Self-propelled reverse corn harvester

A corn harvester, reverse-type technology, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of easy rollover, inconvenient operation, and high center of gravity of corn harvesters, and achieve the effect of lowering the center of gravity and reducing the turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

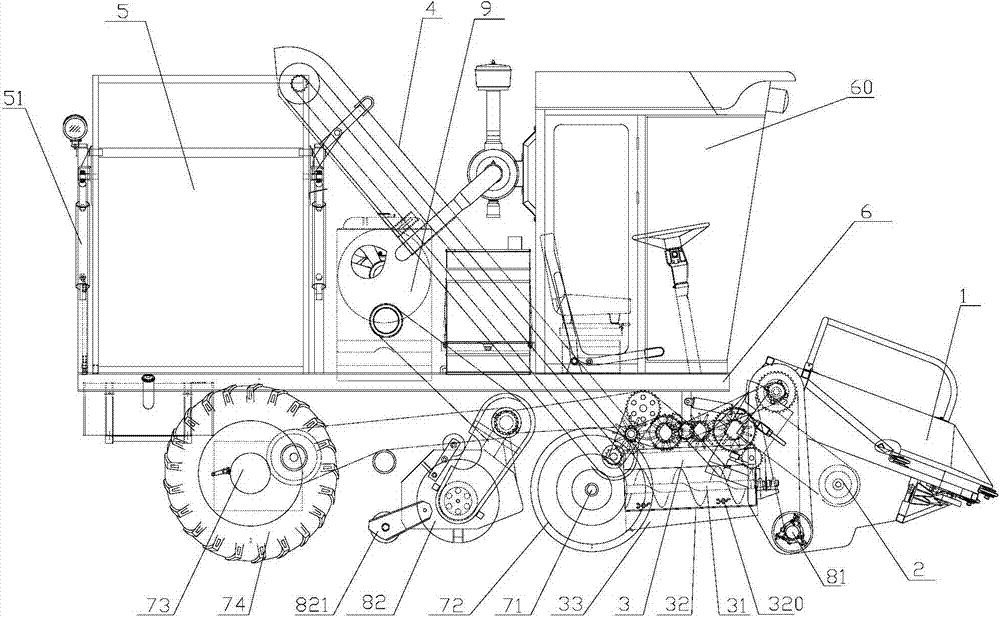

[0019] Such as figure 1 As shown, the preferred embodiment of the present invention mainly includes a harvesting mechanism 1, a small lifter 2, a peeling mechanism 3, a large lifter 4, a granary 5, a chassis 6, a cab 60, a front axle 71, a steering wheel 72, and a rear axle 73, driving wheel 74, front returning field machine 81, middle field returning machine 82, diesel engine 9, etc. In order to simplify the drawings, for those skilled in the art, known structures or structures that can be clearly inferred, figure 1 It does not show, for example, a hydraulic system including a hydraulic pump, multiple oil cylinders, hydraulic pipelines, hydraulic valves, etc., a transmission mechanism including multiple pulleys or multiple chain sprockets, and a reduction box.

[0020] Specifically, the chassis 6 has a plate-shaped platform, above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com