Method for rolling external tube thread, rolling head and rolling equipment thereof

A technology of external thread and rolling head, which is applied in the field of pipe products and pipe processing machinery, and can solve problems that affect the promotion and application of rolling pipe external thread technology, hidden safety hazards of pipe external thread products, and large outer diameter of rolling, etc. Achieve the effect of reducing material cost, reliable and mature process, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0181] The following is an example of the on-site installation of a galvanized welded pipe for gas with a specification of DN32, a length of 6000 mm, and a wall thickness of 3.5 mm, which is commonly used in the gas industry. Figure 1 to Figure 6 , Figure 15 to Figure 20 as well as Figure 45 to Figure 46 , compared with the existing rolling processing process for pipe external thread, the aforementioned purpose, technical solution and beneficial effect of the present invention will be further described in detail.

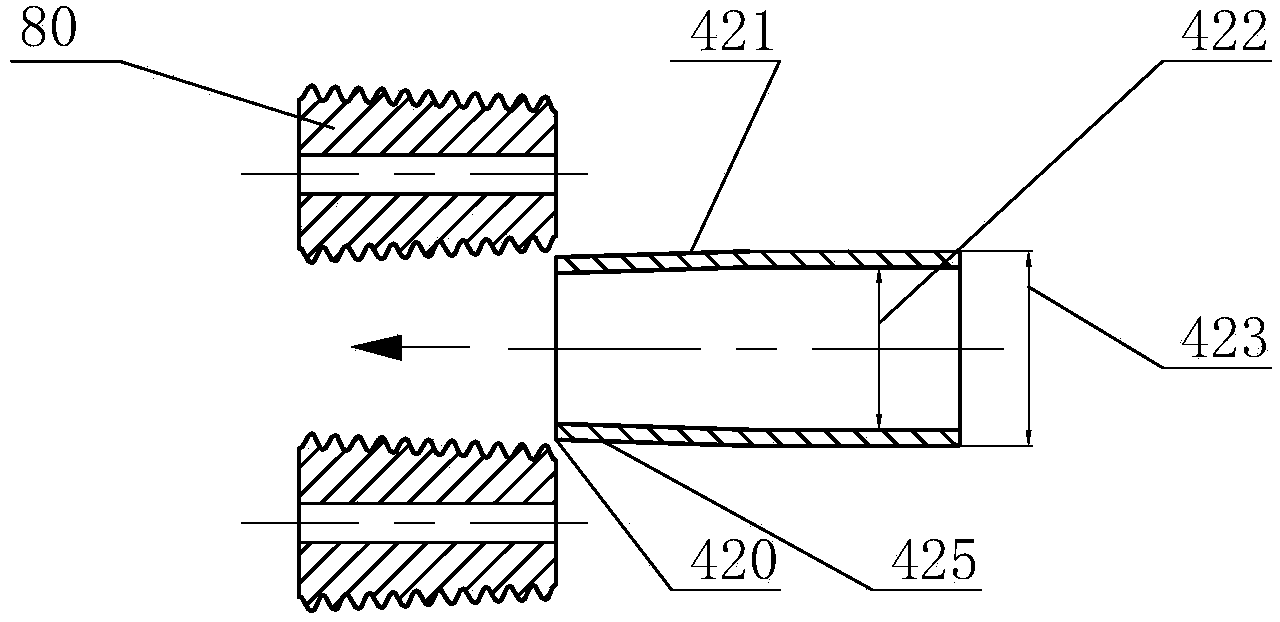

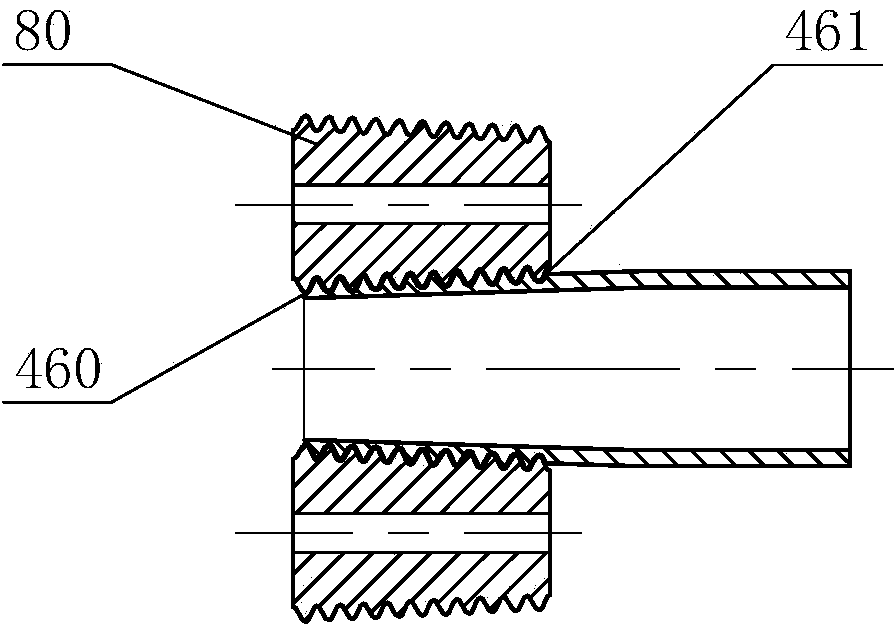

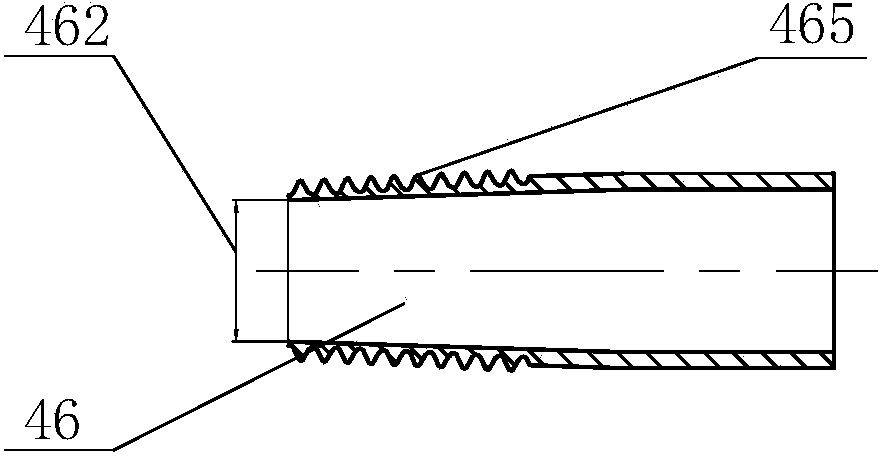

[0182] According to the existing national standard "Welded steel pipe for low-pressure fluid transmission" (GB3091-2008), the outer diameter 423 of the DN32 gas special galvanized steel pipe is 42.4 mm, the ordinary wall thickness is 3.50 mm, and the inner diameter 422 is 35.40 mm. Such as figure 1 As shown, using the existing rolling pipe external thread process, using a large-tonnage axial stamping device, first process the conical surface 425 of 1:16; as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com