Fully-surrounded block pressing machine

A briquetting machine, fully enclosed technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large size of the machine, occupy a large space, inconvenient operation, etc., and achieve the same size, good permeability, and equal quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

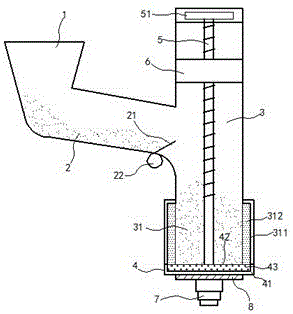

[0012] exist figure 1 In the shown embodiment, the fully enclosed briquetting machine includes a feed port 1, a storage bin 2, a briquette bin 3 and a transport plate 4; the feed port 1 is set at the upper end of the storage bin 2; The output port of the storage bin 2 is equipped with a material blocking plate 21, and the material blocking plate 21 is driven by a control motor 22; The middle part of the cylinder wall is connected; a driving screw 5 is installed at the axis of the briquetting chamber 3, and the driving screw 5 is driven by a driving motor 51; the lower end of the driving screw 5 is not threaded, that is, the driving The rod wall at the lower end of the screw mandrel 5 is smooth; a press-fit block 6 is sleeved on the drive screw mandrel 5, and the surface of the press-fit block 6 is rough; The inner wall slides up and down; a discharge port 31 is provided at the lower end of the briquette bin 3, and the transport plate 4 matches the size of the discharge port 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com