Molding apparatus for glass fiber reinforced plastic product

A molding equipment and FRP technology, applied in the direction of coating, etc., can solve the problems of inconsistent quality of glass products, inability to calculate and control, unsuitable for mass production, etc., and achieve the effect of consistent product wall thickness, simple structure and equal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

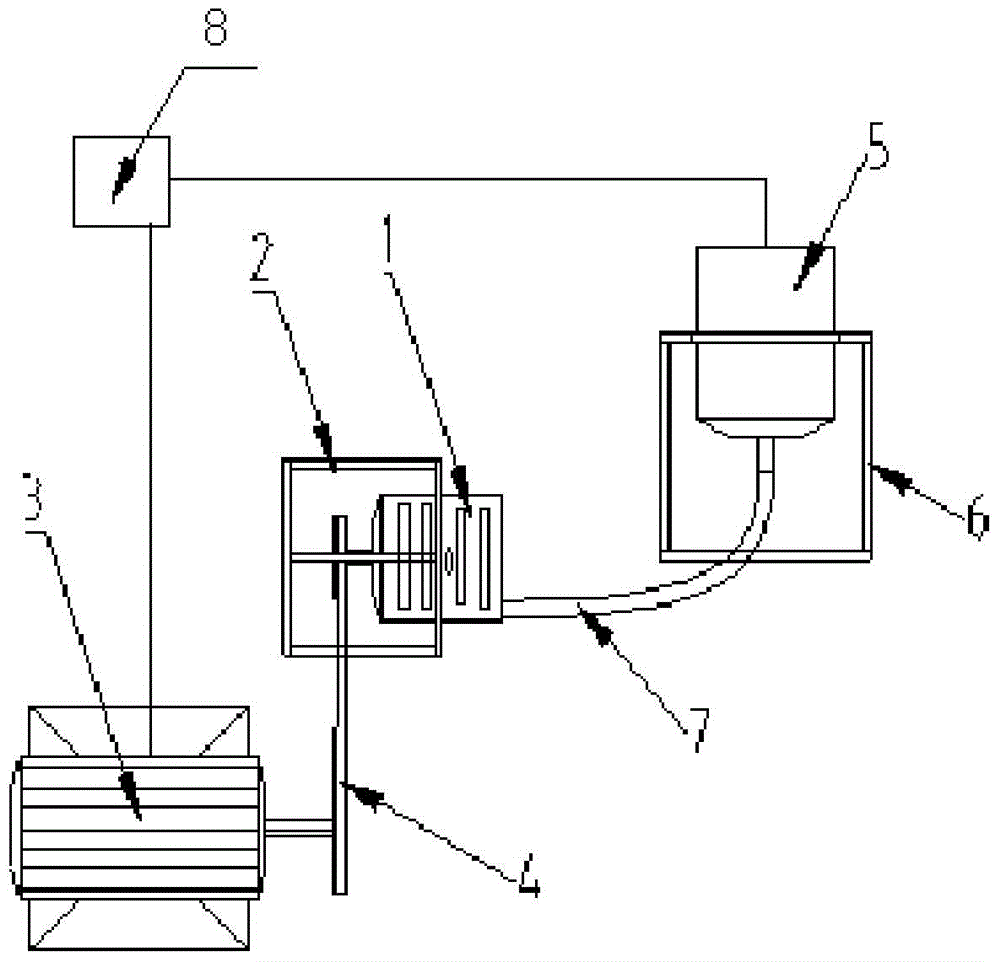

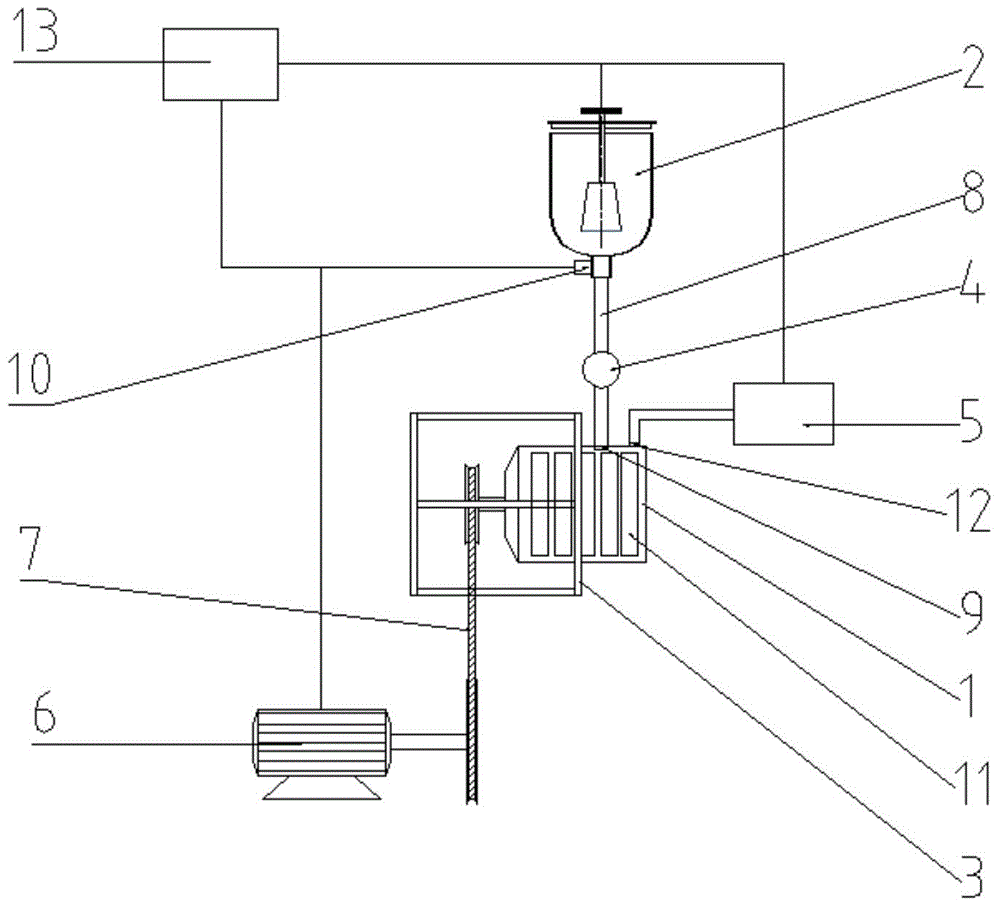

[0020] The present invention will be further described below with reference to the drawings and embodiments.

[0021] Such as figure 2 The glass fiber reinforced plastic product molding equipment shown in this embodiment includes a product female mold 1, a stirrer 2 and a fan 5. The product female mold 1 is mounted on the female mold support 3, and one end of the product female mold 1 is connected with a driving motor 6, The drive motor 6 drives the product female mold 1 to rotate through the belt 7. The product female mold 1 is provided with an electric heating film 11, and the two ends of the electric heating film 11 are connected to the power supply by metal wires. The product female mold 1 is also provided with a demolding air channel. The demolding air passage is connected to the fan 5 through the demolding air nozzle 12. The fan 5 can extract the air from the product female mold 1, or blow air into the product female mold 1. The agitator 2 is installed in the product femal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com