Method and apparatus for producing braided knots on multifilament filaments

A multi-fiber, woven knot technology, used in textiles and papermaking, etc., to solve problems affecting woven knot formation, uncertain patterns and strips of carpets, and inability to bring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

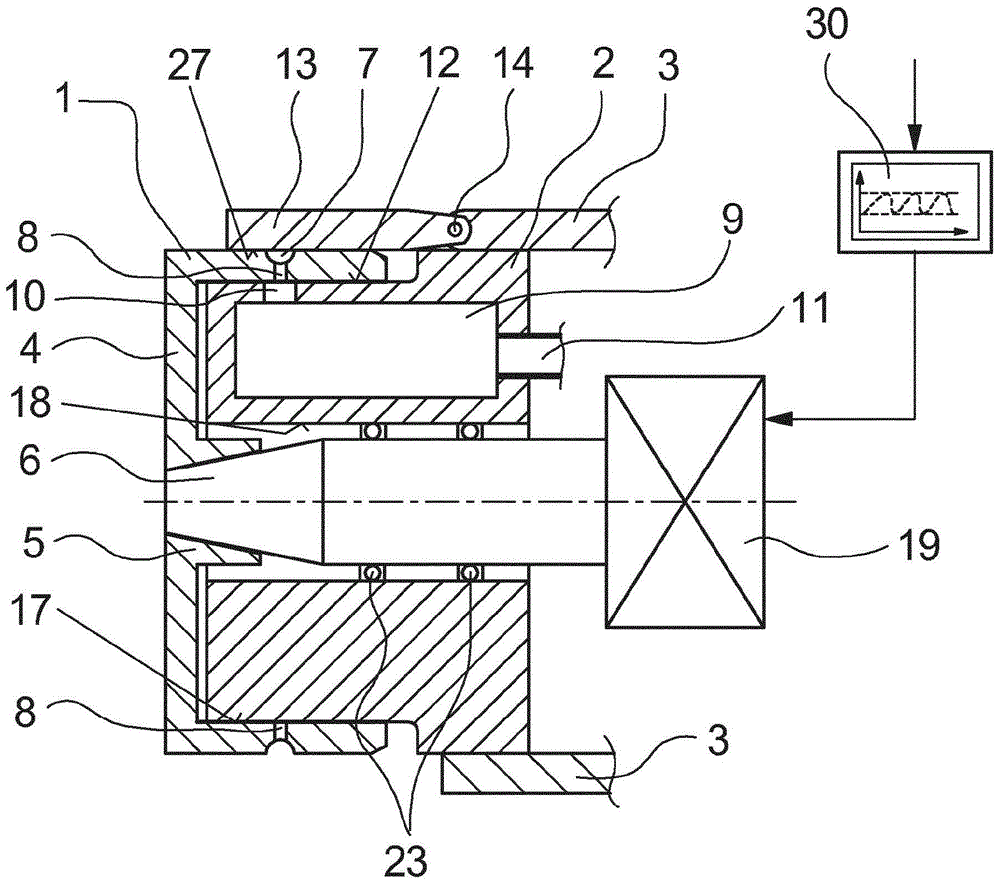

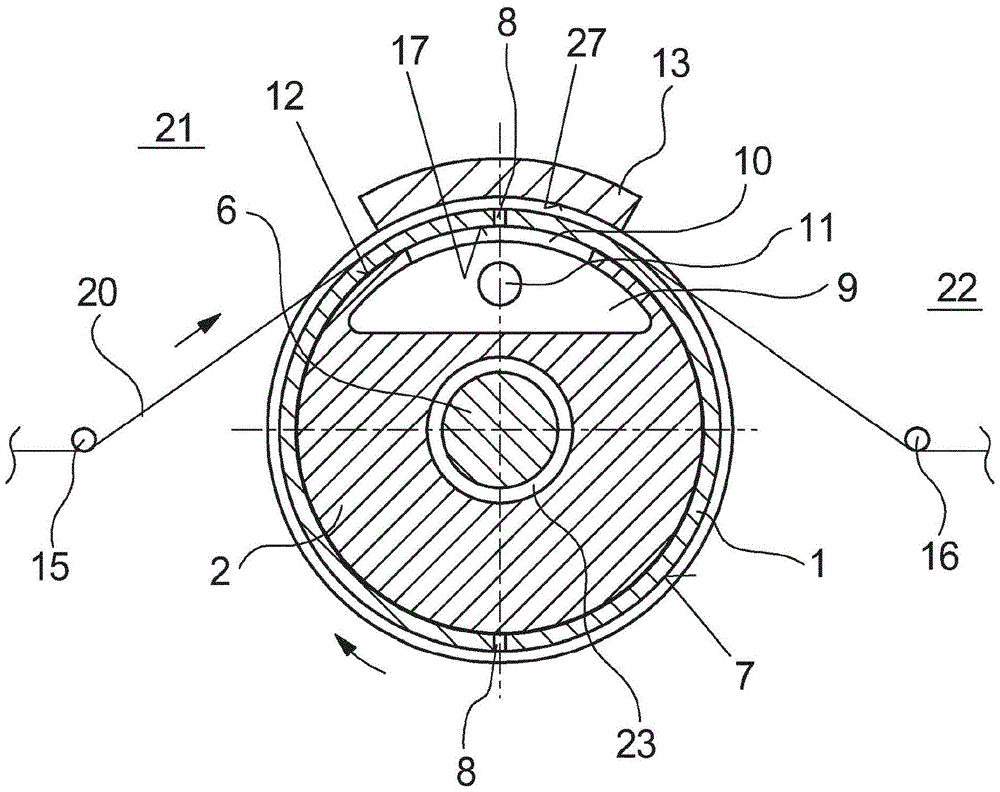

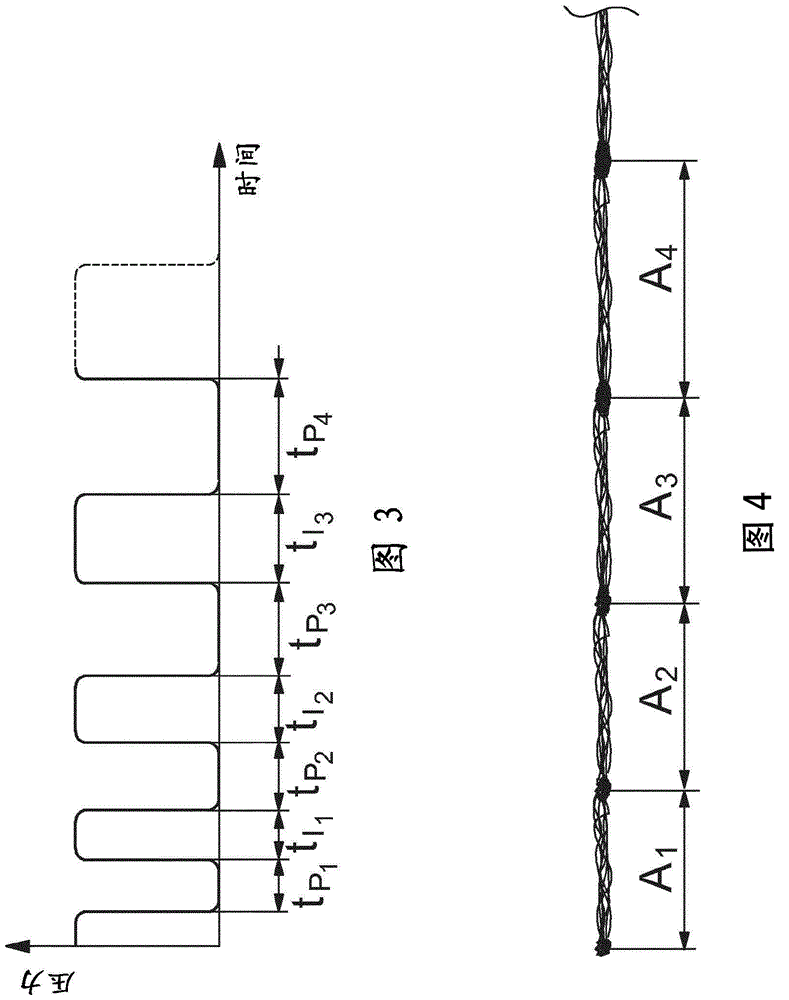

[0034] exist figure 1 with 2 A first exemplary embodiment of the device according to the invention is shown in several views. figure 1 This embodiment is shown in longitudinal section, while in figure 2 This embodiment is shown in cross-section in FIG. The following description applies to both figures unless an explicit reference is made to a certain view.

[0035] This exemplary embodiment of the device according to the invention for producing braided knots in multifilament filaments has a rotating nozzle ring 1 which is designed annularly and has a circumferential guide groove 7 . A plurality of nozzle holes 8 lead to the groove bottom of the guide groove 7 and are formed uniformly distributed on the circumference of the nozzle ring. In this exemplary embodiment, two nozzle openings 8 are contained in the nozzle ring 1 . The nozzle holes 8 extend through the nozzle ring 1 as far as the inner sliding surface 17 .

[0036] The nozzle ring 1 is connected to the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com