Tab-gluing device and method of use thereof

A technology of gluing device and tabs, applied in auxiliary devices, metal processing equipment, welding equipment, etc., can solve the problems of uneven heating of metal, unreliable products, easy bubbles, etc., to achieve no bubbles in appearance and power consumption Small, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

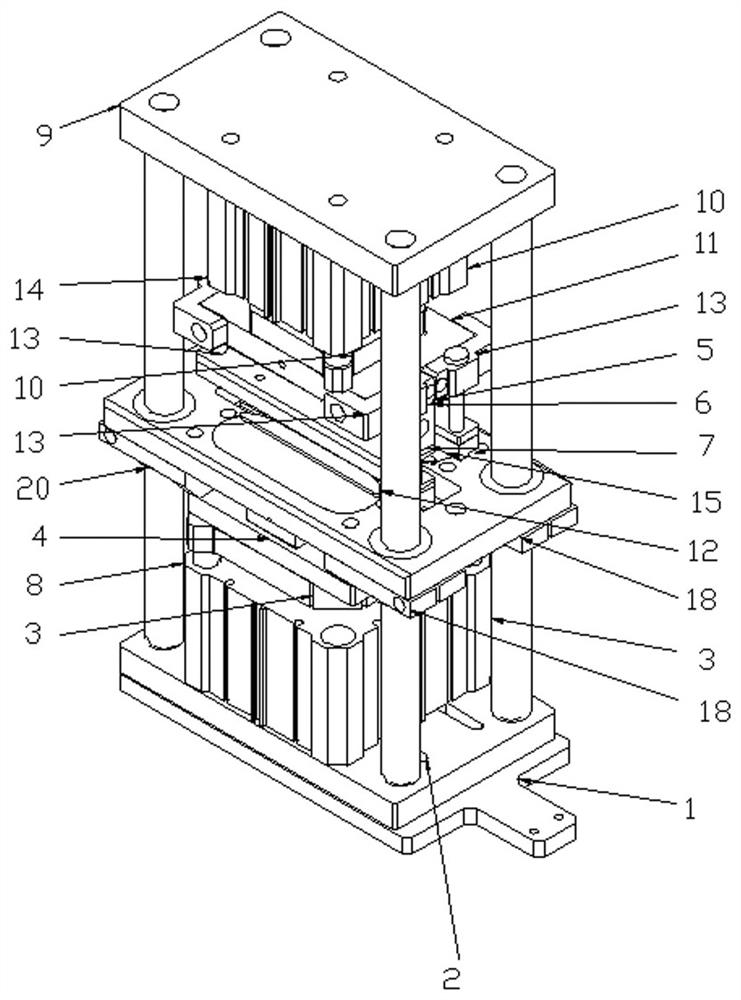

[0019] see figure 1 As shown, the present invention relates to a tab gluing device, which includes a frame, an upper pressing assembly, a lower pressing assembly, and a metal belt power supply mechanism, and the upper pressing assembly and the lower pressing assembly are arranged symmetrically up and down in the frame. The upper pressing assembly includes the first cylinder mounting plate 9, the first cylinder 10, the first heat insulation plate 5, the first copper plate mounting plate 11, the first copper plate 6, and the pressing mechanism. The first cylinder 10 is fixed on the first On a cylinder mounting plate 9, the first copper plate mounting plate 11 is arranged on the output shaft of the first cylinder 10, the first copper plate 6 is fixed on the first copper plate mounting plate 11, and the pressing mechanism is set Below the first copper plate 6; the lower pressing assembly includes a second cylinder mounting plate 2, a second cylinder 3, a second copper plate mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com