Maturing method of Chinese wolfberry brandy

A wolfberry brandy and brandy technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of large volatilization loss, high cost, and long aging period of wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

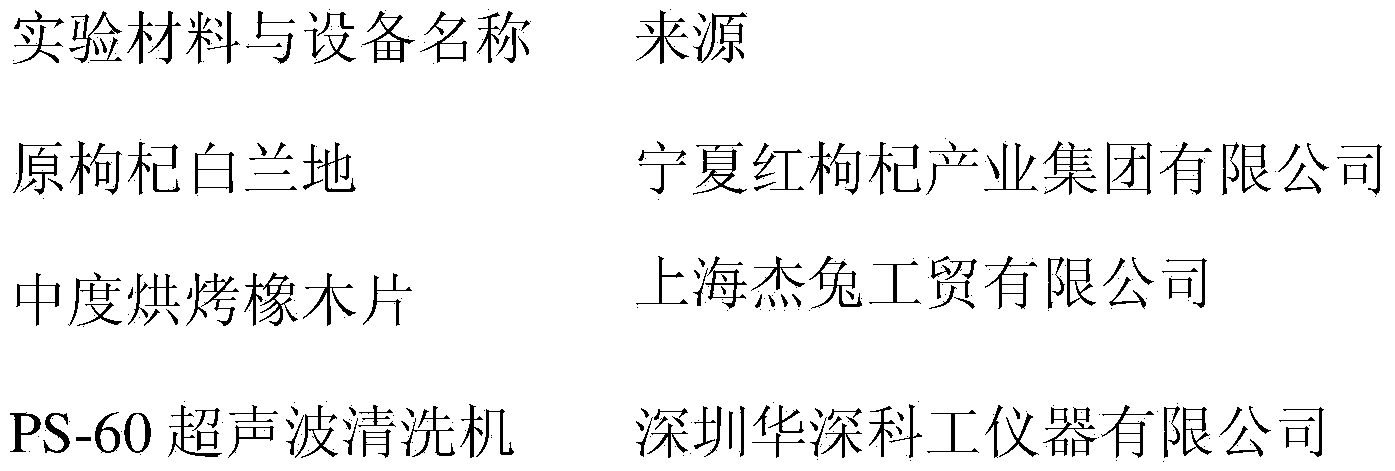

Method used

Image

Examples

Embodiment 1

[0018] Take moderately toasted oak chips, set the microwave heating power to 500W (85% power output), heat for 60s, and set aside.

[0019] Take double-distilled brandy (69% alcohol volume fraction) and place it in a conical flask, adjust the alcohol volume fraction to 50% with distilled water, and then add 4g / L prepared oak chips. Put the triangular flask in the ultrasonic generator (PS-60 ultrasonic cleaning machine), under the conditions of power 360W, temperature 50°C, frequency 40kHz, treat for 1.0h, twice a day (interval 12 hours), the treatment cycle is 1 moon. Finally, it is aged for another 2 months, and the alcohol volume fraction is adjusted to 41% with distilled water before filling.

[0020] After sensory evaluation, the quality of the produced brandy can reach the level of oak barrel aging for 1-2 years.

Embodiment 2

[0022] Take moderately toasted oak chips, set the microwave heating power to 600W (85% power output), heat for 20s, and set aside.

[0023] Take double-distilled brandy (71% alcohol volume fraction), adjust the alcohol volume fraction to 55%, and then add 2g / L prepared oak chips. Place the triangular flask in an ultrasonic generator (PS-60 ultrasonic cleaning machine), under the conditions of power 600W, temperature 25°C, frequency 40kHz, treat for 0.5h, 4 times a day (interval 8 hours), the period is 0.5 months, Then aged for another 1 month. After adjusting the alcohol volume fraction to 41%, it can be filled. Other content is identical with embodiment 1.

Embodiment 3

[0025] Take moderately toasted oak chips, set the microwave heating power to 600W (85% power output), heat for 60s, and set aside.

[0026] Take double-distilled brandy (alcohol volume fraction 68-72%), adjust the alcohol volume fraction to 55%, and then add 2g / L prepared oak chips. Put the triangular flask in the ultrasonic generator (PS-60 ultrasonic cleaning machine), under the conditions of power 360W, temperature 25°C, frequency 40kHz, treat for 1.0h, twice a day (interval 12 hours), the cycle is 0.5 months, Then aged for another 1 month. After adjusting the alcohol volume fraction to 41%, it can be filled. Other content is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com