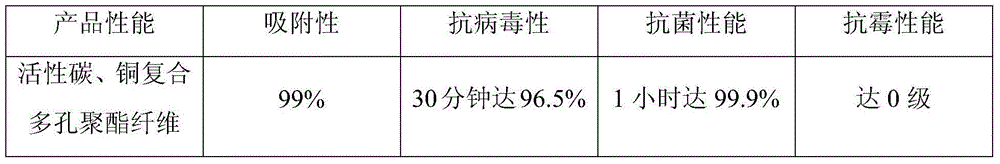

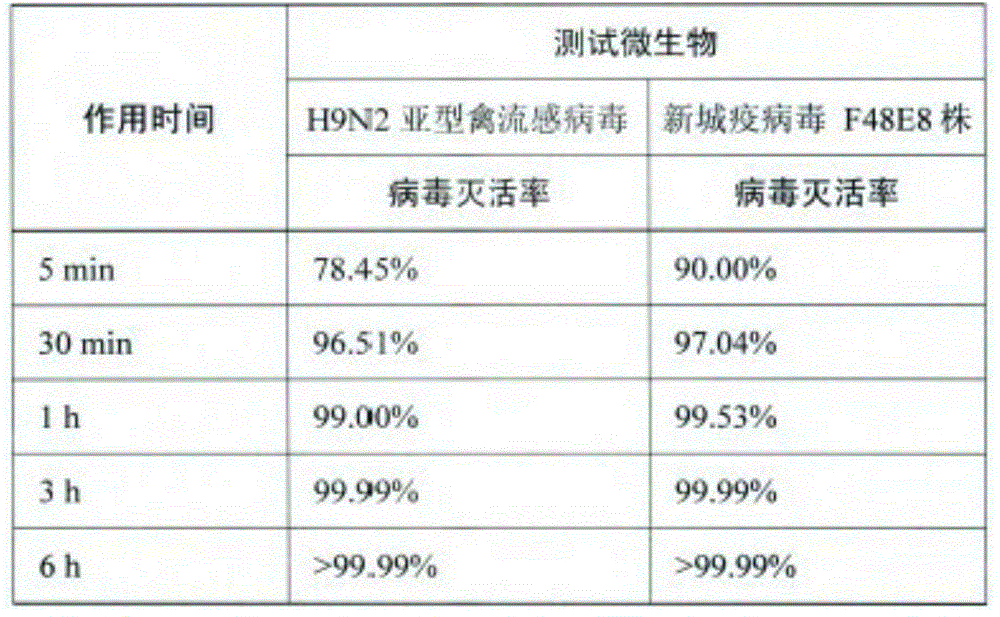

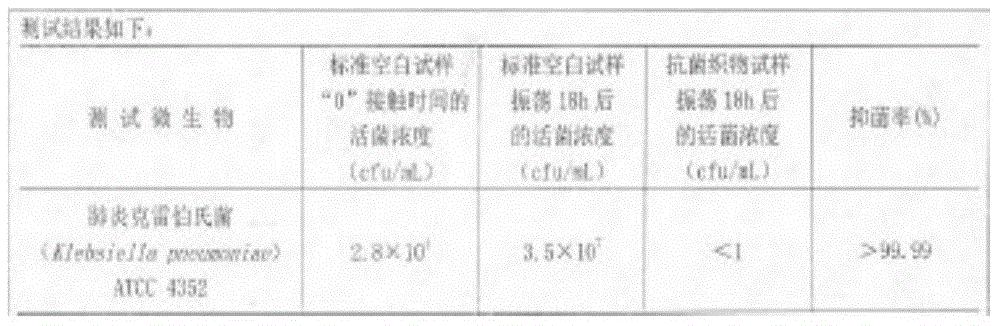

High-adsorbability antibacterial mildew-proof active carbon fiber and production method thereof

A technology of fiber and polyester fiber, applied in the field of carbon fiber and its manufacturing, can solve the problems of high processing and production cost of activated carbon fiber materials, easy mildew of microorganisms, etc., achieve low cost, reduce production cost, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following process steps are completed in the same equipment:

[0026] 1. Prepare porous polyester fiber by supersaturated gas method.

[0027] The molding process of foamed materials generally goes through three main stages, namely, the formation of bubble nuclei, the expansion of bubbles, and the immobilization of bubbles. The specific process steps are: (1) Make nitrogen fully infiltrate polyester PET fiber under high pressure;

[0028] (2) Rapidly reduce the pressure to normal pressure; (3) Foam in a constant temperature furnace.

[0029] Use the positive and negative pressure system in the magnetron sputtering furnace (add a silicone ring with electromagnetic wire near the furnace door inside the furnace chamber, and control the internal suction and external pressure of the silicone ring through electromagnetic control to ensure that the furnace can meet the positive pressure, Negative pressure impact), at room temperature (25°C) with 8MPa pressure to fully in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com