Welding process of 5G large die casting

A welding process and die-casting technology, which is applied in the welding process field of 5G large-scale die-casting parts, can solve the problems of large volume and area of the die-casting machine, low production efficiency, and high manufacturing cost, so as to improve the production efficiency, reduce the production cost, and achieve stable welding. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

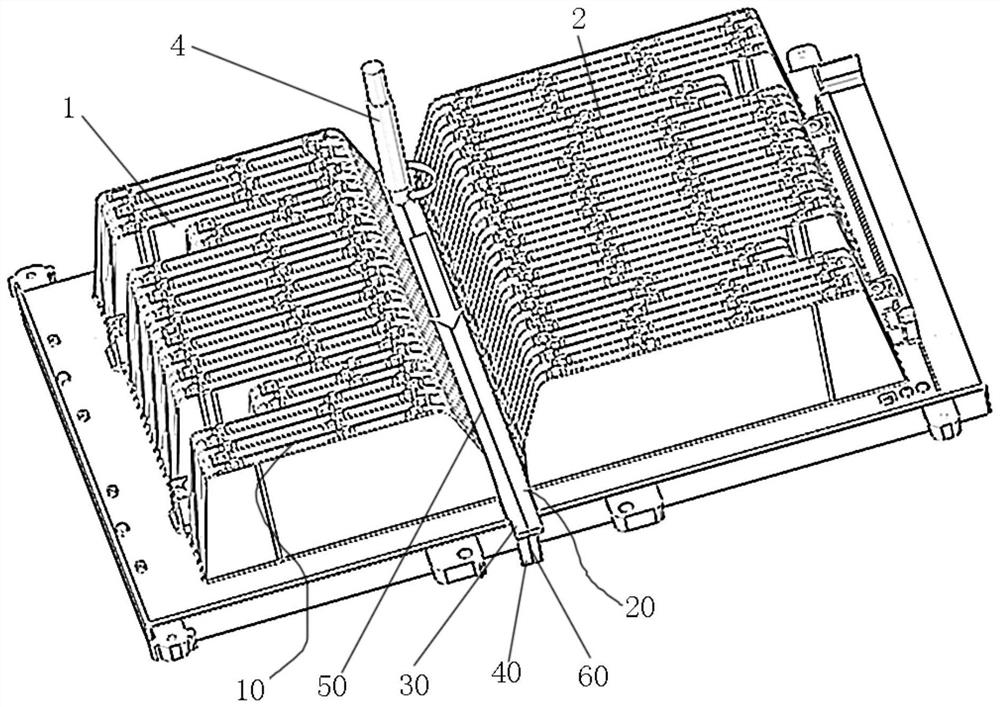

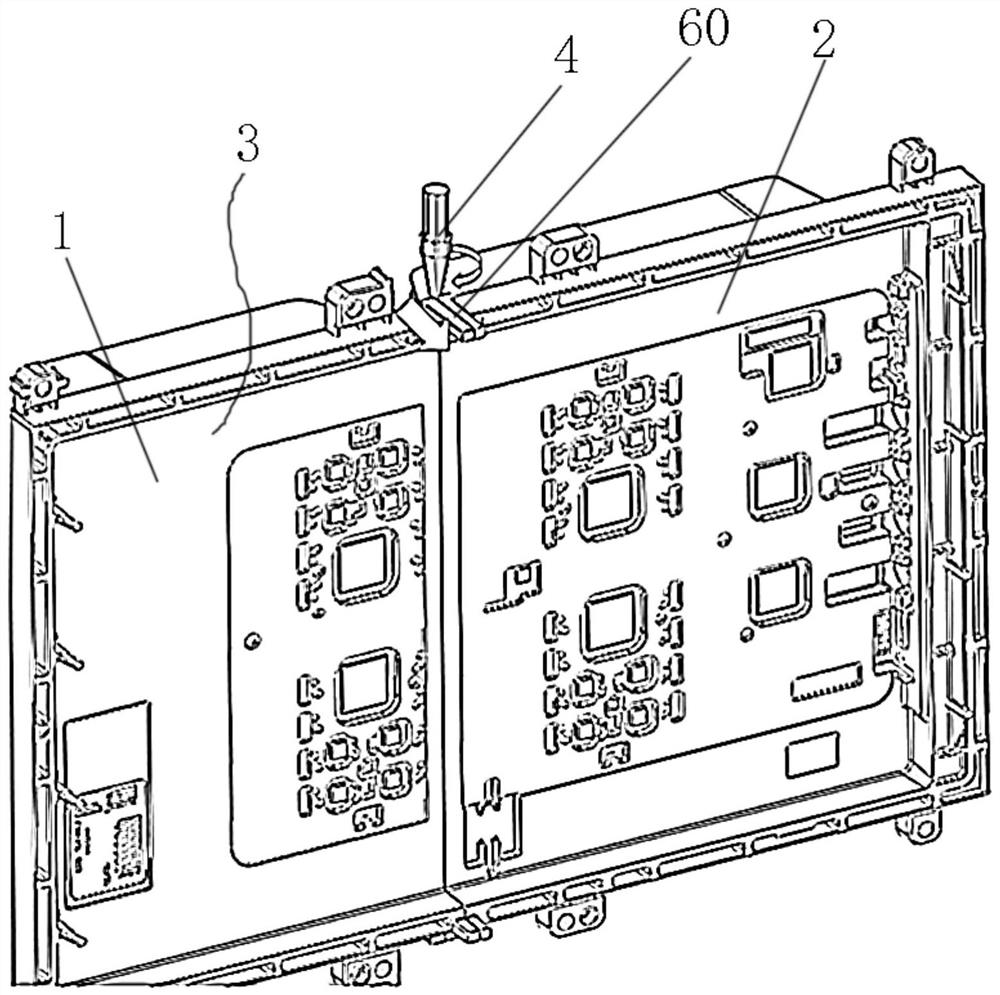

[0028] Specific examples, see figure 1 and figure 2 , the two-part casting is specifically the first casting 1 and the second casting 2 . The first casting 1 is die-casted by a 1650t die-casting machine, and the second casting 2 is die-casted by a 2500t die-casting machine. The die-casting manufacturing precision of the two parts of the die-casted parts is high and the production cost is reduced;

[0029] The materials of the first casting 1 and the second casting 2 are specifically aluminum-silicon alloy with high thermal conductivity;

[0030] The thickness of the welded seam connected by friction stir welding to the opposite upper surface of the splicing seam is 7.6mm, with complete penetration;

[0031] Friction stir welding is used to weld the side joints 60 on both sides of the corresponding side of the side convex welding area 30, the thickness of the weld seam is 5mm, and the weld seam is not penetrated, and then supersonic cold spraying is required to subsequently ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com