A kind of house building integrated assembly wall and assembly method

A building and wall technology, applied in the direction of building, building components, building materials, etc., can solve the problems of positioning frame occupying space and mass, inconvenient operation, etc., to achieve the effect of convenient transportation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

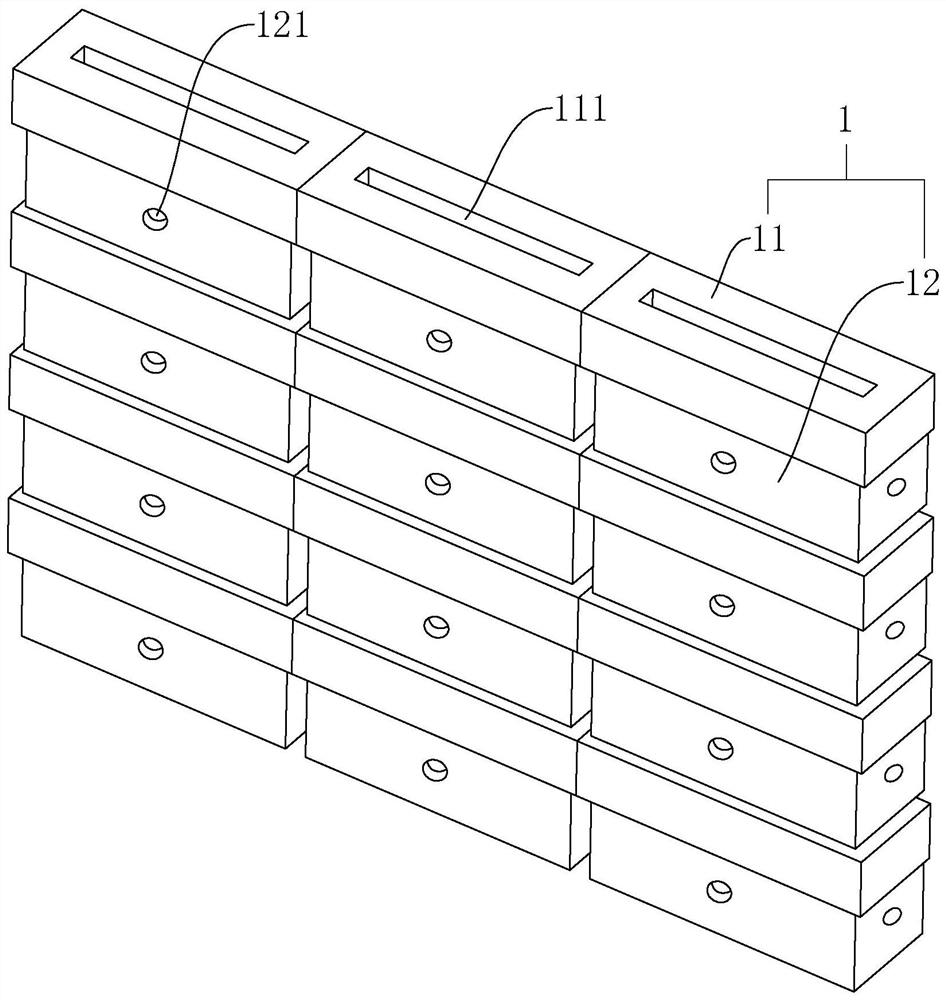

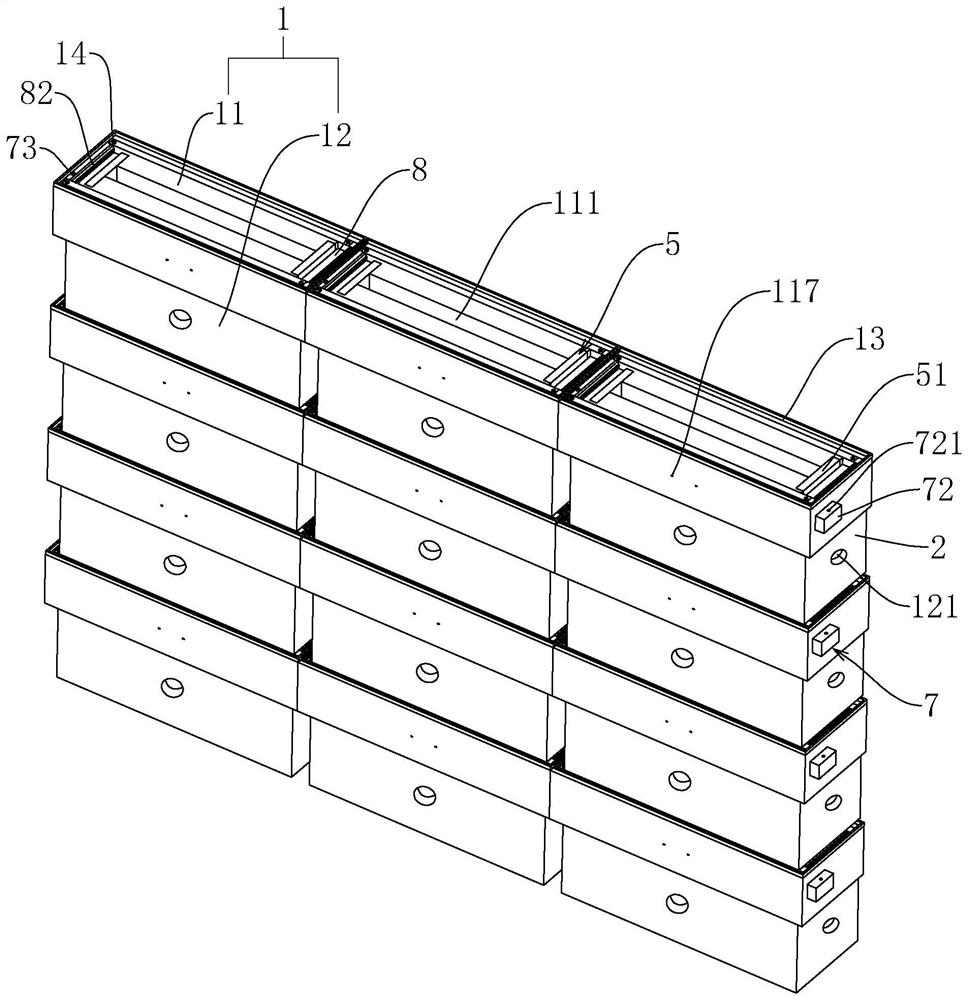

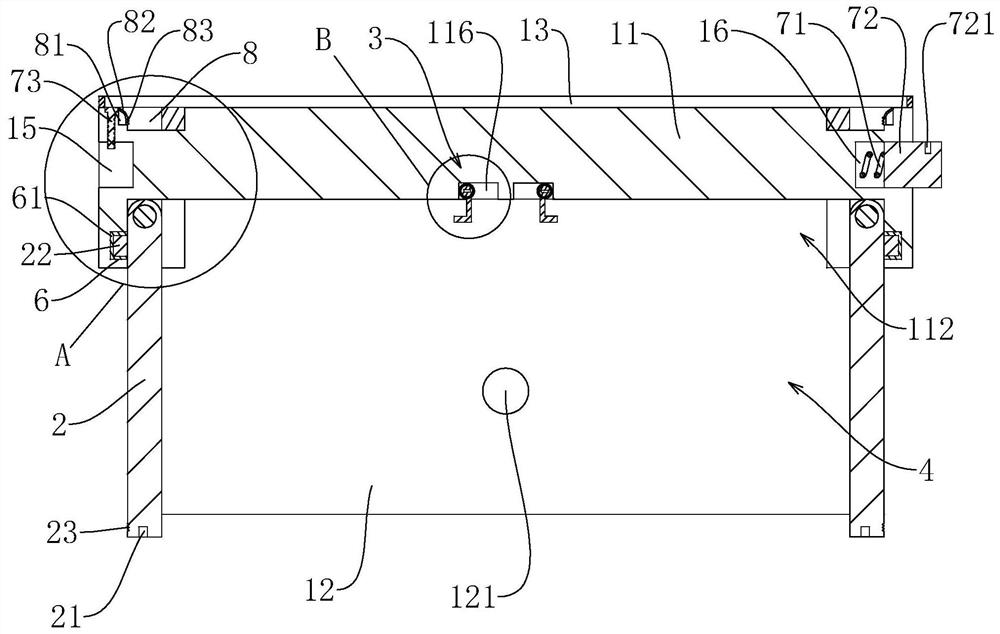

[0046] This embodiment discloses a house construction integrated assembly wall, such as figure 2 , image 3 As shown, it includes multiple sets of positioning frames 1 spliced with each other and concrete slabs (not shown in the figure) poured in the positioning frames 1. Each set of positioning frames 1 includes a base plate 11 and two pieces connected to the front and back of the base plate 11 respectively. The side plate 12 at the end is detachably connected to the base plate 11. The lower end surface of the base plate 11 is provided with a mounting groove 112 extending in the horizontal direction, and a support plate 2 is respectively hinged at the left and right ends of the mounting groove 112. The length of the support plate 2 is less than 1 / 2 of the length of the mounting groove 112, and the mounting groove 112 It can be used to store the support plate 2 to reduce the occupied space when the positioning frame 1 is moved or stored.

[0047] Such as figure 2 , Im...

Embodiment 2

[0058] This embodiment discloses a method for assembling a building integrated wall assembly, which includes the following steps:

[0059] S1. Turn the rotating shaft 31 so that the connecting rod 32 drives the first stop block 33 to move out of the first stop groove 21, and then turn the support plate 2 to a vertical state until the block 22 is inserted into the slot 6;

[0060] S2. Insert the second stop block 51 into the second stop hole 118, and the stop block 52 extends into the stop groove 119. At this time, the second stop block 51 abuts against the opposite side of the two support plates 2 and can limit the support Plate 2 rotates;

[0061] S3. Insert the two side plates 12 into the T-shaped slots 113 at the front and rear ends of the base plate 11 respectively, and then fix the side plates 12 through the mounting bolts 14;

[0062] S4. Assemble one layer of positioning frame 1 sequentially along the horizontal direction, insert the fastening block 72 in the previous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com