Interwoven composite fiber for improving pavement performance of asphalt mixture

An asphalt mixture and composite fiber technology, which is applied in the field of interwoven composite fibers to achieve good asphalt holding capacity, improve high temperature stability and durability, and high stiffness and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

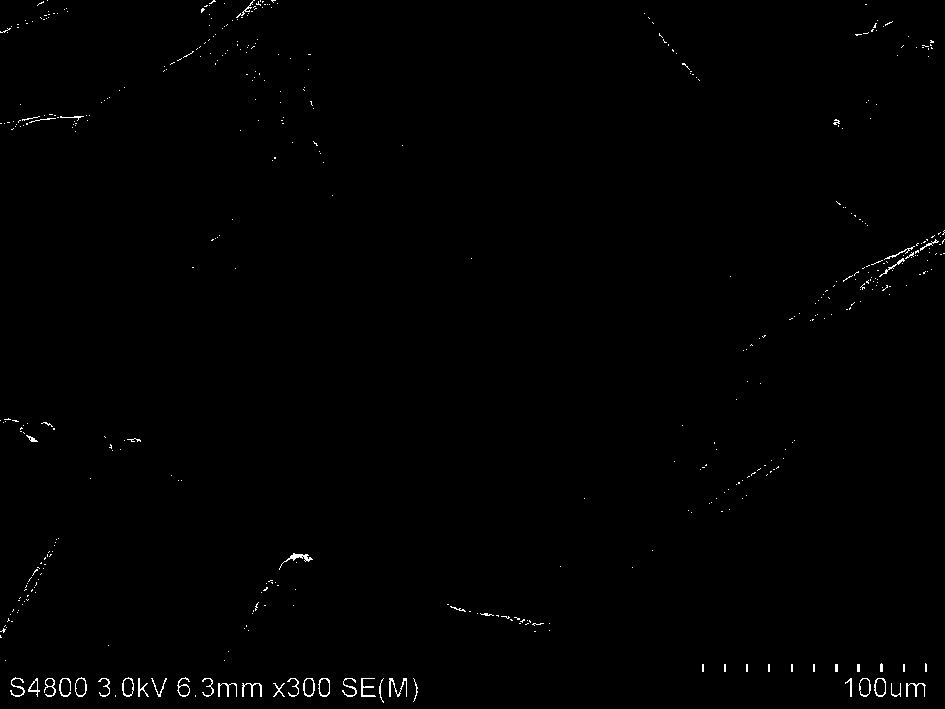

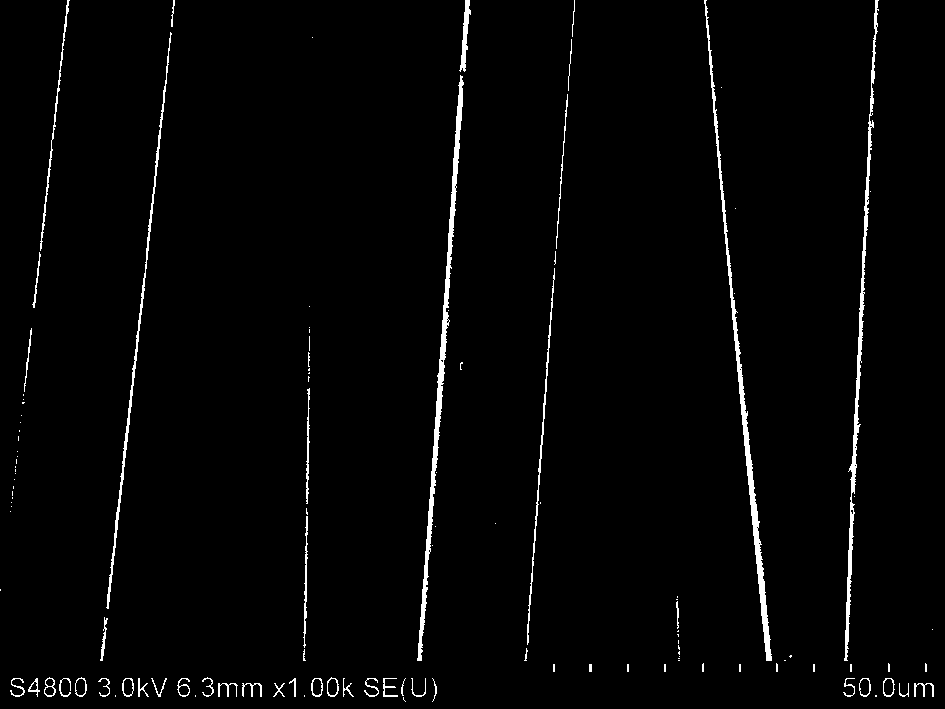

Image

Examples

Embodiment 1

[0056] An interwoven composite fiber for improving road performance of asphalt mixture, including components: A fiber: B fiber: C fiber=1:1:2.

[0057] The using method of the interwoven composite fiber of the present invention is as follows:

[0058] The amount of interwoven composite fiber is 0.3% of the total mass of asphalt mixture. In the mixing process, the interwoven composite fiber is added in the "dry method" process. First, the interwoven composite fiber and aggregate are dry-mixed for 60 seconds to make them evenly dispersed in the mineral material, and then the base asphalt is added and mixed. Mix for 60s, finally add mineral powder, mix for 60s, the total mixing time is 3min.

Embodiment 2

[0060] An interwoven composite fiber for improving the road performance of asphalt mixture, including components: A fiber: B fiber: C fiber = 1:1:1.

[0061] The using method of the interwoven composite fiber of the present invention is as follows:

[0062] The amount of interwoven composite fiber is 0.3% of the total mass of asphalt mixture. In the mixing process, the interwoven composite fiber is added in the "dry method" process. First, the interwoven composite fiber and aggregate are dry-mixed for 60 seconds to make them evenly dispersed in the mineral material, and then the base asphalt is added and mixed. Mix for 60s, finally add mineral powder, mix for 60s, the total mixing time is 3min.

Embodiment 3

[0064] An interwoven composite fiber for improving road performance of asphalt mixture, including components: A fiber: B fiber: D additive = 3:2:3.

[0065] The using method of the interwoven composite fiber of the present invention is as follows:

[0066] The amount of interwoven composite fiber is 0.3% of the total mass of asphalt mixture. In the mixing process, the interwoven composite fiber is added in the "dry method" process. First, the interwoven composite fiber and aggregate are dry-mixed for 60 seconds to make them evenly dispersed in the mineral material, and then the base asphalt is added and mixed. Mix for 60s, finally add mineral powder, mix for 60s, the total mixing time is 3min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com