Mechanized production equipment for Chinese art paper

A production equipment and technology of rice paper, applied in paper machine, paper making, textile and paper making, etc., can solve the problems of difficult to achieve mechanical batch production and uniform thickness of paper, and achieve the effect of reducing pulp loss, uniform thickness and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further limited:

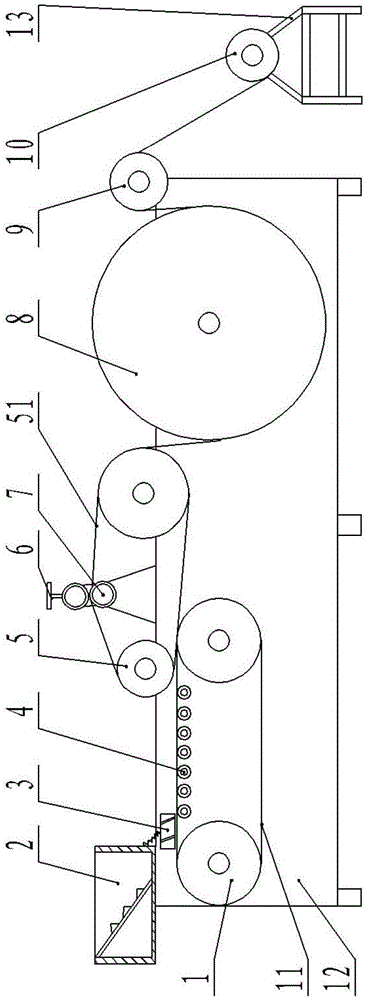

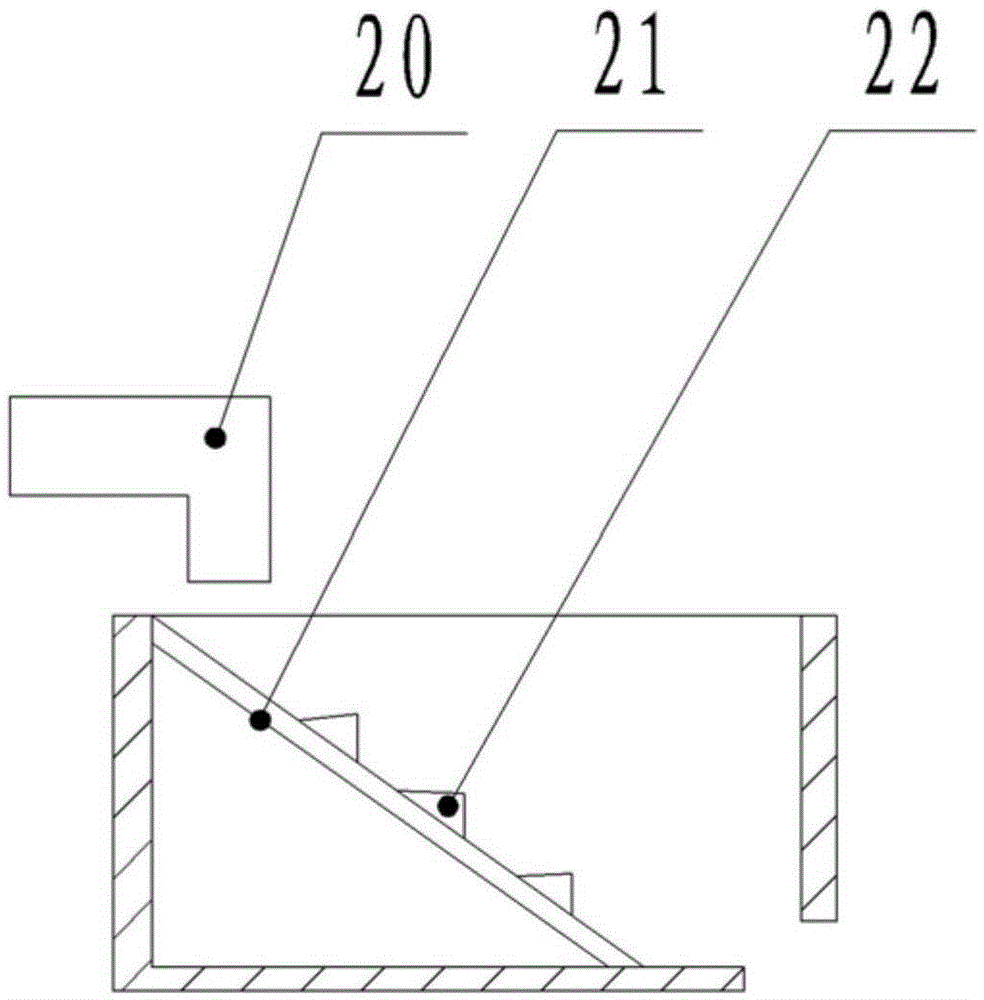

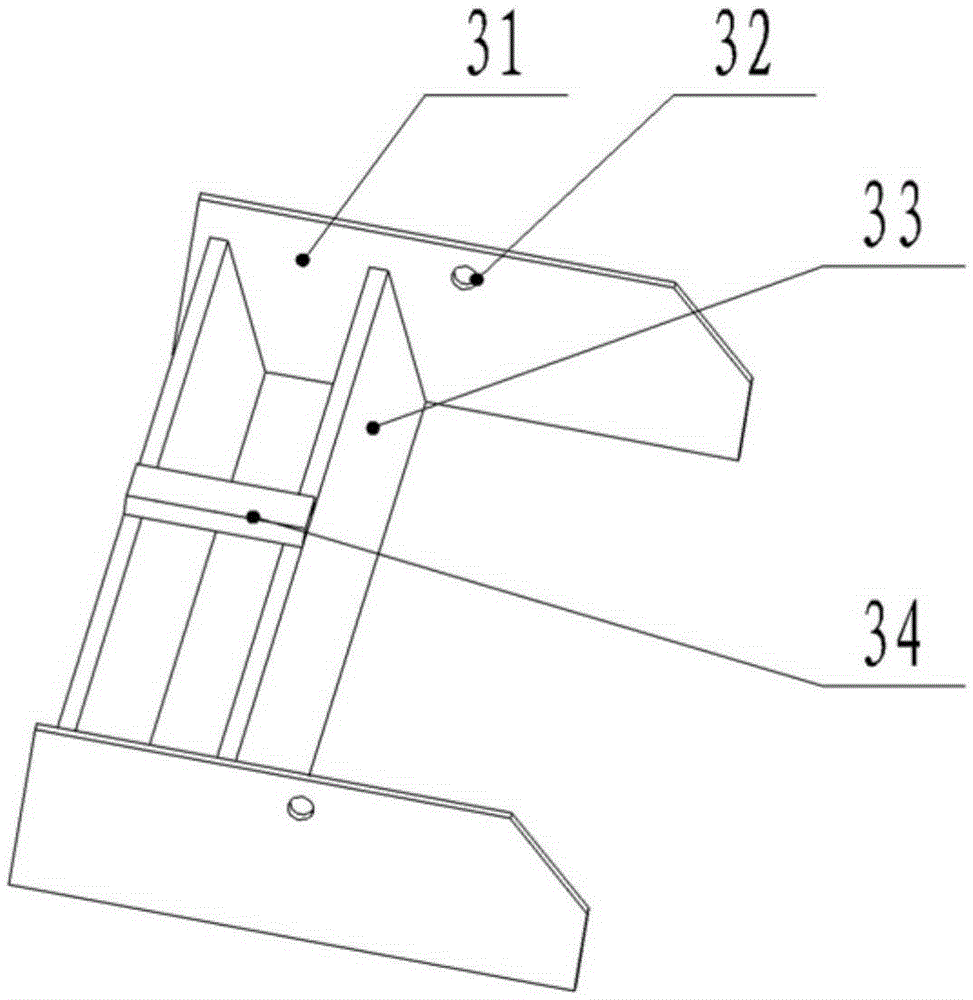

[0017] like figure 1 As shown, a kind of rice paper mechanized production equipment comprises bamboo curtain support 12, and described bamboo curtain support 12 both sides are provided with preforming cylinder 1, and described bamboo curtain support 12 top is provided with idler 4, and described preforming cylinder 1 Bamboo curtains 11 are arranged on the outside and above the supporting roller 4, and a pulp bucket 2 is arranged on the left side of the bamboo curtain bracket 12, and a pulp laying auxiliary device 3 is connected to the lower right side of the pulp bucket 2 through a chain, and the preforming drum 1 A pair of dewatering rollers 5 and a pair of extruding rollers 7 are arranged on the upper right side. The forming blanket 51 is wound on the outside of the pair of dewatering rollers 5 and passes between the pair of extruding rollers 7. The righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com