A shielded motor stator cavity cooling structure

A shielded motor and cooling structure technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of shielded motor failure, unsatisfactory heat dissipation effect, poor air heat transfer effect, etc., to ensure safe and stable operation, The effect of avoiding the failure of the shielded motor and meeting the sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

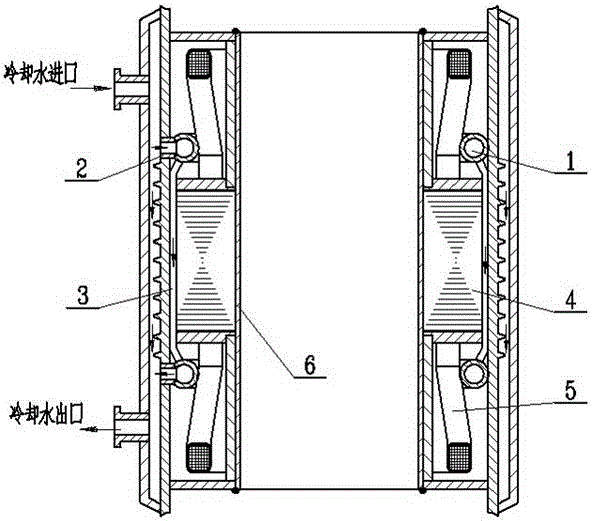

[0025] Such as figure 1 As shown, in the prior art, in order to solve the heat dissipation problem of the sealed inner cavity of the stator, the method of setting a cooling water jacket on the outer wall of the motor stator cylinder is mainly adopted, and the heat transfer between the secondary cooling water and the outer wall of the motor stator cylinder is used. Take away the heat of the inner cavity of the stator for cooling. In view of the poor effect of this cooling method, on the basis of this solution, this embodiment provides a shielded motor stator cavity cooling structure, which is provided with cooling water pipes 1 in the airtight cavity at both ends of the shielded motor stator core 4 , the cooling water pipe 1 communicates with the cooling water jacket on the outer wall of the shielded motor stator cylinder. In this embodiment, a cooling structure is provided in the motor stator barrel to form a cooling water inflow and outflow circuit, which can effectively tak...

Embodiment 2

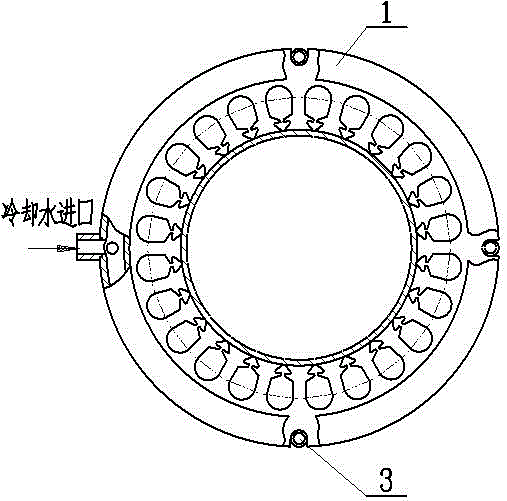

[0027] Such as figure 1 with figure 2As shown, this embodiment has made further improvements on the basis of Embodiment 1. The number of cooling water pipes 1 in this embodiment is 2, and one is respectively arranged in the airtight cavity at both ends of the stator core 4 of the shielded motor. The water pipe 1 is annularly arranged in the airtight cavity at both ends of the stator core 4 of the shielded motor. The pipe wall of the cooling water jacket is sealed and connected to prevent the cooling water from entering the closed stator cavity. Wherein the cross section of the cooling water pipe 1 is circular. In practical application, if the space in the airtight cavity is large, multiple cooling water pipes 1 can be arranged in the airtight cavity at both ends to enhance the effect of heat dissipation and cooling; the cross section of the cooling water pipe 1 can also be any other regular or irregular Shapes, such as regular hexagons, regular octagons, trapezoids, etc. ...

Embodiment 3

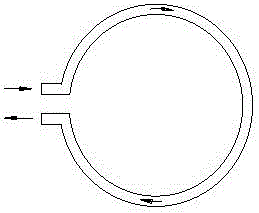

[0029] Such as image 3 As shown, on the basis of Embodiment 2, there are two connecting pipes 2 in this embodiment, which are located on the same side of the annular surface of the cooling water pipe 1 . The cooling water pipes 1 at both ends of the stator core 4 respectively form a secondary cooling water inflow and outflow circuit. Since the two connecting pipes 2 are located on the same side of the annulus of the cooling water pipe 1, the secondary cooling water enters the cooling water pipe 1 through one of the connecting pipes 2, and flows through the closed cavity along the cooling water pipe 1 for a circle and then flows from the other A connecting pipe 2 flows out and flows back to the cooling water jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com