Patents

Literature

52results about How to "Eliminate hidden dangers in production safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

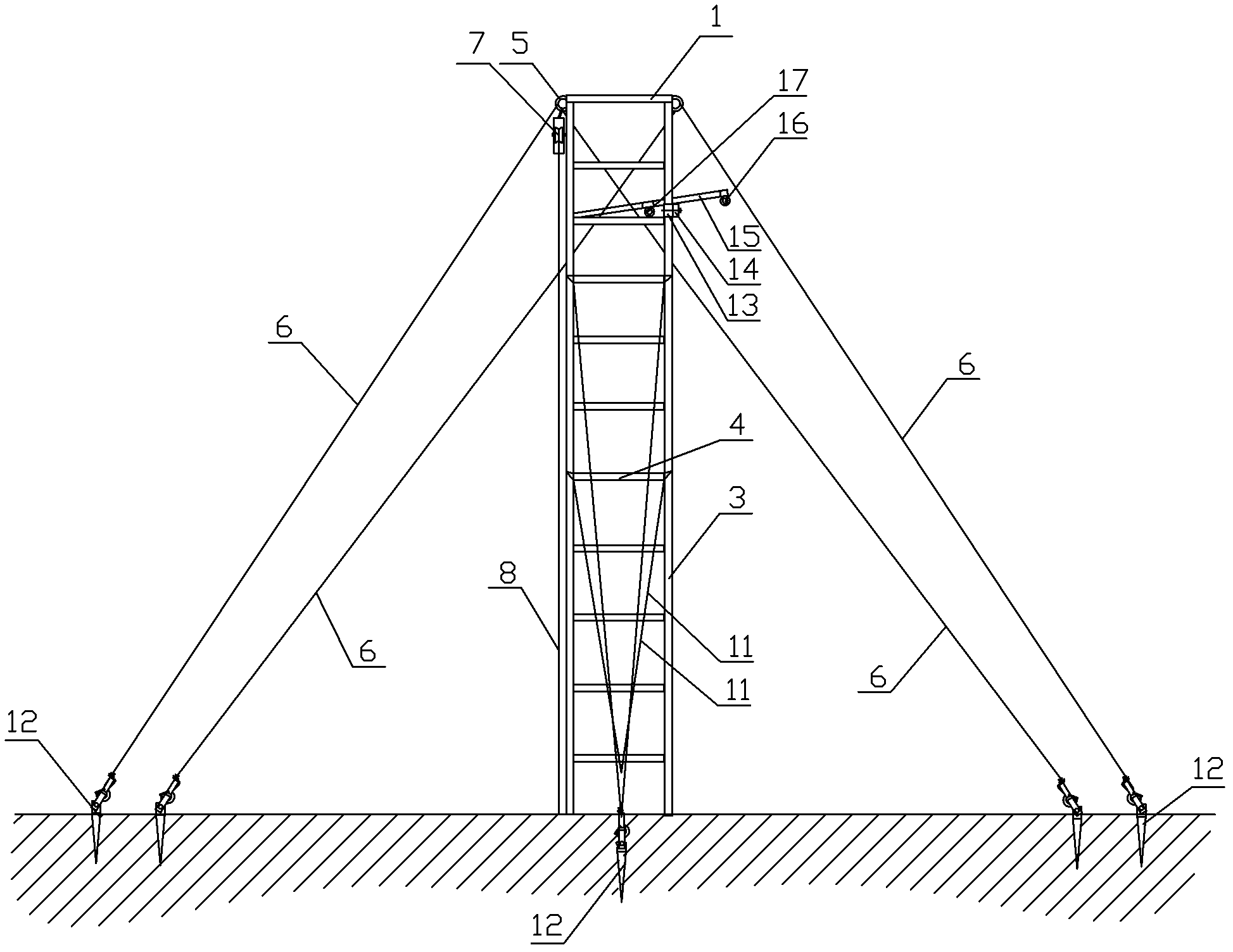

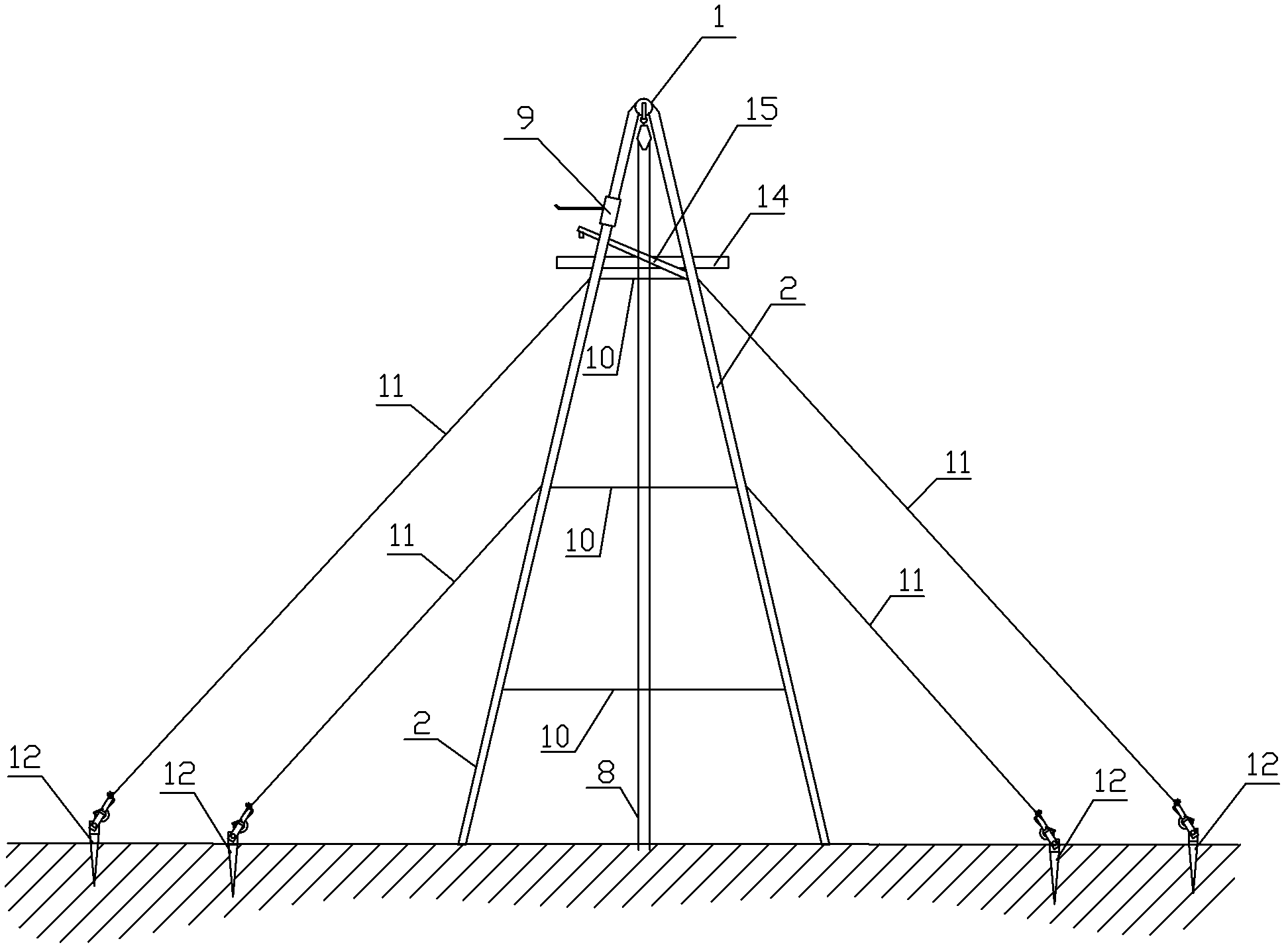

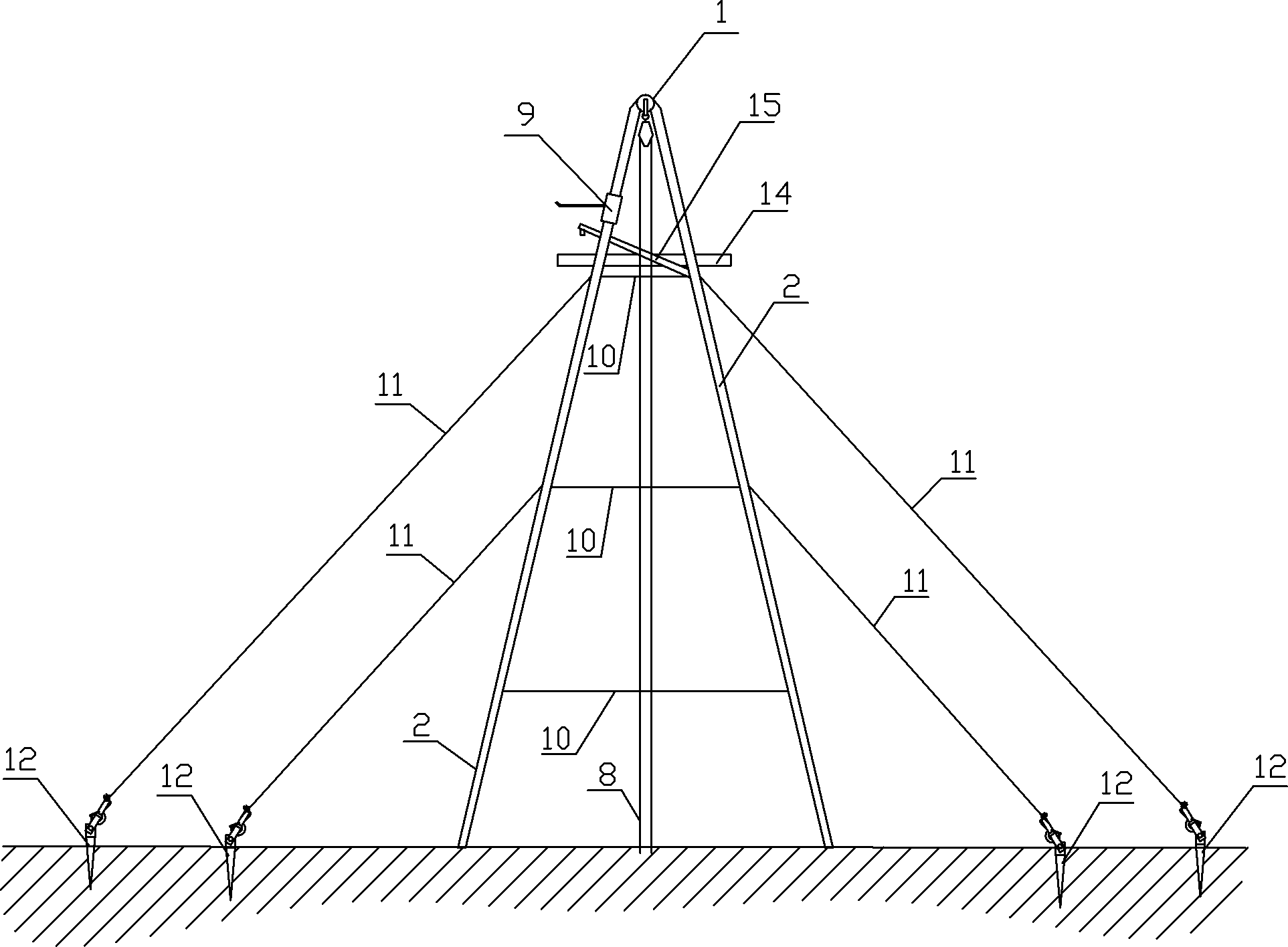

Live replacement method for static contact of 220 kV flexible busbar

ActiveCN102664358AMeet the requirements of the equipotential operation lawReduce volumeSwitchgearSocial benefitsBusbar

The invention relates to the field of GW6 series alternating high-voltage isolating switches of a flexible busbar in a power grid 220 kV substation and particularly relates to a live replacement method for a static contact of the 220 kV flexible busbar. The live replacement method for the static contact of the 220 kV flexible busbar is characterized in that operation persons ascend to the position below the flexible busbar along an insulation herringbone ladder and subject the static contact of the flexible busbar to live replacement by means of using an idiostatic method to transfer potentials, and the live replacement method includes a detachment step and an installation step. Compared with replacement methods in prior art, the live replacement method for the static contact of the 220 kV flexible busbar has the advantages that the insulation herringbone ladder is used as an insulation manned platform and meets the requirement of an equipotential operation method, and the insulation herringbone ladder is small in size, can be lifted below the flexible busbar, and is applicable to live replacement operation for static contacts of GW6 series sing-column and double-column vertical opening type isolating switches of the 220 kV flexible busbar; the live replacement method is capable of promoting scientific and technological progress and has obvious social benefits and economical benefits; and the live replacement method fills the gap in the live replacement projects of the static contacts of the isolating switches and has a broad application prospect and a popularization value in national grid systems.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

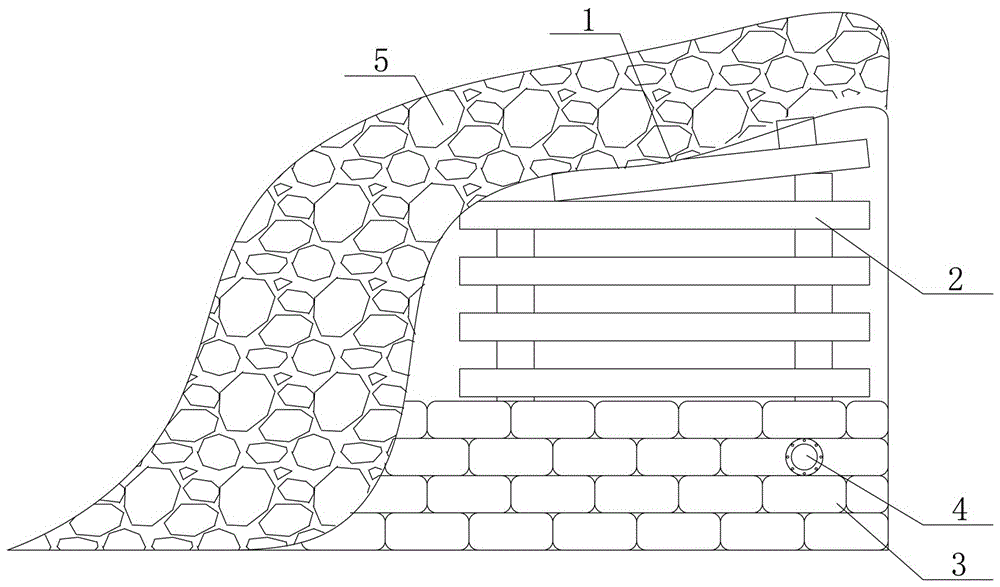

Down coal face goaf water dredging structure and dredging method thereof

InactiveCN106640187AAvoid flooding the roadwayEliminate hidden dangers in production safetyMining devicesDrainageCoalOperating environment

The invention relates to a down coal face goaf water dredging structure. The structure includes a fish scale net covering a collapsed top plate, after top plate gangue collapses, a goaf is no longer filled freely, and the fish scale net is used for covering to achieve the effects of protecting the top plate and catching the gangue; a nog shaped like a Chinese character 'Jing' is erected below the collapsed top plate and used for supporting the collapsed top plate; a water-retaining wall is built at the lower side of the nog shaped like a Chinese character 'Jing', and the goaf and the water-retaining wall are used for building a weir to form a water sump. The structure further includes a water discharge pipe, the water-retaining wall is provided with at least one water discharge pipe to connect space outside the water-retaining wall and the water sump. The invention further provides a down coal face goaf water dredging method. The down coal face goaf water dredging structure has the advantages that water dredging is conducted from a source, water and coal are separated, water blasting of a tunnel is avoided, and the production security hidden danger is eliminated; the discharged water is few in impurity, damage to a drainage system is reduced, and the electric charge is saved; the dredging project is reduced, manpower is reduced, and the work efficiency is improved; the operating environment is purified, and the production efficiency and the quality standardization level are improved.

Owner:XIAOYUN COAL MINE JINING MINING IND GRP CO LTD

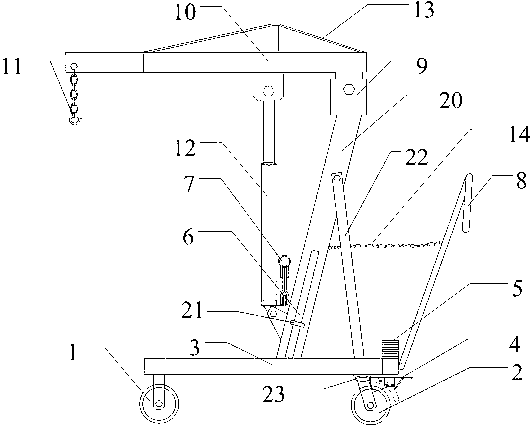

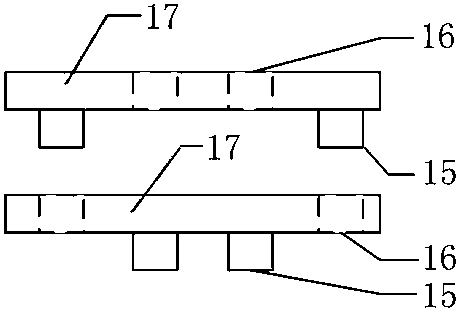

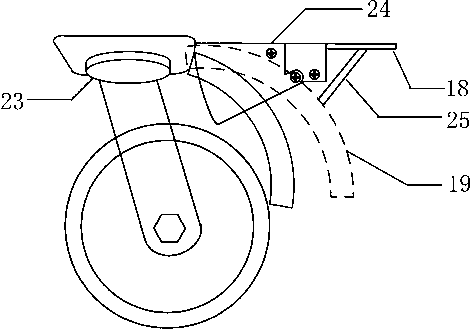

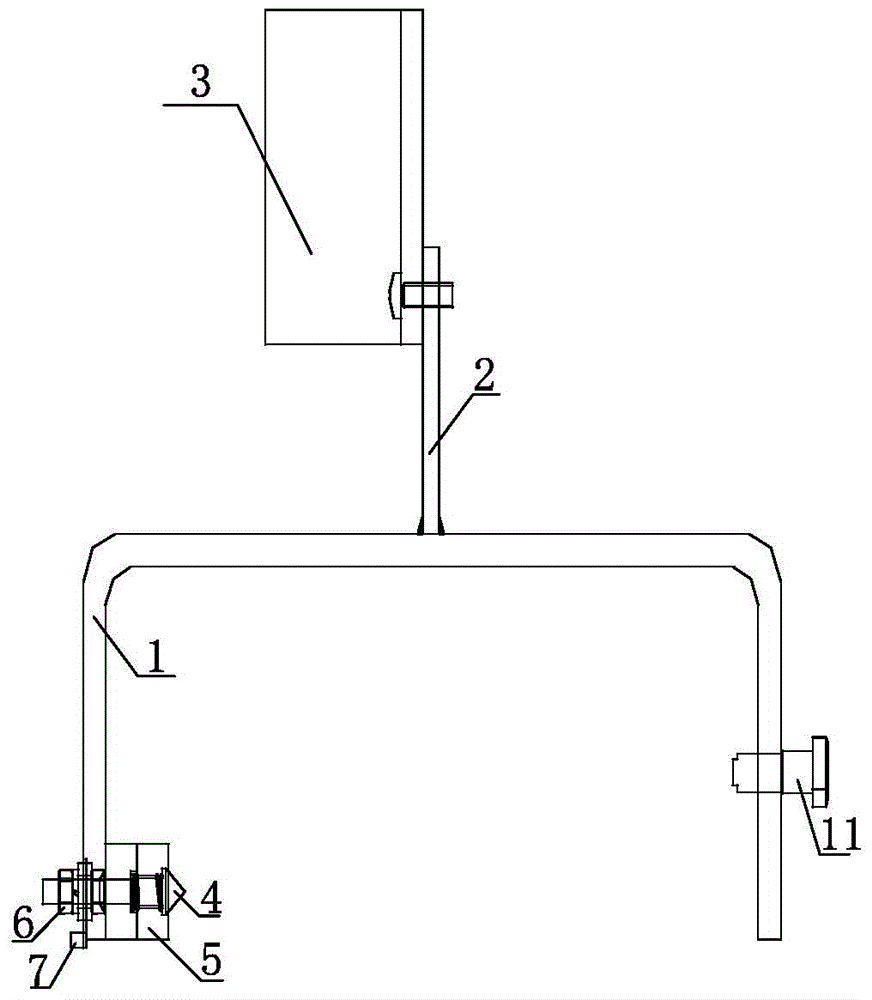

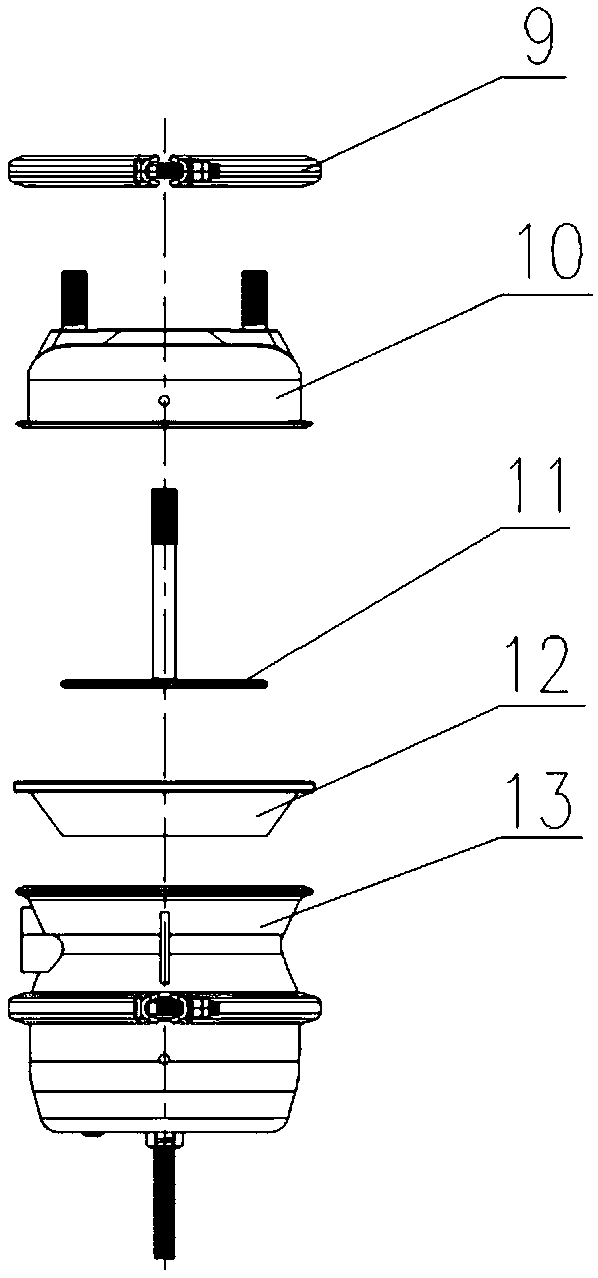

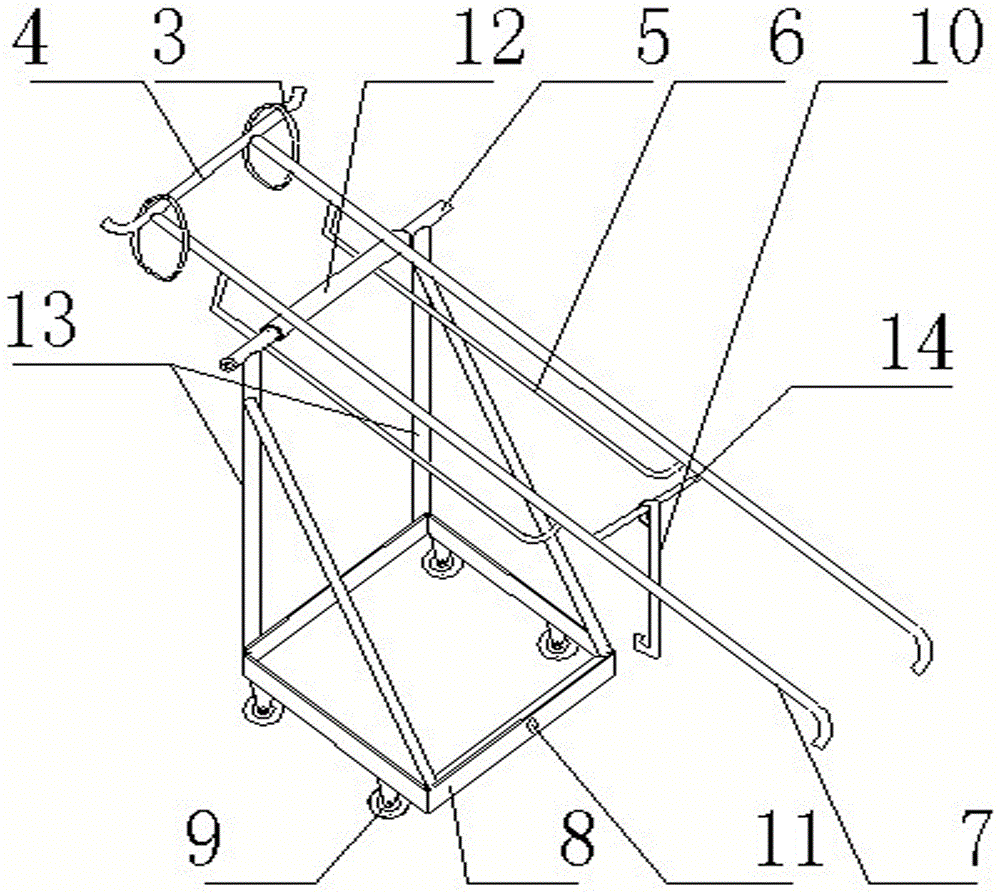

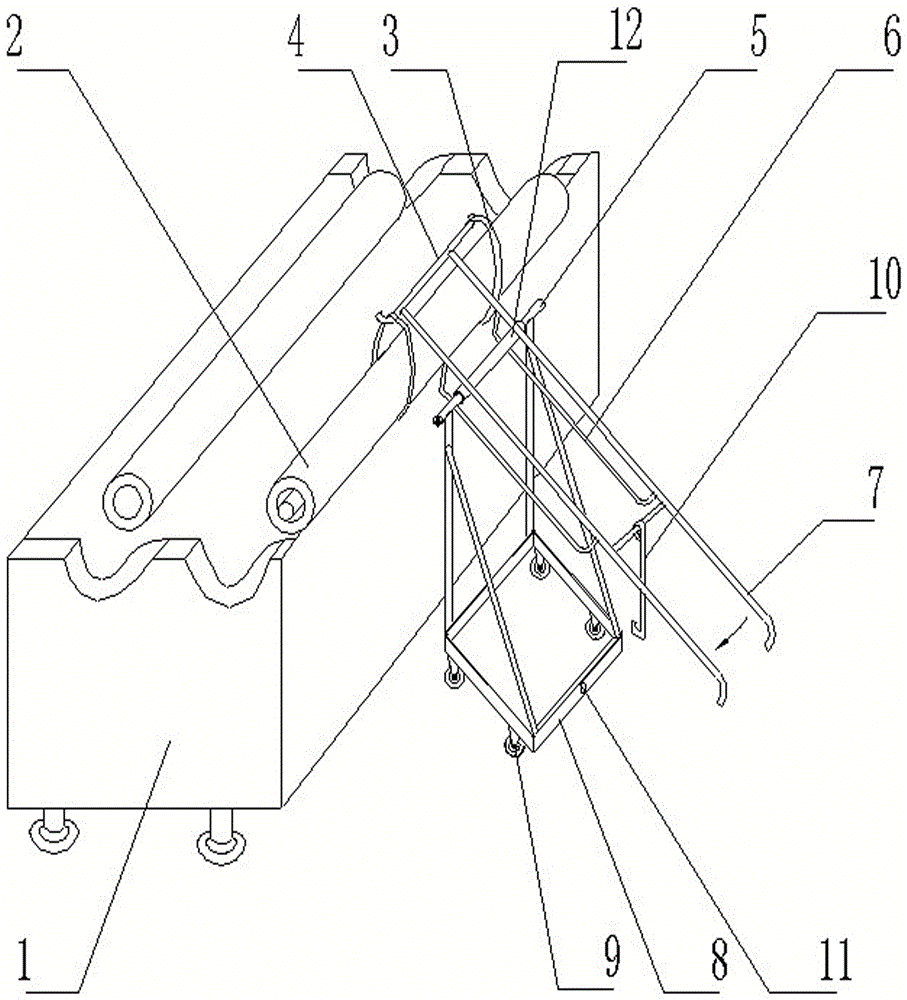

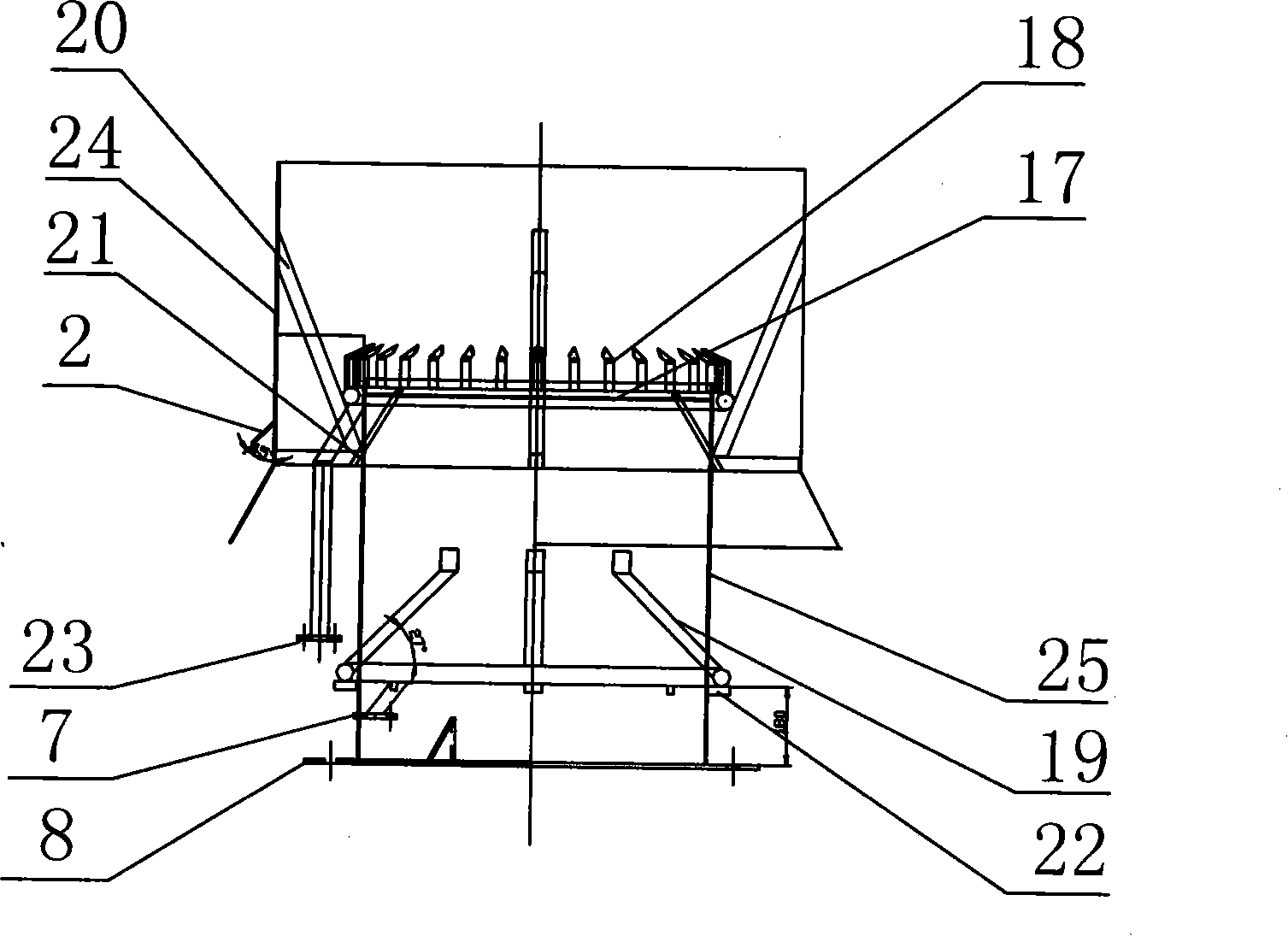

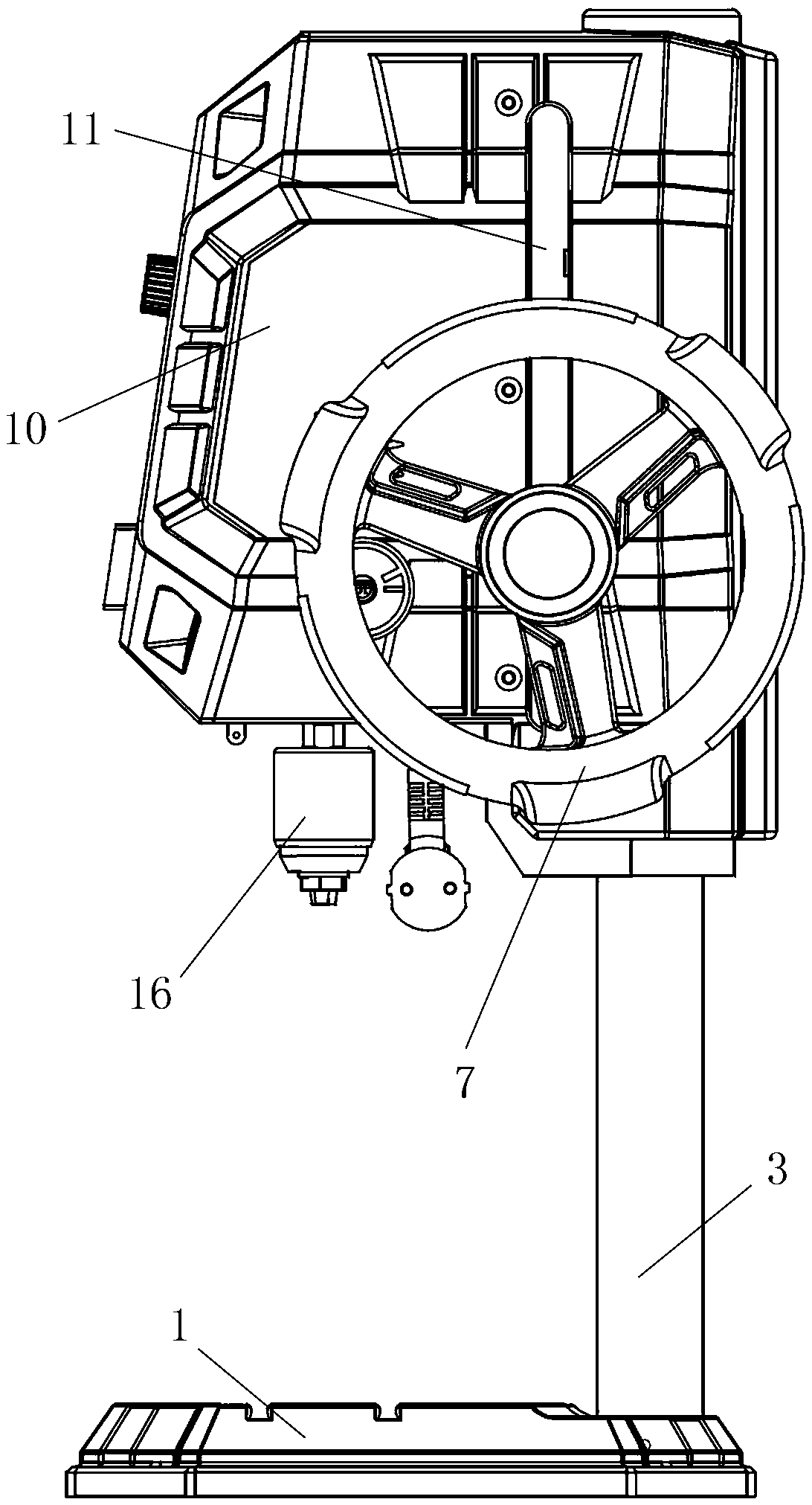

Versatile cable trench cover plate lifting vehicle of transformer substation

InactiveCN103130140AAvoid accidents involving personal injuriesEliminate hidden dangers in production safetyPortable liftingHandrailAutomotive engineering

The invention discloses a versatile cable trench cover plate lifting vehicle of a transformer substation. The versatile cable trench cover plate lifting vehicle comprises a load-bearing base plate (3), a directional wheel (1), a universal wheel (2), a brake unit (4), a lifting vehicle cross beam (10), a lifting vehicle body (20), a material hanging hook (11) and a handrail (8), wherein the lifting vehicle cross beam (10) is connected with a hydraulic jack (12), the lower end of the hydraulic jack (12) is provided with a hydraulic jack operating opening (7), the lifting vehicle body (20) is provided with an operating rod inserting ring (21), and a jack operating rod (6) is inserted inside the operating rod inserting ring (21). By the aid of the versatile cable trench cover plate lifting vehicle, hurting of persons due to crashing can be effectively avoided when workers move a cable trench cover plate manually, the hidden danger of safety production can be eliminated, and the versatile cable trench cover plate lifting vehicle is high in site practicability; and simultaneously, the usage of the device can effectively eliminate damage of the cable trench cover plate during frequent opening and closing, so that the tripping of high-tension lines of the transformer substation, which is caused by the fact that various small animals enter a cable tunnel through the damaged cover plate, can be prevented, and the safety and the reliability of power supply can be effectively guaranteed.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

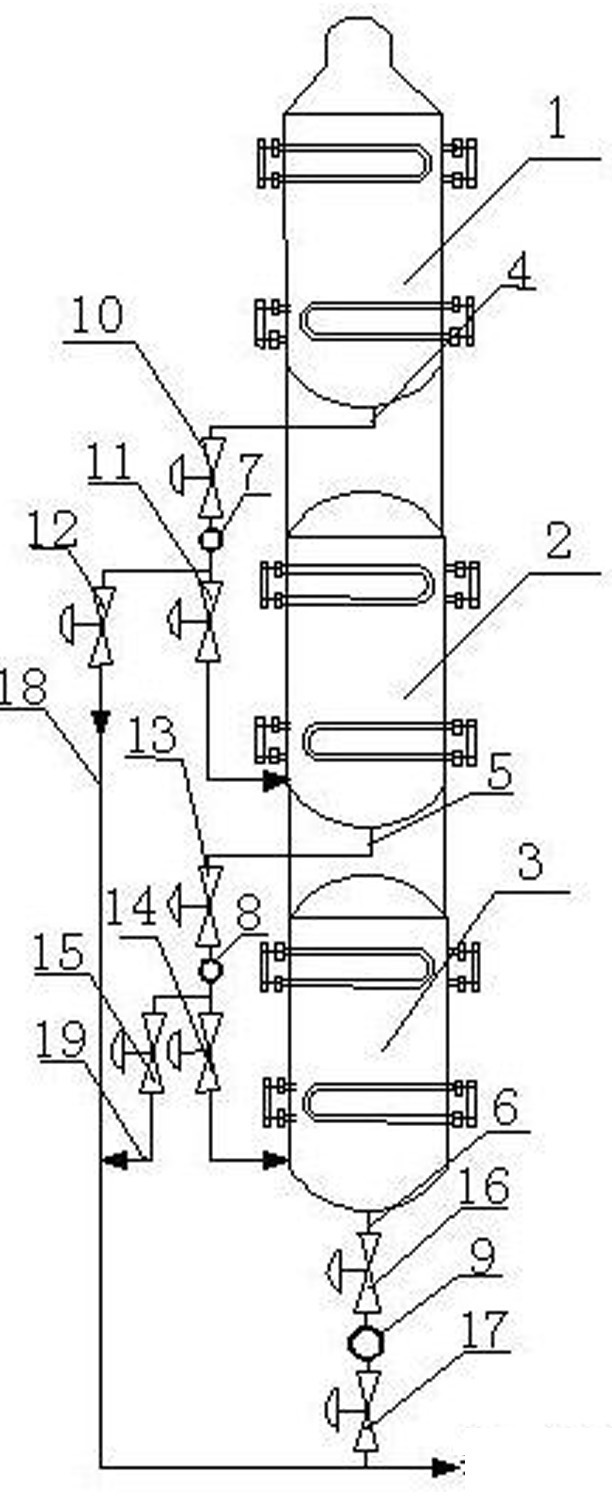

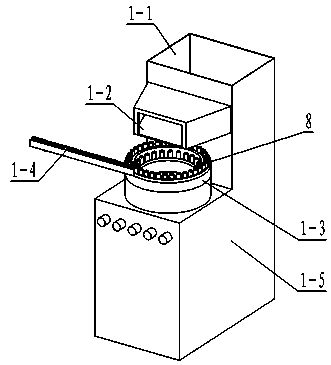

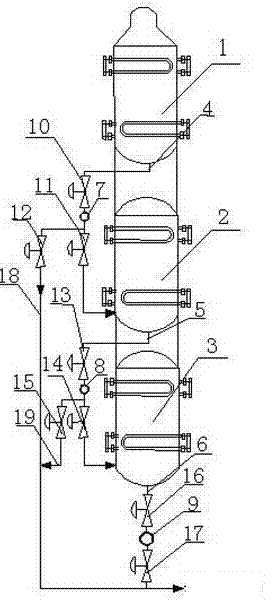

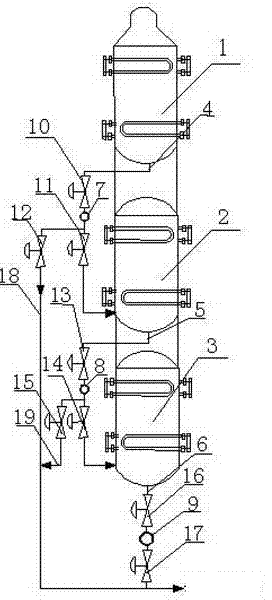

Method for reducing discharge of oxidization raffinate

ActiveCN101955161AReduce sewage lossReduce corrosionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphoric acidPulp and paper industry

The invention provides a method for reducing the discharge of oxidization raffinate, comprising the following steps of: discharging the oxidization raffinate in an upper tower of an oxidization tower to the bottom of a middle tower through an upper tower raffinate discharging pipe so that the oxidization raffinate is mixed with hydrogenation liquid and air entering the middle tower; discharging the oxidization raffinate in the middle tower to the bottom of a lower tower through a middle tower raffinate discharging pipe so that the oxidization raffinate is mixed with hydrogenation liquid and air entering the lower tower; and discharging out the oxidization raffinate at the bottom of the lower tower through a lower tower raffinate discharging pipe, adding water to dilute the oxidization raffinate and then sending to a sewage treatment system. The invention has the functions of improving the oxidization yield of the hydrogenation liquid, reducing the consumption of materials such as phosphoric acid and the like, reducing the product cost of the sewage treatment and improving the product quality, and is beneficial for the solving of the safety problem in the oxidization process when producing hydrogen peroxide by using an anthraquinone method.

Owner:湖南双阳高科化工有限公司

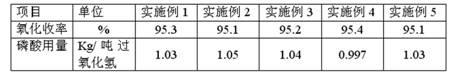

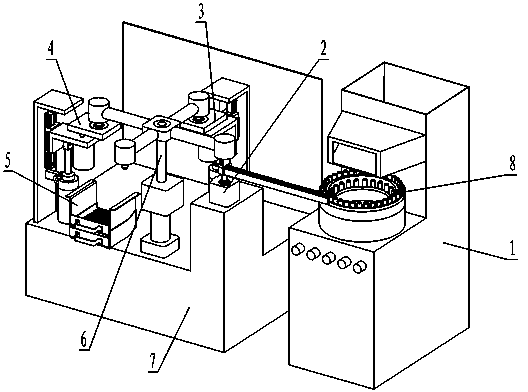

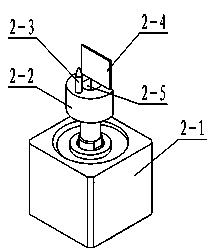

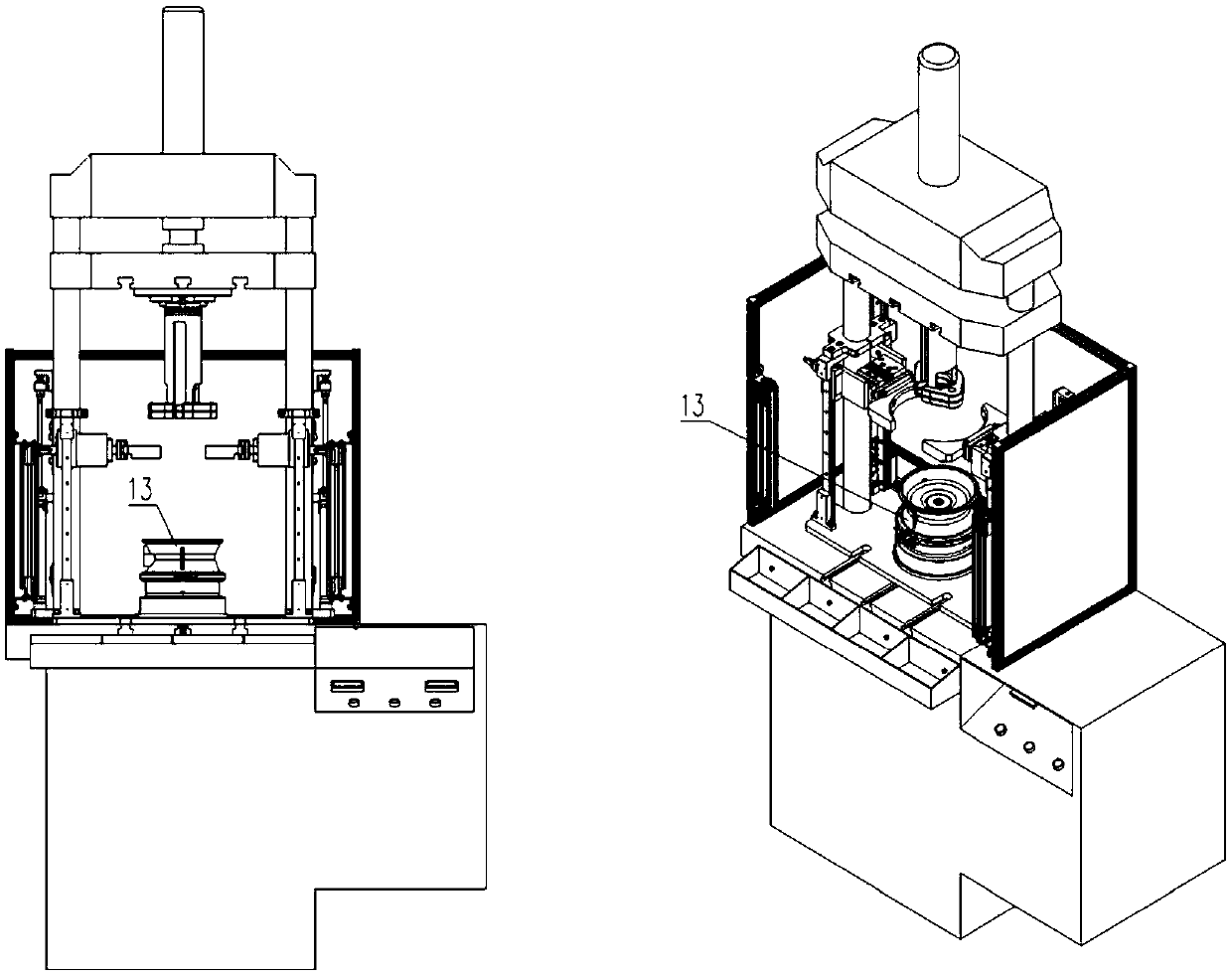

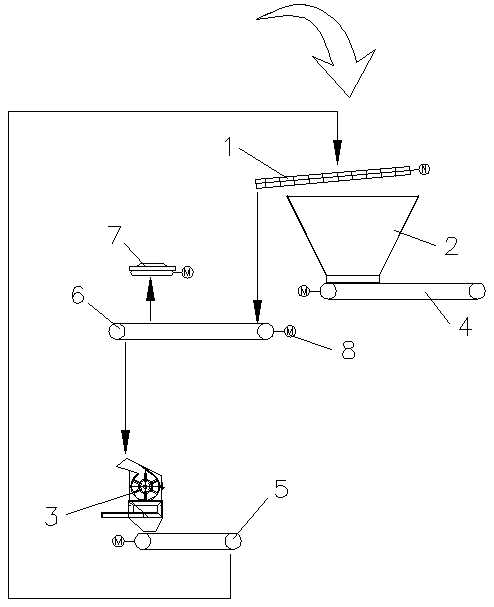

Grinding device for electrode cap of spot welding machine

ActiveCN103817573AAchieve grindingGuaranteed grinding qualityGrinding machinesGrinding feedersEngineeringSpot welding

The invention discloses a grinding device for an electrode cap of a spot welding machine, which is used for realizing automatic grinding operation of the electrode cap of the spot welding machine. The grinding device comprises an automatic loading mechanism, an electrode cap clamping mechanism, an automatic grinding mechanism, an automatic discharge mechanism, an electrode cap conveying mechanism and a base, wherein the tail end of the automatic loading mechanism is matched with the electrode cap clamping mechanism, the electrode cap clamping mechanism, the automatic grinding mechanism and the automatic discharge mechanism are arranged at the periphery of the base in sequence, the electrode cap conveying mechanism is arranged in the middle of the base, and the electrode cap is switched in different stations through rotating the electrode cap conveying mechanism. The grinding device has the advantages of high automation degree, long continuous working time, and capabilities of reducing the labor intensity of operators, improving the working efficiency, guaranteeing the grinding quality of the electrode cap and eliminating the hidden danger in aspect of safety production.

Owner:长城汽车股份有限公司平湖分公司

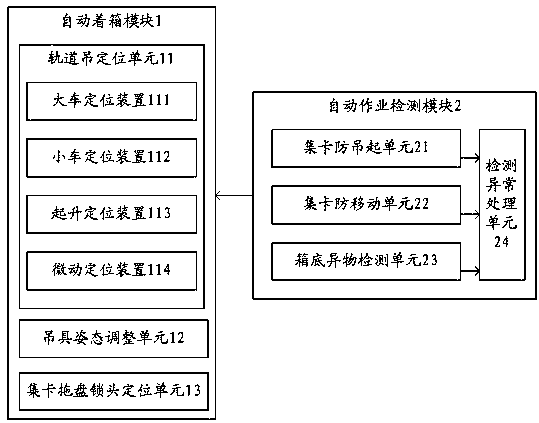

Automatic container terminal stock yard landside automatic operation system and control method thereof

InactiveCN109795953AIncrease success rateRealize fully automated operationSafety gearForeign matterEngineering

The invention discloses an automatic container terminal stock yard landside automatic operation system and a control method thereof. The automatic container terminal stock yard landside automatic operation system comprises an automatic loading box module composed of a track crane positioning unit, a crane attitude adjustment unit and a container truck towing disk lock head positioning unit and anautomatic operation detection module composed of a container truck anti-hoisting unit, a container truck anti-movement unit and a box bottom foreign body detection unit. The track crane positioning unit realizes the positioning of a target container by a track crane; the crane attitude adjustment unit acquires and controls the alignment between a crane and the target container based on target container information; the container truck towing disk lock head positioning unit is used for acquiring and positioning the position of a lock head based on an image of the container truck towing disk lock head; and the container truck anti-hoisting unit, the container truck anti-movement unit and the box bottom foreign body detection unit are used for analyzing whether container truck hoisting, container truck movement or anomalies exist in the box bottom or not during the automatic operation of the acquired image, and the automatic detection technology is used instead of manual detection to realize the full automatic operation of the track crane landside.

Owner:QINGDAO PORT INT +1

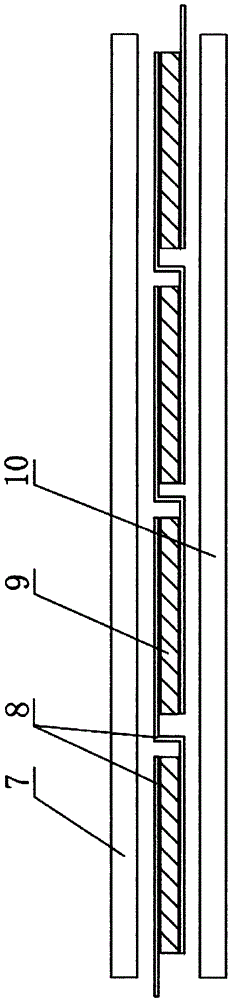

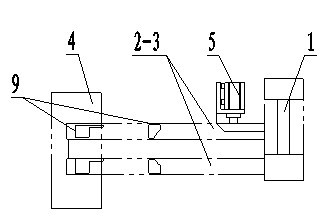

Measuring apparatus for current of busbar in aluminum cell, and measuring system and method for anode current

ActiveCN106283120ASolve the defect that the measurement needs to directly load the measurement device on the anode guide rodReduce generation processCurrent/voltage measurementElectrical resistance and conductanceElectrolysis

Embodiments in the invention provide a measuring apparatus for the current of a busbar in an aluminum cell, and a measuring system and method for anode current. The busbar current measuring apparatus is applied to measurement of busbar current of the aluminum cell, and is arranged on a busbar which is located at one side of an anode rod of the aluminum cell. The busbar current measuring apparatus comprises a snapping rack and a busbar current collector, wherein the snapping rack comprises a busbar voltage and temperature collector and a locking device respectively arranged at two ends of the snapping rack; the busbar current measuring apparatus is fixed on the busbar which is located at one side of the anode rod via the busbar voltage and temperature collector and the locking device; and the busbar current collector is arranged on the snapping rack and used for determining the resistance of the busbar according to busbar temperature fed back by the busbar voltage and temperature collector, acquiring the current of busbar located at one side of the anode rod according to the resistance of the busbar and equidistant voltage of the busbar fed back by the busbar voltage, and sending the current. An anode current measurement scheme provided in the embodiments in the invention overcomes the defect that a measuring apparatus needs to be directly loaded on the anode rod during measurement of anode current in the prior art.

Owner:BEIJING HUASUO TECH

Brick building process of bottom of steel ladle

InactiveCN102500753AReduce the times of ladle up and downLower ladle timesMelt-holding vesselsBrickMaterials science

The invention discloses a brick building process of the bottom of a steel ladle. The brick building process comprises the following steps of: dividing the bottom of the steel ladle into a plurality of square-shaped prebuilding block areas, manufacturing a corresponding mold according to the plurality of square-shaped prebuilding block areas, then manufacturing corresponding prebuilding blocks in the mold, and lifting the prebuilding blocks into the corresponding square-shaped prebuilding block areas after the prebuilding blocks are integrated. According to the brick building process, the prebuilding can be carried out on the bottom of the steel ladle in the prebuilding block mold, so that an operator can operate without needing to wait for cooling of the steel ladle, and the brick building process is very beneficial to reasonable arrangement of the building production tasks of the steel ladle. Simultaneously, according to the process, the building quality of the bottom of the steel ladle also can be improved, the labor intensity of workers is reduced and the potential safety hazard of the workers is reduced.

Owner:MCC BAOSTEEL TECH SERVICE

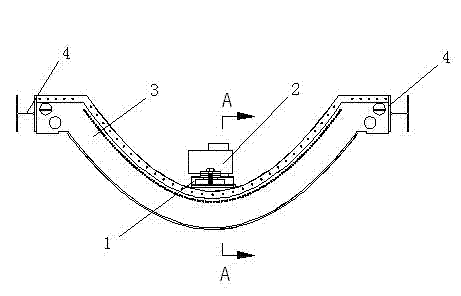

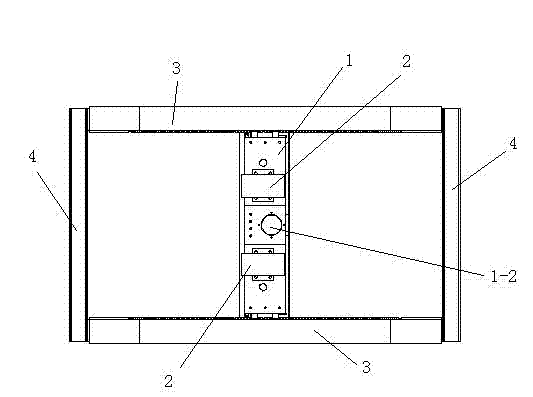

Vibration shaper of saddle plate

InactiveCN102229179AHigh dimensional accuracyReduce labor intensityCeramic shaping apparatusDrive wheelVehicle frame

The invention discloses a vibration shaper of a saddle plate. The vibration shaper comprises a walking vehicle, a vibrator, an upper baffle plate, a lower baffle plate, a pressing plate assembly, two arc-shaped track assemblies and two cross beams; the two cross beams are respectively fixed at two end parts of the arc-shaped track assemblies; the walking vehicle comprises a vehicle frame, a driving device, walking driving wheels and first guide wheels; each arc-shaped track assembly comprises a track box, arc-shaped synchronous strips and arc-shaped guide rails; the walking driving wheels at two sides of the walking vehicle are respectively meshed with the arc-shaped synchronous strips of the arc-shaped track assemblies; the first guide wheels at two sides of the walking vehicle are respectively matched with the arc-shaped guide rails of the two arc-shaped track assemblies in a rolling mode; the vibrator comprises a vibration motor, a vibration transmission piece and a vibration bottom plate; and the vibration bottom plate is positioned below the vehicle frame. The saddle plate manufactured by the vibration shaper provided by the invention has high size accuracy, and the manufacturing process is time-saving and labor-saving.

Owner:常州天普马鞍板有限公司

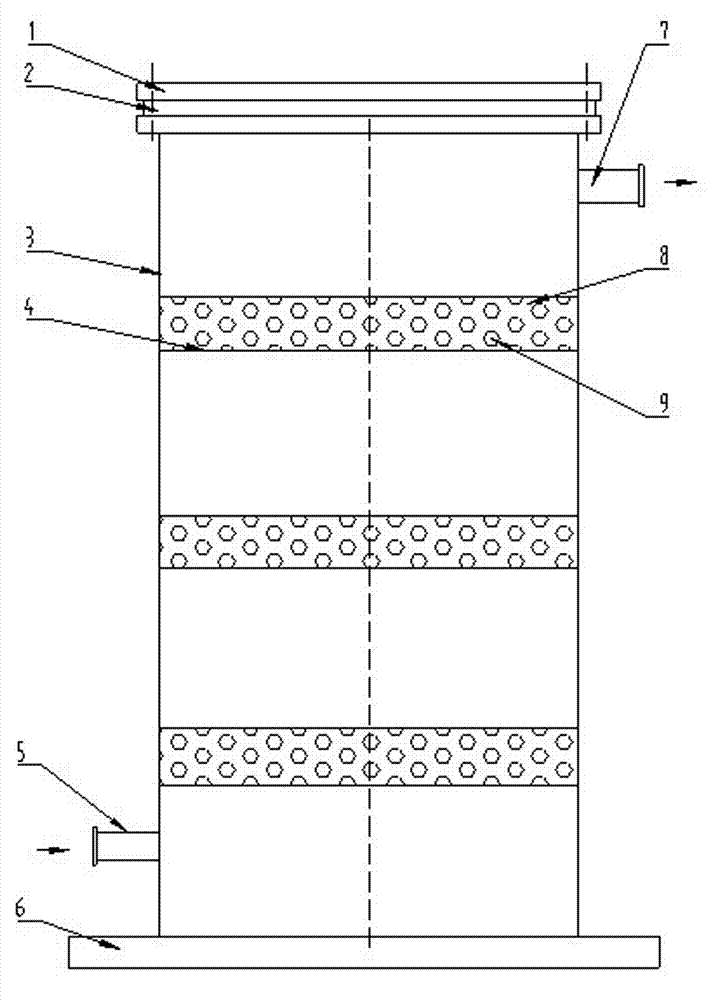

Automatic fuel gas tempering blocking device

InactiveCN103550878AEasy to disassembleEnsure production safetyFire rescueBoring toolsExhaust pipeFuel gas

The invention relates to an automatic fuel gas tempering blocking device. The automatic fuel gas tempering blocking device comprises a base and a barrel body, wherein the barrel body is fixed on the base; a seal cover and a gas exhaust pipe are arranged above the barrel body; a gas intake pipe is arranged below the barrel body; a plurality of baffle layers are uniformly distributed between the parts of the gas intake pipe and the gas exhaust pipe in the barrel body, and are respectively provided with irregular fillers; clearances are formed among the irregular fillers. The automatic fuel gas tempering blocking device provided by the invention is simple in structure and convenient to operate, and blocks fuel gas tempering automatically under accidental conditions so as to eradicate the safety hazard.

Owner:叶安生

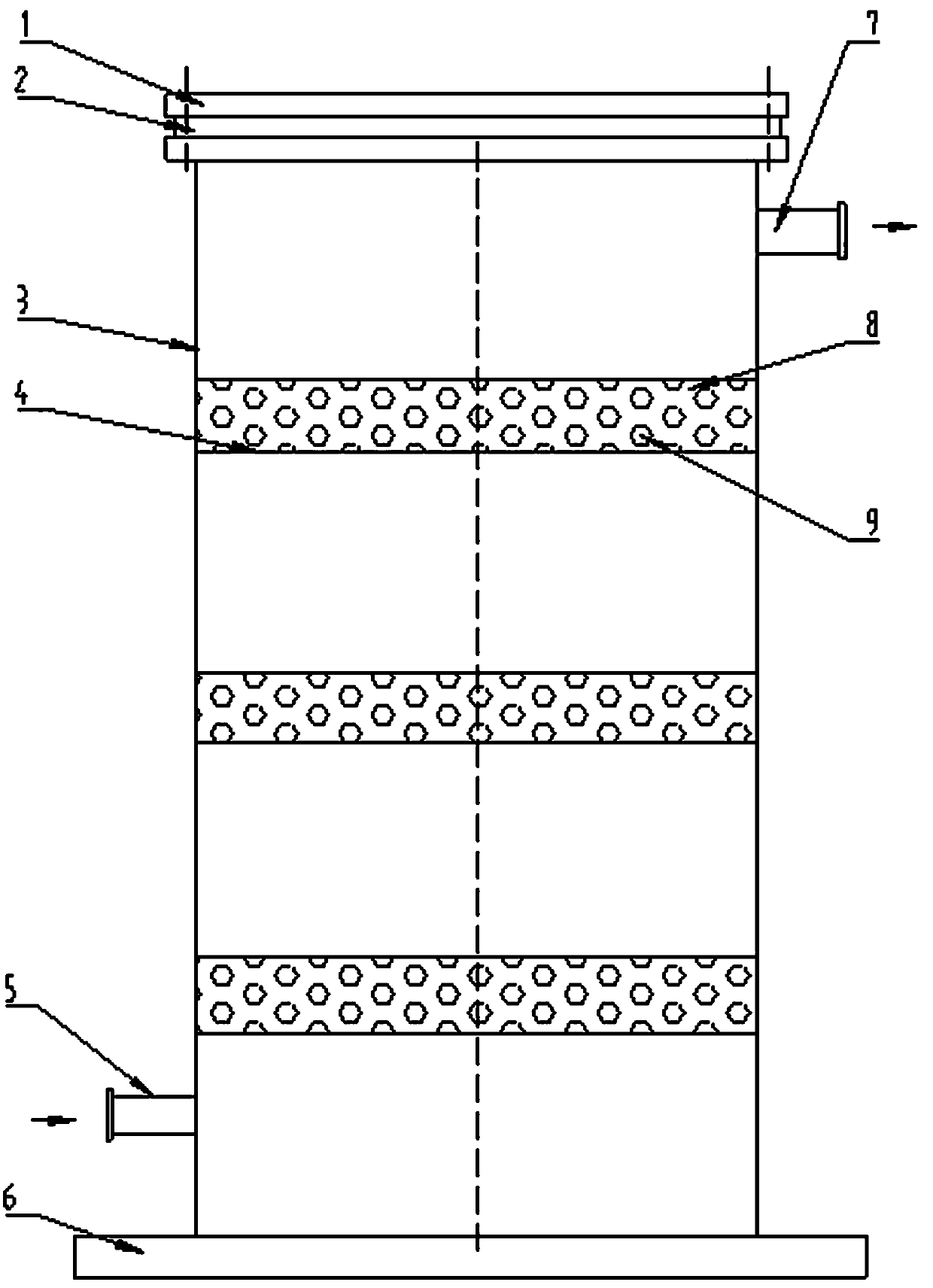

Cold drum or crude benzene section waste gas treatment device and intelligent pressure maintaining and oxygen control method

PendingCN109099312AReduce cost and process difficultyReduce the burden of pollution controlPipeline systemsBenzeneEngineering

The invention provides a cold drum or crude benzene section waste gas treatment device and a pressure maintaining oxygen control method. The cold drum or crude benzene section waste gas treatment device includes a controller, a gas compressor, a material storage tank, a collection and pressure storage tank, a treatment tank, pressure sensors and an oxygen concentration detector, the collection andpressure storage tank communicates with the material storage tank through a first pipeline, the first pipeline is provided with the gas compressor connected with the controller, the collection and pressure storage tank collects waste gas generated by the material storage tank for storage and reservation, the collection and pressure storage tank communicates with the material storage tank for pumping air from the material storage tank or pressure supplying and air returning through a second pipeline, the treatment tank communicates with the material storage tank through a third pipeline, the first, second and third pipelines are provided with valves connected with the controller correspondingly, the material storage tank and the collection and pressure storage tank are provided with the pressure sensors connected with the controller, the controller can intelligently control opening and closing of the valves and the gas compressor according to real-time collected data, and the purposesof intelligent pressure maintaining and oxygen control are achieved.

Owner:彭圭

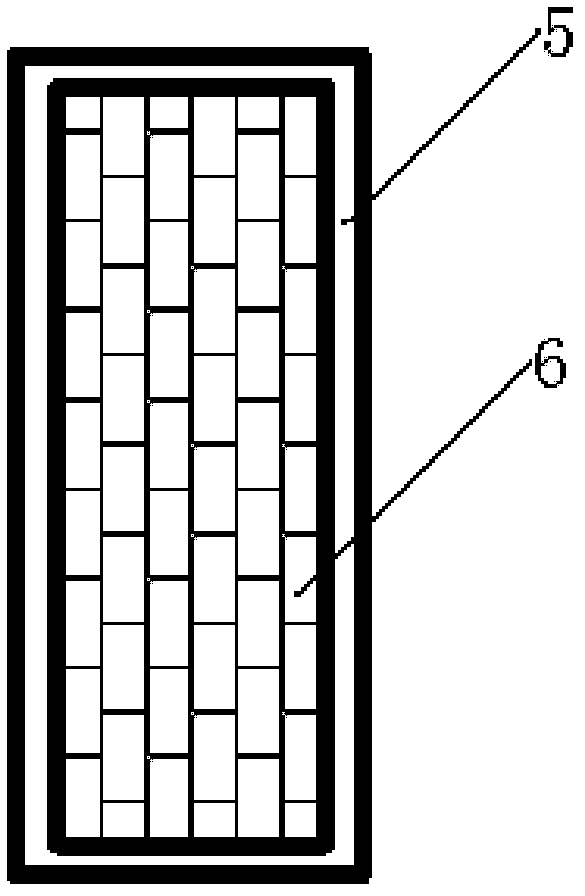

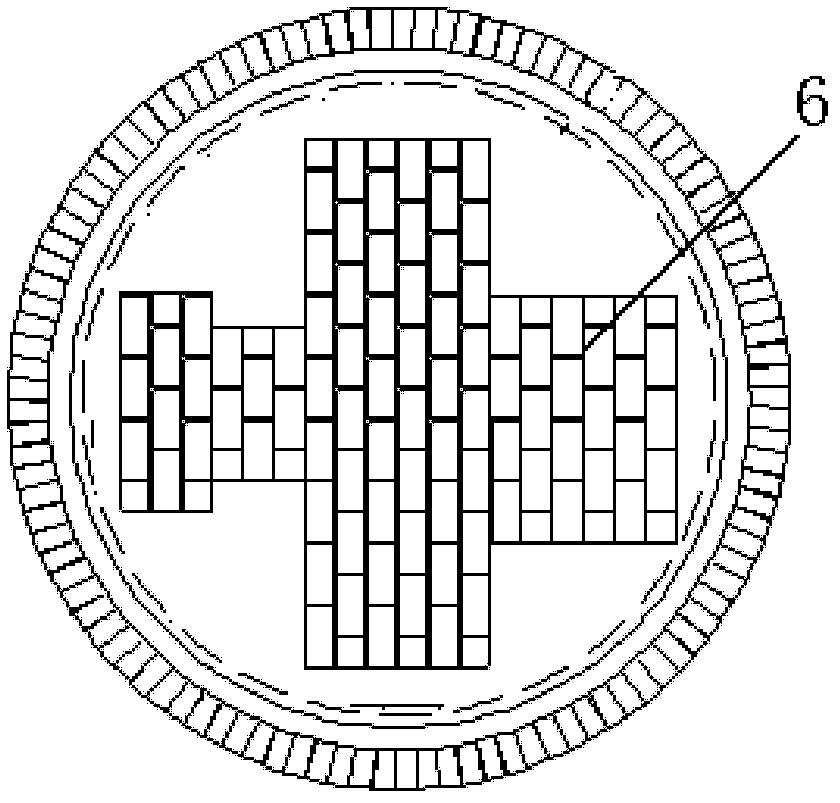

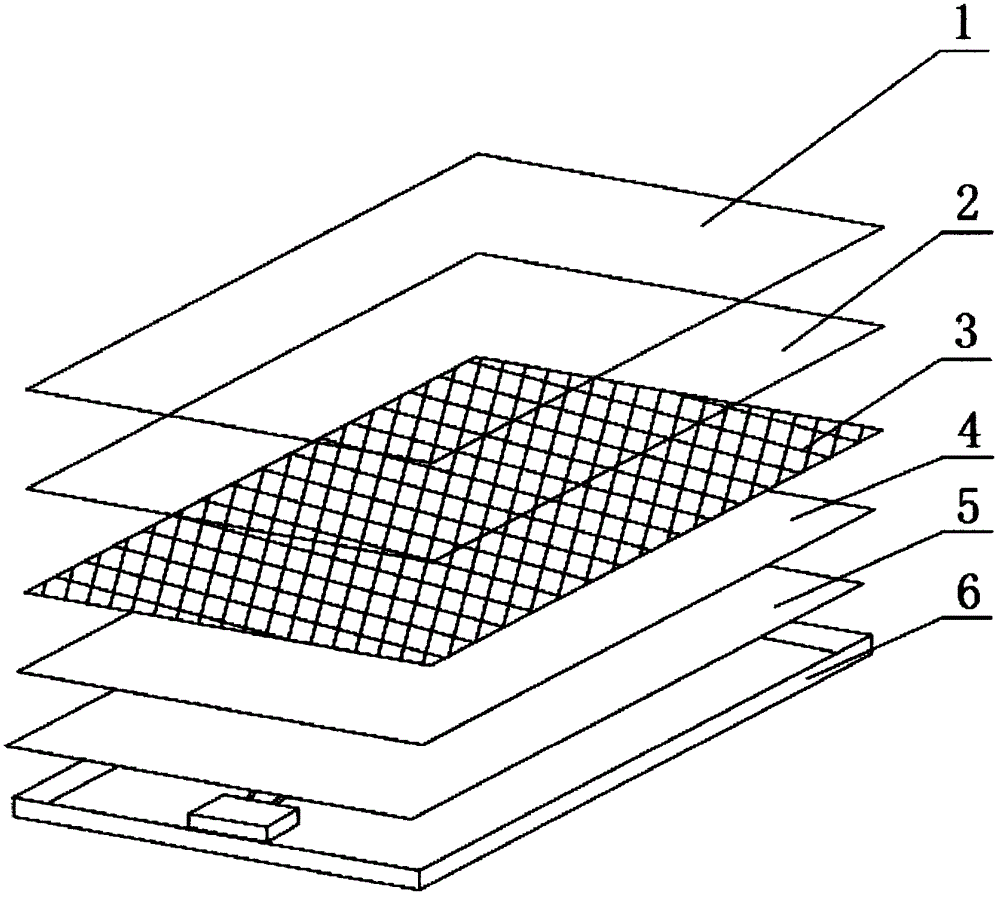

Welding-free, lamination-free, dismantable and recyclable photovoltaic assembly

InactiveCN106159011ASafe and easy to operateNo emissionsFinal product manufacturePhotovoltaic energy generationInterior spaceBackplane

The invention discloses a welding-free, lamination-free, dismantable and recyclable photovoltaic assembly. A plurality of battery sheets are connected in series through a plurality of double-sided conductive adhesive tapes so as to form a battery sheet string. The photovoltaic assembly is provided with a front-surface material, double-sided conductive adhesive tapes, a battery sheet string, double-sided conductive adhesive tapes and a back plate which are distributed from top to bottom sequentially; one surface of each double-sided conductive adhesive tape is in adhesive connection with the anode or cathode of the corresponding battery sheet, and the other surface of each double-sided conductive adhesive tape is in adhesive connection with the lower surface of the front-surface material or the upper surface of the back plate; and the adhesive connection between the double-sided conductive adhesive tapes and the front-surface material, adhesive connection between the double-sided conductive adhesive tapes and the battery sheets, and the adhesive connection between the double-sided conductive adhesive tapes and the back plate are dismantable adhesive connection. The manufacture process of the photovoltaic assembly includes the following steps that: the battery sheets are connected in series through the double-sided conductive adhesive tapes so as to form the battery sheet string; the battery sheet string is laid between the front-surface material and the back plate, and the battery sheet string, the front-surface material and the back plate can be boned together through the double-sided conductive adhesive tapes dismantably; and the edge of the photovoltaic assembly is sealed through insulating transparent adhesive tapes, and the interior space of the photovoltaic assembly is vacuumized during a sealing process. The photovoltaic assembly of the invention has the advantages of no need for welding, no need for lamination, energy-saving performance, environmental friendliness, high safety, operational easiness, recyclability and the like.

Owner:嘉兴市贝格电子有限公司

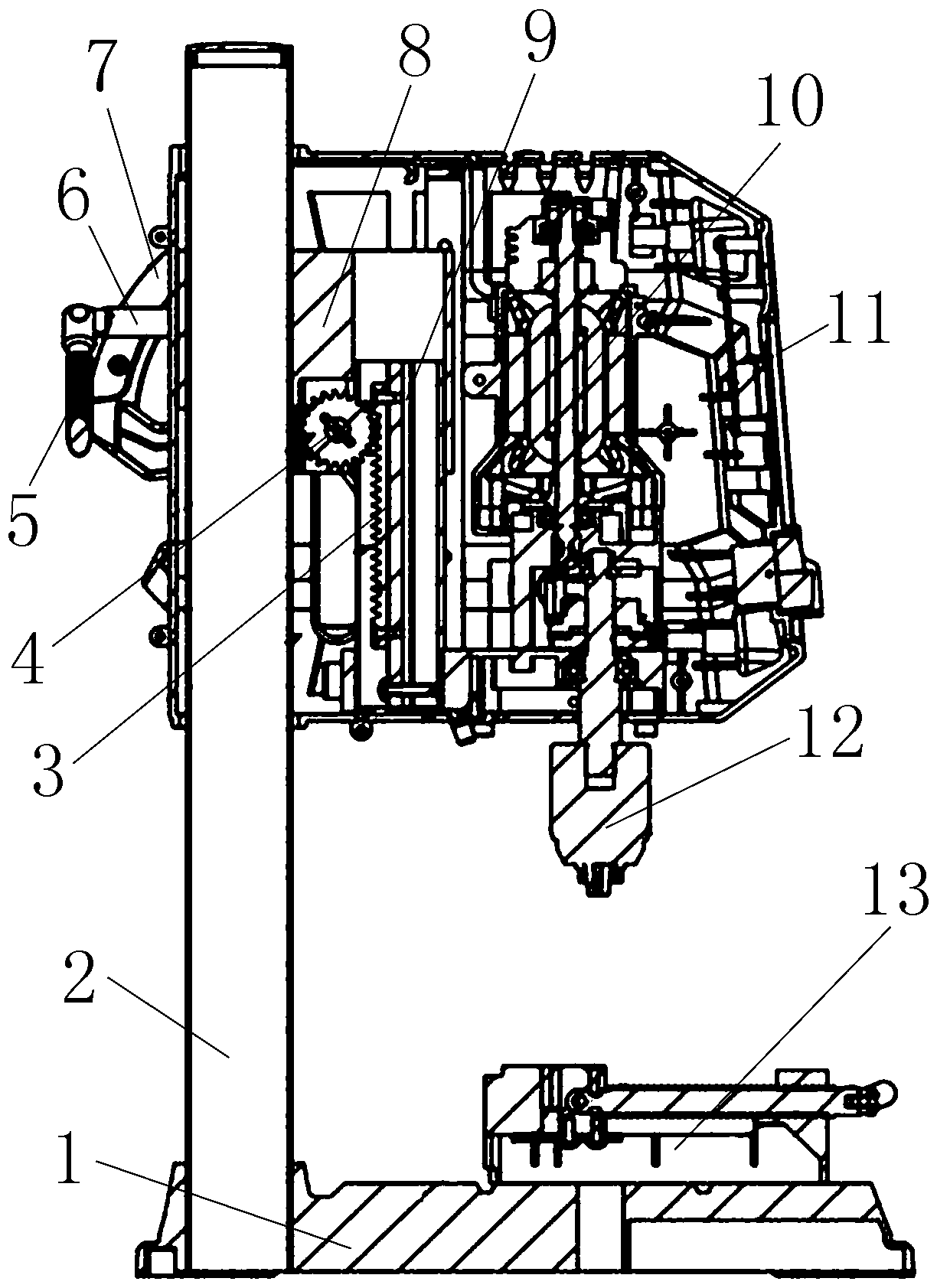

Loading and unloading device for engine cylinder block machining

ActiveCN102642148ASmall range of motionLower lifting heightMetal working apparatusLocking mechanismCylinder block

A loading and unloading device for engine cylinder block machining is used for solving the problem of loading and unloading of the engine cylinder block machining. The loading and unloading device comprises a cylinder block hoisting control unit, a cylinder block translation mechanism, a translation locking mechanism, a fixing support, a cylinder block hoisting mechanism and a base, wherein the cylinder block hoisting control unit is arranged at one end of the cylinder block translation mechanism, a workpiece is delivered to the cylinder block translation mechanism through a raceway, the cylinder block translation mechanism and the translation locking mechanism are installed in a matching mode, the cylinder block translation mechanism is installed on the fixing support, and the bottom surface of the fixing support and the cylinder block hoisting mechanism are installed in a matching mode, and the cylinder block hoisting mechanism is installed on the base. The loading and unloading device for the engine cylinder block machining has the advantages of being convenient to operate, accurate in positioning, safe and reliable, low in equipment cost investment, and small in occupied space; not only the accuracy of positioning of engine cylinder block workpieces is improved, the machining quality of the workpieces is guaranteed, but also cylinder block falling accidents are avoided, and the hidden danger in safety production aspects is eliminated.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

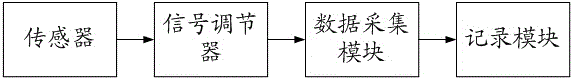

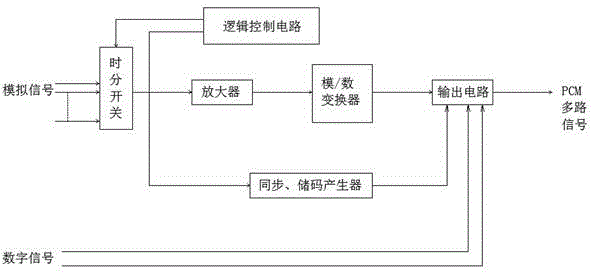

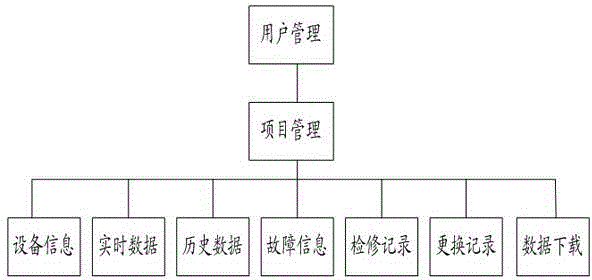

Recreation facility safety monitoring recorder and method

InactiveCN104808575AEfficient managementReliable dataProgramme control in sequence/logic controllersRecreationData information

The invention provides a recreation facility safety monitoring recorder and a method. The recorder comprises a data acquisition module used for acquiring the recreation facility data information and a recording module used for storing and recording the data information acquired by the data acquisition module. The recorder has the advantages that the recorder is a highly-scientific product adopting the PLC technology, sensor technology and human-computer interactive technology comprehensively, and the operation states of recreation facilities can be monitored, recorded and stored in real time; the recorder is mainly applied to the recreation facilities and is capable of recording and storing the safety operation states of recreation facilities in real time, the illegal operations can be detected scientifically, actual and reliable data can be provided to managers for effective facility management, accidents are prevented and suppressed effectively, safe production risks are eliminated, detailed data can be queried by the quality supervision department, and evidence-based quantitative management can be implemented by the management department in the system executing process.

Owner:SHENZHEN PLAYFUN DIGITAL TECH CO LTD

Loading and unloading device for engine cylinder block machining

ActiveCN102642148BSmall range of motionLower lifting heightMetal working apparatusLocking mechanismEngineering

A loading and unloading device for engine cylinder block machining is used for solving the problem of loading and unloading of the engine cylinder block machining. The loading and unloading device comprises a cylinder block hoisting control unit, a cylinder block translation mechanism, a translation locking mechanism, a fixing support, a cylinder block hoisting mechanism and a base, wherein the cylinder block hoisting control unit is arranged at one end of the cylinder block translation mechanism, a workpiece is delivered to the cylinder block translation mechanism through a raceway, the cylinder block translation mechanism and the translation locking mechanism are installed in a matching mode, the cylinder block translation mechanism is installed on the fixing support, and the bottom surface of the fixing support and the cylinder block hoisting mechanism are installed in a matching mode, and the cylinder block hoisting mechanism is installed on the base. The loading and unloading device for the engine cylinder block machining has the advantages of being convenient to operate, accurate in positioning, safe and reliable, low in equipment cost investment, and small in occupied space; not only the accuracy of positioning of engine cylinder block workpieces is improved, the machining quality of the workpieces is guaranteed, but also cylinder block falling accidents are avoided, and the hidden danger in safety production aspects is eliminated.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

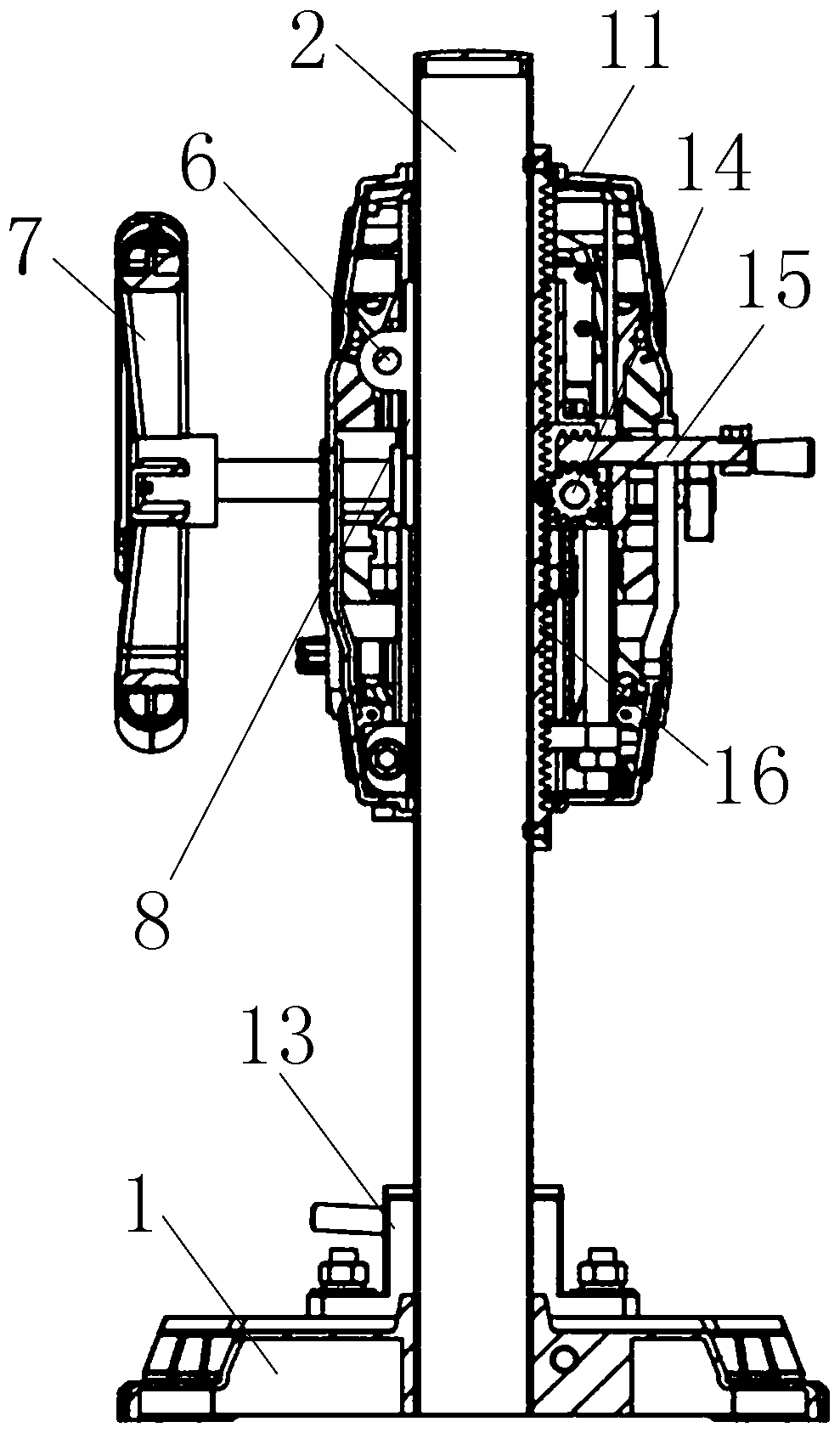

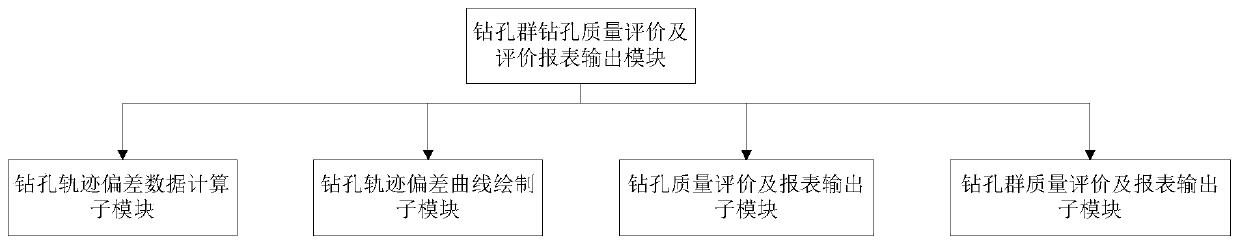

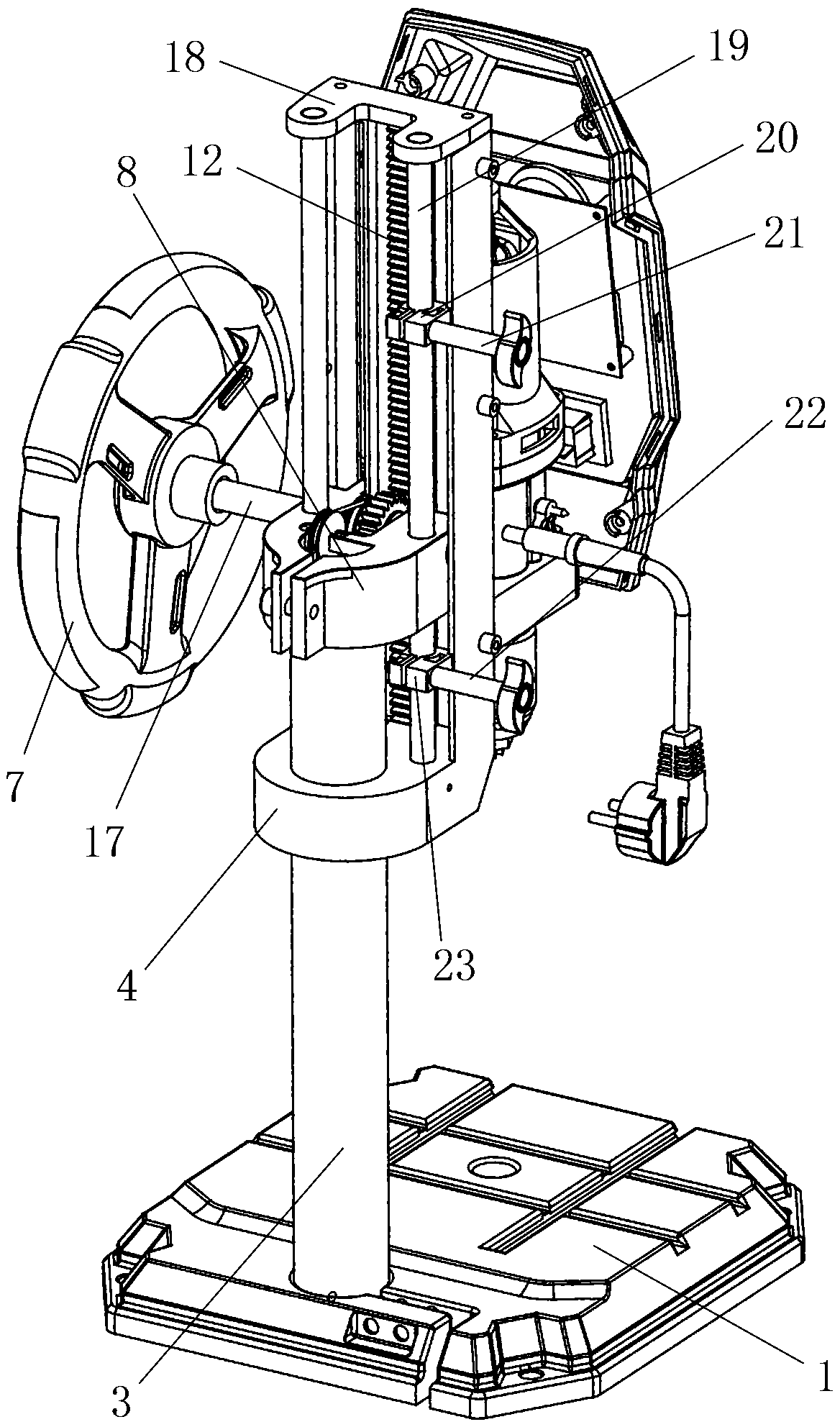

Vertical drilling machine

PendingCN110756850AEasy to operateEliminate hidden dangers in production safetyBoring/drilling machinesPilot holeGear wheel

The invention discloses a vertical drilling machine, which comprises a vertical column, a base, a driving device and a drill chuck. The vertical column is arranged on the base, a drilling lifting mechanism is further included and comprises a mechanism box, a lifting rack, a gear, a lifting shaft, a spring and a connecting seat, a through hole is formed in one side of the mechanism box and matchedwith the vertical column, a guiding hole is formed in the other side of the mechanism box and matched with the lifting shaft, and a notch is formed in the lower part of the guiding hole; the lifting shaft is of a semi-hollow structure, a long groove is formed in one side face of a solid part of the other half of the lifting shaft, and the lifting rack is arranged in the long groove; the gear meshes with the lifting rack and is arranged on a gear shaft, and a handwheel is arranged at one end of the gear shaft; a spring connecting plate is arranged at the upper end of the mechanism box and located near the upper end of the guiding hole, the upper end of the spring is connected to the spring connecting plate, and the lower end of the spring is connected to the inner lower part of the semi-hollow structure of the lifting shaft; and the connecting seat is arranged at the lower end of the lifting shaft, and the driving device is arranged on the connecting seat.

Owner:YANCHENG BAODING POWER TOOLS

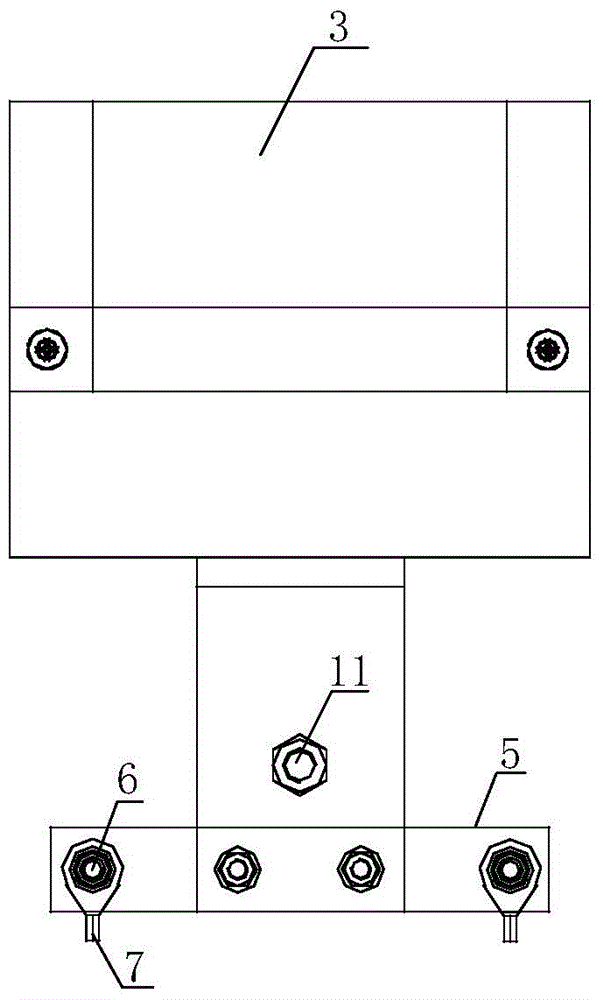

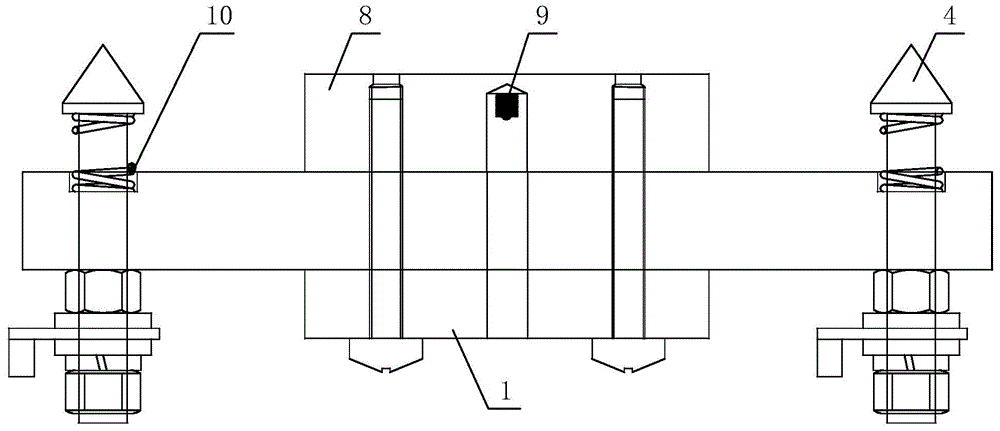

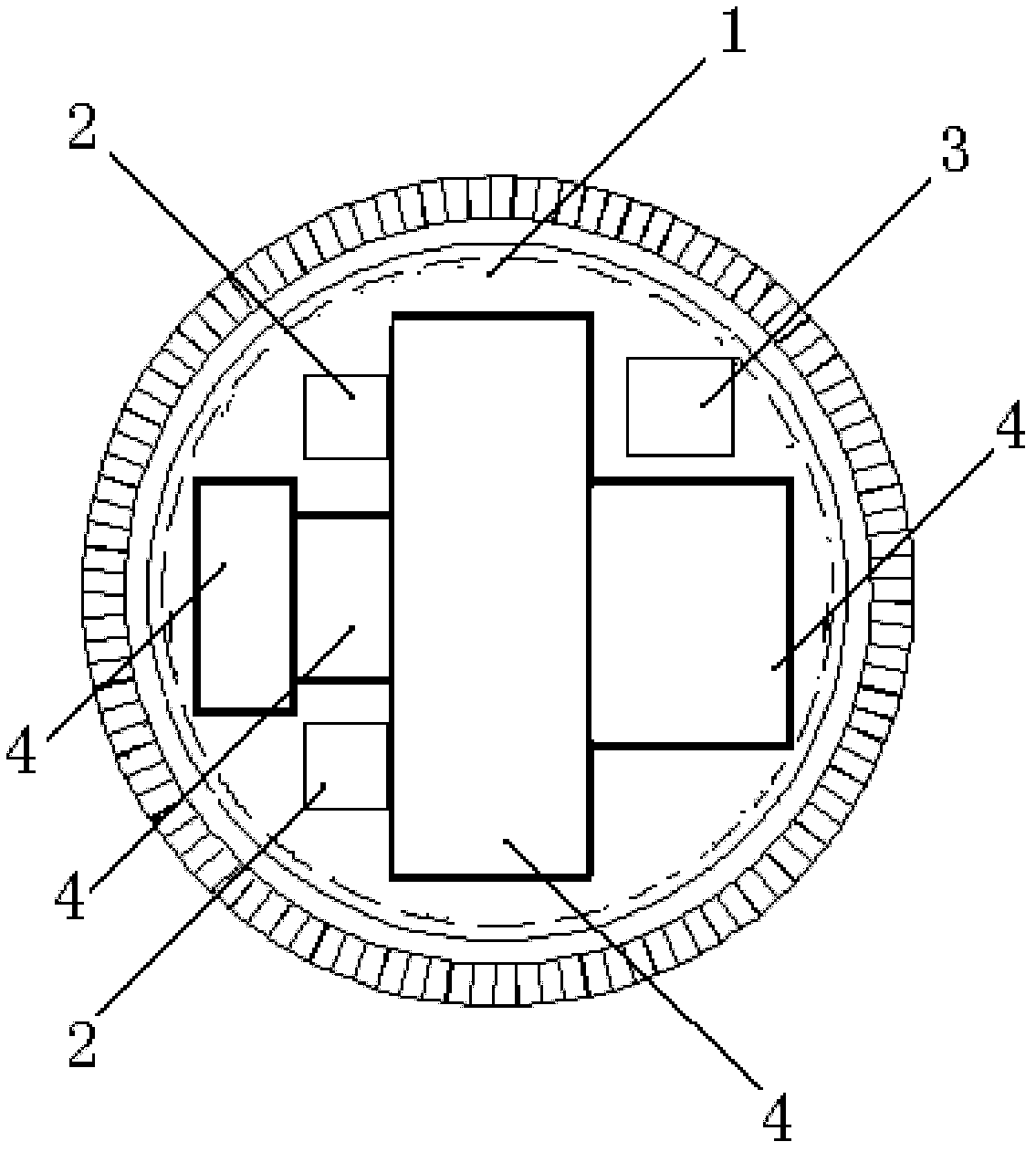

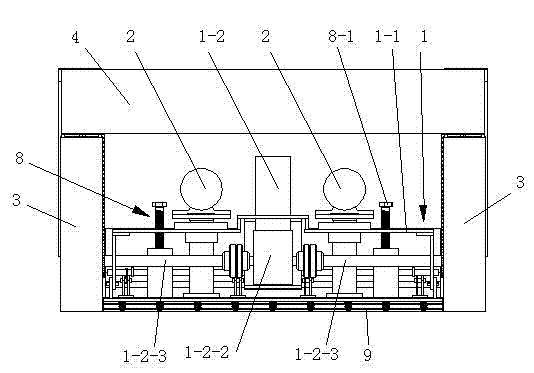

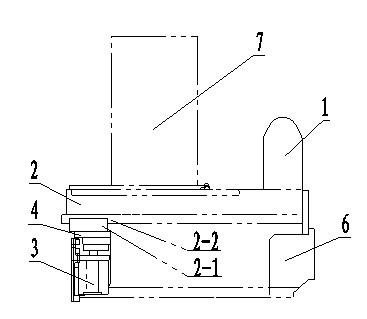

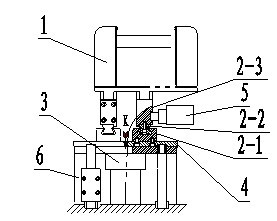

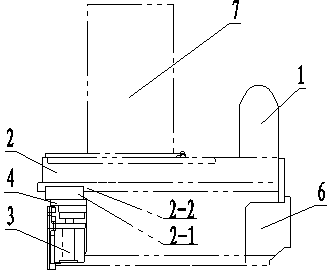

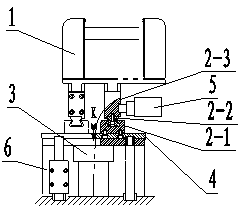

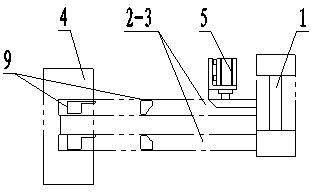

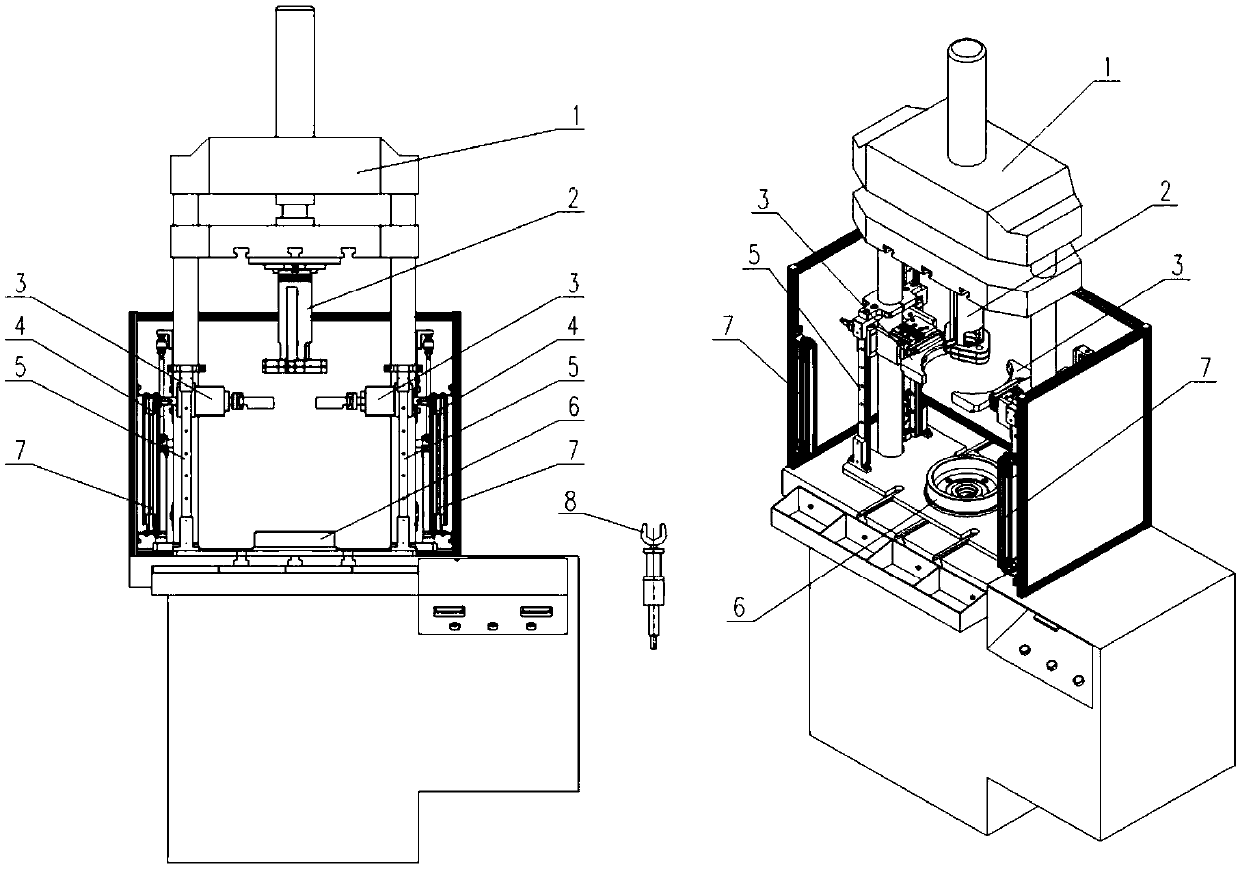

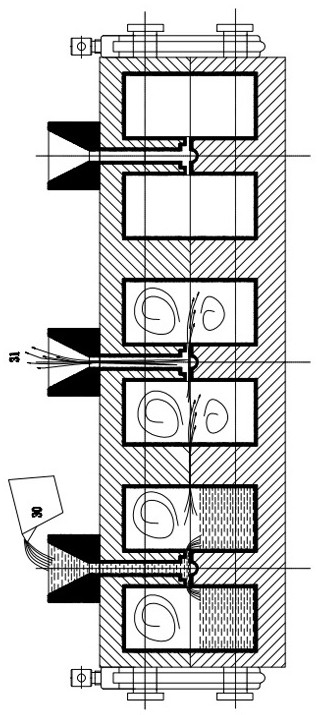

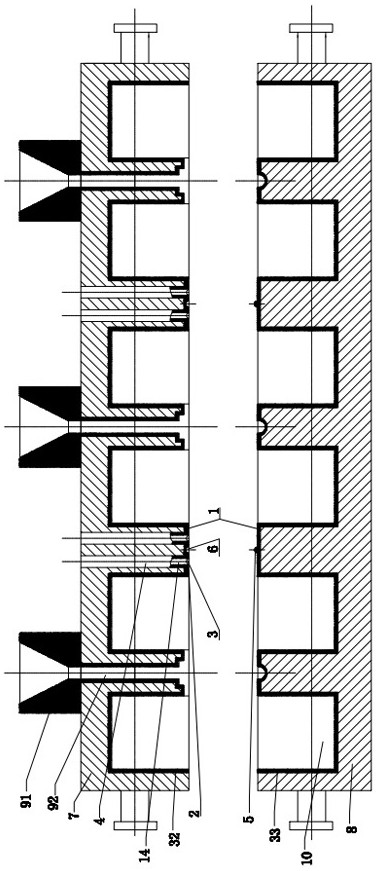

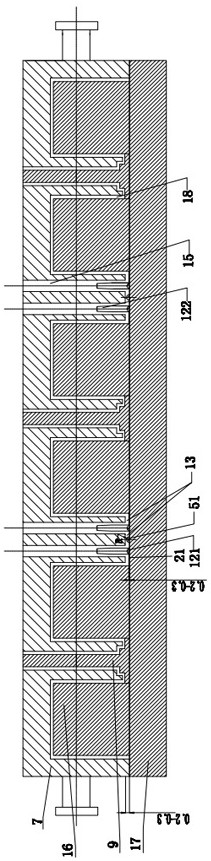

Assembling and holding mechanism for diaphragms of spring cylinders

PendingCN109551203AReduce the workload of manual pressingSimple structureMetal working apparatusControl systemPressure sensor

The invention relates to an assembling and holding mechanism for diaphragms of spring cylinders. The mechanism comprises a double-column hydraulic press (1) and a control system; an upper tool (2), apositioning seat (6) and a first proximity switch are mounted on the double-column hydraulic press (1); sliding rails (5) are mounted on front and back sides of two stand columns; the tops of the sliding rails (5) and the stand columns are sleeved with gas claw advancing components (3); second proximity switches are mounted on the gas claw advancing components (3); gas claw descending components (4) are mounted on left and right sides of the two stand columns; third proximity switches are mounted on the gas claw descending components (4); the gas claw advancing components (3) are movably connected with the gas claw descending components (4); and the first proximity switch, the second proximity switches and the third proximity switches are connected with the control system. According to themechanism, automatic press-fitting is realized through the press, the press-fitting position is controlled through a pressure sensor, the diaphragms are held and strengthened automatically through the gas claw advancing components, the consistency of the assembly quality of products is guaranteed, and the assembly efficiency is improved.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

Structure and method for preventing gas blow-by during pouring of multi-component casting mold for sand-lined iron mold casting

PendingCN114210929AIncrease productivityMeet the production process requirementsFoundry mouldsFoundry coresStructural engineeringProcess engineering

The invention relates to a structure and a method for preventing gas blow-by during sand-lined iron mold casting pouring, and belongs to the field of machinery. The device comprises an upper iron mold, a lower iron mold, anti-gas-channeling sand-coated layers, two independent exhaust systems and a gas partition system, the parting planes of the upper iron mold and the lower iron mold are each provided with one anti-gas-channeling sand-coated layer, and the two independent exhaust systems and the gas partition system are arranged on the anti-gas-channeling sand-coated layers. The exhaust system comprises an exhaust gap, an exhaust groove and a plurality of exhaust holes in the exhaust groove; the gas blocking system comprises a gas blocking and isolating convex strip and a gas blocking and isolating groove which are matched with each other, the gas blocking and isolating convex strip is arranged between the two exhaust systems of the two adjacent components of the lower iron mold, and the gas blocking and isolating groove is arranged between the two exhaust systems of the two adjacent components of the upper iron mold. The mold is simple and reasonable in structural design, safe and reliable, the production efficiency of the iron mold is improved, the production operation procedure is simplified, the cost is low, and the use requirement is met.

Owner:浙江省机电设计研究院有限公司

Lifting tool trolley for top roller of mercerizing machine

Owner:ANHUI HUAMAO TEXTILE

Gas backfire automatic blocking device

The invention relates to an automatic fuel gas tempering blocking device. The automatic fuel gas tempering blocking device comprises a base and a barrel body, wherein the barrel body is fixed on the base; a seal cover and a gas exhaust pipe are arranged above the barrel body; a gas intake pipe is arranged below the barrel body; a plurality of baffle layers are uniformly distributed between the parts of the gas intake pipe and the gas exhaust pipe in the barrel body, and are respectively provided with irregular fillers; clearances are formed among the irregular fillers. The automatic fuel gas tempering blocking device provided by the invention is simple in structure and convenient to operate, and blocks fuel gas tempering automatically under accidental conditions so as to eradicate the safety hazard.

Owner:叶安生

Screening, crushing and reusing device

PendingCN109500060AConsistent feeding sizeQuality assuranceSolid waste disposalSolid separationTreatment effectEngineering

The invention discloses a screening, crushing and reusing device which comprises a screen, a temporary storage hopper, a conveyor and a crusher. The screen is correspondingly arranged on the upper part of the temporary storage hopper; the conveyor comprises multiple first conveyors; the first conveyors are correspondingly arranged on a discharge hole of the temporary storage hopper; one end of thescreen is located on the outer part of the temporary storage hopper and is arranged corresponding to the crusher below; the screen is of an inclined structure; and the lower part of the inclined endof the screen is arranged corresponding to a feed inlet of the crusher. The screening, crushing and reusing device further comprises a second conveyor, wherein a discharge hole of the crusher is located on the upper part of one end of the second conveyor; and the other end of the second conveyor is arranged corresponding to the screen. According to the screening, crushing and reusing device provided by the invention, the feeding sizes of dangerous wastes are ensured to be consistent, so that a treatment effect and the quality of treated matters are ensured; due to automatic operation, the safety production hidden danger is eliminated; by adopting a loader or a grab crane or a lifting tipping bucket for feeding, the diversity in treatment is realized; and the production cost is reduced, andthe production efficiency is improved.

Owner:CHANGSHU JINCHENG MACHINE

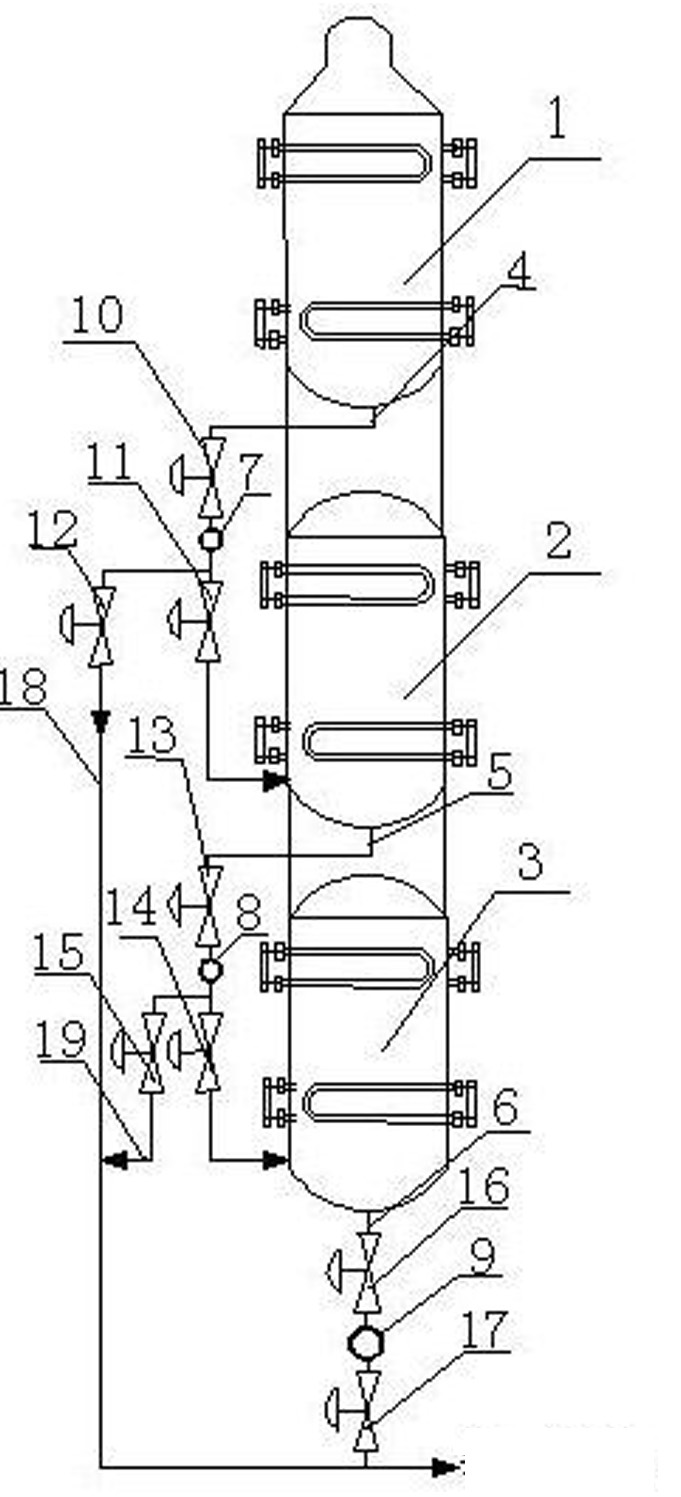

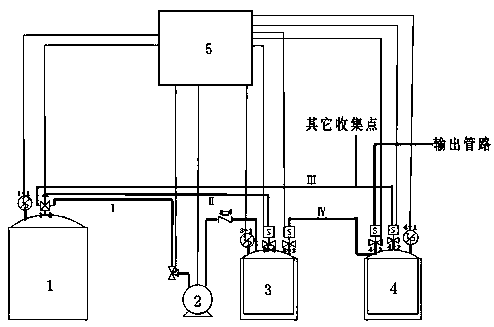

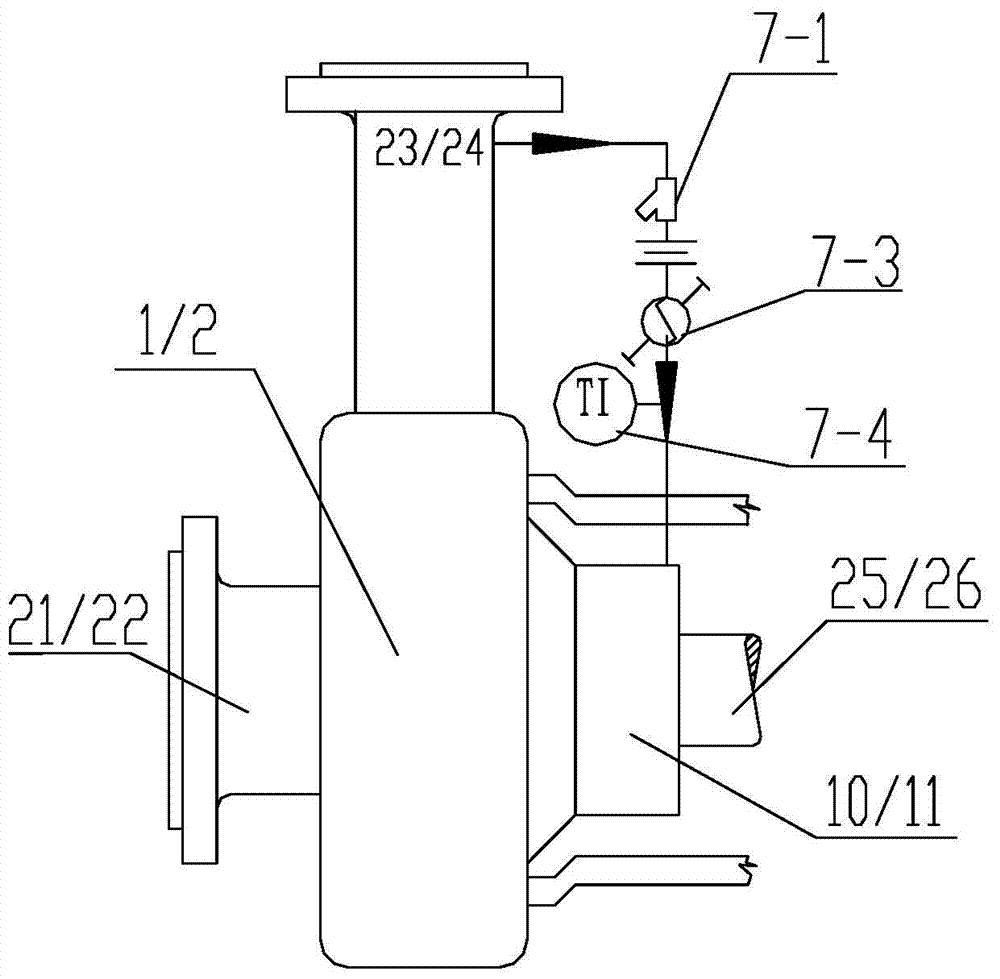

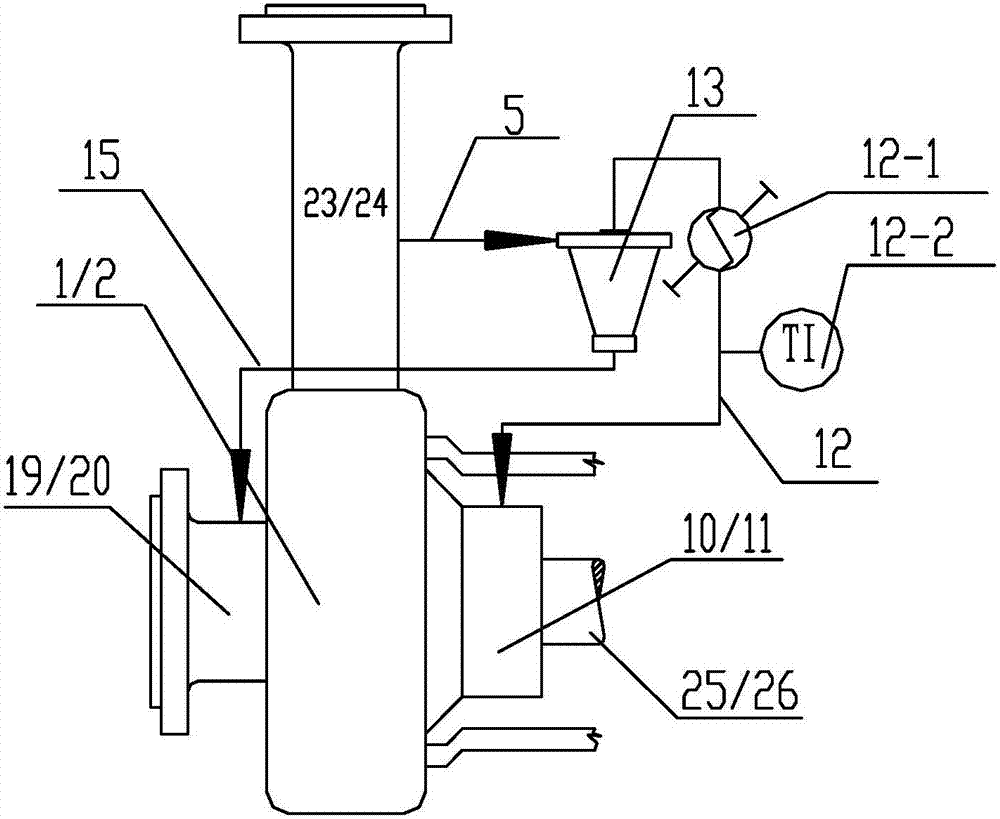

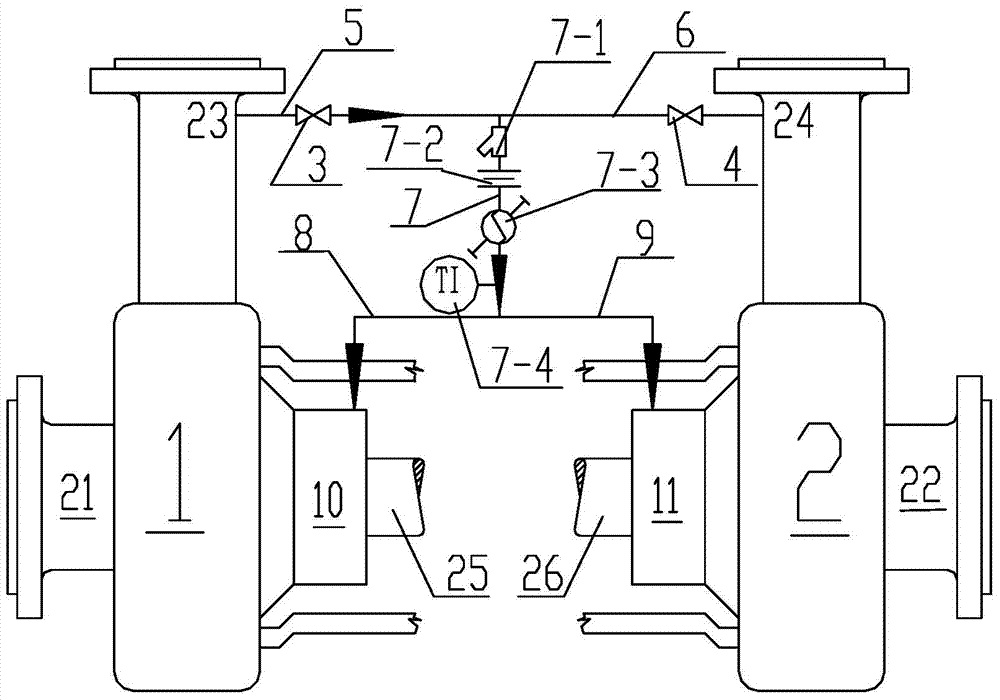

Shaft seal auxiliary flushing system for centrifugal pump and axial flow pump

ActiveCN104791306BThe fluid material parameters are the sameEliminate hidden dangers in production safetyPump componentsPumpsCentrifugal pumpAxial-flow pump

A shaft seal auxiliary flushing system for a centrifugal pump and for an axial-flow pump, provided with a main operating pump (1) and a standby pump (2) respectively provided with identical shaft seal flushing systems. The shaft seal flushing system of the main operating pump (1) and the shaft seal flushing system of the standby pump (2) are connected in parallel with each other to constitute common shaft seal flushing systems that are in communication with each other. The common shaft seal flushing systems are such that: a first water outlet pipe (5) connected onto a water outlet (23) of the main operating pump (1) and a first opening / closing valve (3) provided on the first water outlet pipe (5) and used for controlling outflow of flushing water, a second water outlet pipe (6) connected onto a water outlet (24) of the standby pump (2) and a second opening / closing valve (4) provided on the second water outlet pipe (6) and used for controlling outflow of flushing water, and a first fluid guide pipe (7) connected onto a water outlet of the first water outlet pipe (5) and that of the second water outlet pipe (6), where a water outlet of the first fluid guide pipe (7) is respectively connected to a flushing water inlet on a sealing gland (10) of the main operating pump (1) via a third water outlet pipe (8) and to a flushing water inlet on a sealing gland (11) of the standby pump (2) via a fourth water outlet pipe (9). Fluid material parameters in sealed cavities of the main and standby pumps can be kept identical at all times by means of the flushing system.

Owner:邢宇

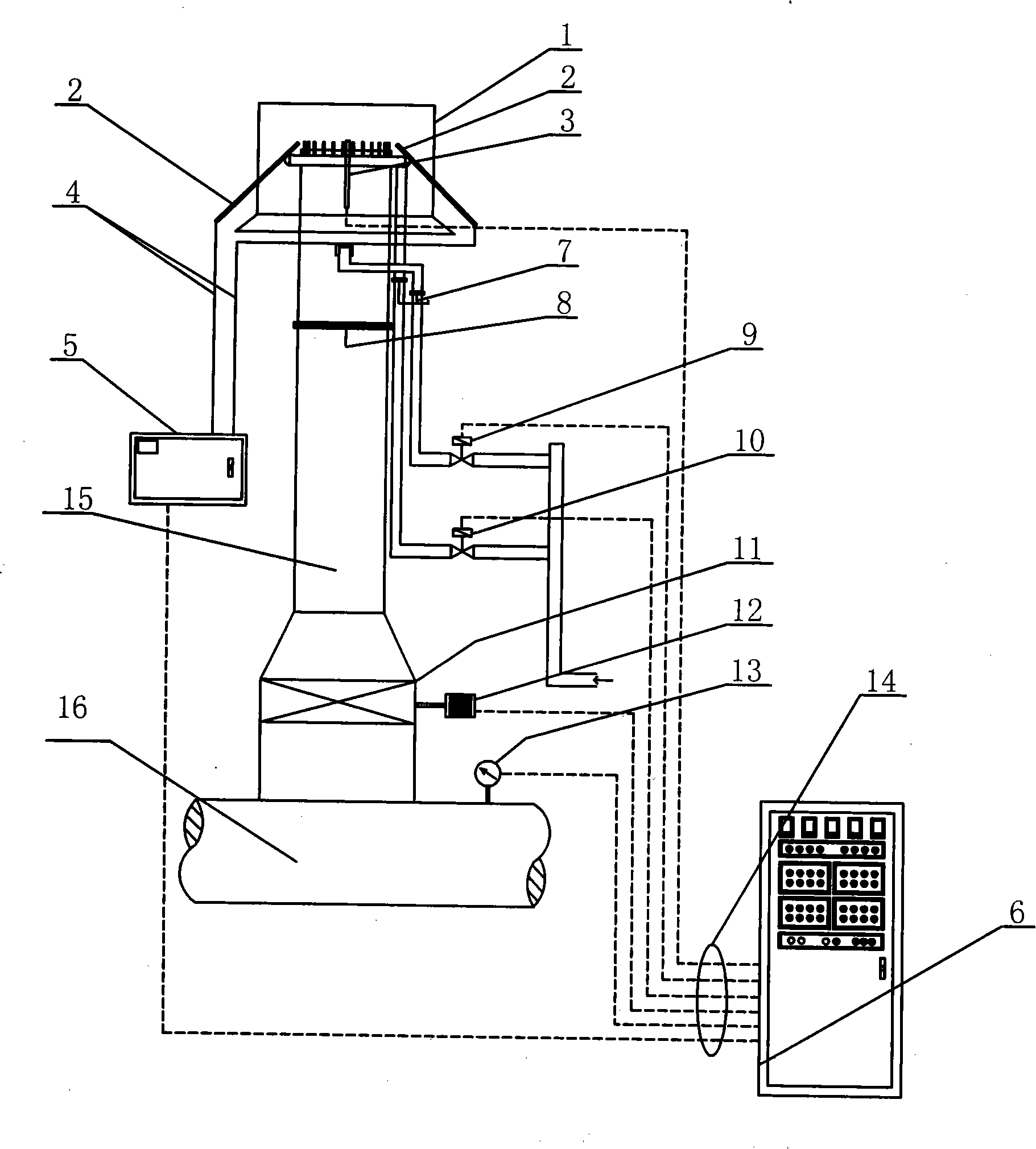

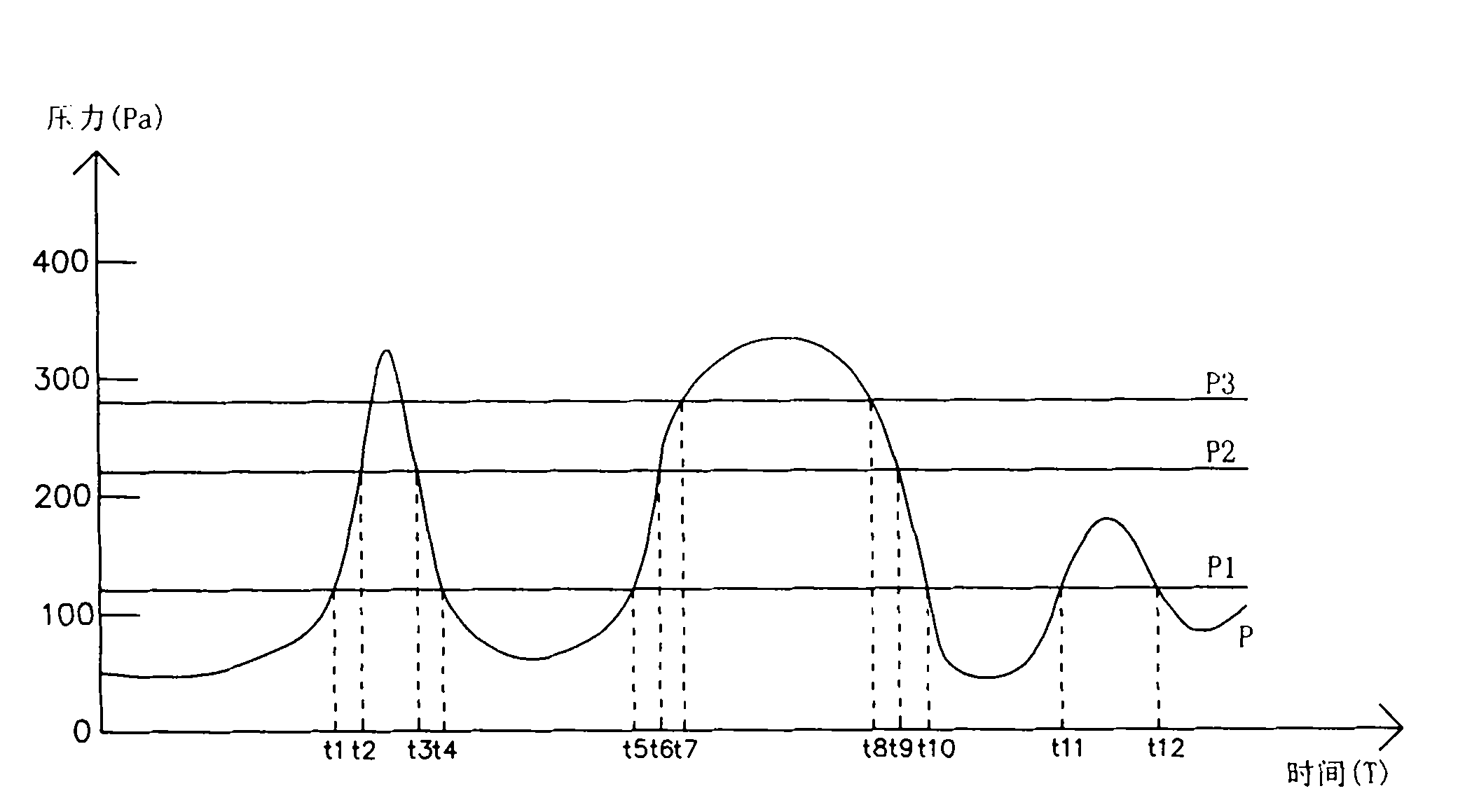

Application of anti-fluctuation diffusion curve in gas collecting pipe diffusion control device of coke furnace

ActiveCN101575524BImprove adaptabilityReduce pollutionCoke oven safety devicesProgramme control in sequence/logic controllersMathematical modelCoke oven

The invention relates to an application of anti-fluctuation diffusion curve in the gas collecting pipe diffusion control device of a coke furnace. In the method, with a PLC control cabinet as the core, the motion of the diffusion valve executing mechanism of the gas collecting pipe is controlled through the continuous monitoring of the pressure of the gas collecting pipe, the fluctuation of the pressure is maintained within a reliable range, and the sequential motions of the associated ignition device, steam fire collection and smoke abatement valve and steam fire extinguishing valve are controlled, so that the igniter, the diffusion executing mechanism, the fire collection valve and the fire extinguishing valve execute corresponding matching motions according to certain logic. By establishing a set of effective mathematical model for pressure and diffusion control, the optimal scheme can be achieved, so that raw gas can be burnt at the torch burner and the diffused gas can be burnt without smoke. The invention has the advantages of rapid response, safety and reliability, good burning effect and environmental protection.

Owner:ACRE AUTOMATION CO LTD MCC

Method for reducing discharge of oxidization raffinate

ActiveCN101955161BReduce sewage lossEmission reductionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesO-Phosphoric Acid

The invention provides a method for reducing the discharge of oxidization raffinate, comprising the following steps of: discharging the oxidization raffinate in an upper tower of an oxidization tower to the bottom of a middle tower through an upper tower raffinate discharging pipe so that the oxidization raffinate is mixed with hydrogenation liquid and air entering the middle tower; discharging the oxidization raffinate in the middle tower to the bottom of a lower tower through a middle tower raffinate discharging pipe so that the oxidization raffinate is mixed with hydrogenation liquid and air entering the lower tower; and discharging out the oxidization raffinate at the bottom of the lower tower through a lower tower raffinate discharging pipe, adding water to dilute the oxidization raffinate and then sending to a sewage treatment system. The invention has the functions of improving the oxidization yield of the hydrogenation liquid, reducing the consumption of materials such as phosphoric acid and the like, reducing the product cost of the sewage treatment and improving the product quality, and is beneficial for the solving of the safety problem in the oxidization process when producing hydrogen peroxide by using an anthraquinone method.

Owner:湖南双阳高科化工有限公司

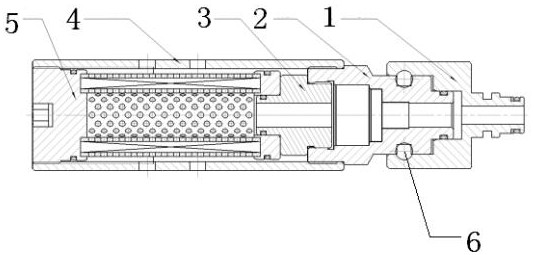

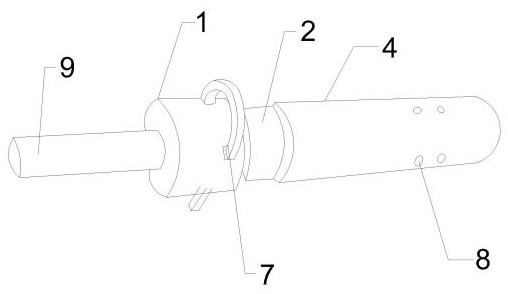

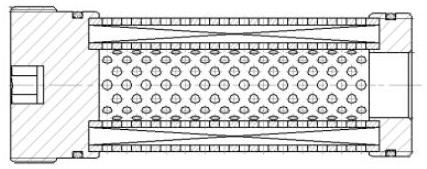

Mining electro-hydraulic control filter element cleaning device and cleaning method thereof

PendingCN113368576AReduce replacementSimple structureStationary filtering element filtersScrew threadIndustrial engineering

The invention provides a mining electro-hydraulic control filter element cleaning device and a method thereof. The device comprises an adapter, a connecting assembly, a shell and a filter element, the filter element is fixed in the shell in a matched mode, one end of the adapter is fixedly connected with the shell through the connecting assembly, and the other end of the adapter is connected with a mining filter element flow testing table; the connecting assembly comprises a connector, a connecting sleeve and a fixing piece, threads are arranged on the side faces of the two ends of the connecting sleeve, one end of the connecting sleeve is in threaded connection with the filter element, the other end of the connecting sleeve is in threaded connection with the connector, one end of the connector is concaved inwards to form a clamping groove, internal threads are arranged in the clamping groove to be connected with the connecting sleeve, and the outer side face of the connector is in threaded connection with the shell. Two mounting holes are correspondingly formed in the other end of the connector and the adapter, the fixing piece penetrates through the mounting holes to fixedly connect the connector and the adapter, and a plurality of drainage holes are formed in the outer side of the shell. The device is simple in overall structure and easy to prepare and operate, equipment is fully utilized, benefits are maximized, and cost is saved.

Owner:西安重装澄合煤矿机械有限公司

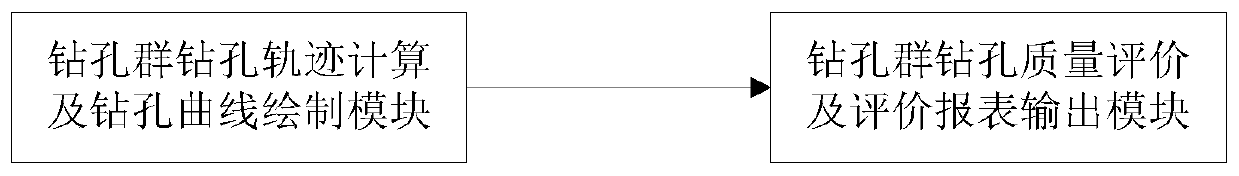

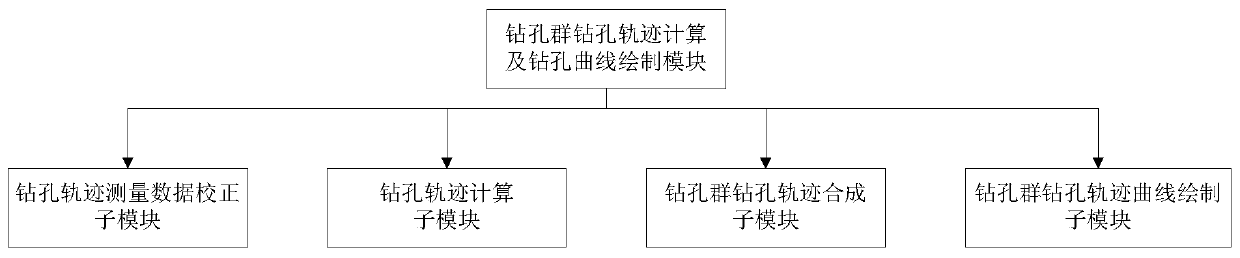

A method and device for evaluating the quality of boreholes in a group of boreholes in a coal mine

The invention belongs to the technical field of drilling and relates to a drilled hole group drilling quality evaluation method and device, in particular to a coal mine underground drilled hole group drilling quality evaluation method and device. The device comprises a drilled hole group drilling track calculating and drilling curve drawing module and a drilled hole group drilling quality evaluating and evaluating report outputting module, the drilled hole group drilling track calculating and drilling curve drawing module is used for calculating drilled hole group drilling tracks, drawing two-dimensional curve and three-dimensional curve of the drilling tracks and visually displaying distribution of drilled hole group under a coal mine, the drilled hole group drilling quality evaluating and evaluating report outputting module is used for evaluating drilling track quality, outputting evaluating data and result in a report form and outputting distribution of blind areas and dangerous sources for the convenience of technical personnel to check drilling completion circumstance, timely find potential safety hazards and deal with the potential safety hazards.

Owner:BEIJING HEKANG SCI & TECH DEV

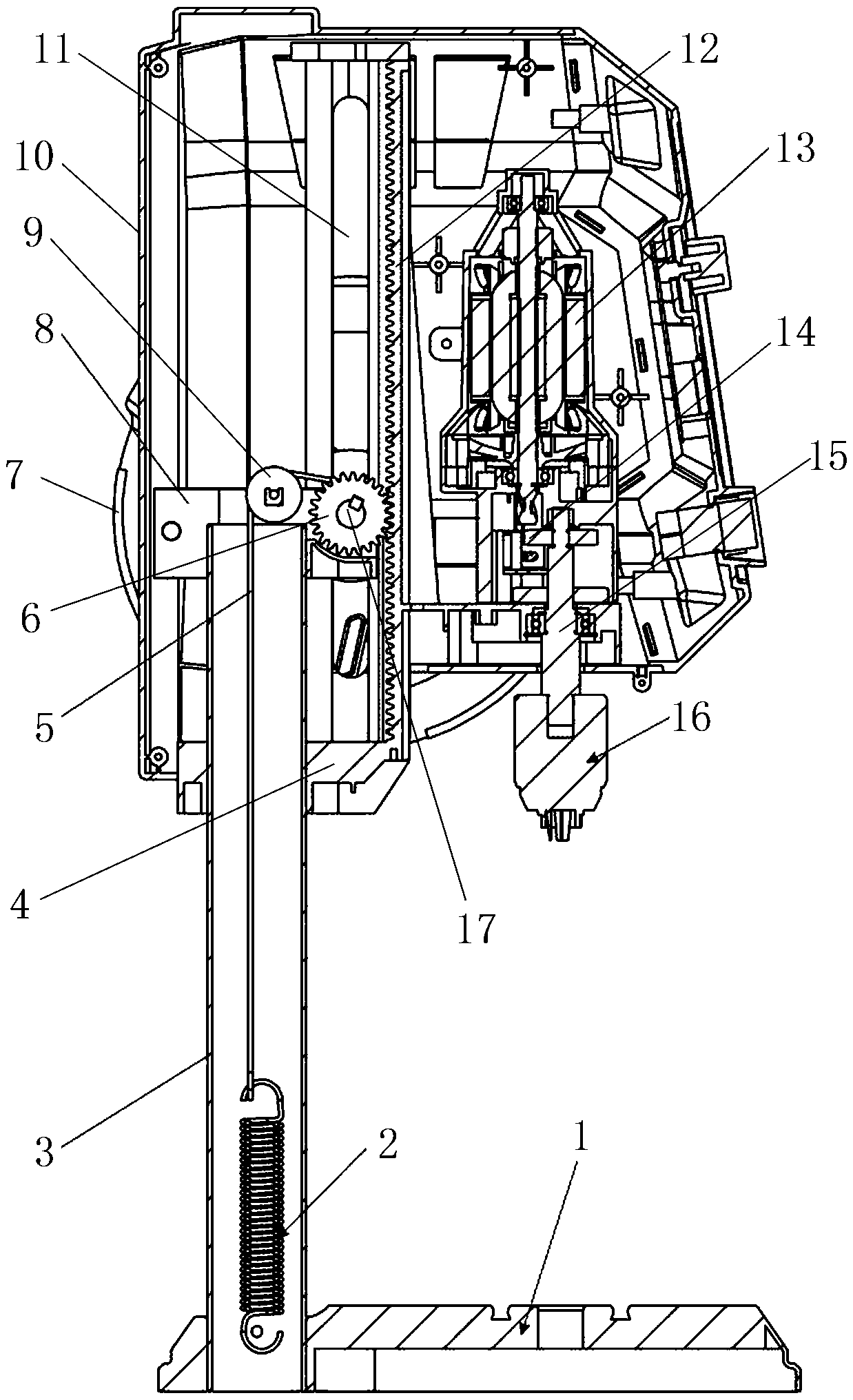

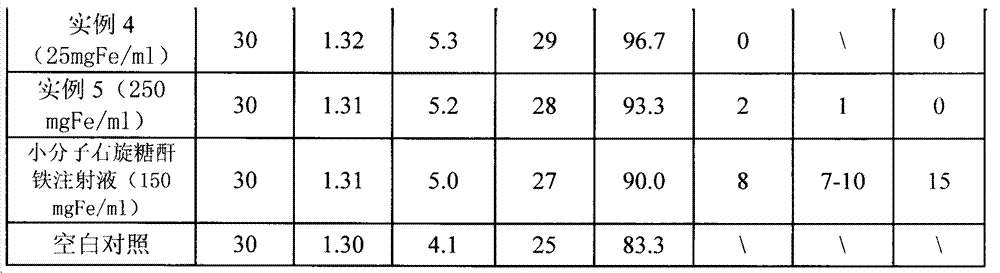

Vertical type drilling machine

PendingCN110480048AEliminate hidden dangers in production safetySimple structureBoring/drilling machinesAgricultural engineeringDrilling machines

The invention discloses a vertical type drilling machine. The vertical type drilling machine comprises a stand column, a bottom seat, a rack, a gear, a housing, a drive device and a drill chuck, wherein the housing comprises a top and a bottom, the lower end of the stand column is arranged on the bottom seat, the drive device is arranged in the right portion of the housing, the drill chuck is arranged on the drive device, the drill chuck is located on the outer side of the bottom of the right portion of the housing, the bottom face of the left portion of the housing is installed in the stand column in a penetration mode, a pull spring is further arranged, the stand column is of a hollow structure, a clamping sleeve is arranged on the upper end portion of the stand column, the rack is arranged in the housing, the rack is located on the left side of the drive device, two end portions of a gear shaft are arranged on the clamping sleeve, a lengthways long slot is formed in the housing, oneend of the gear shaft is located in the lengthways long slot, a hand wheel is located on the outer side of the lengthways long slot, the pull ring is located in the stand column, the lower end of thepull spring is arranged on the lower portion of the interior of the stand column, the upper end of the pull spring is connected with one end of a steel rope, and the other end of the steel rope is connected with the bottom of the interior of the housing through a pulley arranged on the clamping sleeve.

Owner:YANCHENG BAODING POWER TOOLS

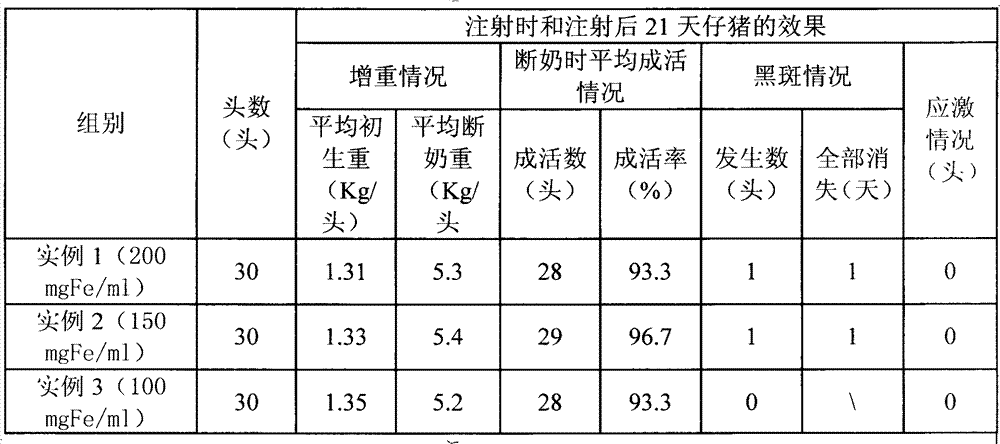

Preparation method of super-micro molecular iron dextran

ActiveCN102429865BReduce lossEmission reductionOrganic active ingredientsMetabolism disorderFiltrationPotassium cyanide

The invention discloses a method for preparing super-micro molecular iron dextran by using super-micro molecular dextran (a weight-average molecular weight being 3,000-6,000Da) as a raw material. After the super-micro molecular dextran is subjected to oxidation, complexing, desalting, concentration preparation, filtration and encapsulation sterilization, an iron dextran injection product with an iron content of 25-250 mg / ml can be obtained, and the super-micro molecular iron dextran can be used for preventing and treating the iron-deficiency anemia of piglets and livestocks. According to the method for preparing the super-micro molecular iron dextran, a conventional potassium cyanide method and an alkali method are replaced by adopting oxydol / aqueous alkali oxidation, and a sodium hypochlorite method is improved; an alcohol precipitation method is replaced by using an electric dialyser method to remove the sodium chloride in iron dextran solution; simultaneously, the impurity removal working procedure of an intermediate product is further omitted; the production cost is decreased; the energy consumption is decreased; the production period is shortened; the toxicity is decreased; the emission of waste gas, waste water and industrial residues is reduced; the environmental pollution is reduced; and the production potential safety hazard caused by the usage of flammable and explosive alcohol is eliminated.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

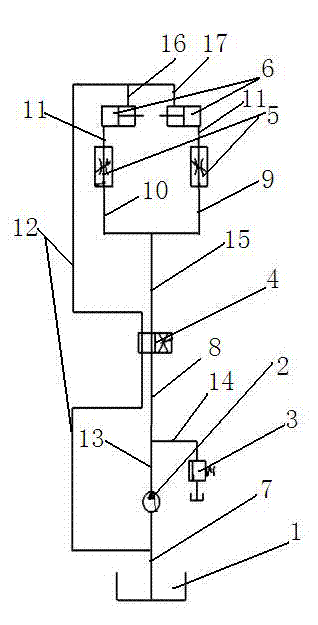

Hydraulic device of transformer substation cable drum carriage

The invention discloses a hydraulic device of a transformer substation cable drum carriage. The hydraulic device of the transformer substation cable drum carriage comprises an oil tank (1), wherein the oil tank (1) is connected with a manual one-way quantitative hydraulic pump (2) through an oil pipe. The hydraulic device of the transformer substation cable drum carriage is characterized in that the manual one-way quantitative hydraulic pump (2) is respectively connected with a pressure release valve (3) and a two-station two-way control valve (4) through oil pipes; the two-station two-way control valve (4) is respectively connected with two current regulating valves (5) through oil pipes; each current regulating valve (5) is connected with an oil cylinder (6) through an oil pipe; the oil cylinder (6) is connected with the oil tank (1) through the two-station two-way control valve (4) and an oil pipe. The hydraulic device of the transformer substation cable drum carriage is simple and practical in structure, a cable can be rolled and lifted safely and reliably, and the safety and the reliability of power supply are ensured.

Owner:SHANDONG UNIV +2

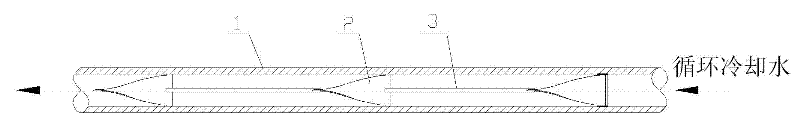

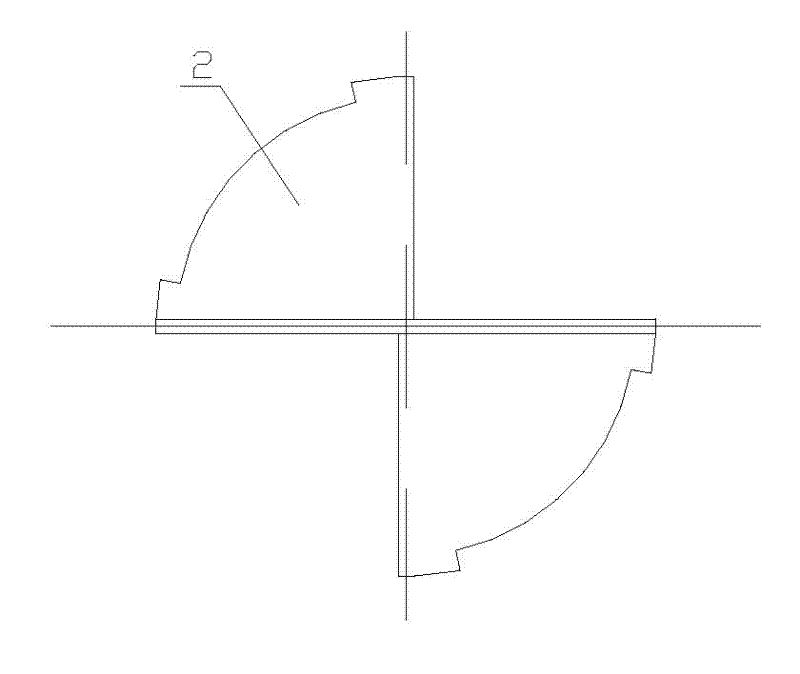

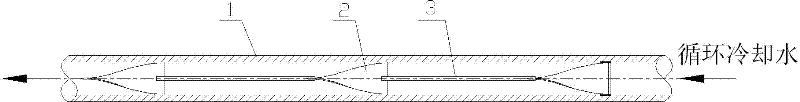

Device capable of reducing water recirculation rate of supporting beam in heating furnace effectively

InactiveCN102221297AGuaranteed cooling effectPrevent adhesionFurnace coolingWater vaporCooling effect

The invention discloses a device capable of reducing water recirculation rate of a supporting beam in a heating furnace effectively, namely at least three spiral-type spoilers are connected to and arranged in a supporting beam cooling water pipe through a plurality of connecting rods sequentially, and the first spiral-type spoiler is fixedly connected with the inner wall of a cooling water pipe along the water flow direction of the cooling water pipe of the supporting beam. By using the device, the adhesion of circulated water vapor bubbles on the inner wall surface of the supporting beam is avoided, the cooling effect of the supporting beam is ensured, the safety production hazard is eradicated, and the running energy consumption of the cooling circulation system is reduced.

Owner:BAOSTEEL IND FURNACE ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com