Measuring apparatus for current of busbar in aluminum cell, and measuring system and method for anode current

A bus current and measurement device technology, applied in the field of aluminum electrolysis, to achieve the effect of reducing production processes, reducing production costs, and eliminating hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

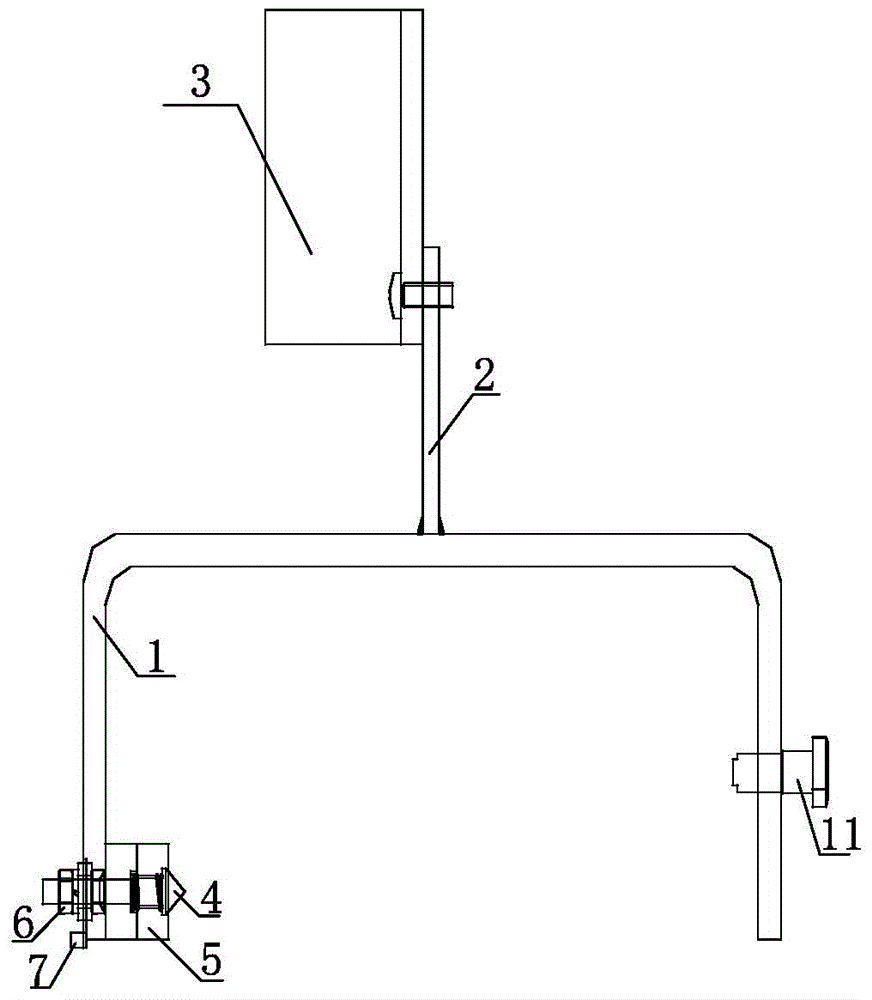

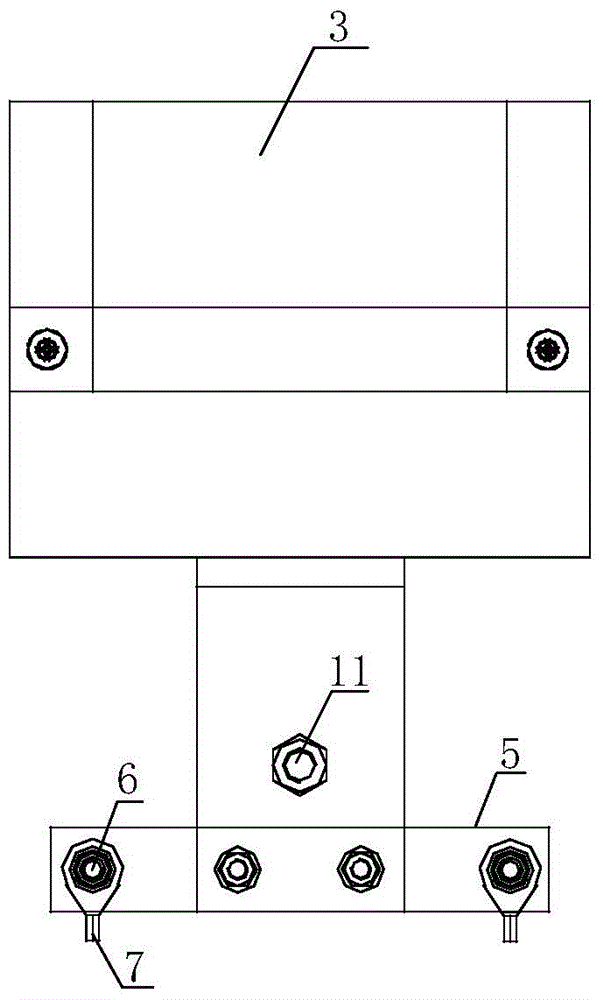

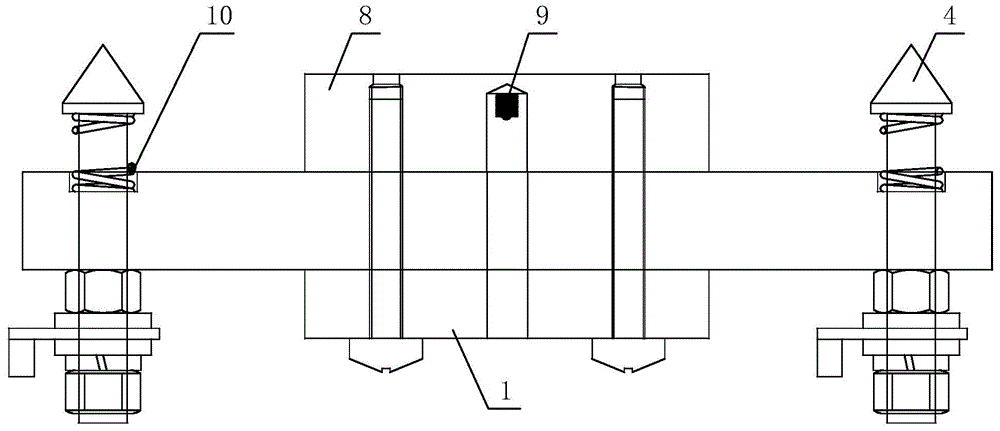

[0027] figure 1 It is the front view of the aluminum electrolytic cell bus current measuring device according to the embodiment of the present invention; figure 2 It is a side view of an aluminum electrolytic cell bus current measuring device according to an embodiment of the present invention; image 3 It is a schematic structural diagram of a bus voltage and temperature collector according to an embodiment of the present invention; Figure 4 It is a structural schematic diagram of an aluminum electrolytic cell bus current measuring device installed on the bus on one side of the anode guide rod according to the embodiment of the present invention. refer to Figure 1 to Figure 4 , the embodiment of the present invention aluminum electrolytic cell bus current measuring device is applied to the measurement of the bus current in the aluminum electrolytic cell, such as Figure 4 As shown, the bus current measuring device is arranged on the bus on the side of the anode guide ro...

Embodiment 2

[0044] Figure 5 It is a schematic diagram of an aluminum electrolytic cell anode current measurement system according to an embodiment of the present invention. Such as Figure 5 As shown, the aluminum electrolytic cell anode current measurement system of the embodiment of the invention is applied to the anode current measurement of the aluminum electrolytic cell, including a control device ( Figure 5 Not shown in) and the bus current measuring device in the two above-mentioned embodiment one; Wherein,

[0045] The two busbar current measuring devices are respectively equidistantly arranged on the busbars on both sides of the anode guide rod, and each busbar current measuring device is used to measure the busbar current on one side of the anode guide rod and send it to the control device;

[0046] The control device is used to respectively receive the bus currents on both sides of the anode guide rod measured by the two bus current measuring devices, and obtain the anode c...

Embodiment 3

[0058] What needs to be explained here is that the measurement method of the embodiment of the present invention is based on the measurement device for the busbar current of the aluminum electrolytic cell in the first embodiment and the anode current measurement system of the aluminum electrolytic cell in the second embodiment. The current measurement device for the tank busbar and the anode current measurement system for the aluminum electrolytic cell will not be described in detail.

[0059] Figure 6 It is a flow chart of the method for measuring the anode current of an aluminum electrolytic cell according to an embodiment of the present invention. combine Figure 1 to Figure 6 As shown, the method for measuring the anode current of the aluminum electrolytic cell in the embodiment of the present invention includes:

[0060] Step S11, the bus current measuring devices arranged on both sides of the anode guide rod respectively measure the bus current on both sides of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com