Rice cake production device

A production device and rice cake technology, which is applied in food science, metal processing, presses, etc., can solve problems such as low work efficiency, high labor intensity, and product quality differences, and achieve consistent shape and size, improve production quality, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

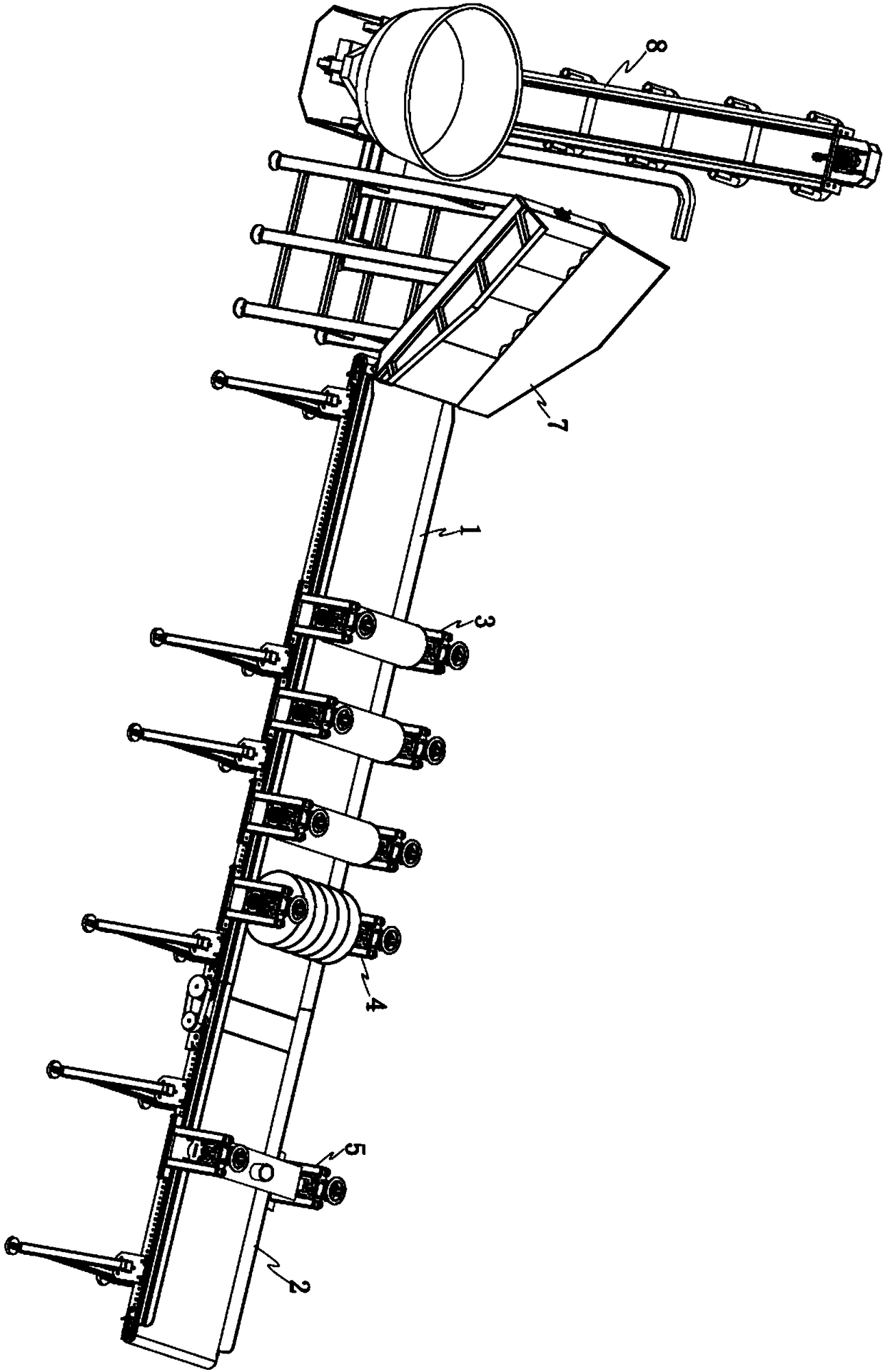

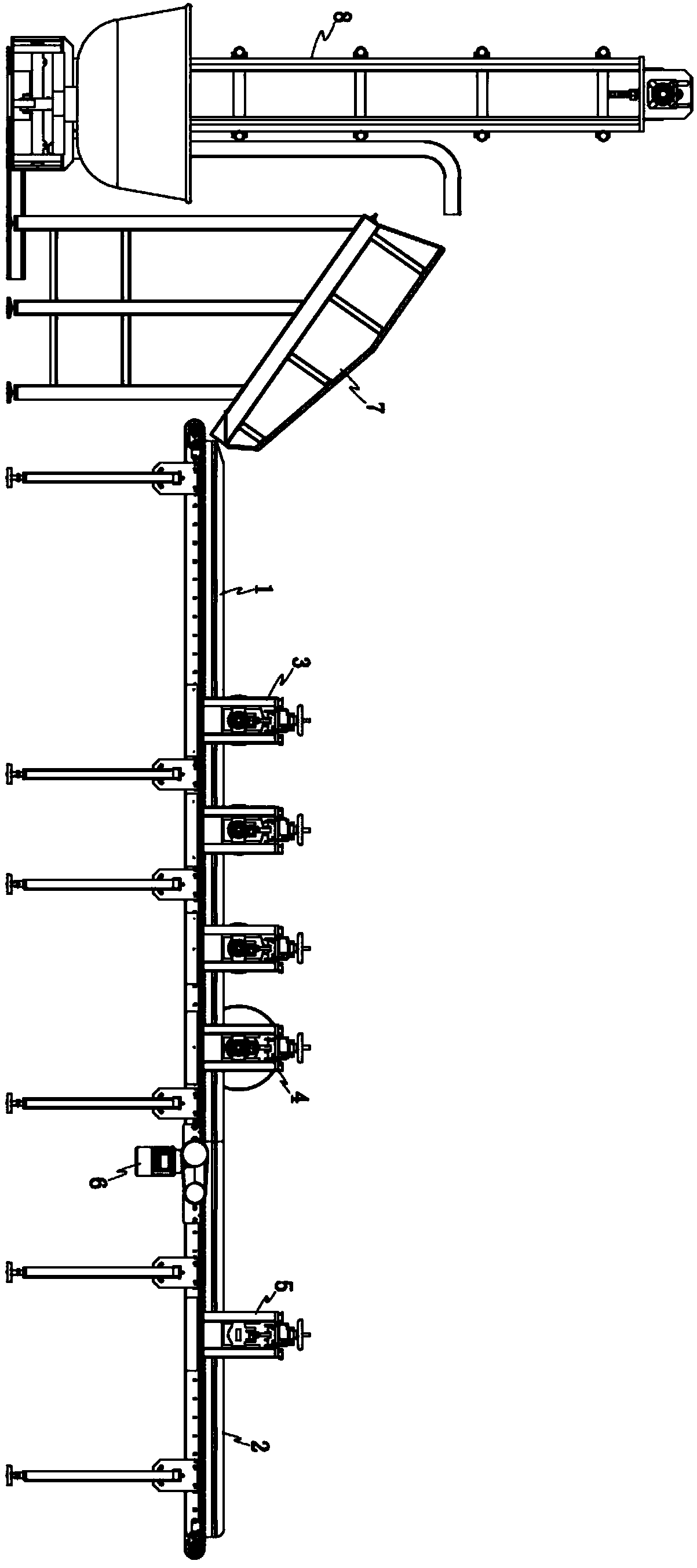

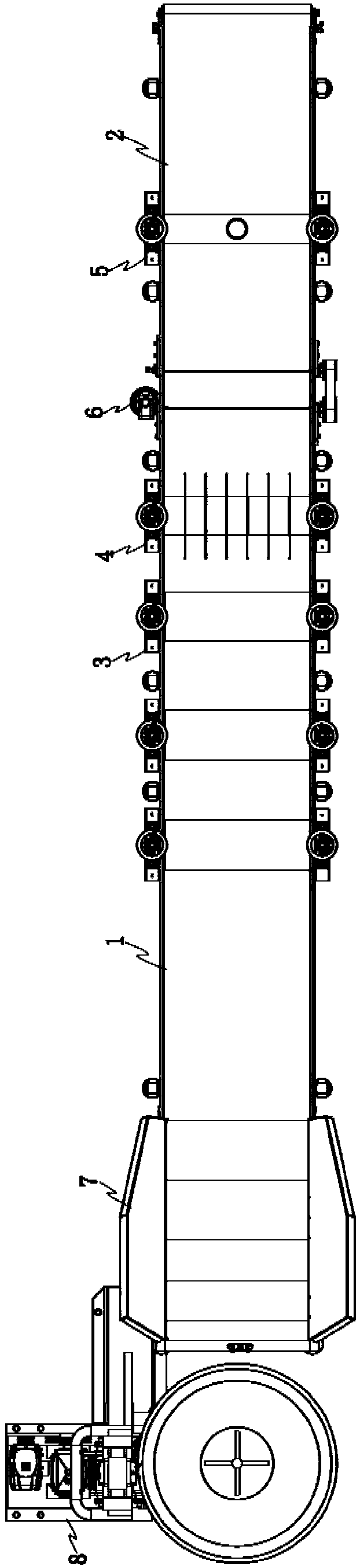

Image

Examples

Embodiment 1

[0042] When the rice cake production device processes the rice flour, the rice flour is first added to the mixing pot 813, then the stirring motor 820 is started, and the stirring rod 814 is driven by the stirring motor 820 to rotate to stir the rice flour. The lifting motor 802 drives the gearbox 803 to rotate, and the gearbox 803 drives the sliding seat 804 through belt transmission, and crawls upwards along the guide rail 808 on the lifting frame 807, and when the sliding seat 804 moves upwards, the lifting bracket 815 and the brackets on the bracket 815 Stir the pot 813, while the guide fixed plate shaft 818 on the side end surface of the support frame 815 runs along the running guide groove plate 811, when the guide fixed plate shaft 818 moves to the top of the running guide groove plate 811, the guide fixed plate shaft 818 and the running guide groove Plate 811 top inner sidewall surface interacts, and forces guide fixed plate shaft 818 to move along the horizontal plate ...

Embodiment 2

[0044] During rice cake production device processing of rice noodles, the U-shaped heating tube 704 imported into the plate frame 7 is energized in advance, and the arc heating groove 705 on the surface of the material guide plate 703 is charged by the U-shaped heating tube 704. When the rice flour ball falls to After the material guide plate 703 is on, because the supporting foot frame 701 of importing the plate frame 7 is an inclined underframe, the rice noodle ball slides down along the material guide plate 703 under the action of gravity, and in the process of sliding, the arc heating groove 705 pairs The rice noodle is heated and baked until the rice noodle slides onto the first conveyor belt 1, and is introduced into the plate frame 7 to realize heating while conveying the rice noodle.

Embodiment 3

[0046] During the processing of rice flour by the rice cake production device, the first conveyor belt 1 transports the rice flour balls to the second conveyor belt 2 on the front end side, wherein during the conveying process on the first conveyor belt 1, the rice flour balls are arranged in parallel on the first conveyor belt in turn. The rolling shaft 9 of the rolling mechanism 3 on the conveyor belt 1 is rolled flattened and compacted, and then the flattened rice noodle ball is rolled and cut into strips by the rolling cutting shaft 10 surface annular blade of the rolling cutting mechanism 4, and finally The first conveyer belt 1 conveys the sheet-shaped rice noodle balls to the second conveyer belt 2 on the front end side, and the cutter 13 of the vertical cutting mechanism 5 on the second conveyer belt 2 is driven by the vertical cutting driving cylinder 11 to drive the slices The strip-shaped rice noodles are punched into block rice cakes step by step in an orderly manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com