How the stop is formed

A technology of stoppers and moldings, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of loss, water resistance reduction, etc., and achieve the effects of improving productivity, preventing peeling, and improving fastening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

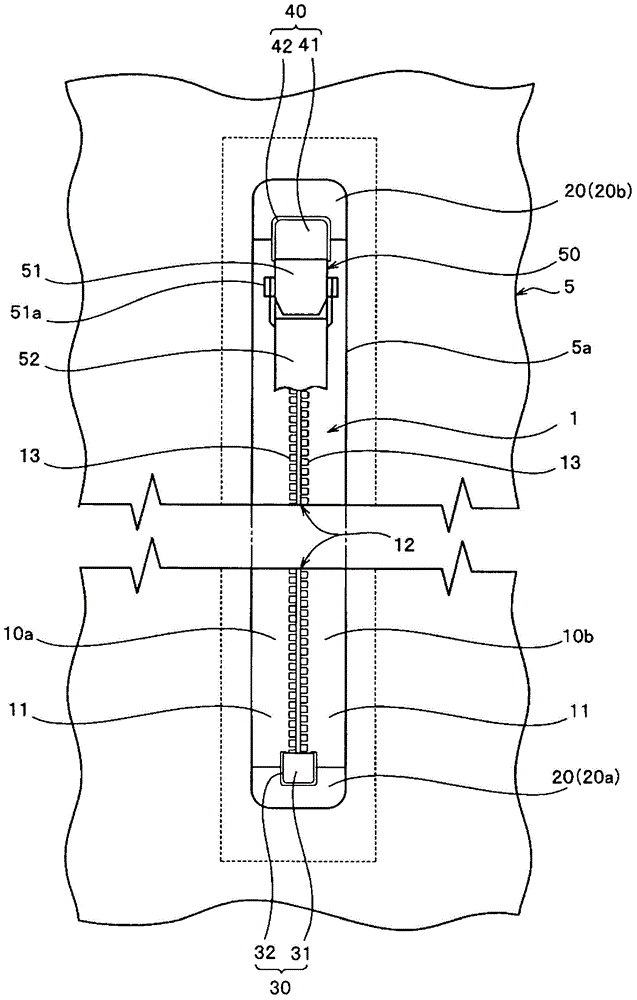

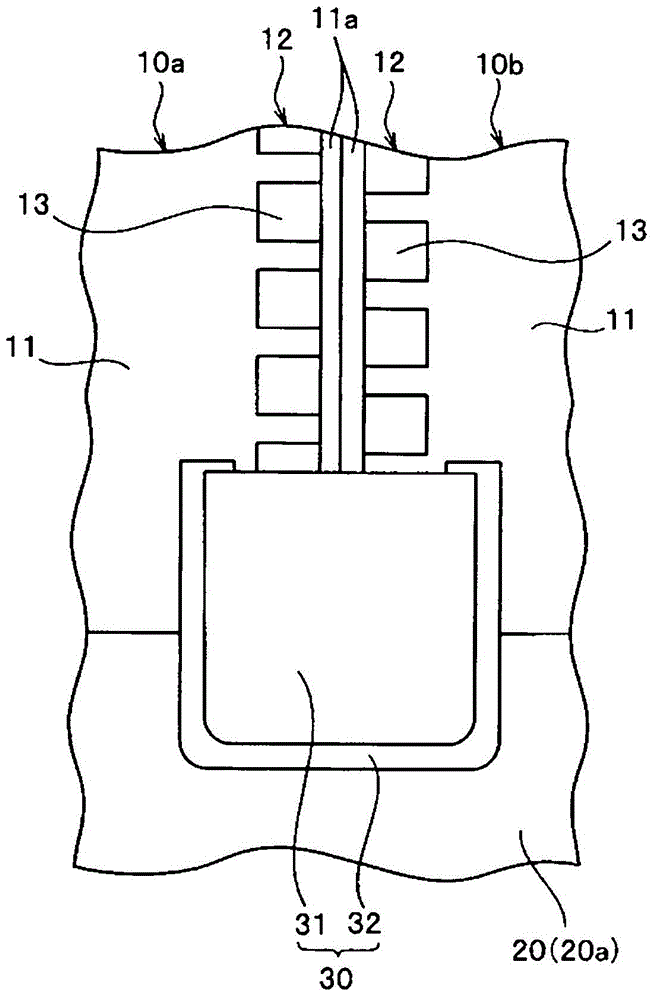

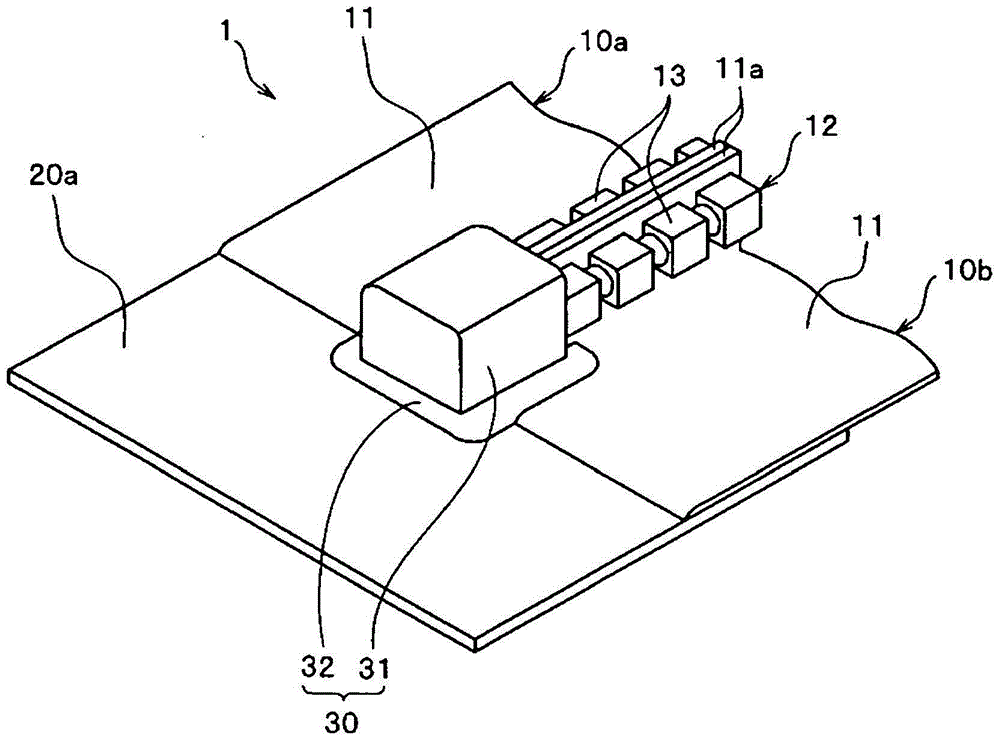

[0072] figure 1 It is a plan view showing the state where the airtight and waterproof slide fastener (hereinafter simply referred to as "waterproof slide fastener") according to the first embodiment is equipped on a slide fastener-attached product. in addition, figure 2 It is a plan view of the first stopper arranged on the waterproof zipper, image 3 is a perspective view of the first stop. also, Figure 9 It is a perspective view of the second stopper arranged on the waterproof zipper, Figure 10 It is a sectional view showing the protruding part arranged in the vicinity of the second stopper.

[0073] In addition, in the following description, the tape length direction of the airtight waterproof tape is defined as the front-rear direction, especially in the present embodiment 1, the direction in which the slider is slid by engaging the left and right fastener elements is referred to as the front, The direction in which the slider is slid by separating the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com