to the length direction of the limbs in a parallel manner (see figure 1 ), the T-rib spacing is 200...

Embodiment 2

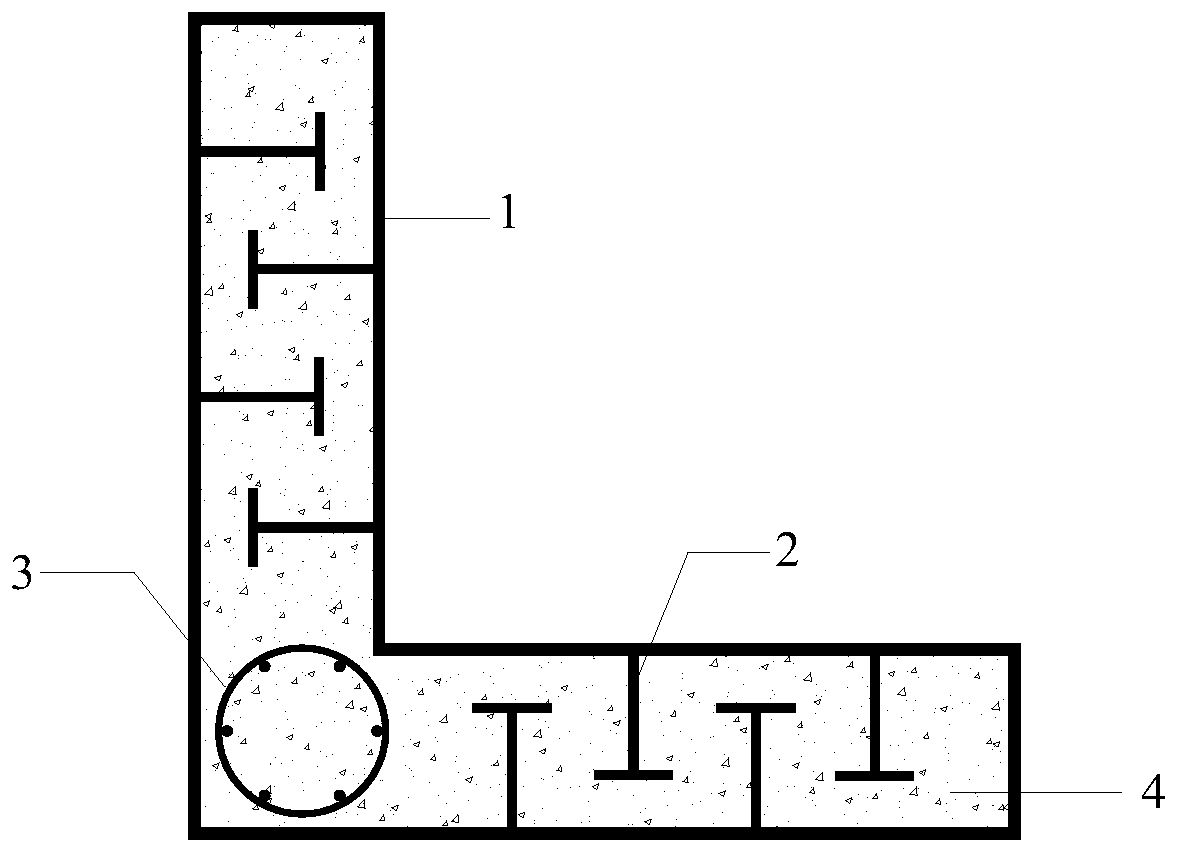

[0038] In this embodiment, the T-shaped ribs have regular hexagonal holes evenly spaced on the web (see Figure 4 ), the opening process such as Figure 8 Shown: Cut from the right end of the web along the predetermined dotted line to produce two webs ① and ②, and stagger the two webs ① and ②, so that the half of the regular hexagonal hole on the ① web is aligned with the ② web There is half a regular hexagonal hole in the plate, and then, at the horizontal section where the two holes are connected, the two webs ① and ② are welded to form by using butt joint full penetration welds. The formed web with regular hexagonal holes is as follows: Figure 9 shown. In this embodiment, due to the small thickness of the L-shaped special-shaped column limbs, the open T-shaped ribs are welded to the inner walls of the two steel pipes opposite to the length direction of the limbs in a staggered manner (see figure 2 ), the T-rib spacing is 150 mm, and the height of the T-rib web section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com