Automatic fuel gas tempering blocking device

An automatic, gas-fired technology, used in fire rescue, medical science, dentistry, etc., can solve problems such as safety production accidents, and achieve the effect of ensuring production safety, easy operation, and automatic blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

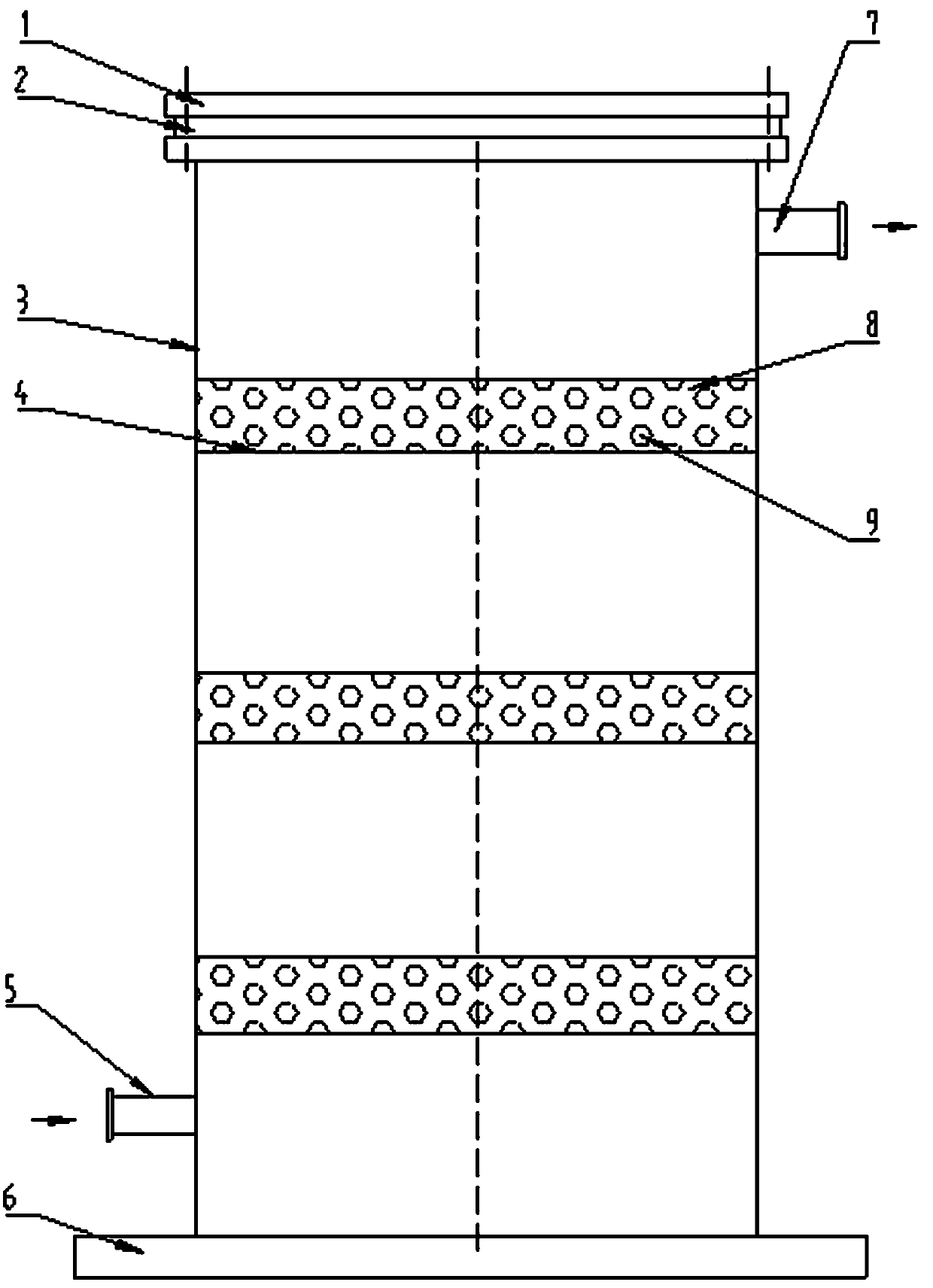

[0013] The irregular filler 9 of the present invention is the cobblestone that is convenient to collect. The shape of the cobblestone is smooth, and the gap 8 naturally formed after the interlayer 4 is stacked is fine and irregular. In addition, the cobblestone has good heat absorption performance, which strengthens the flame retardant effect.

[0014] Before operation, place pebbles of different diameters in the interlayer 4 respectively, and the order of placement is: the diameter of the cobblestones in several interlayers 4 gradually becomes smaller from bottom to top, which can better absorb heat and flame-retardant. During operation, the gas inlet pipe 5 introduces gas with a certain pressure, and the gas overflows from the gaps 8 formed by stacking cobblestones in several interlayers 4, and the gas that overflows is introduced into the work area by the gas outlet pipe 7 for use. When the gas delivery device fails and the operator does not take blocking measures, temperin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com