Method used for rapid sorting of lithium ion batteries

A sorting technology for lithium-ion batteries, applied in secondary battery charging/discharging, secondary battery repair/maintenance, sorting, etc., can solve problems such as single sorting parameters, insufficient data accuracy, and increased sorting costs , to achieve the effect of simple operation, overall performance guarantee and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

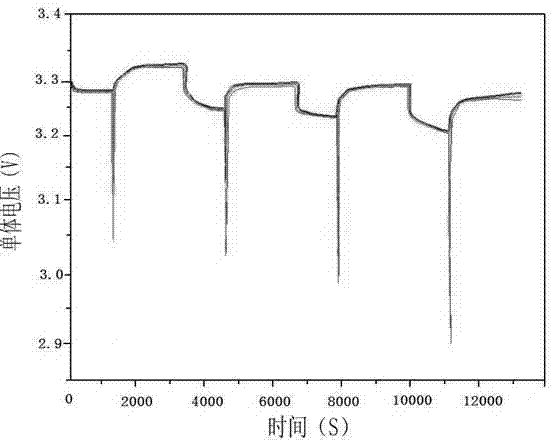

Embodiment 1

[0028] A method for rapidly sorting lithium-ion batteries, comprising the following steps:

[0029] ①. Select 100 lithium-ion batteries with a rated capacity of 60Ah, use the chemical composition capacity detection cabinet to perform three charge-discharge cycles at a charge-discharge rate of 0.5C at room temperature, and finally set the SOC of the battery to 50%.

[0030] ②. Collect the discharge capacity, total charge capacity, constant current charge capacity, and constant current ratio (constant current ratio = constant current charge capacity / total charge capacity, counted by percentage) of each single lithium-ion battery during the third charge and discharge. .

[0031] ③. After the test, unload the lithium-ion battery from the capacity separation test cabinet, and place it at room temperature for 24 hours to ensure the stability of the battery.

[0032] ④. After standing still, use a voltage internal resistance tester to test the open circuit voltage and internal resis...

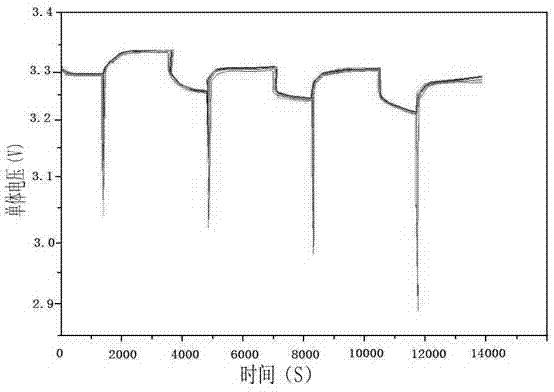

Embodiment 2

[0044] A method for rapidly sorting lithium-ion batteries, comprising the following steps:

[0045] ①. Select 100 power lithium-ion batteries with a rated capacity of 92Ah, use the chemical composition capacity detection cabinet to perform three charge-discharge cycles at a charge-discharge rate of 0.3C at room temperature, and finally set the SOC of the battery to 50% .

[0046]②. Collect the discharge capacity, total charge capacity, constant current charge capacity, and constant current ratio (constant current ratio = constant current charge capacity / total charge capacity, counted by percentage) of each single lithium-ion battery when it is charged and discharged for the third time .

[0047] ③. After the test, unload the lithium-ion battery from the composition and capacity testing cabinet, and place it at room temperature for 48 hours to ensure the stability of the battery.

[0048] ④. After standing still, use a voltage internal resistance tester to test the open circu...

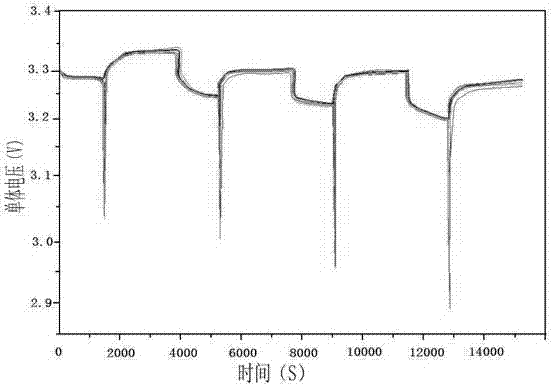

Embodiment 3

[0060] ①. Select 100 power lithium-ion batteries with a rated capacity of 200Ah, use the chemical composition and capacity detection cabinet to perform charge and discharge cycles at a charge and discharge rate of 0.2C for 3 times at room temperature, and finally set the SOC of the battery to 50%.

[0061] ②. Collect the discharge capacity, total charge capacity, constant current charge capacity, and constant current ratio (constant current ratio = constant current charge capacity / total charge capacity, counted by percentage) of each single lithium-ion battery when it is charged and discharged for the third time .

[0062] ③. After the test, unload the lithium-ion battery from the composition and capacity testing cabinet, and place it at room temperature for 36 hours to ensure the stability of the battery.

[0063] ④. After standing still, use a voltage internal resistance tester to test the open circuit voltage and internal resistance of each single lithium-ion battery, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com