A water curtain water cyclone spray booth

A spray booth and water spin technology, applied in the field of spray booths, can solve problems such as difficulty in handling, environmental pollution, and environmental pollution, and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

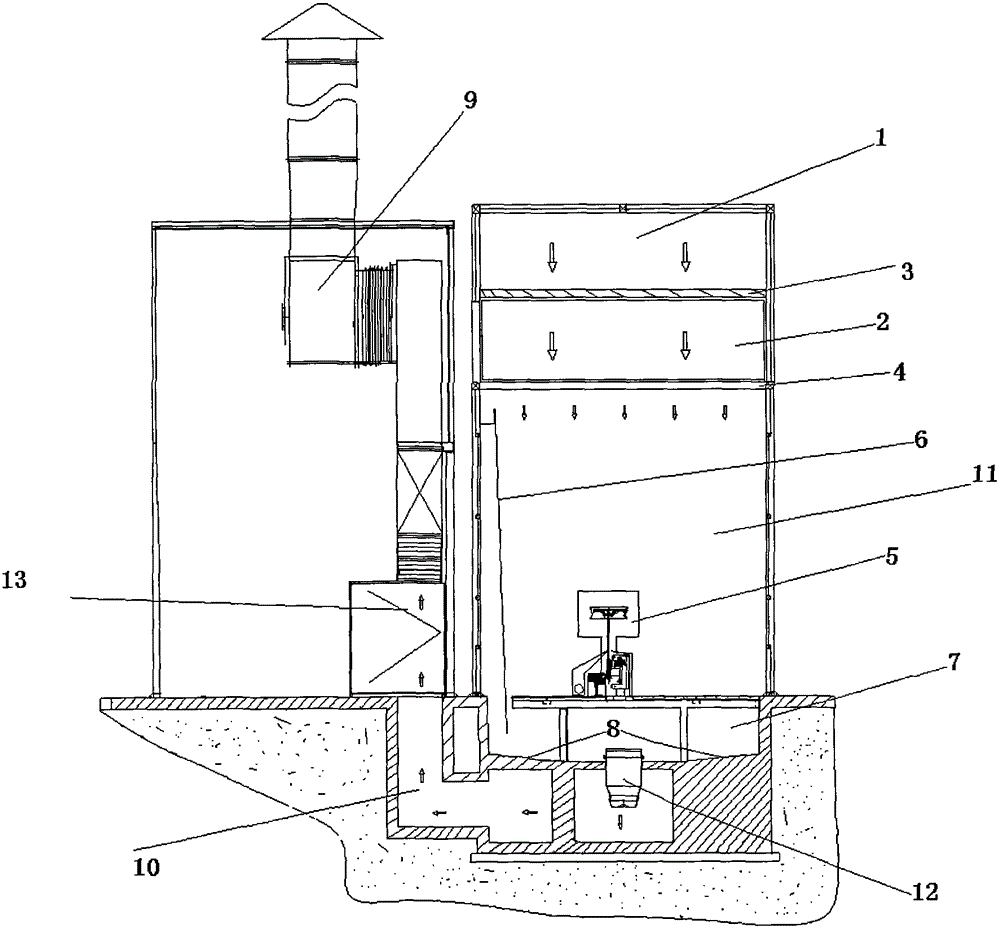

[0018] A water curtain hydrocyclone spray booth, such as figure 1 As shown, a primary filter cotton 3 is arranged between the dynamic pressure box 1 and the static pressure box 2, and a sub-high-efficiency filter layer 4 is arranged between the static pressure box 2 and the spraying operation room 11, and the spraying operation room 11 is provided with a spraying workpiece 5, and the spraying operation The side wall of the chamber 11 is provided with a first water curtain 6, and the bottom of the sprayed workpiece 5 is provided with a water tank 7, and the bottom periphery of the water tank 7 is provided with a second water curtain 8, and the bottom of the water tank 7 is provided with a water cyclone 12, and the water cyclone 12 It is connected with the exhaust fan 9 through the exhaust duct 10 .

[0019] The material of the first water curtain 6 and the second water curtain 8 is stainless steel. Primary filter cotton is synthetic fiber filter cotton and non-woven filter cot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com