Vibration shaper of saddle plate

A vibration molding machine and saddle technology, which is applied to ceramic molding machines and manufacturing tools, can solve the problems of time-consuming and labor-intensive work, high labor intensity of workers, and low dimensional accuracy of saddle boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

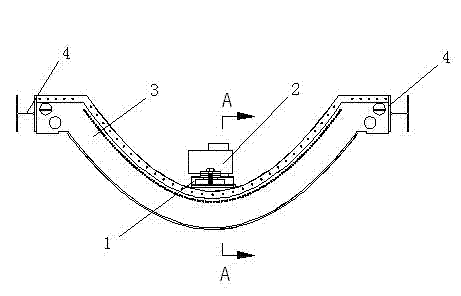

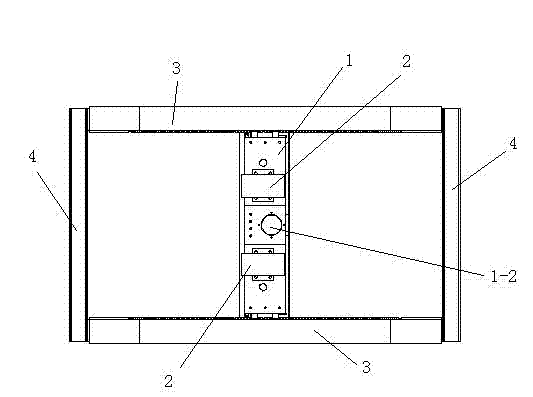

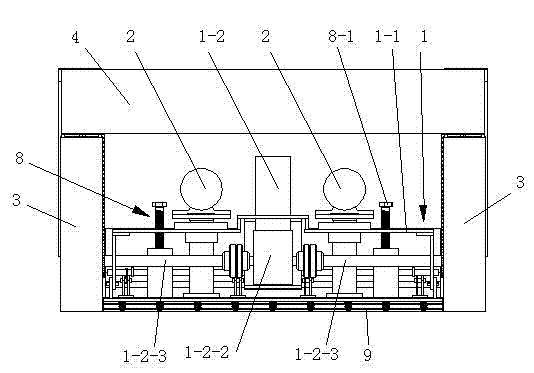

[0035] Such as Figure 1~16 As shown, the saddle plate vibration forming machine of the present invention includes a traveling vehicle 1, a vibrator 2, two arc track assemblies 3 and two beams 4, and the two beams 4 are respectively fixed on the two arc track assemblies. The two ends of 3, the trolley 1 includes a vehicle frame 1-1, a driving device 1-2, a driving driving wheel 1-3 and a first guide wheel 1-4, and the driving device 1-2, the first guide wheel 1-4 are all mounted on the frame 1-1, the driving device 1-2 is connected to the driving wheels 1-3 on both sides of the frame 1-1, and the arc track assembly 3 includes a track box 3-1 , arc-shaped synchronous strip 3-2 and arc-shaped guide rail 3-3, arc-shaped synchronous strip 3-2 and arc-shaped guide rail 3-3 are all fixed on the track box 3-1, and the two sides of the vehicle fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com