Assembling and holding mechanism for diaphragms of spring cylinders

A technology of spring cylinder and diaphragm, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems such as inapplicable spring cylinder diaphragm assembly process, reduce the workload of manual pressing, avoid hidden dangers in production safety, The effect of improving product assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

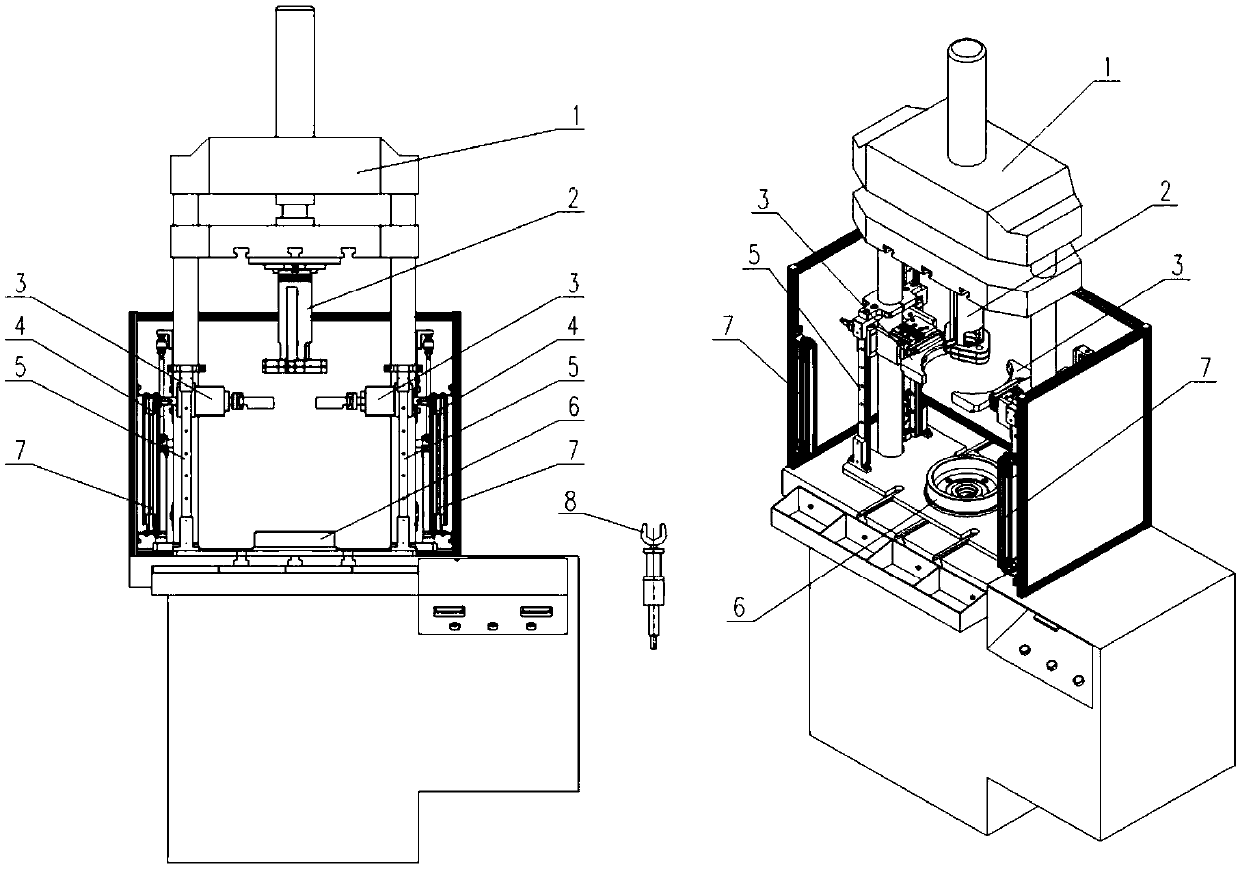

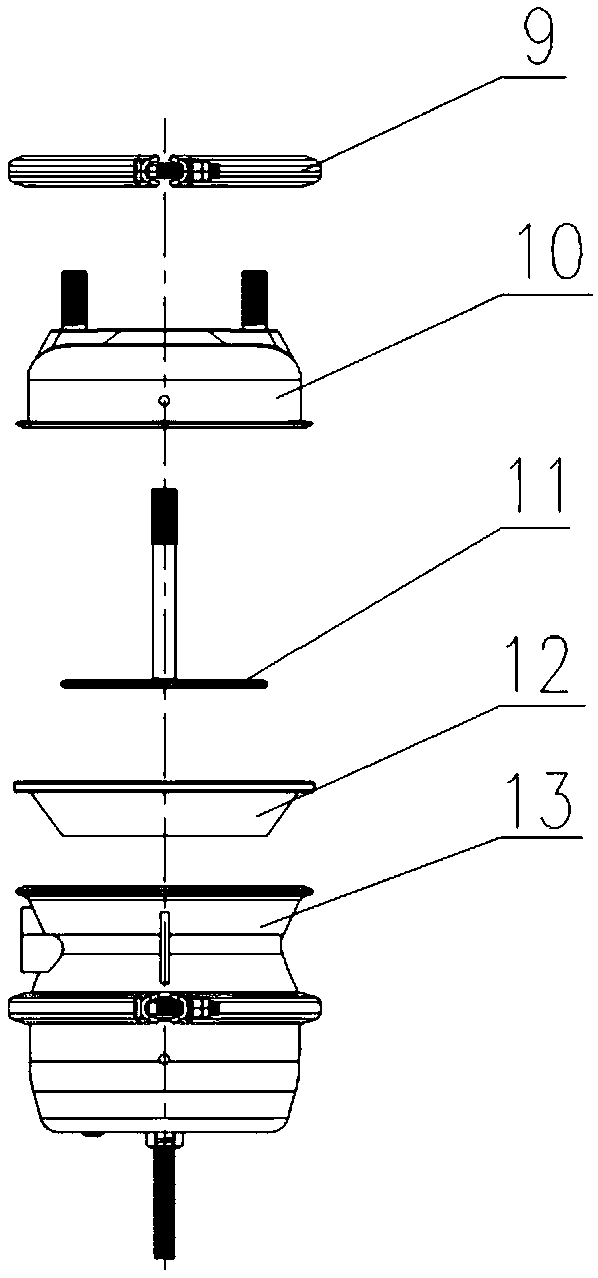

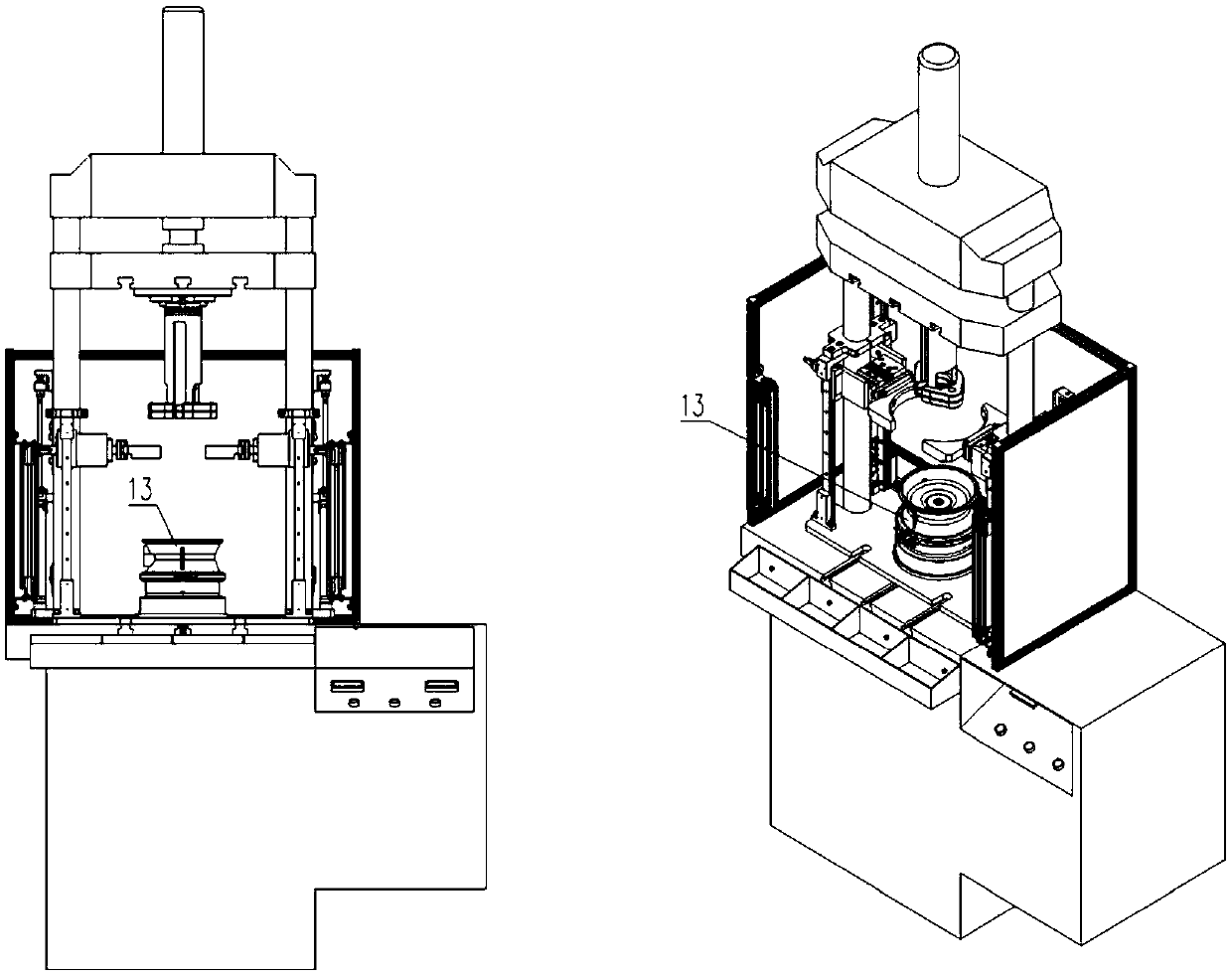

[0032] Combine below Figure 1-12 Describe in detail the technical solution of the spring cylinder diaphragm assembly clamping mechanism:

[0033] The spring cylinder diaphragm assembly clamping mechanism includes a double-column hydraulic press 1 and a control system. The double-column hydraulic press 1 includes two columns, an upper beam, a lower beam and a movable beam. Tooling 2, a positioning seat 6 is installed at the center of the lower beam, a first proximity switch is installed on the double-column hydraulic press 1, and slide rails 5 are installed on the front and rear sides of the lower beam close to the two columns. The top of the rail 5 and the column are equipped with an air claw advancing assembly 3, and the air claw advancing assembly 3 is equipped with a second proximity switch, and the air claw descending assembly 4 is installed on the left and right sides of the lower beam close to the two columns , the third proximity switch is installed on the air claw de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com