Super wear-resistant cast steel grinding ball and preparation method thereof

A super wear-resistant and cast steel technology, applied in the field of wear-resistant materials, can solve the problems of low cost performance, high cost, non-wear resistance, etc., and achieve the effect of reducing labor intensity, improving production efficiency, and realizing clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

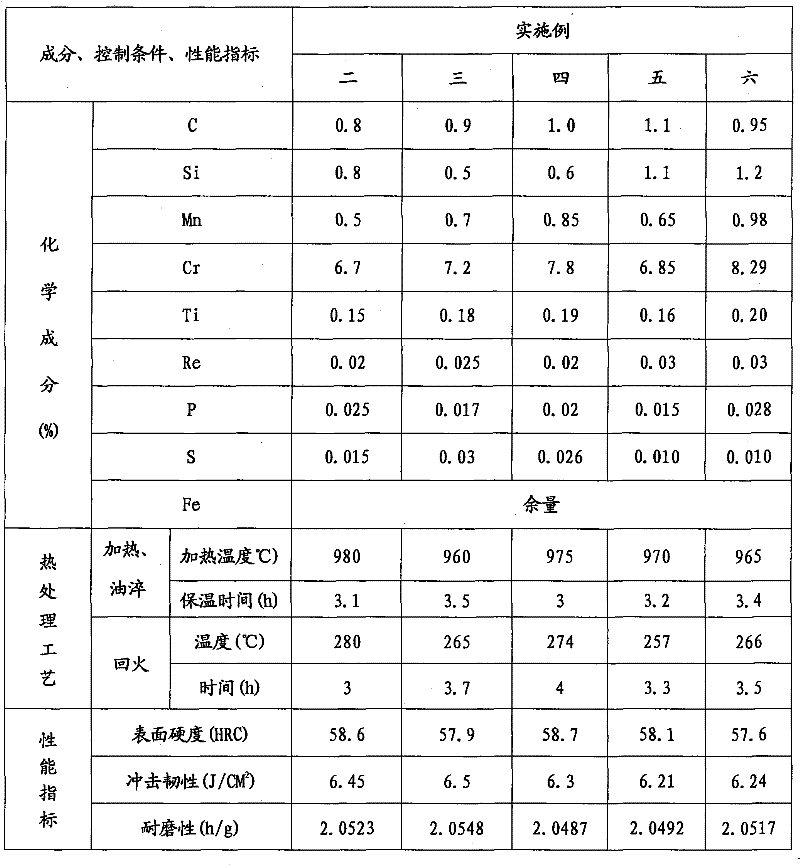

[0075] Embodiment two - embodiment six

[0076] Embodiment 2-Embodiment 6 are respectively a kind of super wear-resistant cast steel grinding balls, and their respective chemical compositions are shown in the following table.

[0077] Embodiment two—the super wear-resistant cast steel grinding ball of embodiment six is prepared according to the following method steps:

[0078] (1) Casting

[0079] After the molten metal containing the chemical composition described in claim 1 or 2 is formed by mechanized lost foam casting, it is cleaned to obtain a casting;

[0080] (2) heating, oil quenching

[0081] Put the casting obtained in the previous step into a high-temperature resistance furnace and heat it to the corresponding temperature, hold it for a corresponding time, then carry out oil quenching, cool it in the oil to below 200°C, and discharge the oil;

[0082] (3) Tempering

[0083] Put it into the tempering furnace, raise the temperature to the corresponding tempering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com