Optical fiber sensor on basis of carbon fiber materials

A technology of optical fiber sensor and carbon fiber material, which is applied in the direction of transmitting sensing components with optical devices, can solve the problems of being susceptible to external electromagnetic interference, reducing the service life of the sensor, and affecting the accuracy of measurement, so as to avoid being easily corroded, Accurate measurement accuracy and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

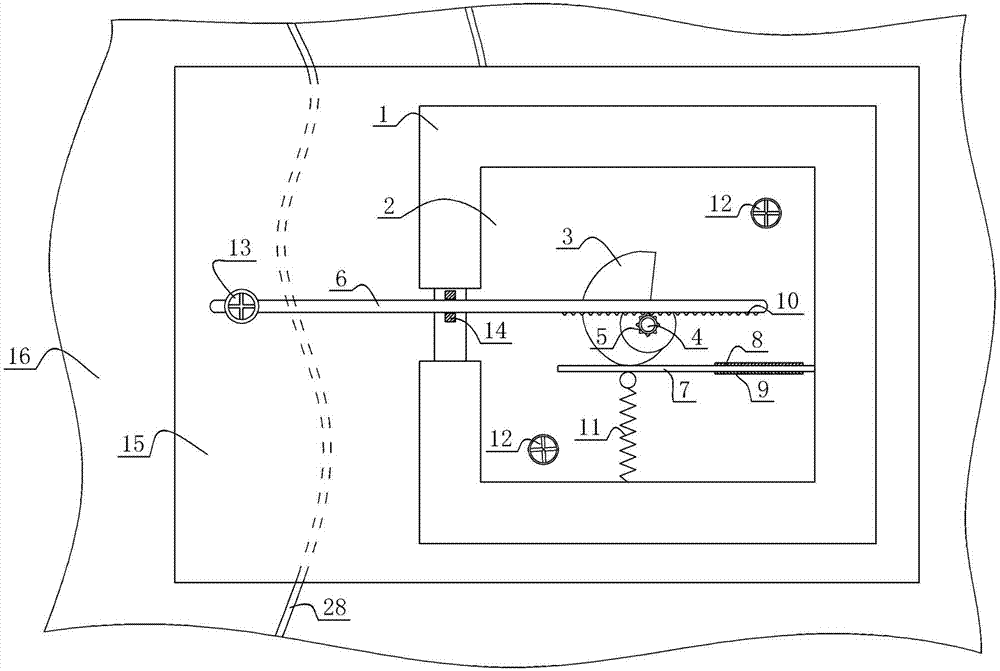

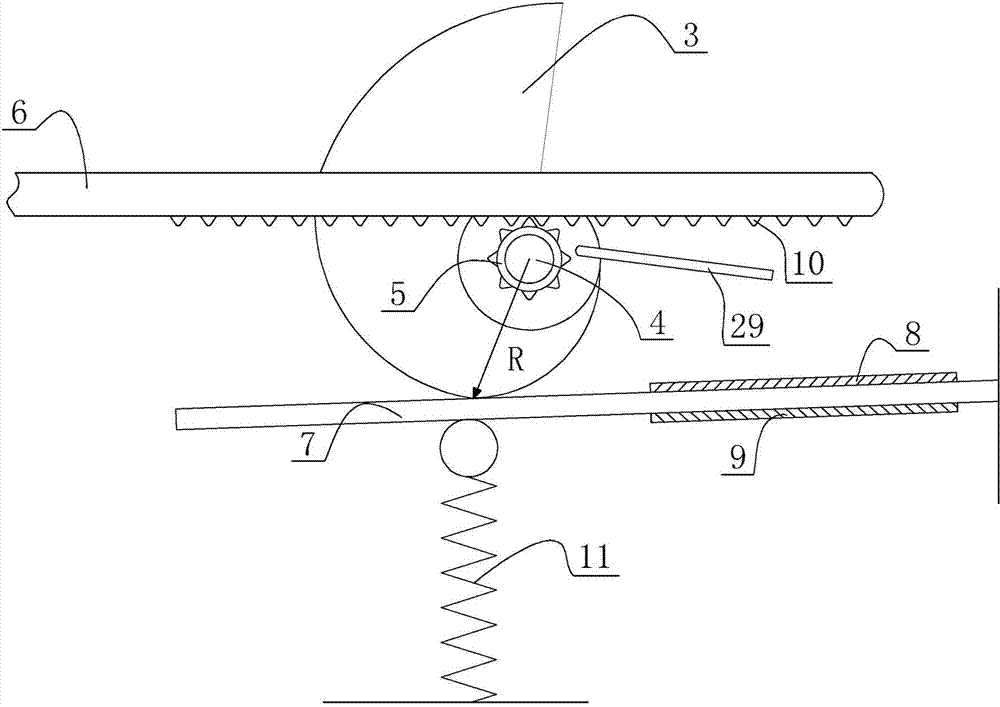

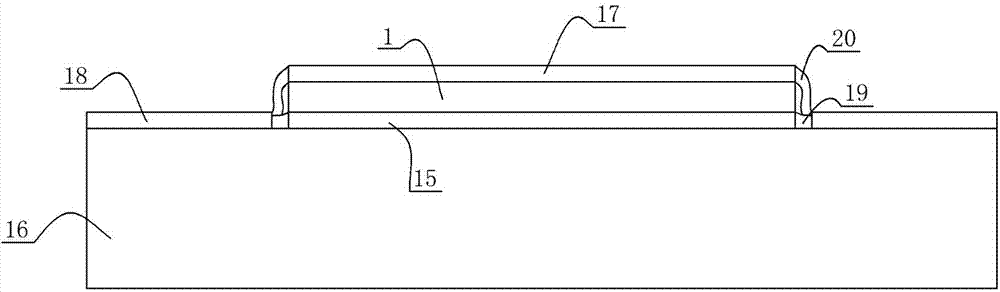

[0026] Such as figure 1 As shown, the structure diagram of the optical fiber sensor of the present invention is provided, which includes a ring frame 1, a fixed plate 2, a spiral cam 3, a fixed shaft 4, a gear 5, a detection arm 6, a cantilever beam 7, an upper fiber grating 8, a lower Fiber grating 9, gear rack 10, support spring 11; the ring frame 1 and the fixing plate 2 shown are used for fixing and supporting, the inside of the ring frame 1 is a cavity, and the ring frame 1 and the fixing plate 2 can be made of hard carbon fiber board material. The fixing plate 2 is fixed on one side of the ring frame 1 . The helical cam 3 is arranged on the fixed plate 2 through the rotating shaft 4 to ensure the free rotation of the helical cam 3 , and the gear 10 is fixed with the fixed shaft 4 . The right end of the detection arm 6 is located in the inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com